Our Nimonic 75 alloy plate is a rock-solid nickel-chromium alloy built for high-temperature strength and durability. Packed with nickel, chromium, and a touch of titanium, it delivers excellent resistance to oxidation and creep, making it a favorite for applications up to 800°C. This alloy is a workhorse for industries needing reliable performance under intense heat, like gas turbines and aerospace components. Our Nimonic 75 plates are crafted to keep things running smoothly, no matter how hot it gets.

Comparison Table: Nimonic 75 vs. Other High-Temperature Alloys

Parameter | Nimonic 75 | Other High-Temperature Alloys |

|---|---|---|

Nickel Content | 70% min | 40-60% typically |

Chromium Content | 18-21% | 15-20% typically |

Titanium Content | 0.2-0.6% | 0-2% typically |

Tensile Strength (MPa) | 700-850 | 600-900 |

Oxidation Resistance | Excellent up to 800°C | Moderate to good up to 700-900°C |

Max Operating Temp (°C) | 800 | 600-1000 |

Weldability | Good | Moderate to good |

Applications | Turbines, aerospace | General high-temperature use |

Industry Analysis

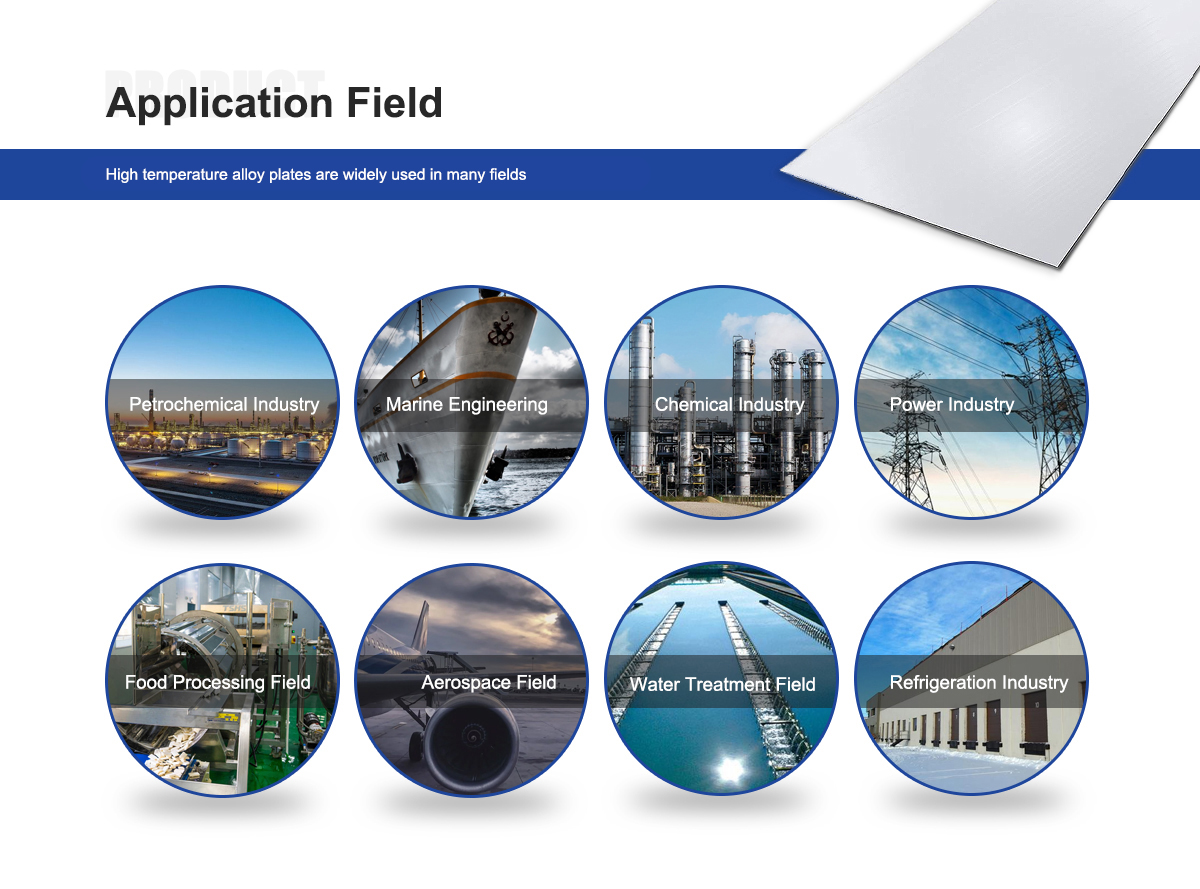

The high-temperature alloy market is heating up, driven by demand in aerospace, power generation, and industrial furnaces. Valued at USD 99.98 billion in 2024, it’s expected to hit USD 145.9 billion by 2034, with a CAGR of 3.8%. The push for efficient, high-performance engines and sustainable energy solutions is fueling growth, with alloys like Nimonic 75 playing a key role due to their reliability in extreme conditions. Challenges include volatile raw material costs and complex manufacturing, but the need for durable, heat-resistant materials keeps the market strong, especially in aerospace and energy sectors.

