Our Inconel 690 welded tube is a high-performance nickel-chromium alloy engineered for nuclear reactor steam generator systems. With ~60% nickel and ~30% chromium, it’s built to resist stress corrosion cracking and oxidation in high-radiation, high-temperature environments. Perfect for steam generator tubing and heat exchangers, this welded tube ensures reliable performance up to 1800°F (982°C). Its high chromium content forms a protective oxide layer, while its welded design offers cost-effective strength. Easy to fabricate and weld, our Inconel 690 tube is a top choice for nuclear engineers needing durability and safety.

The nuclear power industry is gaining momentum, driven by global demand for clean, reliable energy and advancements in reactor technology. The nuclear steam generator market is projected to grow through 2030, fueled by the need for materials that meet stringent safety and performance standards in high-radiation environments. Inconel 690 welded tube is a standout, offering unmatched resistance to stress corrosion cracking and oxidation. With sustainability trends emphasizing durable materials that reduce maintenance and enhance reactor efficiency, our tube aligns perfectly with the industry’s focus on long-term, eco-friendly solutions.

Comparison Table: Inconel 690 vs. Other Nickel-Based Alloys

Parameter | Inconel 690 | Inconel 600 | Hastelloy C-276 | |

|---|---|---|---|---|

Nickel Content | ~60% | ~72% | ~61% | ~57% |

Chromium Content | ~30% | ~14-17% | ~21-23% | ~16% |

Iron Content | ~9% | ~6-10% | ~5% | ~5% |

Max Operating Temp | 1800°F (982°C) | 2000°F (1093°C) | 1800°F (982°C) | 1900°F (1038°C) |

Corrosion Resistance | Superior in nuclear environments | Good in reducing environments | Excellent in seawater and acids | Superior in harsh acids |

Oxidation Resistance | Excellent | Excellent | Very good | Good |

Tensile Strength | ~100 ksi | ~93 ksi | ~120 ksi | ~100 ksi |

Key Applications | Nuclear steam generators, chemical processing | Furnace components, chemical processing | Offshore equipment, aerospace | Chemical processing, pollution control |

Our Inconel 690 welded tube excels in critical applications:

Nuclear Power: Used in steam generator tubing and heat exchangers, resisting stress corrosion in high-radiation environments.

Chemical Processing: Supports piping and reactors exposed to corrosive chemicals and high temperatures.

Petrochemical Industry: Powers heat exchangers in refineries, handling harsh, high-heat conditions.

Aerospace: Enhances high-temperature components like exhaust systems, resisting oxidation.

Power Generation: Ensures reliability in boiler tubing for efficient energy production.

Its corrosion resistance and durability make it ideal for nuclear steam generator systems.

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 825 | ||

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.02-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

Our Inconel 690 welded tube sets the benchmark for nuclear reactor applications. We produce tubes that meet stringent ASTM B163 and ASME SB-163 standards, ensuring top-tier quality for steam generator systems. Unlike others, we offer customized solutions—specific diameters, wall thicknesses, and lengths tailored to your project needs. Our global supply chain guarantees consistent availability, and our DFARS-compliant products are perfect for nuclear and defense projects. Every batch is rigorously tested for corrosion resistance, tensile strength, and creep performance, so you get tubes that perform reliably. Our 24/7 support team is ready to tackle your project challenges, making us the partner you can trust.

Why Our Inconel 690 Welded Tube is the Best Choice

Our Inconel 690 welded tube is built for nuclear reactor steam generator systems that demand reliability and durability. Its superior resistance to stress corrosion cracking and high-temperature performance ensures your systems stay safe and efficient in the harshest conditions. With the nuclear industry prioritizing safety and sustainability, our tube delivers long-term value by minimizing maintenance and enhancing performance. Ready to power your nuclear projects? Contact us for a quote today and see how our Inconel 690 welded tube can transform your operations.

