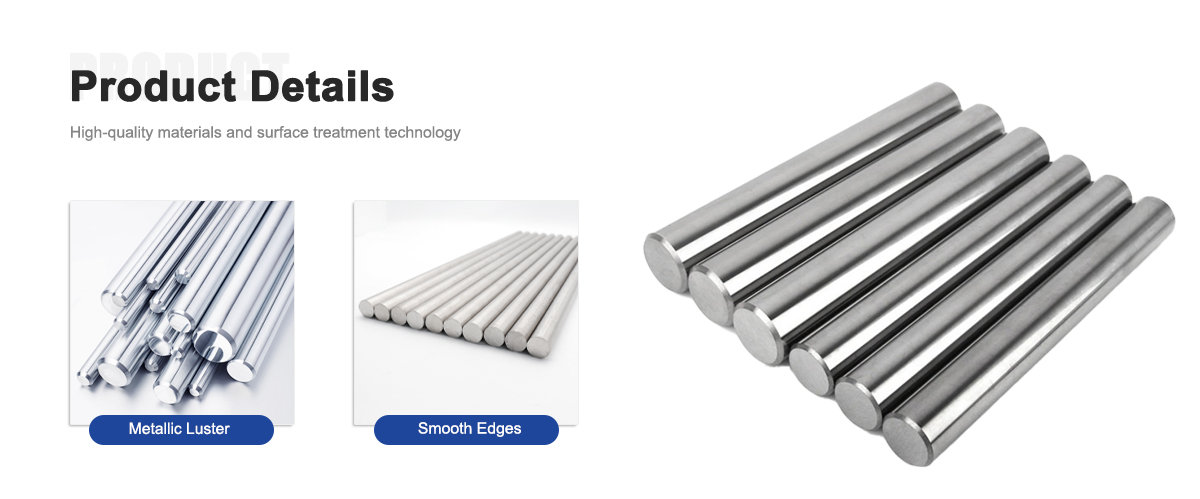

DLX provides high-quality 1Cr13Al4 FeCrAl bars engineered specifically for household appliances and small-scale heating devices. This iron-chromium-aluminum alloy, containing 13% chromium and 4% aluminum, offers a perfect combination of corrosion resistance, durability, and high-temperature stability, making it ideal for ovens, toasters, electric heaters, and other home appliances.

For more details, pls directly contact us

The 1Cr13Al4 FeCrAl alloy forms a stable aluminum oxide layer when exposed to heat, providing excellent oxidation and corrosion resistance. The chromium content enhances strength and high-temperature performance, allowing the bars to maintain their shape and mechanical integrity even under continuous operation at temperatures up to 1,100°C. These properties ensure longer service life and minimal maintenance in household heating applications.

Alloy Nomenclature Performance | 1Cr13Al4 | 0Cr21Al6 | 0Cr23Al5 | 0Cr27Al7Mo2 | ||||

Chemical Compostion (%) | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

Re | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | |

Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

-- | -- | -- | -- | -- | -- | -- | ||

Max.Continuous service temp. of element | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

Resistivity at 20C(μΩ.m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

Density(g/cm) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

Thermal Conductivity(KJ/m.h) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | -- | |

Coefficient of lines expansion(αx10-6/℃) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

Melting Point Approx(degree) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

Tensile Strength(N/mm) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

Elongation at rupture(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

Variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

Repeat Bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

Hardness(H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

continuous service time(Hours/ ºC) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥80/1350 | ≥80/1350 | |

Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Shape | Size (mm) |

Wire | 0.05-7.5 |

Rod | 8-50 |

Ribbon | (0.05-0.35)*(0.5-6.0) |

Strip | (0.5-2.5)*(5-180) |

For more details, pls directly contact us

DLX 1Cr13Al4 bars are manufactured with high precision, available in custom diameters, lengths, and surface finishes. The bars can be machined, cut, or bent to fit various appliance designs, ensuring perfect fit and reliable performance. Whether used as heating elements, support rods, or structural components inside household devices, the alloy maintains consistent resistivity and uniform heat distribution, improving overall appliance efficiency.

