Our GH1140 superalloy strip is built to handle the toughest industrial environments, delivering unbeatable strength and oxidation resistance where extreme heat is the norm. This nickel-iron-chromium alloy is a game-changer for high-temperature applications, and we’re here to show you what makes it stand out, how it fits into industry trends, and why our product is the top choice for your projects.

For more details, pls directly contact us.

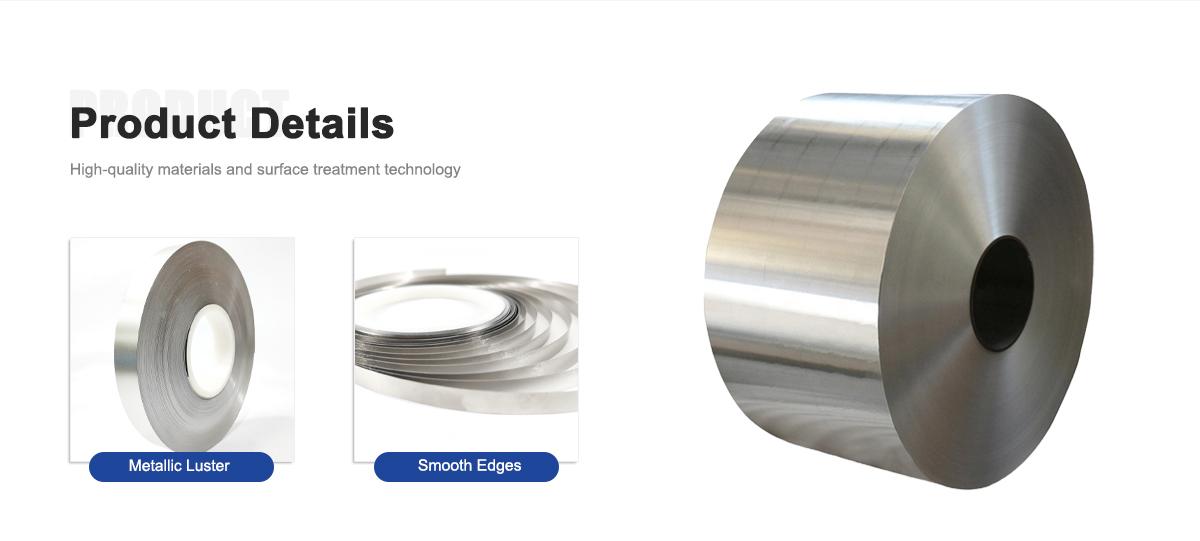

GH1140 is a nickel-iron-chromium superalloy designed to thrive in blistering heat and harsh conditions. With a robust mix of nickel, iron, and chromium, it forms a protective oxide layer that shrugs off oxidation and corrosion, performing reliably up to 850°C (and hitting 1000°C for short bursts). Its high creep resistance and tensile strength make it perfect for industrial components like furnace parts, heat exchangers, and turbine components. Our GH1140 strips are precision-rolled to ensure uniform thickness and a smooth surface, ready for the most demanding applications.

