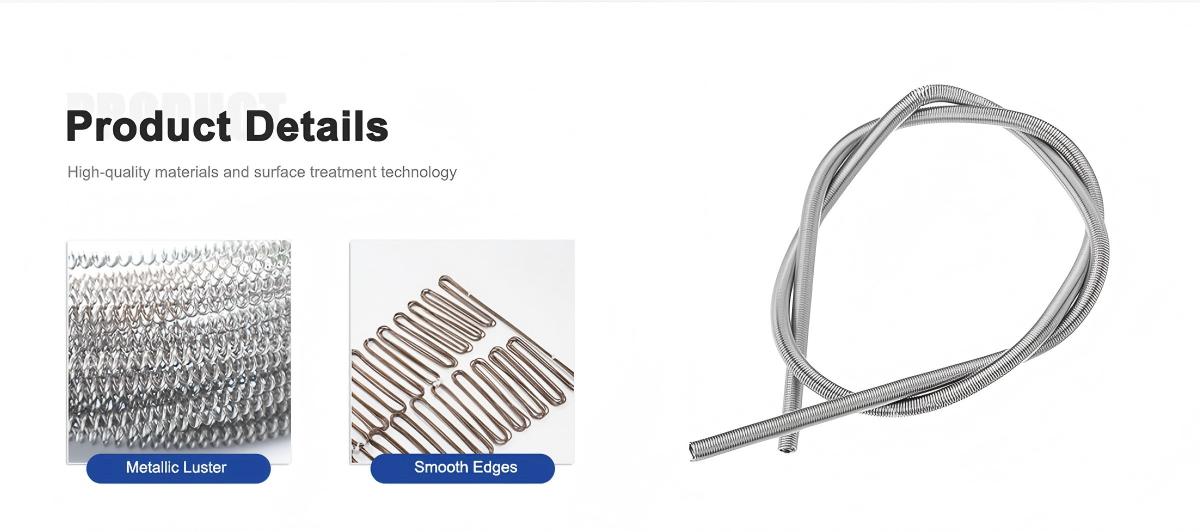

Our Premium 0Cr27Al7Mo2 FeCrAl Kiln Bar is the gold standard for high-temperature heating solutions. Crafted from an advanced iron-chromium-aluminum alloy with 26.5-27.8% chromium, 6-7% aluminum, and a touch of molybdenum, this kiln bar is built to dominate in extreme conditions. It can handle temperatures up to 1400°C (2552°F), making it the go-to choice for advanced kilns that demand top-tier performance. The secret lies in its protective aluminum oxide (Al₂O₃) layer, which forms at high temperatures to fend off oxidation and corrosion like a champ.