Applications Across Industries

While primarily used in household appliances, the bars are also suitable for small electric heaters, kitchen equipment, and specialized domestic heating devices. Manufacturers of ovens, toasters, and electric kettles rely on 1Cr13Al4 bars to deliver safe, long-lasting heating performance, reducing failures and enhancing user satisfaction. The material’s corrosion resistance makes it particularly effective in humid or acidic environments, common in kitchen appliances.

Comparison Table: FeCrAl Bar Series

| Alloy | Cr % | Al % | Max Temp (°C) | Resistivity (Ω·mm²/m) | Tensile Strength (MPa) | Typical Application |

|---|---|---|---|---|---|---|

| 0Cr12Al4 | 12 | 4 | 1,100 | 1.15 | 520 | Standard heating bars, small appliances |

| 1Cr13Al4 | 13 | 4 | 1,100 | 1.20 | 540 | Corrosion-resistant household appliance bars |

| 0Cr15Al5 | 15 | 5 | 1,200 | 1.25 | 540 | Industrial heating and furnace bars |

| 0Cr18Al6 | 18 | 6 | 1,250 | 1.30 | 560 | Heavy-duty heat treatment and chemical reactors |

Household appliance manufacturers increasingly demand materials that combine durability with high-temperature stability and corrosion resistance. Modern appliances must be energy-efficient, safe, and reliable, driving the need for superior FeCrAl alloys. DLX’s 1Cr13Al4 bars meet these requirements by offering consistent quality, high resistivity, and long-term performance, supporting appliance manufacturers in delivering premium products to the market.

DLX differentiates itself by providing precision-engineered FeCrAl bars with rigorous quality control. Each bar is tested for resistivity, tensile strength, and dimensional accuracy, ensuring consistent performance across every batch. Our team can supply custom sizes, pre-machined parts, or bent shapes to suit specific appliance designs. With DLX, manufacturers gain a reliable supplier capable of delivering both high-quality materials and technical support.

Durability and Reliability

1Cr13Al4 FeCrAl bars are built to withstand the demands of continuous household appliance operation. Their corrosion resistance prevents early degradation, while high-temperature stability maintains mechanical integrity. The alloy’s uniform resistivity ensures even heat distribution, reducing hot spots and improving appliance longevity. Using DLX bars translates to fewer maintenance issues and higher consumer satisfaction.

DLX understands that appliance designs vary significantly. That’s why we offer custom fabrication, engineering support, and material selection guidance. Clients can choose the exact bar dimensions, surface treatments, or machining requirements to match their specific appliance needs. Our team works closely with manufacturers to ensure optimal performance, safety, and durability in final products.

The 1Cr13Al4 FeCrAl bar from DLX is an ideal choice for corrosion-resistant, high-performance household appliance heating components. With excellent oxidation resistance, stable high-temperature performance, and durable construction, these bars ensure consistent operation, long service life, and superior appliance reliability. DLX combines precision manufacturing, customization, and expert technical support, making our FeCrAl bars the preferred solution for household appliance manufacturers seeking dependable, high-quality materials.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What material is 1Cr13Al4 FeCrAl bar made of?

Iron-Chromium-Aluminum alloy with 13% Cr and 4% Al.What is its maximum operating temperature?

Up to 1,100°C in continuous use.What are the main applications?

Household appliances, heating elements, oven bars, toaster components, and electric heaters.Is this alloy resistant to corrosion?

Yes, it provides excellent resistance to oxidation and mild chemical corrosion.Can the bar be customized in size or shape?

Yes, DLX provides bars in various lengths, diameters, and surface finishes.Which industries benefit most from 1Cr13Al4 bars?

Household appliance manufacturers, electric heating equipment, kitchen equipment, and small home devices.Does DLX provide high-quality fabrication?

Yes, precision drawing, machining, and quality inspection ensure accuracy and consistency.Why choose 1Cr13Al4 over standard heating materials?

Higher corrosion resistance, stable high-temperature performance, and longer service life in household applications.