In the world of high-temperature furnace operations, stability and durability are everything. Furnace operators are constantly seeking materials that can withstand extreme heat while maintaining reliable performance over extended periods. One of the most proven solutions for this demanding environment is the 0Cr19Al3 FeCrAl bar. At DLX, we specialize in delivering high-quality FeCrAl bars that not only meet industry requirements but also set new benchmarks for reliability, efficiency, and cost-effectiveness.

For more details, pls directly contact us

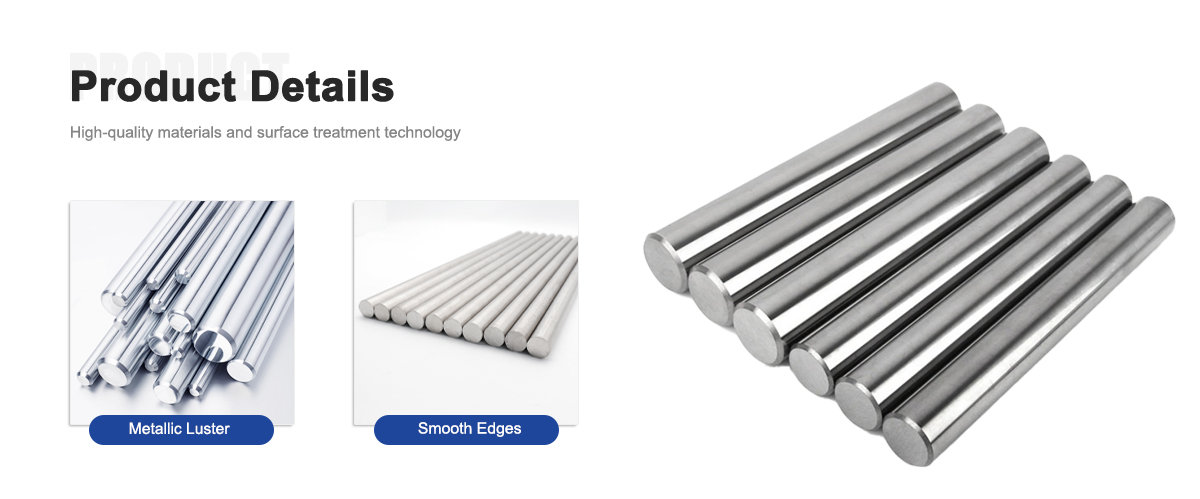

The 0Cr19Al3 FeCrAl bar is a resistance alloy made of iron, chromium, and aluminum. The unique combination of elements gives it excellent high-temperature oxidation resistance, ensuring consistent performance in demanding thermal processing applications. When exposed to high temperatures, the aluminum content forms a dense aluminum oxide (Al₂O₃) film on the surface. This protective layer prevents further oxidation, allowing the material to function reliably in furnaces running above 1200°C.

