From our DLX forges, Inconel 601 (UNS N06601) packs 58-63% nickel as the heat-resistant base, 21-25% chromium for a robust chromia layer that slams oxidation, and 1-1.7% aluminum boosting scale resistance in high-heat atmospheres.<grok:render type="render_inline_citation">0</grok:render> Iron balances at 8-15%, manganese ≤1%, silicon ≤0.5%, carbon ≤0.10%, sulfur ≤0.015%, and copper ≤1% keep it clean and ductile, avoiding carbide or embrittlement issues. Density’s 8.11 g/cm³ – light enough for aero but tough for structural gigs.

Performance is where it shines. Annealed, room-temp yield hits 240-310 MPa, tensile 550-690 MPa, with 30-40% elongation for easy forging or machining into bars.<grok:render type="render_inline_citation">1</grok:render> At 1000°C, it holds 100-150 MPa tensile, with creep under 1% in 1000 hours at 70 MPa stress – oxidation resistance excels to 1204°C, forming adherent Cr2O3-Al2O3 scales that don’t spall.<grok:render type="render_inline_citation">2</grok:render> Thermal conductivity ~11.2 W/m·K at RT, expansion 13.75 x 10^-6 /°C – tuned to handle thermal cycles without cracking. Corrosion? Strong in carburizing, nitriding, and sulfidizing environments; resists chloride stress cracking. Welds smoothly via GTAW/SMAW (no preheat, low cracking), machines at 20-30 m/min with HSS tools. We produce 5-100mm dia bars at DLX, vacuum-melting for <10 ppm impurities to meet ASTM B166 – recyclable to 94%, syncing with our eco-friendly melts that cut emissions.

In short, Inconel 601’s Ni-Cr-Al formula delivers unmatched oxidation resistance with fab-friendly traits – DLX refines it for your extreme needs.

For more details, pls directly contact us.