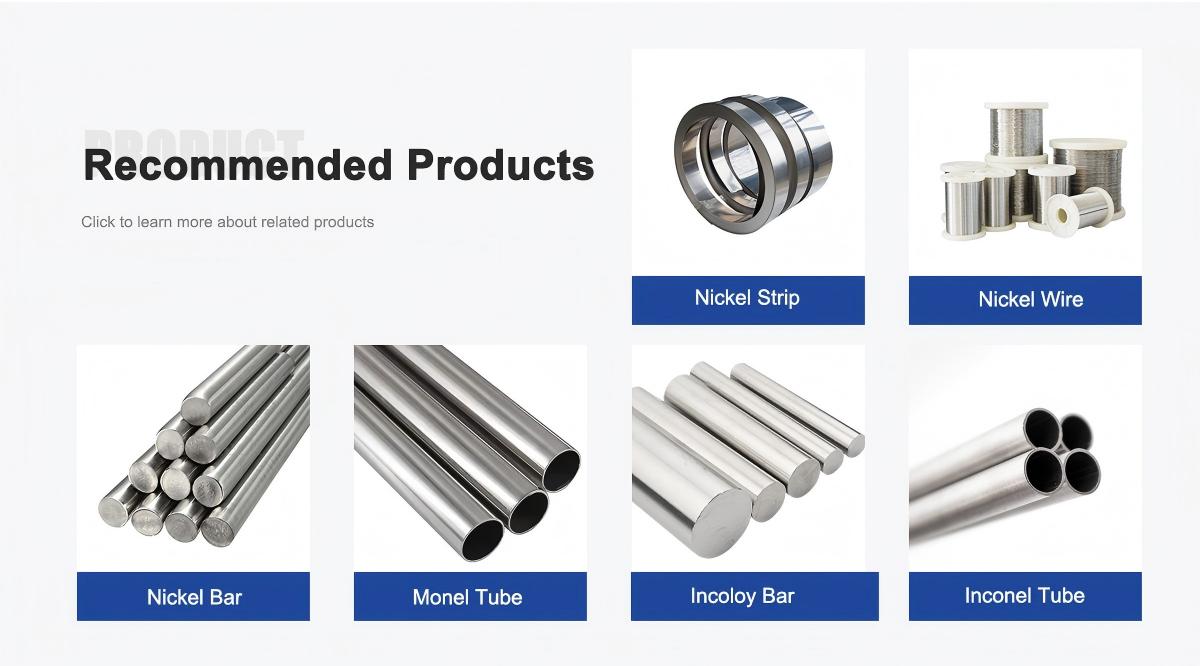

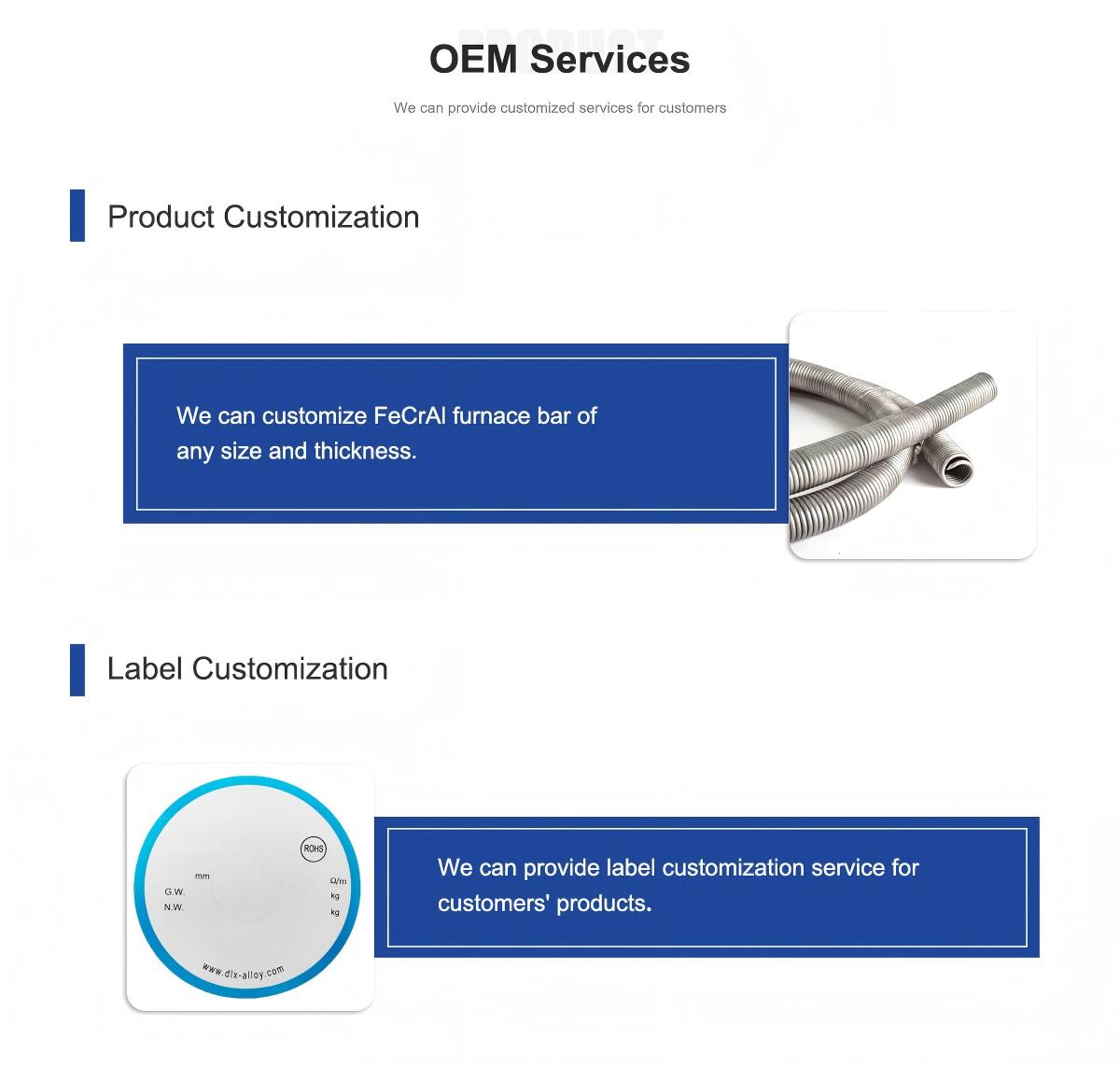

With an electrical resistivity of around 1.53 μΩ·m, this alloy delivers efficient, precise heating for industrial kilns, furnaces, and more. Its tensile strength—ranging from 680 to 830 MPa—ensures it stands up to the toughest thermal stresses, while the molybdenum boost enhances creep resistance for long-term reliability. Whether you’re firing advanced ceramics, processing metals, or melting glass, our 0Cr27Al7Mo2 Kiln Bar keeps things running smoothly. We can customize it into bars, strips, or wires to match your exact specs, ensuring a perfect fit for your setup.

Priced at $28-50/kg, this kiln bar is a premium investment that pays off with unmatched durability and performance. It’s designed for businesses that need the best in high-temperature heating without compromising on quality or longevity.

For more details, pls directly contact us

The high-temperature alloy market is thriving, and our 0Cr27Al7Mo2 FeCrAl Kiln Bar is at the forefront. With industries like ceramics, metallurgy, and aerospace pushing the limits of thermal processing, demand for robust heating elements is soaring. Market forecasts predict a CAGR of 4-6% for high-temperature alloys through 2030, driven by growing production needs and innovations in manufacturing. From small-scale kilns to massive industrial furnaces, companies need components that can handle extreme heat without breaking down.

Sustainability is a major driver in today’s market. Businesses are under pressure to cut energy use and emissions, and our 0Cr27Al7Mo2 Kiln Bar delivers. Its high efficiency and long lifespan reduce energy waste and replacement frequency, helping you meet eco-friendly goals while keeping costs in check. The rise of automation and smart manufacturing is also fueling demand for precision components. Our kiln bar’s ability to maintain consistent performance at extreme temperatures makes it a perfect match for automated systems that require reliability and accuracy.

Customization is a big trend. Industries are moving away from one-size-fits-all solutions, demanding heating elements tailored to their specific processes. Whether it’s precise temperature control for ceramic firing or high-heat stability for aerospace applications, our ability to deliver custom shapes and sizes sets us apart. However, the industry faces challenges like volatile raw material costs for chromium, aluminum, and molybdenum. We’ve mitigated this by optimizing our supply chain, ensuring stable pricing and fast delivery for our customers.

