Our GH4169 superalloy plate, also known as Inconel 718 , is a heavy-hitter in the world of high-performance materials. This nickel-based superalloy, loaded with chromium, molybdenum, and niobium, delivers exceptional strength, corrosion resistance, and heat tolerance up to 700°C. It’s a go-to for aerospace applications where components face extreme stress, high temperatures, and corrosive environments. From turbine blades to rocket engines, our GH4169 plates are built to perform reliably in the toughest conditions.

Comparison Table: GH4169 vs. Other Superalloys

Parameter | GH4169 (Inconel 718) | Other Superalloys |

|---|---|---|

Nickel Content | 50-55% | 40-50% typically |

Chromium Content | 17-21% | 15-20% typically |

Molybdenum Content | 2.8-3.3% | 3-8% typically |

Tensile Strength (MPa) | 1200-1400 | 800-1100 |

Corrosion Resistance | Excellent (pitting, SCC) | Moderate to good |

Max Operating Temp (°C) | 700 | 600-900 |

Weldability | Excellent | Moderate |

Applications | Aerospace, turbines | General high-temp use |

Industry Analysis

The superalloy market is soaring, driven by aerospace and energy sectors demanding lightweight, high-strength materials. Valued at USD 99.98 billion in 2024, it’s projected to hit USD 145.9 billion by 2034, with a CAGR of 3.8%. Aerospace, particularly, is pushing for advanced alloys like GH4169 to meet stricter fuel efficiency and performance standards. Additive manufacturing is transforming production, with GH4169’s compatibility enabling intricate, high-strength components. Challenges like rising nickel costs and complex manufacturing persist, but the demand for durable, high-performance materials keeps the market robust.

Item | Nimonic80A | Nimonic 90 | GH1140 | GH3625 | GH3536 | GH4169 | |

C | ≤0.08 | ≤0.1 | ≤0.13 | 0.06-0.12 | ≤0.1 | 0.05-0.15 | ≤0.08 |

Mn | ≤2 | ≤1 | ≤1 | ≤0.7 | 3.14-4.15 | -- | ≤0.35 |

Fe | rest | ≤3 | ≤1.5 | rest | ≤0.5 | -- | rest |

P | ≤0.04 | ≤0.02 | -- | ≤0.025 | -- | -- | -- |

S | ≤0.03 | ≤0.015 | ≤0.015 | ≤0.015 | -- | -- | ≤0.01 |

Si | ≤1 | ≤1 | ≤1 | ≤0.8 | -- | -- | ≤0.35 |

Cu | -- | -- | ≤0.2 | -- | -- | -- | ≤0.3 |

Ni | 24-27 | rest | -- | 35-40 | rest | rest | 50-55 |

Co | -- | ≤2 | 15-21 | -- | ≤1.00 | 0.5-2.5 | ≤1.00 |

Al | ≤0.35 | 1-1.8 | 1-2 | 0.2-0.6 | ≤0.4 | ≤0.5 | 0.2-0.8 |

Ti | 1.9-2.35 | 1.8-2.7 | 2-3 | 0.7-1.2 | ≤0.4 | ≤0.15 | 0.7-1.15 |

Cr | 13.5-16 | 18-21 | 18-21 | 20-23 | 20-23 | 20.5-23 | 17-21 |

Nb | -- | -- | -- | -- | -- | -- | 4.75-5.5 |

Mo | 1-1.5 | -- | -- | 2-2.5 | 8-10 | 8-10 | 2.8-3.3 |

B | 0.001-0.1 | ≤0.008 | ≤0.02 | -- | -- | -- | -- |

V | 0.1-0.5 | -- | -- | -- | -- | -- | -- |

W | -- | -- | -- | 1.4-1.8 | -- | 0.2-1 | -- |

Zr | -- | ≤0.15 | ≤0.15 | -- | -- | -- | -- |

Pb | -- | -- | ≤0.002 | -- | -- | -- | -- |

Ce | -- | -- | -- | ≤0.05 | -- | -- | -- |

Size Range | |

Wire | 0.5-7.5mm |

Rod/Bar | 8.0-200mm |

Strip | (0.50-2.5)*(5-180)mm |

Tube | custom made |

| Plate | custom made |

For more details, pls directly contact us.

