Our High-Temperature 0Cr21Al6 FeCrAl Kiln Bar is a game-changer for industries needing reliable, high-performance heating solutions. Made from an iron-chromium-aluminum alloy, this kiln bar packs 21% chromium and 6% aluminum, with iron as the backbone. This combo delivers top-notch resistance to oxidation and corrosion, even when the heat’s cranked up to 1350°C (2462°F). The secret sauce? A protective aluminum oxide (Al₂O₃) layer that forms at high temperatures, keeping the bar safe from wear and tear in harsh environments.

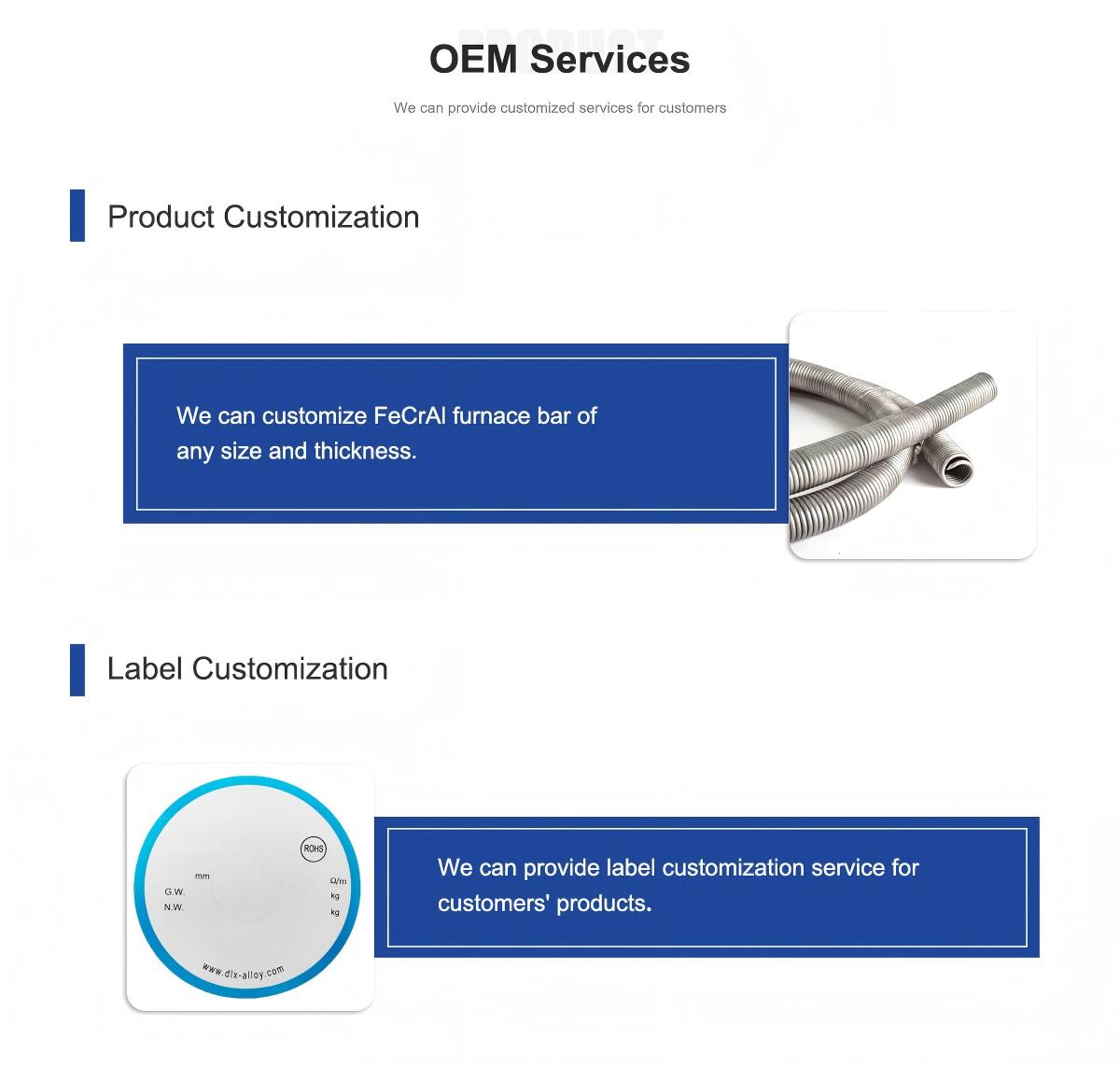

We’ve designed this kiln bar to shine in demanding settings like industrial kilns, heat treatment furnaces, and ceramic processing lines. Its high electrical resistivity—around 1.45 μΩ·m—makes it perfect for heating elements that need to stay efficient and stable. Plus, it’s got solid mechanical strength (630-780 MPa tensile strength) and can handle cyclic heating without breaking a sweat. Whether you need bars, strips, or wires, we can customize the 0Cr21Al6 to fit your exact specs, ensuring it slots right into your thermal processing setup.

What sets our kiln bar apart is its balance of performance and cost. It’s a high-value option that delivers premium-grade results without the premium-grade price tag. From small-scale ceramic kilns to massive industrial furnaces, this alloy keeps things running smoothly, saving you downtime and maintenance costs.

For more details, pls directly contact us

The industrial heating sector is heating up—pun intended. With global demand for ceramics, glass, and metals on the rise, kilns and furnaces are working overtime. The FeCrAl alloy market, including our 0Cr21Al6 Kiln Bar, is seeing steady growth, driven by industries like metallurgy, aerospace, and chemical processing. According to recent trends, the global market for high-temperature alloys is projected to grow at a CAGR of around 4-5% through 2030, fueled by advancements in manufacturing and energy efficiency.

One big driver is the push for sustainability. Industries are under pressure to cut energy use and emissions, and that’s where efficient heating elements like our 0Cr21Al6 come in. Its high resistivity and durability mean less energy waste and fewer replacements, aligning with eco-friendly goals. Plus, the rise of automation and smart manufacturing is boosting demand for reliable, long-lasting components that can handle extreme conditions without constant upkeep.

