When it comes to manufacturing high-performance turbine blades that need to withstand high heat and aggressive oxidation, Nimonic75 seamless strip has proven to be one of the most reliable materials in the game. Our company has been delivering precision-rolled Nimonic75 strips to industries that can’t afford to compromise on thermal stability, surface integrity, or dimensional consistency.

Nimonic75 is a nickel-chromium-based alloy that performs exceptionally well under oxidizing conditions, particularly at temperatures reaching up to 1050°C. It was originally developed for aerospace engine parts, but due to its outstanding oxidation resistance, it is now widely used in gas turbines, industrial heating systems, and nuclear reactor applications.

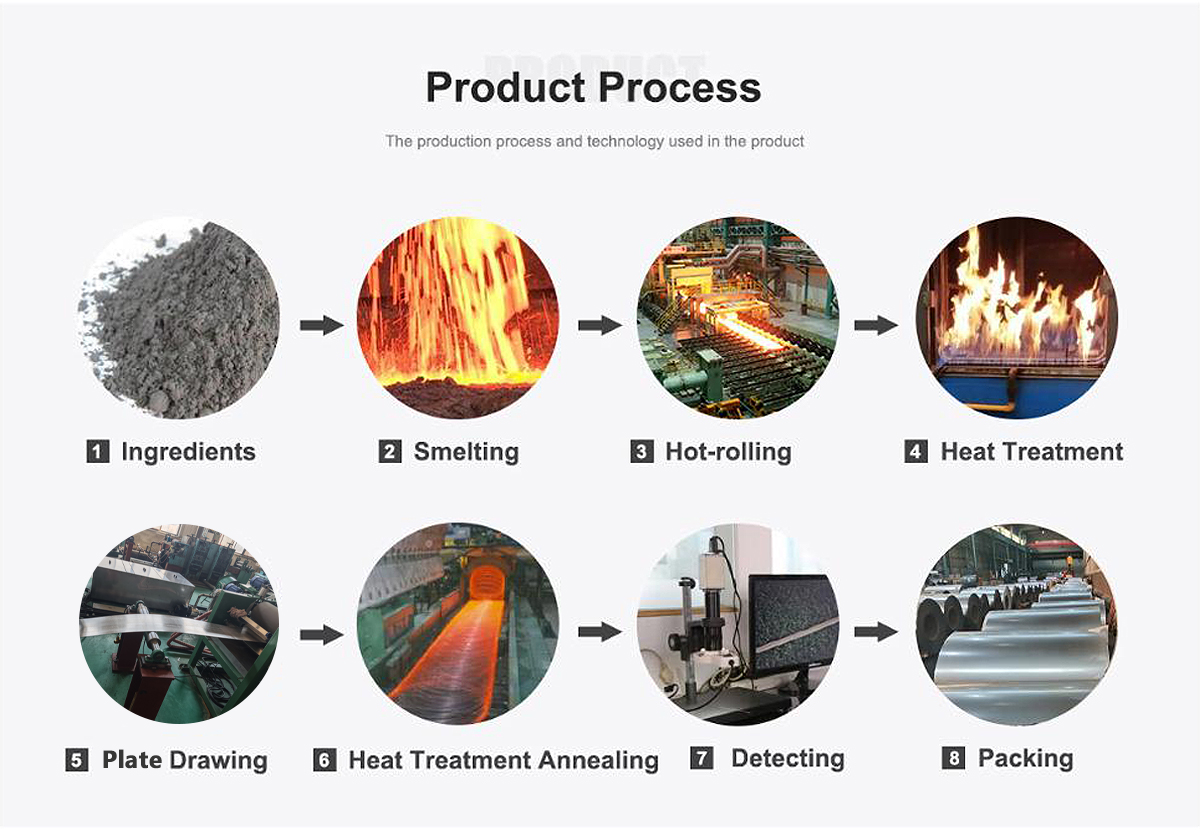

Our seamless strip production process eliminates the risk of weak weld lines or material fatigue. Every coil we deliver meets strict international aerospace standards, with customizable thicknesses down to microns and ultra-smooth surface finishes that reduce post-processing needs.

For more details, pls directly contact us.

The turbine blade market is moving toward longer service cycles, higher thrust-to-weight ratios, and materials that can resist environmental degradation. With increasing demand for energy efficiency and reliability, Nimonic75’s consistent mechanical strength and oxidation resistance make it a go-to material in both OEM and MRO sectors.

We’ve seen a growing need for ultra-thin seamless strips for precision blades and thermal shields — especially in aerospace and next-gen power generation. The industry is also trending toward cleaner alloys with controlled trace elements, which we already integrate in our in-house melting and refining process.

