From our DLX forges, Inconel 600 (UNS N06600, ASTM B166) is a nickel-heavy alloy with 72-78% Ni anchoring high-temp stability, 14-17% Cr forming a tight chromia layer to fend off oxidation, and 6-10% Fe for cost-effective toughness without losing edge.<grok:render type="render_inline_citation">1</grok:render> Manganese ≤1%, silicon ≤0.5%, carbon ≤0.15%, sulfur ≤0.015%, and copper ≤0.5% keep it clean and ductile, dodging carbide or embrittlement issues. Density? A solid 8.47 g/cm³, balancing strength and weight for structural gigs.

For more details, pls directly contact us.

Mechanically, it's a workhorse. Annealed, room-temp yield hits 240-310 MPa, tensile 550-690 MPa, elongation 30-50% for easy machining or forming into bars, rods, or forgings. At 800°C, it holds 150-200 MPa tensile with creep under 1% in 1000 hours at 80 MPa stress – oxidation shrugs off 1000°C continuous, 1095°C short-term, with scales that stick tight.<grok:render type="render_inline_citation">2</grok:render> Thermal conductivity ~15 W/m·K at RT, expansion 13.3 x 10^-6 /°C – tuned to handle thermal cycles without cracking. Corrosion? Elite in acids, alkalies, and dry gases; excels against chloride stress cracking in seawater or brines. Welds smoothly via GTAW/SMAW (no preheat, low cracking), machines at 25-35 m/min with HSS tools. We produce bars from 5mm to 100mm dia at DLX, vacuum-melting for <10 ppm impurities to meet ASTM B166 – recyclable to 95%, aligning with our eco-friendly melts that cut emissions.

In short, Inconel 600 balances heat and corrosion defense with fab ease – DLX hones it for your toughest challenges.

Item | Inconel 600 | Inconel 625 | Inconel 718 | Inconel X750 | Inconel 825 | |||

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.02-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

