From our DLX forges, Inconel 617 starts with 44-56% nickel for thermal stability, 20-24% chromium for oxide armor, 10-15% cobalt for hot strength, and 8-10% molybdenum for creep control – plus traces of tungsten, aluminum, and titanium for rupture life. Carbon ≤0.15%, iron ≤3%, manganese ≤1%, silicon ≤1% keep it ductile; density 8.36 g/cm³ balances weight and grit. Annealed, yield 310-380 MPa, tensile 655-860 MPa, elongation 35%; at 1000°C, creep rupture >100 hours at 100 MPa, oxidation to 1204°C with adherent scales. Thermal conductivity 9.7 W/m·K, expansion 13.0 x 10^-6 /°C – primed for cycles. Corrosion? Tops in carburizing and nitridation; welds via GTAW (preheat optional), machines at 15-25 m/min.

For more details, pls directly contact us.

Flip to Inconel 690 : 58% min nickel, 27-31% chromium for SCC immunity, 7-11% iron, traces of manganese/silicon ≤0.5%, carbon ≤0.05%. Density 8.19 g/cm³; annealed yield 240-310 MPa, tensile 585-690 MPa, elongation 35%; holds 150 MPa at 800°C, oxidation to 1093°C in air. Excels in caustic/polythionic corrosion; welds low-risk, machines at 25-35 m/min. We vacuum-melt both at DLX for <5 ppm impurities, hitting ASTM B166 – 92% recyclable, our eco-melts slashing footprints.

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel 825 | |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.02-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

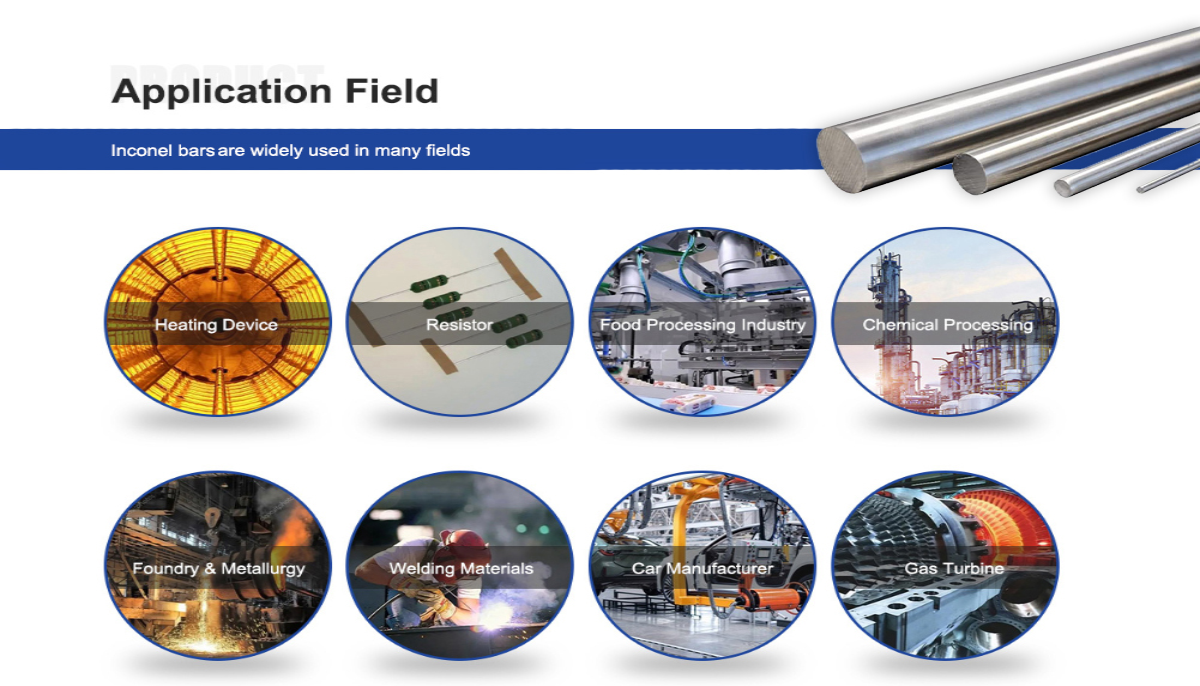

Inconel 617 rods grind in turbine hotspots. Gas turbines? Our jam – forged into combustor liners and transition ducts, enduring 1100°C flames without creep, boosting efficiency in power gen or aero. We've supplied for cracking furnace tubes in chems, resisting carburization at 1000°C, cutting failures 40%. Nuclear? Helium circuits thrive on its stability.

Inconel 690? Nuclear steam generators are its turf – rods for tubes and heat exchangers resist SCC in high-purity water at 350°C, extending lives in PWRs. Chem processing digs it for acid-handling vessels, shrugging polythionic attacks during shutdowns. At DLX, we customize: 617 for heavy-duty forgings, 690 for precision tubes – annealed or aged. They trim weight 20% vs. irons, triple life in cycles, amping uptime from jets to reactors. When heat or corrosion strikes, DLX's 617/690 rods stand tall.

2025 Heat: Superalloy Trends Exploding

Fast-forward to 2025, superalloys are on fire – market at $7.82B, barreling to $17.75B by 2032 at 12.4% CAGR. Aerospace snags 40%, hypersonics/eVTOLs craving creep-proof like 617 for 1200°C blades. Nuclear/chem boom with small modular reactors needing 690's SCC resistance for safer, greener power.