Item | Nimonic80A | Nimonic 90 | GH1140 | GH3625 | GH3536 | GH4169 | |

C | ≤0.08 | ≤0.1 | ≤0.13 | 0.06-0.12 | ≤0.1 | 0.05-0.15 | ≤0.08 |

Mn | ≤2 | ≤1 | ≤1 | ≤0.7 | 3.14-4.15 | -- | ≤0.35 |

Fe | rest | ≤3 | ≤1.5 | rest | ≤0.5 | -- | rest |

P | ≤0.04 | ≤0.02 | -- | ≤0.025 | -- | -- | -- |

S | ≤0.03 | ≤0.015 | ≤0.015 | ≤0.015 | -- | -- | ≤0.01 |

Si | ≤1 | ≤1 | ≤1 | ≤0.8 | -- | -- | ≤0.35 |

Cu | -- | -- | ≤0.2 | -- | -- | -- | ≤0.3 |

Ni | 24-27 | rest | -- | 35-40 | rest | rest | 50-55 |

Co | -- | ≤2 | 15-21 | -- | ≤1.00 | 0.5-2.5 | ≤1.00 |

Al | ≤0.35 | 1-1.8 | 1-2 | 0.2-0.6 | ≤0.4 | ≤0.5 | 0.2-0.8 |

Ti | 1.9-2.35 | 1.8-2.7 | 2-3 | 0.7-1.2 | ≤0.4 | ≤0.15 | 0.7-1.15 |

Cr | 13.5-16 | 18-21 | 18-21 | 20-23 | 20-23 | 20.5-23 | 17-21 |

Nb | -- | -- | -- | -- | -- | -- | 4.75-5.5 |

Mo | 1-1.5 | -- | -- | 2-2.5 | 8-10 | 8-10 | 2.8-3.3 |

B | 0.001-0.1 | ≤0.008 | ≤0.02 | -- | -- | -- | -- |

V | 0.1-0.5 | -- | -- | -- | -- | -- | -- |

W | -- | -- | -- | 1.4-1.8 | -- | 0.2-1 | -- |

Zr | -- | ≤0.15 | ≤0.15 | -- | -- | -- | -- |

Pb | -- | -- | ≤0.002 | -- | -- | -- | -- |

Ce | -- | -- | -- | ≤0.05 | -- | -- | -- |

Size Range | |

Wire | 0.5-7.5mm |

Rod/Bar | 8.0-200mm |

Strip | (0.50-2.5)*(5-180)mm |

Tube | custom made |

| Plate | custom made |

For more details, pls directly contact us.

Our Nimonic 75 alloy plate thrives in:

Gas Turbine Components: Perfect for blades and vanes enduring high heat and stress.

Aerospace Parts: Used in engine components and exhaust systems for its strength and oxidation resistance.

Industrial Furnaces: Resists thermal cycling and oxidation in high-temperature processing.

Power Generation: Ideal for turbine parts in fossil fuel and nuclear plants.

Heat Treatment Equipment: Maintains durability in high-heat industrial applications.

Its ability to withstand heat and stress makes it a trusted choice for critical components.

