Our Inconel 625 strip is engineered for aerospace component manufacturing where corrosion resistance and high strength are critical. This nickel-chromium-molybdenum alloy, enhanced with niobium, delivers exceptional durability in extreme environments, resisting pitting, crevice corrosion, and oxidation up to 1800°F (982°C). Perfect for turbine blades, exhaust systems, and structural components, our strips are precision-rolled to meet tight tolerances and ASTM B443/ASME SB 443 standards. With outstanding weldability and fatigue resistance, Inconel 625 ensures reliable performance in high-stress aerospace applications, from jet engines to spacecraft parts.

For more details, pls directly contact us.

The aerospace industry is soaring, driven by demand for fuel-efficient aircraft, advanced propulsion systems, and space exploration. High-performance alloys like Inconel 625 are in high demand for their ability to withstand corrosive environments and extreme temperatures. Trends show increased adoption of additive manufacturing and lightweight materials to improve fuel efficiency, alongside stricter regulations for emissions and safety. The rise of urban air mobility and reusable rockets is pushing the need for durable, corrosion-resistant components. Despite challenges like supply chain constraints and volatile nickel prices, the aerospace materials market is set to grow through 2030. Our Inconel 625 strip is tailored to meet these evolving needs, balancing performance and cost-efficiency.

Comparison Table

Parameter | Inconel 625 Strip | Typical Competitor Alloy |

|---|---|---|

Nickel Content | ~58% | ~50-55% |

Chromium Content | 20-23% | 15-20% |

Molybdenum Content | 8-10% | 3-5% |

Key Alloying Elements | Niobium, Tantalum | Varies, often less effective |

Max Service Temperature | 1800°F (982°C) | ~1500°F (816°C) |

Corrosion Resistance | Outstanding in acidic and chloride media | Moderate, less effective in harsh conditions |

Tensile Strength | ~120 ksi | ~90-100 ksi |

W_Linkability | Excellent, resists post-weld cracking | Moderate, prone to cracking |

Key Applications | Turbine blades, exhausts, heat shields | General aerospace components |

Fatigue Resistance | High, ideal for cyclic loading | Moderate, less reliable under stress |