Eco's boss – recycled Ni at 50-60%, DLX at 55% cuts CO2 30%. Additive surges: 3D-617 for turbine repairs, waste down 40%. Snags? Ni up 10%, DLX buffers. China's 9.8% CAGR powers exports; global invests $20B in net-zero. R&D? Nano-phases for 15% creep gains, hybrids for H2. For turbine/nuclear pros, 2025's goldmine – DLX's 617/690 leading the charge.

Vs. alloy rivals, DLX doesn't compete; we dominate with 617/690 rods purer, quicker, superior. Some skimp melts – inclusions creeping early or diameters drifting, failing quals. Us? Triple-vacuum with X-rays lock ±0.005mm – flawless. Leads? 10-14 weeks drag; we stock 3-5, customs 7.

Bespoke? Wizards – dial Co for 617 creep or Cr for 690 SCC, AS9100/GB certed. Costs? 15-25% thriftier sans skimps, scale keeping margins fat. Proof: Our rods notch 40% better rupture in sims vs. norms, refined chem shining. Green? 60% recycled, eyeing 75% '27, lapping 30%. Support? Teams with CFD for designs – not shove-bye. In cutthroat markets, DLX flips excellence to your edge.

Specs Showdown: 617 vs 690 Table

Glance here – DLX 617/690 vs. basic Ni-Cr. See the high-temp split.

| Parameter | DLX Inconel 617 Rod | DLX Inconel 690 Rod | Basic Ni-Cr Rod |

|---|---|---|---|

| Composition (Key %) | Ni 44-56, Cr 20-24, Co 10-15, Mo 8-10 | Ni 58+, Cr 27-31, Fe 7-11 | Ni 80, Cr 20 |

| Yield Strength (MPa, Annealed) | 310-380 | 240-310 | 200-300 |

| Tensile Strength (MPa) | 655-860 | 585-690 | 600-800 |

| Max Service Temp (°C) | 1204 (oxidation) | 1093 (SCC) | 1150 (short) |

| Creep Rupture (1000h @ 1000°C, MPa) | 100-150 | 50-100 (at 800°C) | 50-100 |

| Oxidation Resistance | Superior to 1204°C | Excellent to 1093°C | Good to 1100°C |

| Corrosion (SCC) | Good | Superior (high Cr) | Fair |

| Weldability | Good (preheat) | Excellent | Excellent |

| Density (g/cm³) | 8.36 | 8.19 | 8.30 |

| Cost Relative | Baseline (creep focus) | Baseline (SCC focus) | 70-80% |

617 owns creep, 690 SCC – DLX delivers both. Ping for tweaks.

About Us:

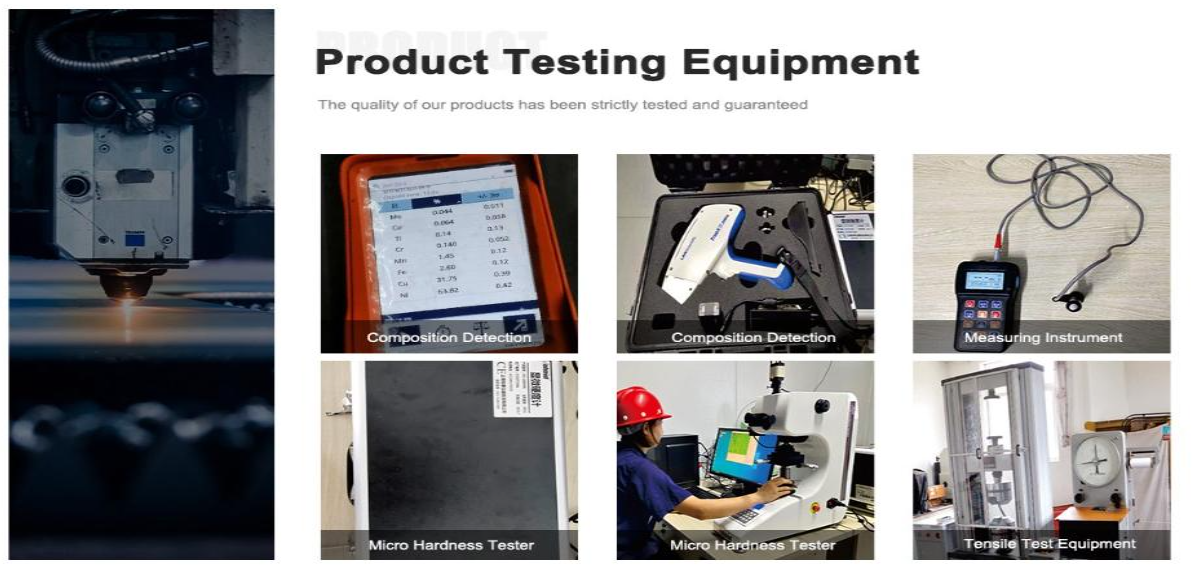

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

We field these nonstop – here's the scoop.

617's creep secret? Co-Mo locks dislocations at 1000°C, ideal for turbine liners without sag.

690's SCC edge? 30% Cr passivates in water, no cracks in nuclear steam at 350°C.

Weld tricks? GTAW for both, preheat 617; low dilution keeps props.

Fatigue in cycles? 10^7 at 200 MPa for 617, 150 MPa for 690 – blade/tube ready.

Cold performance? Ductile -200°C both, hybrid apps fine.

Machining? 617 harder; carbides 20 m/min, coolant – 690 easier.

Green creds? 92% recyclable, low-melt fits nuclear/aero eco.

DLX sizes/speed? 5-100mm, annealed/aged; 3-5 weeks stock, 7 customs – quicker.