DLX Factory, a leading direct manufacturer of high-performance alloys, has expanded its product line to include advanced resistance wire and heating element solutions. With a commitment to quality, reliability, and innovation, DLX continues to support industries requiring precise thermal control, long service life, and consistent performance under extreme conditions.

DLX offers a range of resistance wires, including FeCrAl and NiCr series, each engineered for high-temperature stability, excellent oxidation resistance, and predictable electrical characteristics. FeCrAl Wire s are widely recognized for their superior performance in industrial heaters, kilns, and furnaces, providing consistent heat output over extended operating periods. NiCr wires are preferred in laboratory equipment, precision heating systems, and specialty industrial applications where controlled resistance and thermal uniformity are critical.

Both wire types benefit from DLX’s advanced manufacturing processes, which ensure uniform diameter, chemical composition, and mechanical strength. The result is a product that reliably meets demanding industrial and scientific applications without compromising performance or safety.

Applications Across Industries

DLX resistance wires serve a broad spectrum of industries. In the industrial heating sector, FeCrAl wires are used in ceramic kilns, glass furnaces, and food processing ovens. Their high-temperature tolerance and resistance to oxidation make them ideal for environments that operate continuously at elevated temperatures. NiCr wires are commonly found in laboratory furnaces, temperature-controlled ovens, and specialized industrial equipment requiring precise heating.

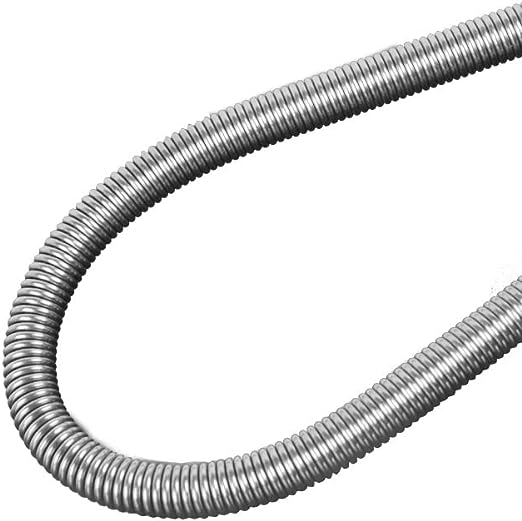

Heating elements manufactured by DLX are customized to meet the specific requirements of each client. This includes tailored wire lengths, diameters, and coil configurations. Such flexibility ensures that the heating elements integrate seamlessly into production lines, laboratory setups, or industrial installations, maximizing efficiency and minimizing maintenance requirements.

The global resistance wire and heating element market is experiencing steady growth, fueled by industrial automation, increased energy efficiency requirements, and technological advances in high-temperature processes. Manufacturers are increasingly seeking materials that offer not only high performance but also durability and environmental compliance.

DLX Factory monitors these trends closely. Our research and development team continuously innovates to improve wire lifespan, enhance oxidation resistance, and optimize thermal efficiency. This proactive approach ensures that DLX products remain at the forefront of market expectations, helping clients improve productivity and reduce operational costs.

Performance Comparison Table

| Property | FeCrAl Wire | NiCr Wire | DLX Heating Elements |

|---|---|---|---|

| Composition | Fe-Cr-Al | Ni-Cr | FeCrAl/NiCr combinations |

| Max Service Temp | 1400°C | 1200°C | Up to 1400°C |

| Oxidation Resistance | High | Moderate | High |

| Electrical Resistance | Stable | Stable | Engineered per design |

| Tensile Strength | Moderate | Moderate | High |

| Applications | Industrial Heating, Kilns | Precision Heating, Lab Use | Custom Heating Solutions |

| Fatigue Resistance | Moderate | Moderate | High |

| Form Availability | Wire, Coil | Wire, Coil | Custom Coils & Elements |

DLX Factory Advantages

DLX Factory distinguishes itself as a direct manufacturer with end-to-end control over the production process. Every batch undergoes stringent quality checks to guarantee uniform composition, diameter, and mechanical properties. Customers benefit from consistent performance, reduced failure rates, and long-term reliability.

Customization is a core strength of DLX. We work closely with clients to optimize wire diameter, length, and configuration, ensuring that each heating element performs precisely as required. Additionally, DLX’s in-house R&D team focuses on improving wire oxidation resistance, thermal efficiency, and mechanical strength, providing products that exceed industry standards.

DLX Factory supplies resistance wires and heating elements to clients worldwide, covering Europe, North America, Asia, and beyond. Our global logistics network ensures timely delivery, while our technical support team provides guidance on product selection, installation, and maintenance.

This international approach allows DLX to meet diverse industrial requirements, whether it’s high-volume industrial heating systems or specialized laboratory equipment. By combining advanced manufacturing capabilities with responsive customer support, DLX builds long-term partnerships and strengthens trust with clients.

Sustainability and Compliance

DLX Factory integrates sustainability into its production processes. We emphasize energy-efficient manufacturing, waste reduction, and adherence to environmental regulations. This not only minimizes environmental impact but also aligns with the growing demand from industries for environmentally responsible suppliers.

The demand for high-performance resistance wire and heating elements is expected to grow as industries continue to automate and optimize high-temperature processes. DLX Factory is well-positioned to capitalize on this trend, providing materials and solutions that enhance efficiency, reliability, and safety in industrial operations.

Our ongoing investment in R&D ensures that we remain at the forefront of innovation. By continuously improving material performance, thermal stability, and customization options, DLX offers solutions that meet the evolving demands of industries across the globe.

In summary, DLX Factory combines high-quality resistance wire, customized heating elements, and exceptional manufacturing capabilities to provide comprehensive solutions for high-temperature applications. With a focus on industry trends, market expansion, and technical excellence, DLX continues to lead in delivering products that empower industries to operate efficiently, safely, and sustainably.