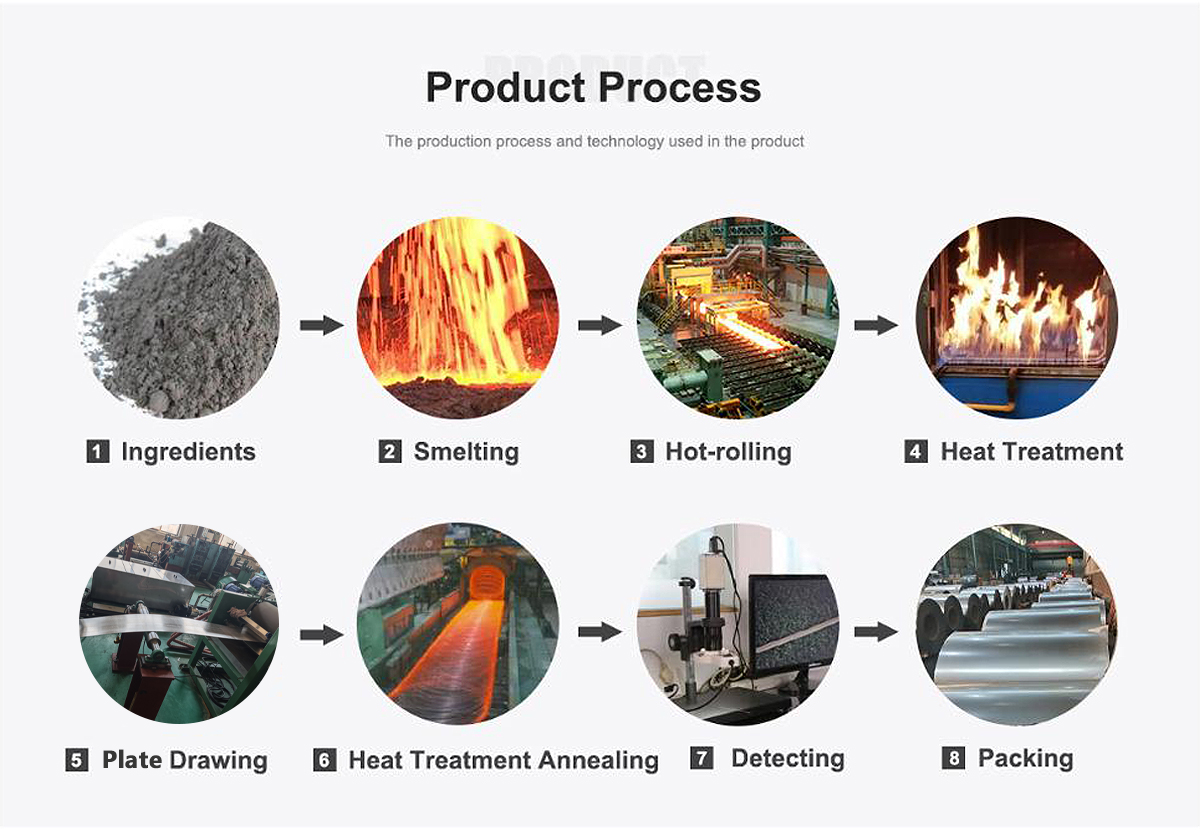

We craft our strips with advanced manufacturing techniques, and the alloy’s heat-treatable nature lets us fine-tune its strength and toughness to meet your specific needs, whether for new builds or component repairs.

Our GH1140 strips are a powerhouse in industrial settings, driving components like furnace linings, heat exchangers, and petrochemical reactors that face intense heat and stress. Its oxidation resistance and durability make it a go-to for power generation turbines and aerospace parts like combustors. You’ll also find it in chemical processing and oil and gas systems, where high temperatures and corrosive environments demand top performance. The strip’s versatility makes it ideal for both manufacturing new parts and extending the life of worn components through repairs.

|

Item |

Nimonic80A |

Nimonic 90 |

GH1140 |

GH3625 |

GH3536 |

GH4169 |

|

|

C |

≤0.08 |

≤0.1 |

≤0.13 |

0.06-0.12 |

≤0.1 |

0.05-0.15 |

≤0.08 |

|

Mn |

≤2 |

≤1 |

≤1 |

≤0.7 |

3.14-4.15 |

-- |

≤0.35 |

|

Fe |

rest |

≤3 |

≤1.5 |

rest |

≤0.5 |

-- |

rest |

|

P |

≤0.04 |

≤0.02 |

-- |

≤0.025 |

-- |

-- |

-- |

|

S |

≤0.03 |

≤0.015 |

≤0.015 |

≤0.015 |

-- |

-- |

≤0.01 |

|

Si |

≤1 |

≤1 |

≤1 |

≤0.8 |

-- |

-- |

≤0.35 |

|

Cu |

-- |

-- |

≤0.2 |

-- |

-- |

-- |

≤0.3 |

|

Ni |

24-27 |

rest |

-- |

35-40 |

rest |

rest |

50-55 |

|

Co |

-- |

≤2 |

15-21 |

-- |

≤1.00 |

0.5-2.5 |

≤1.00 |

|

Al |

≤0.35 |

1-1.8 |

1-2 |

0.2-0.6 |

≤0.4 |

≤0.5 |

0.2-0.8 |

|

Ti |

1.9-2.35 |

1.8-2.7 |

2-3 |

0.7-1.2 |

≤0.4 |

≤0.15 |

0.7-1.15 |

|

Cr |

13.5-16 |

18-21 |

18-21 |

20-23 |

20-23 |

20.5-23 |

17-21 |

|

Nb |

-- |

-- |

-- |

-- |

-- |

-- |

4.75-5.5 |

|

Mo |

1-1.5 |

-- |

-- |

2-2.5 |

8-10 |

8-10 |

2.8-3.3 |

|

B |

0.001-0.1 |

≤0.008 |

≤0.02 |

-- |

-- |

-- |

-- |

|

V |

0.1-0.5 |

-- |

-- |

-- |

-- |

-- |

-- |

|

W |

-- |

-- |

-- |

1.4-1.8 |

-- |

0.2-1 |

-- |

|

Zr |

-- |

≤0.15 |

≤0.15 |

-- |

-- |

-- |

-- |

|

Pb |

-- |

-- |

≤0.002 |

-- |

-- |

-- |

-- |

|

Ce |

-- |

-- |

-- |

≤0.05 |

-- |

-- |

-- |

|

Size Range |

|

|

Wire |

0.5-7.5mm |

|

Rod/Bar |

8.0-200mm |

|

Strip |

(0.50-2.5)*(5-180)mm |

|

Tube |

custom made |

| Plate | custom made |

For more details, pls directly contact us.