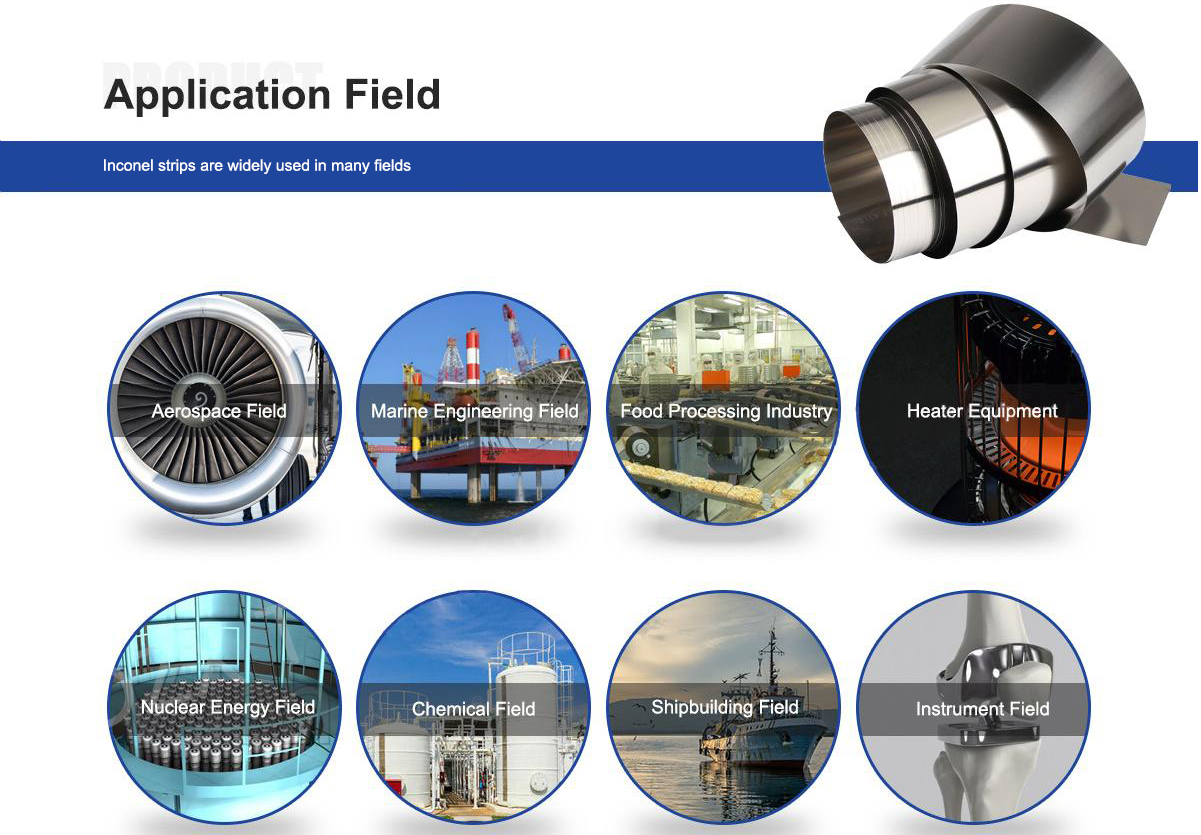

Our Inconel 625 strip shines in aerospace applications where corrosion and heat are relentless. It’s ideal for turbine blades, combustor cans, and exhaust systems in jet engines, thanks to its resistance to high-temperature oxidation and chloride stress-corrosion cracking. In spacecraft, it’s used for structural components and heat shields that face extreme thermal cycles. The alloy’s versatility extends to chemical processing for reactor components and marine applications for propeller blades, where its corrosion resistance tackles saltwater exposure. Wherever high strength and durability are needed, our Inconel 625 strip delivers.

Item | Inconel 600 | Inconel 601 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel 825 | ||

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.02-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

Our Inconel 625 strip sets the bar high. We use state-of-the-art rolling processes to ensure uniform thickness and flawless surfaces, critical for aerospace precision. Every batch is tested for corrosion resistance, tensile strength, and fatigue performance, meeting or exceeding ASTM standards. Unlike some competitors, we offer customizable strip sizes and finishes to fit your exact specifications, ensuring seamless integration into your manufacturing process. Our sustainable production methods—minimizing waste and energy use—deliver a high-quality product with a lower environmental impact. Plus, our optimized supply chain keeps costs competitive, giving you premium Inconel 625 without the premium price.

Why Choose Us?

Our Inconel 625 strip is built for the demands of aerospace manufacturing. With top-notch corrosion resistance, high strength, and reliable performance in extreme conditions, it’s the perfect choice for critical components. We combine precision manufacturing, rigorous quality control, and sustainable practices to deliver a product you can count on. Whether you’re building jet engines, spacecraft, or marine systems, our Inconel 625 strip ensures durability and performance that keep your projects soaring.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

Why is Inconel 625 ideal for aerospace components?

Its nickel-chromium-molybdenum composition offers excellent corrosion resistance and strength up to 1800°F.What aerospace applications use Inconel 625 strip?

Turbine blades, exhaust systems, combustor cans, and spacecraft structural components.How does Inconel 625 handle corrosive environments?

It resists pitting, crevice corrosion, and chloride stress-corrosion cracking, even in harsh conditions.What standards do your Inconel 625 strips meet?

Our strips comply with ASTM B443 and ASME SB 443 for consistent quality.How do your strips compare to competitors?

We provide superior precision, customizable options, and competitive pricing through efficient production.Can Inconel 625 strip withstand high temperatures?

Yes, it maintains strength and oxidation resistance up to 1800°F.Is Inconel 625 suitable for spacecraft?

Absolutely, its durability and thermal resistance make it ideal for heat shields and structural parts.How do you ensure sustainability in production?

We optimize material use and employ energy-efficient processes to reduce waste.