Another trend is customization. Companies aren’t just looking for off-the-shelf solutions anymore—they want tailored components that fit their specific kilns or processes. We’ve seen this in ceramics, where precise temperature control is critical, and in metallurgy, where high-heat consistency is non-negotiable. Our ability to deliver custom shapes and sizes gives us a leg up in meeting these needs.

On the flip side, the industry faces challenges like raw material price volatility. Chromium and aluminum costs can fluctuate, impacting alloy production. But we’ve optimized our supply chain to keep costs stable, ensuring our 0Cr21Al6 Kiln Bar remains competitively priced. Competition is fierce, too, with alternative alloys like nichrome ( Cr20Ni80 ) vying for market share. While nichrome has its strengths, our FeCrAl alloy offers better oxidation resistance at a lower cost, making it a go-to for kiln applications.

| Grade | Chemical Composition (wt%) | Density (g/cm³) | Resistivity (μΩ·m) | Max Operating Temp (°C) | Tensile Strength (MPa) | Features & Applications |

|---|---|---|---|---|---|---|

| 0Cr21Al6 | Cr 20.5–21.5, Al 5.5–6.5, Fe balance | 7.10 | 1.45 | 1250 | 650–750 | Excellent high-temperature oxidation resistance; suitable for industrial furnaces and electric kilns |

| 0Cr23Al5 | Cr 22–24, Al 4.5–5.5, Fe balance | 7.15 | 1.42 | 1200 | 650–750 | Stable resistivity; suitable for medium- to high-temperature heating elements |

| 0Cr27Al7Mo2 | Cr 26–28, Al 6–8, Mo 1.8–2.2, Fe balance | 7.25 | 1.35 | 1400 | 700–800 | Exceptional oxidation resistance and high-temperature strength; ideal for prolonged ultra-high-temperature use |

| 0Cr25Al5 | Cr 24–26, Al 4–6, Fe balance | 7.20 | 1.38 | 1300 | 650–750 | Balanced cost and performance; widely applicable |

| 0Cr21Al4 | Cr 20–22, Al 3.5–4.5, Fe balance | 7.10 | 1.47 | 1150 | 600–700 | Suitable for medium-temperature furnace bars; better ductility |

For more details, pls directly contact us

Our 0Cr21Al6 FeCrAl Kiln Bar is a workhorse across multiple industries, thanks to its versatility and high-temperature prowess. Here’s where it shines:

Ceramics Industry: Used in kiln heating elements for firing pottery, tiles, and advanced ceramics. Its ability to withstand 1350°C ensures consistent, high-quality output.