Competition is fierce, with other alloys like standard FeCrAl grades or nichrome options in the mix. While some alternatives are cheaper, our 0Cr27Al7Mo2 offers unmatched high-temperature performance and creep resistance, making it the premium choice for advanced applications. It’s a high-value solution for industries that can’t afford downtime or subpar results.

| Grade | Chemical Composition (wt%) | Density (g/cm³) | Resistivity (μΩ·m) | Max Operating Temp (°C) | Tensile Strength (MPa) | Features & Applications |

|---|---|---|---|---|---|---|

| 0Cr21Al6 | Cr 20.5–21.5, Al 5.5–6.5, Fe balance | 7.10 | 1.45 | 1250 | 650–750 | Excellent high-temperature oxidation resistance; suitable for industrial furnaces and electric kilns |

| 0Cr23Al5 | Cr 22–24, Al 4.5–5.5, Fe balance | 7.15 | 1.42 | 1200 | 650–750 | Stable resistivity; suitable for medium- to high-temperature heating elements |

| 0Cr27Al7Mo2 | Cr 26–28, Al 6–8, Mo 1.8–2.2, Fe balance | 7.25 | 1.35 | 1400 | 700–800 | Exceptional oxidation resistance and high-temperature strength; ideal for prolonged ultra-high-temperature use |

| 0Cr25Al5 | Cr 24–26, Al 4–6, Fe balance | 7.20 | 1.38 | 1300 | 650–750 | Balanced cost and performance; widely applicable |

| 0Cr21Al4 | Cr 20–22, Al 3.5–4.5, Fe balance | 7.10 | 1.47 | 1150 | 600–700 | Suitable for medium-temperature furnace bars; better ductility |

For more details, pls directly contact us

Our 0Cr27Al7Mo2 FeCrAl Kiln Bar is a powerhouse across a range of high-temperature applications. Here’s where it shines:

-

Ceramics Industry: Powers advanced kilns for firing technical ceramics, porcelain, and tiles, delivering precise heat for superior quality.

-

Metallurgy: Used in heat treatment furnaces for processes like sintering, annealing, and forging, withstanding extreme temperatures and thermal cycling.

-

Glass Manufacturing: Supports high-temperature kilns for melting and shaping glass, ensuring consistent performance for specialty and industrial products.

-

Aerospace: Found in heat treatment systems for aerospace components, where its creep resistance and durability handle demanding conditions.

-

Chemical Processing: Resists corrosion in reactors and heat exchangers, thanks to its protective Al₂O₃ layer and molybdenum-enhanced stability.

-

Energy Sector: Used in boiler systems and gas turbines, where it tackles thermal stress and oxidation in high-heat environments.

With a thermal conductivity of about 46.1 KJ/m·h·°C and a low thermal expansion coefficient (14.7 x 10⁻⁶/°C), this kiln bar stays stable under intense heat. Its magnetic properties up to 600°C and enhanced creep resistance make it adaptable for both industrial and specialized applications, ensuring top performance in the most demanding setups.