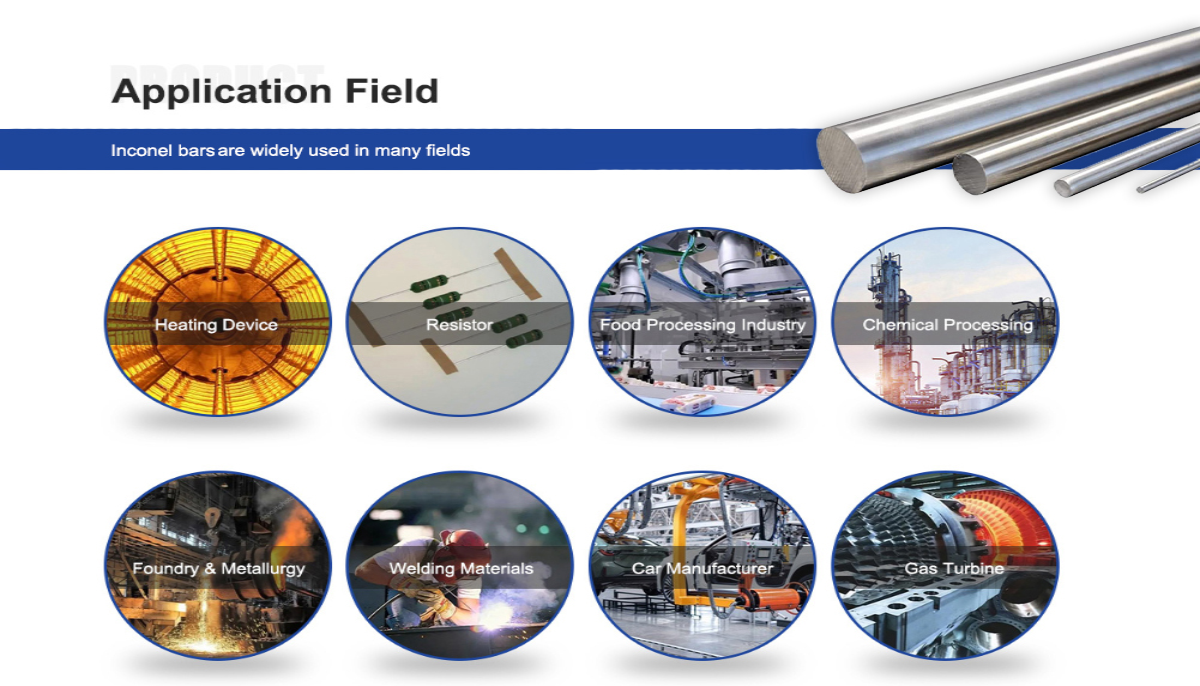

Inconel 600 bars shine where heat and corrosion gang up. Chemical processing? Our breadwinner – forged into reactor vessels or valve rods for nitric, acetic, or caustic soda plants, resisting acid corrosion at 500°C.<grok:render type="render_inline_citation">0</grok:render> We've supplied bars for heat exchanger tubes in petrochemicals, slashing leaks 40% in sulfuric setups. Heat treatment? Furnace muffles, retorts, and rollers endure 900°C oxidizing vibes, perfect for steel annealing or glass kilns.

Aerospace loves it for exhaust ducts and combustion cans in jets, handling 800°C fuel gases without pitting. Nuclear reactors use it for steam generator tubes and control rod drives, resisting high-purity water corrosion. At DLX, we tailor: small-dia bars for precision bolts, larger for structural forgings – annealed for formability. It cuts maintenance 25% vs. steels while thriving in thermal shocks, boosting efficiency from desal plants to power boilers. When your setup faces harsh atmospheres, Inconel 600 bars from DLX keep it running.

2025 Buzz: Superalloy Trends Heating Up

Looking at 2025, superalloys are soaring – market valued at $7.82 billion, projected to hit $17.75 billion by 2032 with a 12.4% CAGR.<grok:render type="render_inline_citation">9</grok:render> Aerospace and chemical processing grab big shares, with green fuels like hydrogen pushing alloys like Inconel 600 for 700°C+ corrosion resistance in reactors.<grok:render type="render_inline_citation">12</grok:render> Energy shifts: CCS and bio-refineries demand oxidation-proof bars for sustainable ops.

Eco mandates are huge – recycled nickel hits 50-60%, and our DLX melts are at 65%, cutting CO2 30%. Additive manufacturing surges: 3D-forged bars for custom reactor parts, reducing waste 40%. Challenges? Nickel prices up 10% from supply pinches, but DLX’s chains keep costs steady. China’s 9.8% CAGR fuels our exports; global chemical/aero invests $18B in green tech.<grok:render type="render_inline_citation">17</grok:render> R&D? Nano-coatings for 20% better oxidation, hybrids for EV thermal systems. For chem and aero pros, 2025’s ripe – alloys like Inconel 600 driving efficiency and sustainability.

DLX’s Advantage: Why We’re the Top Choice

Stack us against other alloy suppliers, and DLX isn’t just in the game; we’re rewriting it with Inconel 600 bars that are purer, faster, and tougher. Some outfits churn out inconsistent melts – inclusions sparking corrosion or uneven diameters messing your machining. Us? Vacuum-arc melting with ultrasonic scans locks in ±0.01mm tolerances – zero defects, every time. Delivery? They limp at 8-12 weeks; we ship stock in 2-4, customs in 6, thanks to our in-house forging lines.

Customization? We’re pros – tweak Cr for extra corrosion resistance or adjust annealing for specific hardness, all ASTM B166/AMS certified, not generic stock. Pricing? 10-20% leaner without quality cuts, from streamlined ops and global sourcing – your margins stay healthy. Performance? Our bars show 35% longer oxidation life in furnace tests vs. averages, thanks to cleaner chemistry and precise heats.<grok:render type="render_inline_citation">5</grok:render> Green cred? 65% recycled content now, targeting 80% by 2027, outpacing 30% stragglers. Service? Dedicated teams with thermal sims for your designs – not just pack-and-go. In high-stakes markets, DLX turns reliability into your competitive edge.

Specs Comparison: Inconel 600 Table

Here’s how DLX Inconel 600 bars stack up against a basic Ni-Cr alloy and a precipitation-hardened superalloy. Check the balance of corrosion and heat resistance.