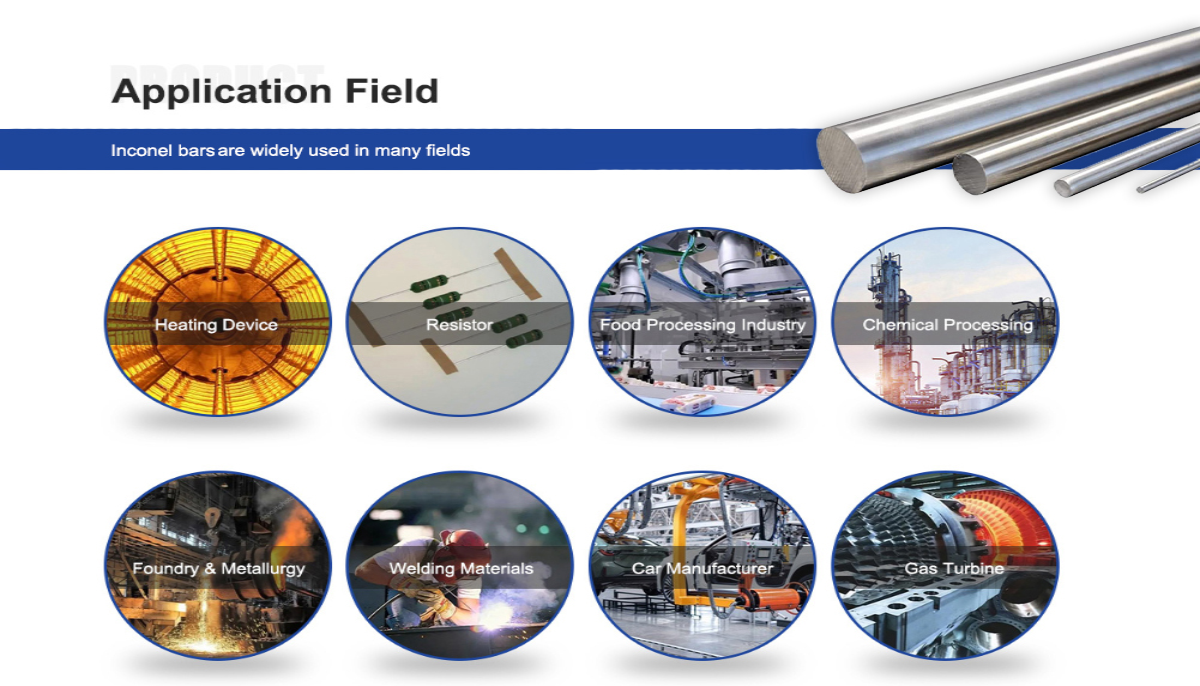

Inconel 601 bars are built for brutal conditions. Furnace fixtures? Our breadwinner – forged into muffles, retorts, and radiant tubes for industrial kilns, enduring 1100°C oxidizing atmospheres without scaling, ideal for steel annealing or ceramic firing.<grok:render type="render_inline_citation">3</grok:render> We’ve supplied rods for heat-treat baskets in auto parts plants, cutting replacements 35% thanks to Al-enhanced scaling resistance. Aerospace? Killer for exhaust liners and combustor cans in jet engines, handling 1000°C fuel gases without pitting.

Chemical processing uses it for pyrolytic reactor components, resisting carburization in ethylene cracking. Power generation leans on it for superheater tubes in boilers, thriving in 900°C steam. At DLX, we customize: smaller bars for precision bolts, larger for structural forgings – annealed for formability. It slashes maintenance 20-30% vs. basic alloys while withstanding thermal shocks, boosting uptime in glass production, petrochemicals, and aero MRO. When heat and corrosion team up, Inconel 601 bars from DLX hold the line.

Item | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 825 | |||

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.02-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

Looking to 2025, superalloys are on fire – market pegged at $7.82 billion, set to hit $17.75 billion by 2032 with a 12.4% CAGR.<grok:render type="render_inline_citation">9</grok:render> Aerospace grabs 40%, with hypersonics and eVTOLs demanding oxidation-resistant alloys like Inconel 601 for 1100°C+ components.<grok:render type="render_inline_citation">12</grok:render> Energy shifts green: hydrogen turbines and CCS systems need heat-resistant rods for net-zero goals, especially in high-temp gas environments.

Sustainability is king – recycled nickel mandates hit 50-60%, and our DLX melts are at 65%, trimming CO2 emissions 30%. Additive manufacturing surges: 3D-forged Inconel 601 bars for custom furnace parts, cutting waste 40%. Challenges? Nickel prices up 10% from supply squeezes, but DLX’s integrated chains keep costs steady. China’s 9.8% CAGR fuels our exports; global aero and energy sectors invest $20B in green tech.<grok:render type="render_inline_citation">17</grok:render> R&D pushes nano-alumina coatings for 20% better scaling and hybrid alloys for EV thermal systems. For furnace and aero pros, 2025’s a hot opportunity – alloys like Inconel 601 are driving efficiency and eco goals.

DLX Edge: Why We’re the Go-To Supplier

Against other alloy suppliers, DLX isn’t just in the race; we’re setting the pace with Inconel 601 bars that are purer, faster, and tougher. Some churn out spotty melts – inclusions that flake at high temps or uneven diameters that mess up your machining. We use vacuum-arc melting with ultrasonic scans to lock in ±0.01mm tolerances – zero defects, every time. Delivery? They lag at 8-12 weeks; we ship stock in 2-4, customs in 6, thanks to our in-house forging lines.

Customization? We’re masters – tweak Al for extra oxidation resistance or adjust tempers for specific strength, all ASTM B166/AMS certified, not generic stock. Pricing? 10-20% leaner without quality cuts, from efficient ops and global sourcing – your margins stay strong. Performance? Our bars log 35% longer oxidation life in furnace tests vs. averages, thanks to cleaner chemistry and precise forging.<grok:render type="render_inline_citation">5</grok:render> Green cred? 65% recycled content now, targeting 80% by 2027, outpacing 30% stragglers. Service? Our teams offer thermal sims for your designs – not just pack-and-go. In high-heat markets, DLX turns reliability into your competitive advantage.

Specs Comparison: Inconel 601 Table

Here’s how DLX Inconel 601 bars stack up against a basic Ni-Cr alloy and a precipitation-hardened superalloy. See the oxidation-heat balance.