Metallurgy: Perfect for heat treatment furnaces, where it supports processes like annealing and sintering. The bar’s creep resistance keeps it stable during long, high-heat cycles.

Glass Manufacturing: Helps maintain precise temperatures in glass-melting kilns, ensuring smooth production of everything from flat glass to specialty products.

Chemical Processing: Used in reactors and heat exchangers handling corrosive gases or liquids. The Al₂O₃ layer protects against chemical degradation.

Energy Sector: Found in boiler components and gas turbine parts, where it tackles high-temperature oxidation and thermal fatigue.

Household Appliances: Powers heating elements in high-end ovens and water heaters, delivering reliable performance for consumers.

Its magnetic properties (up to 600°C) and thermal conductivity (around 46.1 KJ/m·h·°C) make it adaptable to both industrial and domestic uses. Plus, its low coefficient of thermal expansion (14.7 x 10⁻⁶/°C) means it won’t warp under heat stress, ensuring long-term reliability.

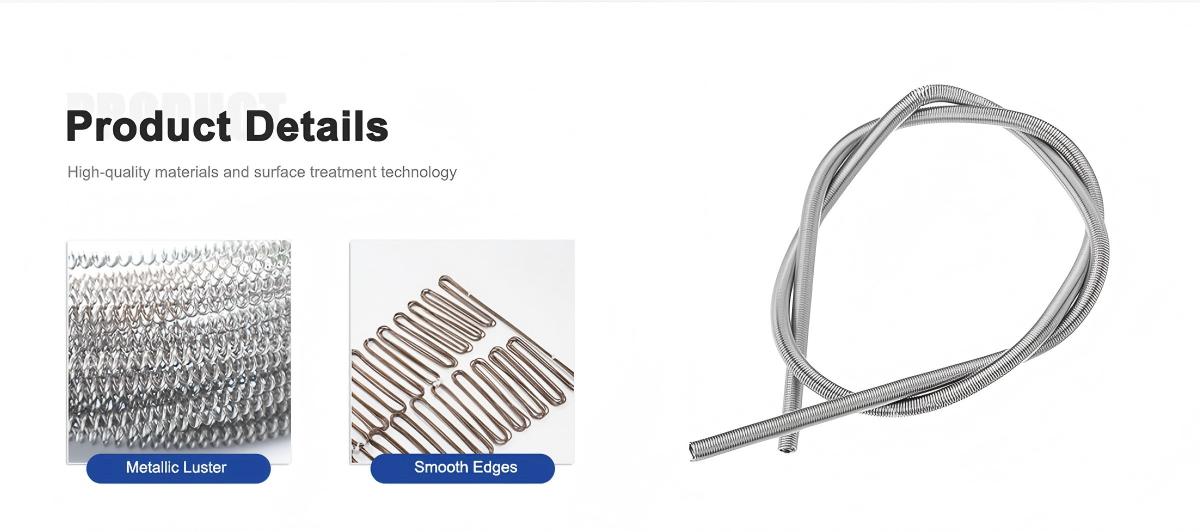

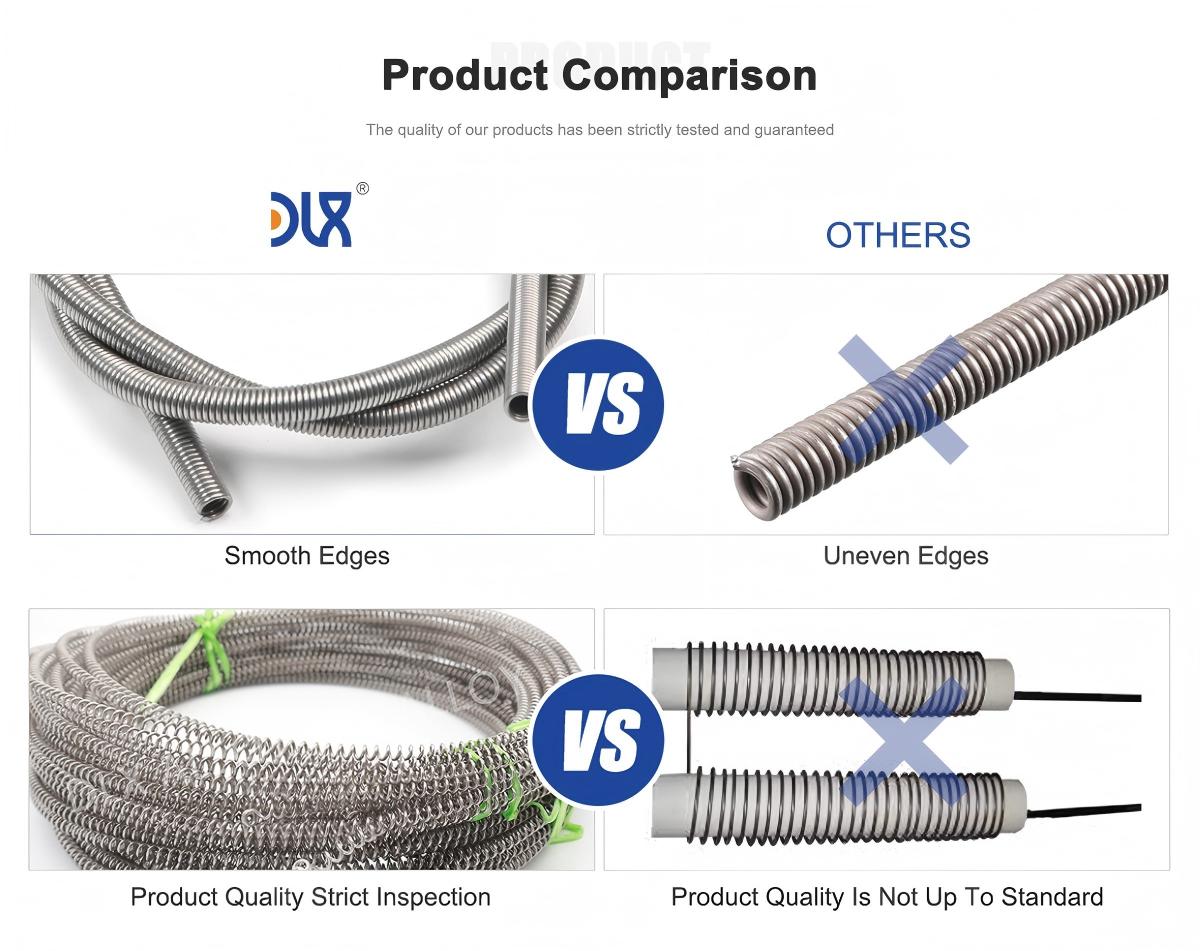

When it comes to high-temperature kiln bars, we know you’ve got options. But here’s why our 0Cr21Al6 FeCrAl Kiln Bar stands out. Unlike some competitors who focus on generic alloys, we specialize in tailoring our products to your exact needs. Need a specific bar length or diameter? We’ve got you covered with custom fabrication that ensures a perfect fit for your kiln. Our manufacturing process uses advanced techniques like vacuum smelting to boost alloy purity, which translates to better performance and longer lifespan.

We also prioritize cost-efficiency. While some companies push pricier alloys with fancy additives, our 0Cr21Al6 delivers top-tier oxidation resistance and durability at a fraction of the cost—think $18-28/kg compared to $28-50/kg for premium grades. This makes it a smart pick for businesses looking to optimize budgets without skimping on quality.