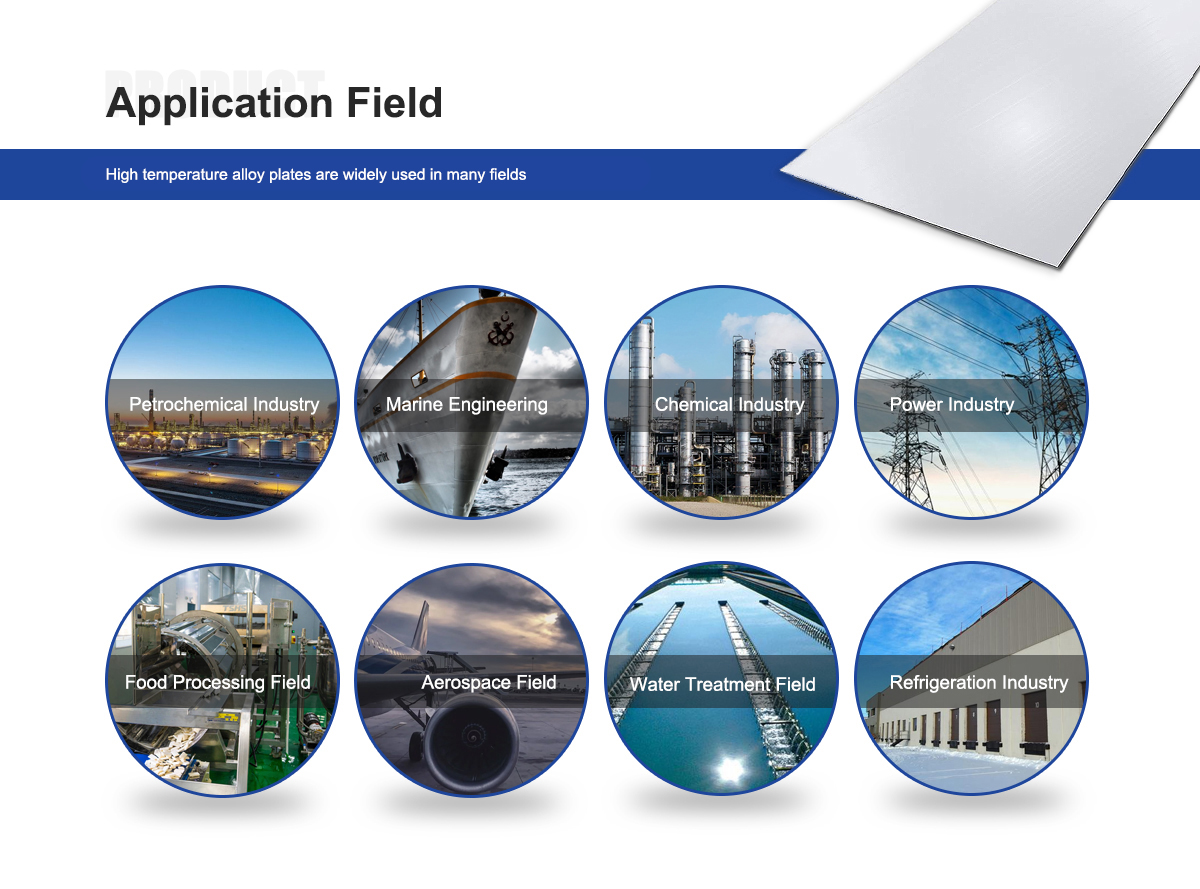

Our GH4169 superalloy plate shines in:

Turbine Blades: Handles high temperatures and stress in jet engines and gas turbines.

Rocket Engines: Resists extreme heat and corrosion in aerospace propulsion systems.

Structural Components: Provides strength and durability for airframes and landing gear.

Nuclear Reactors: Withstands high temperatures and radiation in power generation.

Additive Manufacturing: Ideal for 3D-printed parts due to its excellent weldability.

Its versatility makes it a critical material for high-stakes aerospace and energy applications.