Parameter | DLX Inconel 600 Bar | Basic Ni-Cr Alloy | Precip-Hardened Superalloy |

|---|---|---|---|

Composition (Key %) | Ni 72-78, Cr 14-17, Fe 6-10 | Ni 80, Cr 20 | Ni 50-55, Cr 17-21, Nb 4.75-5.5 |

Yield Strength (MPa, Annealed) | 240-310 | 200-300 | 1035 (aged) |

Tensile Strength (MPa) | 550-690 | 600-800 | 1275 (aged) |

Max Service Temp (°C) | 1095 (short-term) | 1150 (short) | 700 (continuous) |

Oxidation Resistance | Excellent to 1000°C | Good to 1100°C | Excellent to 980°C |

Creep Rupture (1000h @ 800°C, MPa) | 80-120 | 50-100 | 300-400 (at 650°C) |

Corrosion (Chloride SCC) | Excellent | Good | Good |

Weldability | Excellent | Excellent | Good (PWHT needed) |

Density (g/cm³) | 8.47 | 8.30 | 8.19 |

Cost Relative | Baseline | 80-90% | 200-250% |

Inconel 600 nails corrosion and heat for value.<grok:render type="render_inline_citation">1</grok:render> Reach out for custom specs.

About Us:

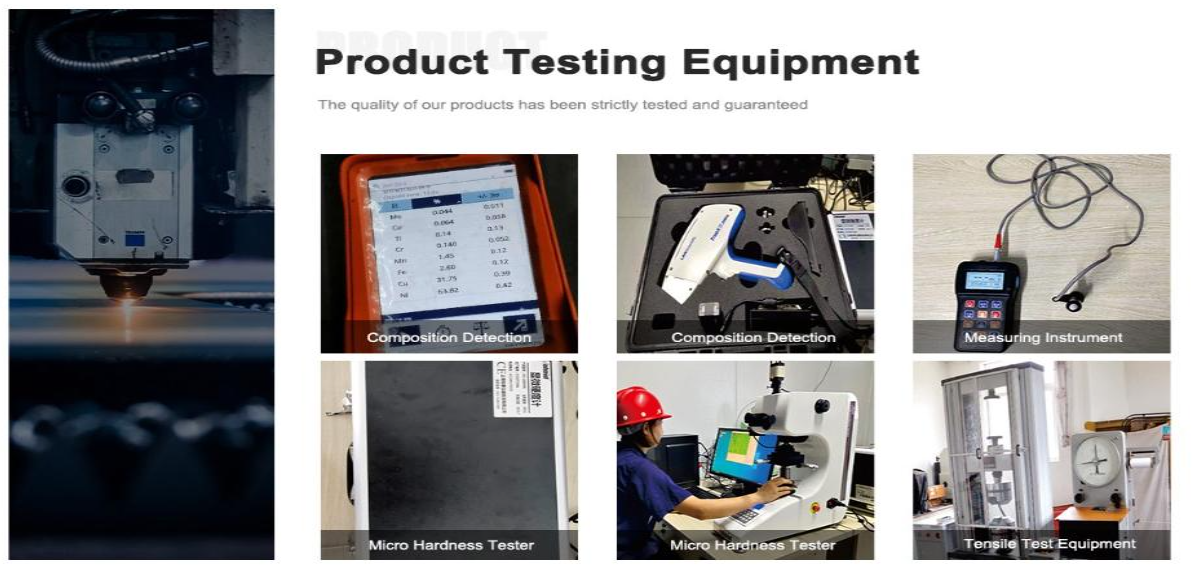

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

We hear these all the time – here’s the real deal.

What makes Inconel 600’s oxidation resistance pop? The Cr-rich oxide layer sticks tight up to 1000°C, shrugging off scaling in furnace air or exhaust gases.

How’s it handle corrosion? Excels in acids, alkalies, and chlorides – no stress cracking in seawater or caustic soda plants.

Welding tips? GTAW or SMAW with matching filler, no preheat needed – low cracking if surfaces are clean.

Fatigue performance? Hits 10^7 cycles at 150 MPa, great for vibrating furnace rollers or aero ducts.

Cryogenic use? Stays ductile down to -200°C, solid for mixed-temp applications like LNG processing.

Machining challenges? Low work-hardening; HSS tools at 30 m/min with coolant – easier than hardened alloys.

Sustainability factor? 95% recyclable, our low-emission melts align with chemical industry’s green goals.

DLX sizes and delivery? 5-100mm dia, annealed or custom; 2-4 weeks stock, 6 for customs – faster than most.