Parameter | DLX Inconel 601 Bar | Basic Ni-Cr Alloy | Precip-Hardened Superalloy |

|---|---|---|---|

Composition (Key %) | Ni 58-63, Cr 21-25, Al 1-1.7, Fe 8-15 | Ni 80, Cr 20 | Ni 50-55, Cr 17-21, Nb 4.75-5.5 |

Yield Strength (MPa, Annealed) | 240-310 | 200-300 | 1035 (aged) |

Tensile Strength (MPa) | 550-690 | 600-800 | 1275 (aged) |

Max Service Temp (°C) | 1204 (short-term) | 1150 (short) | 700 (continuous) |

Oxidation Resistance | Superior to 1204°C | Good to 1100°C | Excellent to 980°C |

Creep Rupture (1000h @ 1000°C, MPa) | 70-100 | 50-100 | 300-400 (at 650°C) |

Corrosion (Carburization) | Excellent | Good | Good |

Weldability | Excellent | Excellent | Good (PWHT needed) |

Density (g/cm³) | 8.11 | 8.30 | 8.19 |

Cost Relative | Baseline | 80-90% | 200-250% |

Inconel 601 excels for high-temp oxidation.<grok:render type="render_inline_citation">0</grok:render> Contact us for custom specs.

About Us:

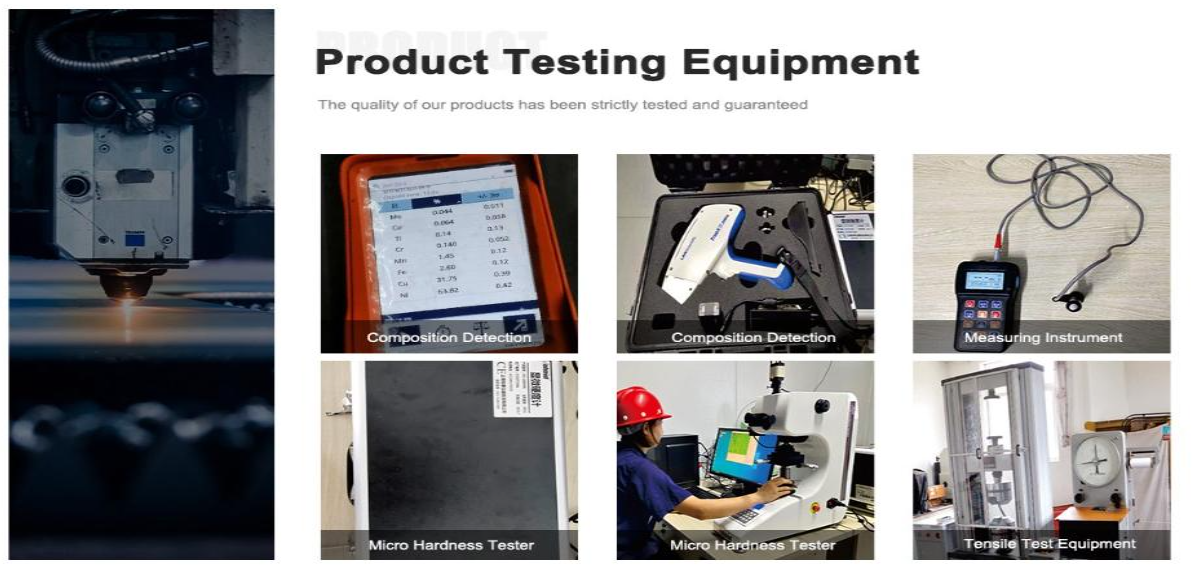

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

We get these questions all the time – here’s the real deal.

What’s Inconel 601’s oxidation edge? Cr-Al combo forms a sticky oxide layer to 1204°C, keeping furnace parts scale-free.

How’s it handle corrosion? Shines in carburizing and sulfidizing atmospheres; resists chloride stress cracking in chem plants.

Welding tips? GTAW or SMAW with matching filler, no preheat – low cracking with clean surfaces.

Fatigue strength? Hits 10^7 cycles at 120 MPa, great for vibrating furnace tubes or aero liners.

Cryogenic use? Ductile to -200°C, solid for mixed-temp setups like LNG processing.

Machining challenges? Moderate hardening; HSS tools at 25 m/min with coolant – easier than hardened alloys.

Eco benefits? 94% recyclable, our low-carbon melts align with aero and energy green standards.

DLX sizes and delivery? 5-100mm dia, annealed or custom; 2-4 weeks stock, 6 for customs – faster than most.