About Us:

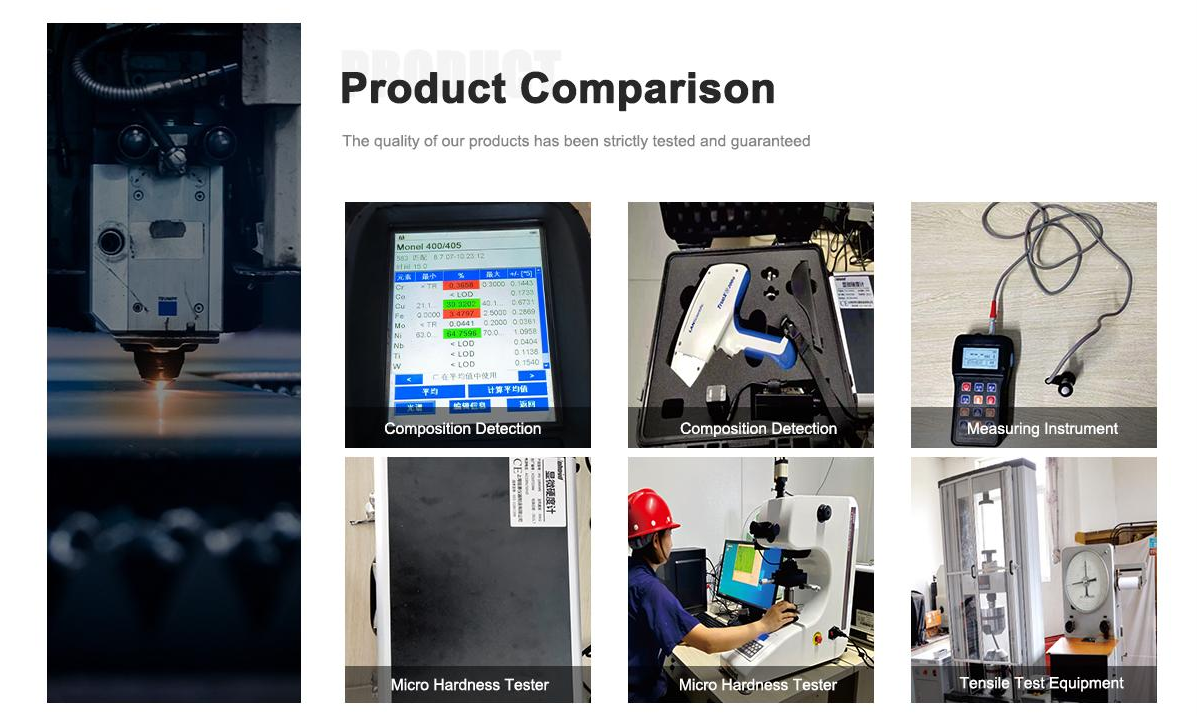

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is Inconel 690 welded tube made of?

It’s a nickel-chromium alloy with ~60% nickel, ~30% chromium, and ~9% iron, designed for superior corrosion and stress resistance.Why is Inconel 690 welded tube ideal for nuclear reactor steam generators?

Its exceptional resistance to stress corrosion cracking and oxidation in high-radiation environments ensures reliability in steam generator systems.What temperatures can Inconel 690 welded tube handle?

It performs reliably up to 1800°F (982°C), maintaining strength and stability in nuclear reactor conditions.What industries use Inconel 690 welded tube?

Nuclear power, chemical processing, aerospace, and petrochemical industries rely on it for corrosion-resistant, high-temperature components.How does Inconel 690 welded tube compare to other alloys?

It offers superior resistance to stress corrosion cracking in nuclear environments, though it may have slightly lower strength than some high-temperature alloys.Is Inconel 690 welded tube weldable?

Yes, it’s optimized for welding with techniques like TIG, ensuring strong, reliable joints for steam generator tubing.What are the mechanical properties of Inconel 690 welded tube?

It has a tensile strength of ~100 ksi, excellent creep resistance, and high ductility, perfect for nuclear applications.How does Inconel 690 welded tube support sustainability?

Its durability reduces maintenance and replacements, lowering costs and environmental impact in nuclear reactor operations.