Our Company’s Advantage

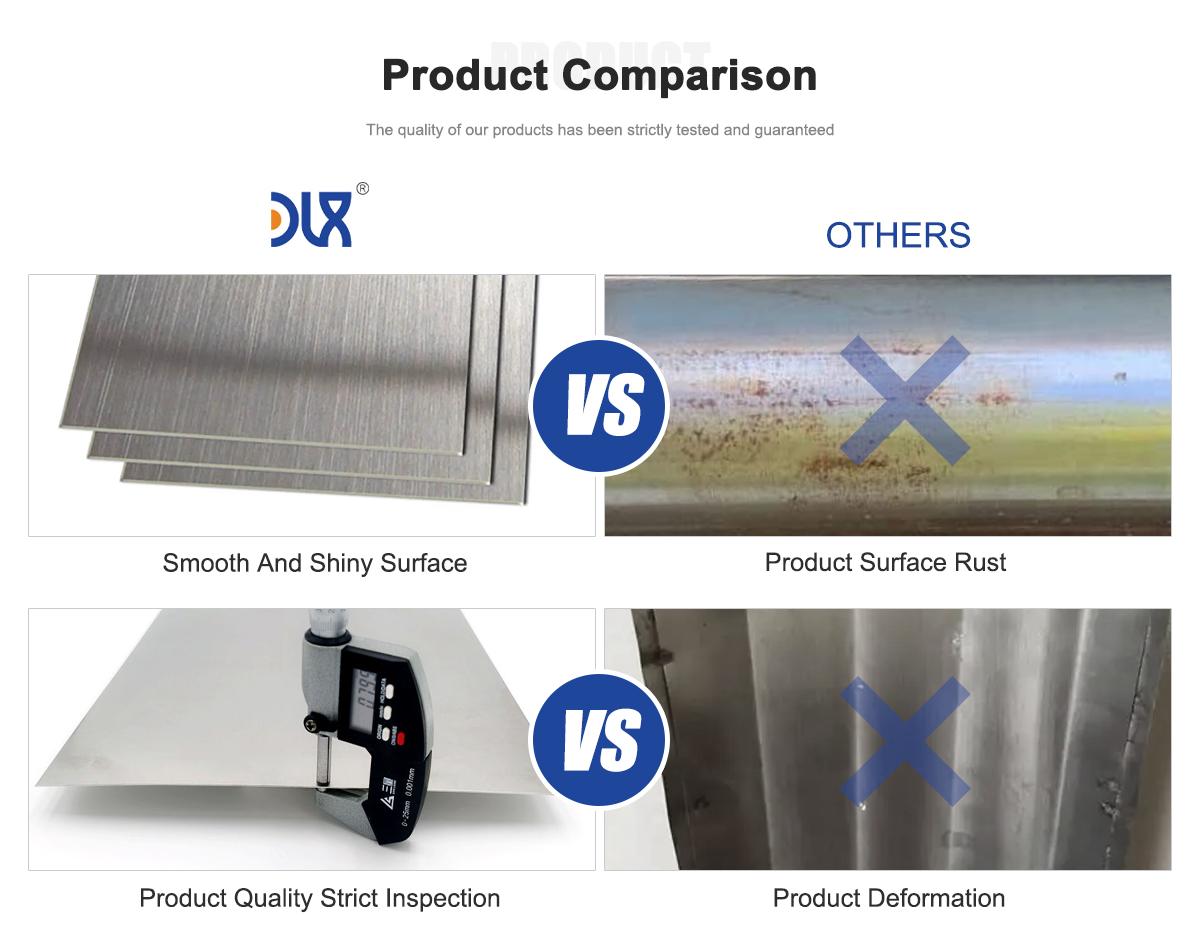

We’re all about delivering GH4169 superalloy plates that set the bar for quality and performance. Our plates are crafted using cutting-edge processes, ensuring precise alloy composition and top-notch mechanical properties. We offer customized solutions—think specific sizes, thicknesses, or finishes—to nail your project’s needs. Every plate meets ASTM standards, backed by strict quality control to guarantee performance in extreme conditions. Our efficient production and supply chain mean faster delivery and competitive pricing, giving you premium materials without the hassle. Choose us for expertise, reliability, and unmatched support in superalloy solutions.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What is GH4169 superalloy plate used for?

It’s used in aerospace for turbine blades, rocket engines, and structural components that demand high strength and heat resistance.Why is GH4169 ideal for aerospace applications?

Its nickel-niobium blend provides outstanding tensile strength and creep resistance at high temperatures.How does GH4169 handle corrosion?

Its high chromium and molybdenum content ensures excellent resistance to pitting and stress-corrosion cracking.Is GH4169 suitable for high-stress environments?

Yes, it offers exceptional fatigue strength and durability under extreme mechanical loads.What industries benefit from GH4169 plates?

Aerospace, gas turbines, nuclear reactors, and high-performance industrial applications rely on its strength.Can GH4169 be used in additive manufacturing?

Absolutely, its weldability makes it perfect for 3D printing complex aerospace parts.How customizable is GH4169?

We offer tailored sizes, thicknesses, and finishes to meet specific project requirements.What are the mechanical properties of GH4169?

It boasts a tensile strength of 1200-1400 MPa and maintains properties at temperatures up to 700°C.