|

Alloy Nomenclature Performance |

0Cr25Al5 |

0Cr21Al6 |

0Cr23Al5 |

0Cr21Al4 |

0Cr27Al7Mo2 |

|||

|

Chemical Compostion (%) |

Cr |

12.0-15.0 |

23.0-26.0 |

19.0-22.0 |

20.5-23.5 |

18.0-21.0 |

21.0-23.0 |

26.5-27.8 |

|

Al |

4.0-6.0 |

4.5-6.5 |

5.0-7.0 |

4.2-5.3 |

3.0-4.2 |

5.0-7.0 |

6.0-7.0 |

|

|

Re |

Opportune |

Opportune |

Opportune |

Opportune |

Opportune |

Opportune |

Opportune |

|

|

Fe |

Rest |

Rest |

Rest |

Rest |

Rest |

Rest |

Rest |

|

|

-- |

-- |

-- |

-- |

-- |

-- |

-- |

||

|

Max.Continuous service temp. of element |

950 |

1250 |

1250 |

1250 |

1100 |

1350 |

1400 |

|

|

Resistivity at 20C(μΩ.m) |

1.25 |

1.42 |

1.42 |

1.35 |

1.23 |

1.45 |

1.53 |

|

|

Density(g/cm) |

7.4 |

7.1 |

7.16 |

7.25 |

7.35 |

7.1 |

7.1 |

|

|

Thermal Conductivity(KJ/m.h) |

52.7 |

46.1 |

63.2 |

60.2 |

46.9 |

46.1 |

-- |

|

|

Coefficient of lines expansion(αx10-6/℃) |

15.4 |

16 |

14.7 |

15 |

13.5 |

16 |

16 |

|

|

Melting Point Approx(degree) |

1450 |

1500 |

1500 |

1500 |

1500 |

1510 |

1520 |

|

|

Tensile Strength(N/mm) |

580-680 |

630-780 |

630-780 |

630-780 |

600-700 |

650-800 |

680-830 |

|

|

Elongation at rupture(%) |

>16 |

>12 |

>12 |

>12 |

>12 |

>12 |

>10 |

|

|

Variation of area(%) |

65-75 |

60-75 |

65-75 |

65-75 |

65-75 |

65-75 |

65-75 |

|

|

Repeat Bending frequency(F/R) |

>5 |

>5 |

>5 |

>5 |

>5 |

>5 |

>5 |

|

|

Hardness(H.B.) |

200-260 |

200-260 |

200-260 |

200-260 |

200-260 |

200-260 |

200-260 |

|

|

continuous service time(Hours/ ºC) |

-- |

≥80/1300 |

≥80/1300 |

≥80/1300 |

≥80/1250 |

≥80/1350 |

≥80/1350 |

|

|

Micrographic structure |

Ferrite |

Ferrite |

Ferrite |

Ferrite |

Ferrite |

Ferrite |

Ferrite |

|

|

Magnetic properties |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

|

|

Shape |

Size (mm) |

|

Wire |

0.05-7.5 |

|

Rod |

8-50 |

|

Ribbon |

(0.05-0.35)*(0.5-6.0) |

|

Strip |

(0.5-2.5)*(5-180) |

For more details, pls directly contact us

This alloy has become a trusted choice across multiple industries. In metallurgy, it is widely used in continuous heating furnaces for steel treatment. In ceramics, it supports kiln operations where stable heat is essential. Glass manufacturing plants use FeCrAl bars to maintain precise furnace conditions, while the electronics sector values their reliability in thermal processing equipment. Heat treatment facilities, which demand both consistency and long service life, often prefer FeCrAl over alternative alloys due to its performance under stress.

As industries move toward higher efficiency and lower maintenance downtime, materials like FeCrAl are becoming increasingly important. Rising energy costs and the push for environmentally friendly operations mean that furnaces need to run longer without interruption. The extended service life of FeCrAl bars reduces replacement frequency, directly lowering maintenance costs and downtime. Moreover, with global industries shifting toward sustainability, the long-lasting performance of FeCrAl alloys contributes to reduced material waste and better overall energy efficiency.

Comparison with Other Materials

While nickel-chromium alloys have traditionally been used for similar applications, 0Cr19Al3 FeCrAl bars provide clear advantages in high-temperature stability. Nickel-chromium materials perform well up to around 1100°C, but FeCrAl extends that performance window by at least 150–200°C. This margin is crucial in furnaces that operate continuously under extreme conditions. Additionally, FeCrAl alloys generally have lower raw material costs compared to nickel-based alloys, making them more attractive for cost-sensitive applications.

Comparative Parameters Table

| Parameter | 0Cr19Al3 FeCrAl Bar | Common NiCr Alloy Bar |

|---|---|---|

| Main Composition | Fe, Cr, Al | Ni, Cr, Fe |

| Max Continuous Temp (°C) | 1250–1300 | 1100–1150 |

| Oxidation Resistance | Excellent (Al₂O₃ film) | Good (Cr₂O₃ film) |

| Service Life | Longer at high temp | Shorter at high temp |

| Ductility | Moderate | Higher |

| Cost Efficiency | High | Moderate to high |

| Applications | Furnaces, heaters, kilns | Furnaces, heaters, elements |

| Customization Options | Wide | Wide |

What sets DLX apart is not just our ability to supply FeCrAl bars but our deep expertise in alloy manufacturing. We carefully control chemical compositions to ensure that every batch meets exacting industry standards. Our production lines are equipped with advanced melting, casting, and rolling technology, ensuring that the material structure is uniform and stable. This translates into products with predictable performance, whether in a small laboratory furnace or a large-scale industrial kiln.

Customization is another strength. Every furnace design has unique requirements, and DLX works closely with customers to provide tailored dimensions, mechanical properties, and surface finishes. We understand that a "one-size-fits-all" approach does not work in thermal processing industries. Instead, we focus on delivering solutions that integrate seamlessly into customer systems.

Beyond manufacturing, DLX offers full technical support. Our team of engineers helps customers choose the right alloy grade, optimize usage, and extend service life in actual applications. This partnership approach ensures that our customers gain more than just a product—they gain reliable performance and long-term operational benefits.

With industries continuing to demand higher performance, the role of FeCrAl bars will only grow. The trend toward energy-efficient furnaces and environmentally responsible operations will keep driving the adoption of materials that offer both high temperature stability and cost efficiency. DLX is positioned to meet this demand with an ongoing commitment to innovation, quality improvement, and customer-focused solutions.

The 0Cr19Al3 FeCrAl bar is not just another furnace material—it is a critical enabler of stable, efficient, and long-lasting furnace operations. Its unique balance of high-temperature resistance, oxidation stability, and cost-effectiveness makes it the preferred choice in industries ranging from metallurgy to electronics. At DLX, we combine this superior material with advanced production, strict quality control, and technical expertise to deliver unmatched performance for our customers worldwide. For companies seeking to optimize furnace operations, DLX’s FeCrAl bars are the clear choice for the future.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

-

What is 0Cr19Al3 FeCrAl bar?

It is a high-temperature resistance alloy bar made from iron, chromium, and aluminum with excellent oxidation resistance. -

What is the maximum operating temperature of 0Cr19Al3 FeCrAl bar?

It can perform stably up to 1250–1300°C in continuous furnace operations. -

What industries commonly use 0Cr19Al3 FeCrAl bar?

It is widely used in metallurgy, ceramics, heat treatment, glass, and electronics industries. -

How does 0Cr19Al3 FeCrAl bar resist oxidation?

The aluminum in the alloy forms a dense Al₂O₃ protective layer on the surface, preventing further oxidation. -

What is the difference between FeCrAl and nickel-chromium alloys?

FeCrAl has better high-temperature oxidation resistance and longer service life, while nickel-chromium alloys have higher ductility. -

Can 0Cr19Al3 FeCrAl bar be customized?

Yes, it can be manufactured in different diameters, lengths, and shapes to meet specific furnace requirements. -

How is DLX ensuring the quality of FeCrAl bars?

Through advanced smelting, precise composition control, and strict testing for mechanical and oxidation performance. -

Why choose DLX for FeCrAl bars?

Because DLX offers consistent quality, competitive pricing, and technical support tailored to high-temperature furnace applications.