Our Company’s Advantage

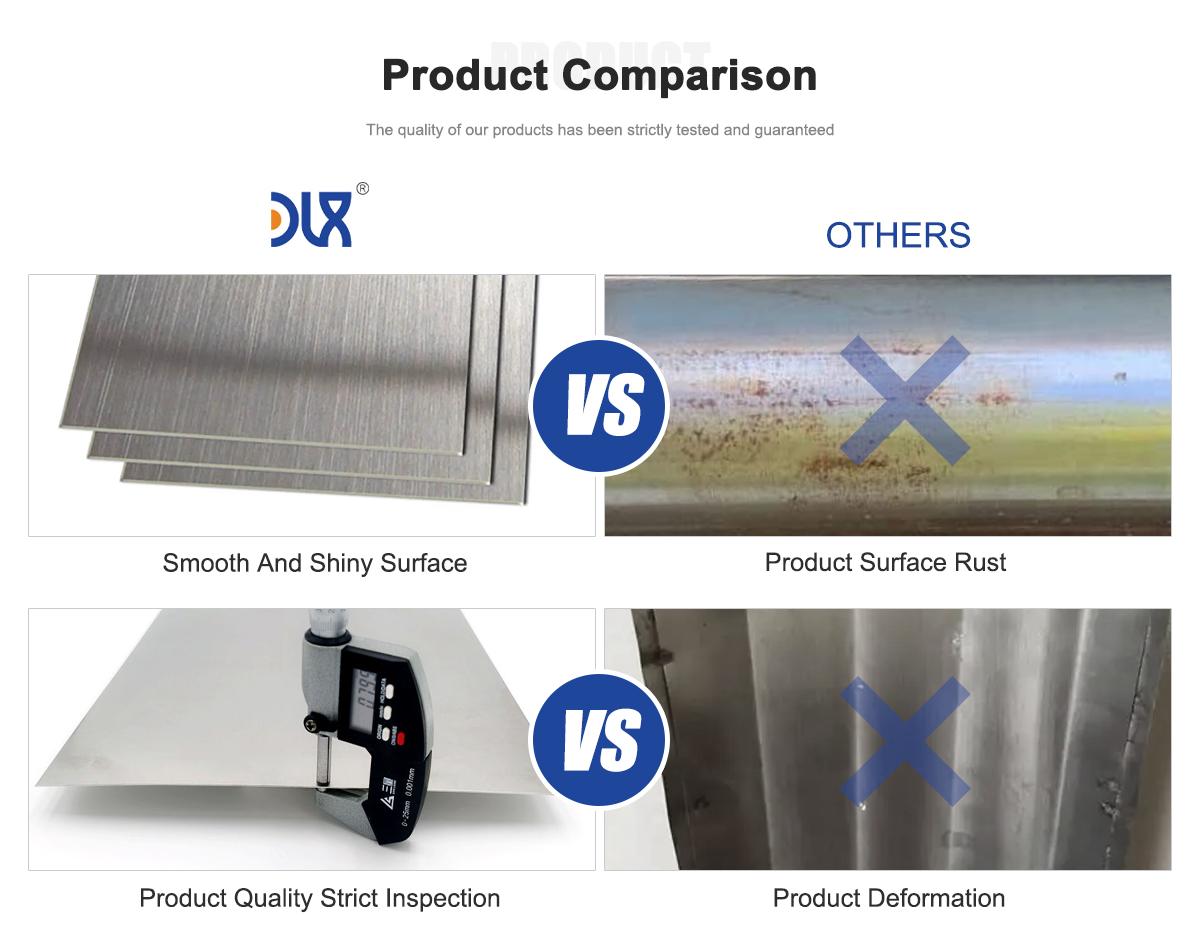

We take pride in offering Nimonic 75 alloy plates that deliver top-notch quality and performance. Our plates are manufactured with precision, ensuring consistent alloy composition and excellent mechanical properties. We provide customized solutions—whether it’s specific sizes, thicknesses, or finishes—to fit your project like a glove. Every plate meets strict industry standards, backed by rigorous quality checks to ensure reliability in high-temperature environments. Our streamlined production and supply chain keep costs competitive and delivery fast, giving you premium materials without the wait. Choose us for expertise, quality, and unbeatable support in high-temperature alloy solutions.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What is Nimonic 75 alloy plate used for?

It’s used in gas turbines, aerospace components, and industrial furnaces where high heat and strength are critical.Why choose Nimonic 75 for high-temperature applications?

Its nickel-chromium base with titanium ensures great strength and oxidation resistance up to 800°C.How does Nimonic 75 handle corrosion?

The high chromium content creates a protective oxide layer, resisting oxidation in harsh environments.Is Nimonic 75 good for high-stress components?

Yes, it offers excellent creep resistance and durability under thermal and mechanical stress.What industries rely on Nimonic 75 plates?

Aerospace, power generation, and industrial heating systems depend on its high-temperature performance.Can Nimonic 75 be welded?

It has good weldability, making it suitable for fabricating complex parts without losing strength.Can Nimonic 75 be customized?

We provide tailored sizes, thicknesses, and finishes to match your specific project needs.What are the mechanical properties of Nimonic 75?

It has a tensile strength of around 700-850 MPa and retains strength at high temperatures.