Item | Nimonic80A | Nimonic 90 | GH1140 | GH3625 | GH3536 | GH4169 | |

C | ≤0.08 | ≤0.1 | ≤0.13 | 0.06-0.12 | ≤0.1 | 0.05-0.15 | ≤0.08 |

Mn | ≤2 | ≤1 | ≤1 | ≤0.7 | 3.14-4.15 | -- | ≤0.35 |

Fe | rest | ≤3 | ≤1.5 | rest | ≤0.5 | -- | rest |

P | ≤0.04 | ≤0.02 | -- | ≤0.025 | -- | -- | -- |

S | ≤0.03 | ≤0.015 | ≤0.015 | ≤0.015 | -- | -- | ≤0.01 |

Si | ≤1 | ≤1 | ≤1 | ≤0.8 | -- | -- | ≤0.35 |

Cu | -- | -- | ≤0.2 | -- | -- | -- | ≤0.3 |

Ni | 24-27 | rest | -- | 35-40 | rest | rest | 50-55 |

Co | -- | ≤2 | 15-21 | -- | ≤1.00 | 0.5-2.5 | ≤1.00 |

Al | ≤0.35 | 1-1.8 | 1-2 | 0.2-0.6 | ≤0.4 | ≤0.5 | 0.2-0.8 |

Ti | 1.9-2.35 | 1.8-2.7 | 2-3 | 0.7-1.2 | ≤0.4 | ≤0.15 | 0.7-1.15 |

Cr | 13.5-16 | 18-21 | 18-21 | 20-23 | 20-23 | 20.5-23 | 17-21 |

Nb | -- | -- | -- | -- | -- | -- | 4.75-5.5 |

Mo | 1-1.5 | -- | -- | 2-2.5 | 8-10 | 8-10 | 2.8-3.3 |

B | 0.001-0.1 | ≤0.008 | ≤0.02 | -- | -- | -- | -- |

V | 0.1-0.5 | -- | -- | -- | -- | -- | -- |

W | -- | -- | -- | 1.4-1.8 | -- | 0.2-1 | -- |

Zr | -- | ≤0.15 | ≤0.15 | -- | -- | -- | -- |

Pb | -- | -- | ≤0.002 | -- | -- | -- | -- |

Ce | -- | -- | -- | ≤0.05 | -- | -- | -- |

Size Range | |

Wire | 0.5-7.5mm |

Rod/Bar | 8.0-200mm |

Strip | (0.50-2.5)*(5-180)mm |

Tube | custom made |

| Plate | custom made |

For more details, pls directly contact us.

Aircraft turbine blades and combustion chambers

Gas turbine engines in power plants

Heat exchangers exposed to high oxidizing environments

High-temperature springs and fasteners

Thermal shielding for reactors and furnace linings

Parameter Comparison Table – Nimonic75 vs Similar Alloys

| Property | Nimonic75 | Inconel 600 | Hastelloy X |

|---|---|---|---|

| Ni Content (%) | ~80 | ~72 | ~47 |

| Cr Content (%) | ~20 | ~14-17 | ~22 |

| Max Operating Temp (°C) | 1050 | 1093 | 1175 |

| Oxidation Resistance | Excellent | Good | Good |

| Formability (Thin Strip) | Excellent | Good | Moderate |

| Weldability | Good | Excellent | Moderate |

| Creep Resistance | High | Medium | High |

| Typical Strip Thickness (mm) | 0.05 – 2.5 | 0.1 – 2.5 | 0.25 – 3.0 |

We don’t just sell materials — we engineer solutions. Our Nimonic75 strips are produced using vacuum induction melting and precision cold rolling, giving our customers enhanced control over microstructure and dimensional tolerances. Our short lead times, rigorous inspection protocols, and flexibility in custom orders allow us to deliver performance-driven strip solutions for even the most demanding environments.

Our in-house R&D team continuously works with aerospace and energy clients to develop alloy upgrades, optimize forming behavior, and predict long-term performance under thermal cycling.

If you're building something that needs to resist oxidation, hold shape under heat, and perform reliably over time, our Nimonic75 seamless strip is the answer. Get in touch with us to explore specifications, request samples, or discuss your custom application needs.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the maximum service temperature of Nimonic75?

Up to 1050°C (1922°F)Is Nimonic75 suitable for aerospace turbine blades?

Yes, it is widely used in aerospace-grade components requiring oxidation resistance.Does Nimonic75 offer good creep resistance?

Yes, it has excellent creep resistance at elevated temperatures.What is the typical thickness range for Nimonic75 seamless strip?

From 0.05 mm to 2.5 mm.Is this alloy corrosion-resistant?

Yes, it has good resistance to oxidation and corrosion, especially at high temperatures.Can Nimonic75 strips be customized in width and surface finish?

Yes, custom width and surface finishes are available.Is it weldable?

Yes, Nimonic75 can be welded using standard techniques.What certification standards does it meet?

Typically conforms to AMS 5599, ASTM B333, and equivalent aerospace standards.