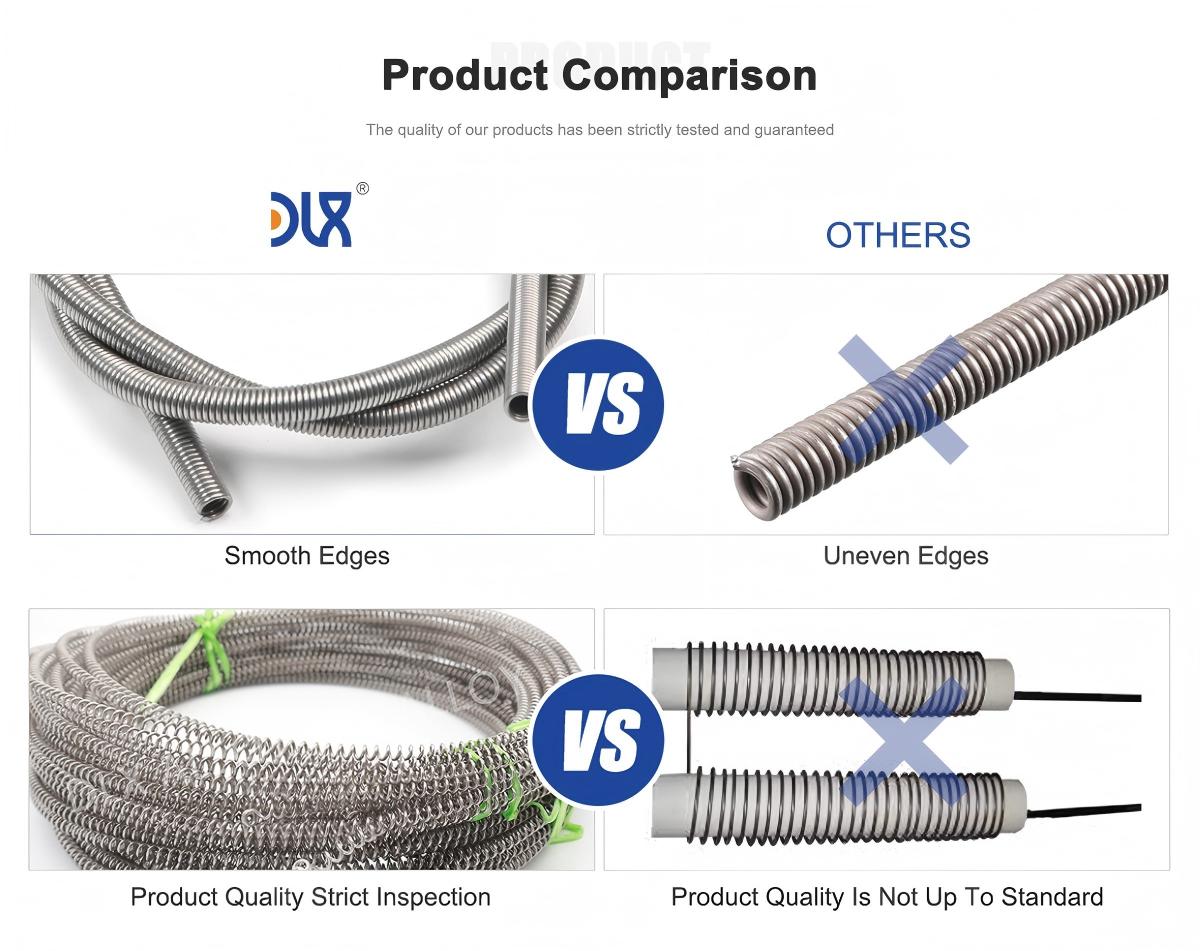

Company Comparison and Our Advantages

When it comes to high-temperature kiln bars, we know you’ve got choices, but our 0Cr27Al7Mo2 FeCrAl Kiln Bar is in a league of its own. Unlike some companies that stick to standard alloys, we focus on delivering premium, customized solutions. Need a specific bar size, shape, or configuration? We’ll craft it to fit your kiln like a glove, ensuring seamless integration and peak performance. Our advanced manufacturing, including vacuum smelting and precision casting, guarantees top-notch alloy purity and durability.

Price is always a factor, and while our 0Cr27Al7Mo2 sits at $28-50/kg, it’s worth every penny. Some competitors offer cheaper alternatives, but they can’t match the high-temperature performance, creep resistance, or longevity of our kiln bar. You’re getting a premium product that delivers long-term value, reducing downtime and replacement costs. It’s an investment that pays off for high-stakes applications.

Our supply chain is a game-changer. We’ve optimized it to handle raw material price fluctuations, ensuring stable costs and quick turnaround times. No more waiting weeks for a critical component—our streamlined process keeps your operations running smoothly. Plus, our technical support team is always on hand, from helping you choose the right alloy to troubleshooting installation. Other companies might leave you hanging; we’re here to make things easy.