Industries like power generation, petrochemical, and aerospace are pushing for materials that can handle higher temperatures to boost efficiency and cut emissions. GH1140’s ability to maintain strength and resist oxidation in extreme heat makes it a key player in these applications. The trend toward sustainable, high-efficiency systems is driving demand for durable, low-maintenance materials, and GH1140’s long lifespan and resistance to thermal fatigue fit perfectly. Precision manufacturing is also a big deal, and our strips’ consistent quality supports complex designs and high-performance systems across industries.

|

Parameter |

GH1140 Alloy |

Other Nickel-Based Alloys |

Stainless Steel |

|---|---|---|---|

|

Max Service Temperature |

Up to 850°C (long-term), 1000°C (short-term) |

Up to 700–800°C |

Up to 600–650°C |

|

Oxidation Resistance |

Excellent (Ni-Fe-Cr oxide layer) |

Good to moderate |

Moderate to low |

|

Creep Strength |

High, resists deformation at 850°C |

Moderate to high |

Low at high temperatures |

|

Corrosion Resistance |

Strong in oxidative environments |

Good in specific conditions |

Moderate, varies by grade |

|

Tensile Strength (Room Temp) |

~900 MPa |

~700–900 MPa |

~500–600 MPa |

|

Elongation (Room Temp) |

~20% |

~15–25% |

~20–40% |

|

Fatigue Resistance |

Excellent, ideal for cyclic loads |

Good to moderate |

Moderate, less suited for high stress |

|

Applications |

Industrial furnaces, petrochemical, aerospace |

Aerospace, industrial |

General industrial, lower temp applications |

We’ve perfected our GH1140 strips to deliver unmatched performance, and here’s why we’re the best pick:

-

Rock-Solid Quality: Our strips achieve near-perfect consistency with minimal defects, ensuring top performance in extreme industrial environments.

-

Precision Manufacturing: We use advanced rolling techniques to produce strips with uniform thickness and a flawless surface, ready for high-heat applications.

-

Tailored Performance: Heat-treatment options let us customize strength and toughness to match your project’s exact demands.

-

Unbeatable Durability: With excellent creep and oxidation resistance, our strips last longer, reducing downtime and maintenance costs.

-

Industry Expertise: We’ve been supplying high-performance alloys to industrial and aerospace leaders for years, so we know how to meet the toughest standards.

Other alloys might struggle with oxidation or lose strength in high heat, but our GH1140 strips keep performing, no matter the challenge. We’ve seen competing materials falter in extreme industrial conditions, while our strips consistently deliver the strength and reliability you need.

Conclusion

Our GH1140 superalloy strips are engineered to conquer extreme heat in industrial applications, offering top-tier strength and oxidation resistance. With unmatched durability and compatibility with high-performance designs, they’re the perfect choice for furnaces, turbines, and petrochemical systems. As industries chase efficiency and reliability, our GH1140 strips are ready to deliver the performance you need to stay ahead. Ready to tackle extreme heat? Our GH1140 alloy is your answer.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is GH1140 used for?

GH1140 is used for industrial components like furnace parts, heat exchangers, and turbine components in extreme heat environments. -

What temperatures can GH1140 withstand?

It performs reliably up to 850°C for continuous use and can handle short-term exposure up to 1000°C. -

How does GH1140 resist oxidation?

Its nickel-iron-chromium composition forms a durable oxide layer, protecting against oxidation in high-heat conditions. -

Is GH1140 suitable for high-stress applications?

Yes, its high creep resistance and tensile strength make it ideal for components under extreme thermal and mechanical stress. -

What are the mechanical benefits of GH1140?

It offers excellent strength, fatigue resistance, and durability in high-temperature industrial settings. -

How does GH1140 compare to other alloys?

It outperforms many nickel alloys and stainless steels in oxidation resistance and strength at elevated temperatures. -

Which industries use GH1140?

Mainly industrial furnaces, power generation, petrochemical, and aerospace for high-heat, high-stress applications. -

Can GH1140 be heat-treated?

Yes, it can be solution-treated and aged to optimize strength and toughness for specific industrial needs.