Our supply chain is another edge. We’ve streamlined sourcing and production to dodge the raw material price swings that plague the industry. This means stable pricing and faster delivery times, so you’re not left waiting when your kiln needs a replacement. Plus, our team offers hands-on technical support, from selecting the right alloy to troubleshooting installation. Other companies might leave you to figure it out—we’re with you every step of the way.

Quality control is non-negotiable for us. Every batch of 0Cr21Al6 undergoes rigorous testing for chemical composition, resistivity, and mechanical strength. This ensures you get a product that meets specs and performs reliably in the field. Competitors might cut corners; we don’t. Our focus on precision engineering means fewer failures and less downtime for your operations.

Finally, we’re big on sustainability. Our kiln bars are designed for energy efficiency, helping you cut power costs and meet environmental regulations. Some alternatives, like nichrome-based bars, can’t match the oxidation resistance of our FeCrAl alloy at high temperatures, meaning more frequent replacements and higher long-term costs. With our 0Cr21Al6, you get a product that lasts longer and performs better, all while keeping your operations greener.

Comparison Parameters Table

Parameter | FeCrAl 0Cr21Al6 Furnace Bar | Other Heating Alloys |

|---|---|---|

Composition | Fe (Bal), Cr (21%), Al (6%) | Varies (e.g., NiCr, FeCr, or other alloys) |

Oxidation Resistance | Superior at high temperatures up to 1350°C | Good, but often limited to 1200-1300°C |

Max Operating Temperature | 1350°C | 1100-1300°C (varies by alloy) |

Resistivity (μΩ·m) | 1.43 | 1.0-1.4 (varies, often lower) |

Mechanical Strength | High, 630-780 MPa tensile strength | Moderate to high (500-700 MPa, varies) |

Workability | Excellent formability for complex shapes | Moderate, may require specialized handling |

Applications | Industrial furnaces, kilns, heat treatment | General heating, less specialized applications |

Durability | Exceptional in high-heat, corrosive settings | Good, but less resistant to extreme oxidation |

Why Choose Our 0Cr21Al6 FeCrAl Kiln Bar?

Our High-Temperature 0Cr21Al6 FeCrAl Kiln Bar is built to deliver unmatched performance in the toughest industrial environments. Its high aluminum content and robust design ensure it stands up to extreme heat and corrosion, making it a trusted choice for kilns, furnaces, and beyond. Whether you’re firing ceramics, treating metals, or producing glass, this kiln bar keeps your operations running smoothly with minimal maintenance.

We’re proud to offer a product that blends cutting-edge alloy technology with practical, cost-effective solutions. With our customization options, competitive pricing, and top-notch support, we’re not just selling kiln bars—we’re helping you power your business forward. Ready to upgrade your heating elements? Our 0Cr21Al6 FeCrAl Kiln Bar is the reliable, high-performance choice you’ve been looking for.

For more details, pls directly contact us

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What is FeCrAl 0Cr21Al6 furnace bar?

It’s a high-performance heating element made from FeCrAl 0Cr21Al6, an iron-chromium-aluminum alloy, designed for durability and high-temperature resistance in industrial furnaces.Why is FeCrAl 0Cr21Al6 ideal for industrial heating?

Its excellent oxidation resistance and ability to withstand temperatures up to 1350°C make it perfect for demanding industrial heating applications.What are the main applications of this furnace bar?

It’s used in industrial furnaces, kilns, heat treatment systems, and electric ovens for consistent high-temperature performance.How does the alloy’s composition enhance performance?

The iron-chromium-aluminum blend provides high resistivity, oxidation resistance, and thermal stability for reliable heating.What environments can this furnace bar resist?

It withstands high-temperature oxidation, corrosive gases, and thermal cycling in harsh industrial settings.What temperature range can it handle?

It performs reliably up to 1350°C, maintaining structural integrity in extreme heat.Is the furnace bar easy to install and maintain?

Yes, its robust design and formability allow easy installation and low maintenance in industrial heating systems.Which industries benefit from this furnace bar?

Metallurgy, ceramics, glass manufacturing, and chemical processing industries rely on its high-temperature durability.