Quality is non-negotiable for us. Every 0Cr27Al7Mo2 Kiln Bar undergoes rigorous testing for chemical composition, resistivity, and mechanical strength. This means you get a product that performs reliably, batch after batch. Some competitors skimp on quality control, leading to failures and costly downtime. With us, you’re getting a kiln bar you can trust to deliver in the toughest conditions.

Sustainability is a core focus. Our 0Cr27Al7Mo2 is designed for energy efficiency, helping you cut power costs and meet environmental standards. Compared to alternatives like nichrome, our FeCrAl Alloy offers superior high-temperature performance and corrosion resistance, meaning fewer replacements and lower long-term costs. It’s a win for your business and the planet.

Comparison Table: 0Cr27Al7Mo2 FeCrAl vs. Other FeCrAl Alloys

|

Alloy Grade |

Cr (%) |

Al (%) |

Mo (%) |

Max Temp (°C) |

Key Advantage |

Price Range ($/kg) |

|---|---|---|---|---|---|---|

|

0Cr27Al7Mo2 |

26.5-27.8 |

6-7 |

1-2 |

1400 |

Premium high-temp performance |

28-50 |

|

0Cr21Al6 |

21 |

6 |

- |

1350 |

High oxidation resistance |

18-28 |

|

0Cr23Al5 |

23 |

5 |

- |

1300 |

Cost-effective corrosion resistance |

8-20 |

|

0Cr25Al5 |

25 |

5 |

- |

1300 |

Enhanced corrosion resistance |

8-20 |

|

0Cr21Al6Nb |

21 |

6 |

- |

1350 |

Superior creep resistance |

18-28 |

Our Premium 0Cr27Al7Mo2 FeCrAl Kiln Bar is engineered for the toughest high-temperature environments, delivering unmatched performance and durability. Its superior corrosion resistance, creep resistance, and high-temperature stability make it the top choice for advanced kilns, furnaces, and more. Whether you’re firing ceramics, processing aerospace components, or melting glass, this kiln bar keeps your operations running at peak efficiency.

We’re proud to offer a product that combines cutting-edge alloy technology with practical, high-value solutions. With our customization options, competitive pricing, and dedicated support, we’re not just selling kiln bars—we’re helping you power your business forward. Ready to elevate your high-temperature heating? Our 0Cr27Al7Mo2 FeCrAl Kiln Bar is the premium, reliable choice you’ve been looking for.

For more details, pls directly contact us

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

-

What is the 0Cr27Al7Mo2 FeCrAl Kiln Bar made of?

It’s an iron-chromium-aluminum alloy with 26.5-27.8% chromium, 6-7% aluminum, and molybdenum, offering superior high-temperature strength and corrosion resistance. -

What’s the maximum operating temperature of the 0Cr27Al7Mo2 Kiln Bar?

It can handle up to 1400°C (2552°F), making it ideal for advanced high-temperature kilns. -

What applications is the 0Cr27Al7Mo2 Kiln Bar used for?

It’s used in high-temperature kilns, heat treatment furnaces, ceramic processing, and glass production for premium heating performance. -

How does the 0Cr27Al7Mo2 alloy resist corrosion?

Its high aluminum and molybdenum content forms a protective Al₂O₃ layer, shielding it from oxidation and corrosion at extreme temperatures. -

Is the 0Cr27Al7Mo2 Kiln Bar suitable for extreme thermal cycling?

Yes, its enhanced creep resistance and stability make it perfect for repeated high-heat cycles. -

Which industries benefit from the 0Cr27Al7Mo2 FeCrAl Kiln Bar?

Ceramics, metallurgy, glass manufacturing, aerospace, and chemical processing industries rely on it for top-tier performance. -

How durable is the 0Cr27Al7Mo2 Kiln Bar?

With a tensile strength of 680-830 MPa, it’s built for exceptional durability in the most demanding high-heat environments. -

Can the 0Cr27Al7Mo2 Kiln Bar be customized?

Absolutely, we offer tailored sizes, shapes, and configurations to fit your specific high-temperature kiln needs.