Our Inconel 625, 617, and 690 plates are engineered to power through the toughest conditions in power plant components. These nickel-based alloys are built for strength, corrosion resistance, and performance in high-heat, high-stress environments. Inconel 625 thrives in acidic and chloride-heavy settings, perfect for boiler tubes and chemical-exposed parts up to 1800°F (982°C). Inconel 617 takes on extreme heat up to 2000°F (1093°C), making it ideal for superheaters and turbine components. Inconel 690 is a champ at resisting stress corrosion cracking, especially in nuclear reactors and flue gas systems. Available in thicknesses from 1/8″ to 2″, we customize these plates to fit your exact component designs.

For more details, pls directly contact us.

The power generation industry is evolving fast, with global demand for cleaner, more efficient energy driving innovation. Power plants—whether fossil fuel, nuclear, or renewable—are under pressure to operate reliably in harsher conditions while meeting strict environmental standards. The market for high-performance materials is growing as plants prioritize components that resist corrosion, withstand high temperatures, and last longer to cut maintenance costs. Inconel 625, 617, and 690 plates are in high demand for their ability to handle everything from flue gas desulfurization to nuclear reactor stresses. As the industry shifts toward sustainability, our plates are a perfect fit for building durable, efficient power plant systems.

Comparison Table

Parameter | Inconel 625 | Inconel 617 | Inconel 690 | Stainless Steel (e.g., 316) |

|---|---|---|---|---|

Max Service Temperature | 1800°F (982°C) | 2000°F (1093°C) | 1900°F (1038°C) | 1600°F (871°C) |

Corrosion Resistance | Superior in acidic/chloride environments | Excellent in oxidizing conditions | Outstanding vs. stress corrosion cracking | Good, weaker in aggressive settings |

Tensile Strength | ~830 MPa, retains at high temps | ~700 MPa, stable at extreme temps | ~680 MPa, reliable under stress | ~515 MPa, weakens at high temps |

Oxidation Resistance | Very good, resists scaling | Outstanding, forms protective oxide layer | Excellent, resists high-temp oxidation | Moderate, prone to scaling |

Weldability | Readily weldable, no post-weld treatment | Readily weldable, no post-weld treatment | Readily weldable, no post-weld treatment | Good, may require post-weld treatment |

Creep Resistance | Moderate, suited for chemical settings | High, ideal for high-temp applications | High, resists deformation under stress | Moderate, limited under thermal stress |

Cost | Higher, long-term savings | Moderate, cost-effective for longevity | Moderate, durable in harsh conditions | Lower, higher maintenance costs |

Applications | Boiler tubes, marine, chemical components | Superheaters, turbine parts | Nuclear reactors, flue gas systems | General industrial, less extreme conditions |

Our Inconel 625, 617, and 690 plates are go-to materials for critical power plant applications. Inconel 625 is used in boiler tubes and heat exchangers exposed to acidic gases or chloride-rich environments. Inconel 617 shines in superheaters, turbine blades, and combustor parts, where its oxidation resistance and high-temperature strength are key. Inconel 690 is a top pick for nuclear reactors and flue gas desulfurization systems, thanks to its resistance to stress corrosion cracking in high-purity water and aggressive chemical settings. From coal-fired plants to nuclear facilities, our plates ensure components stay tough and reliable under extreme conditions.

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel X750 | Inconel 825 |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.02-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

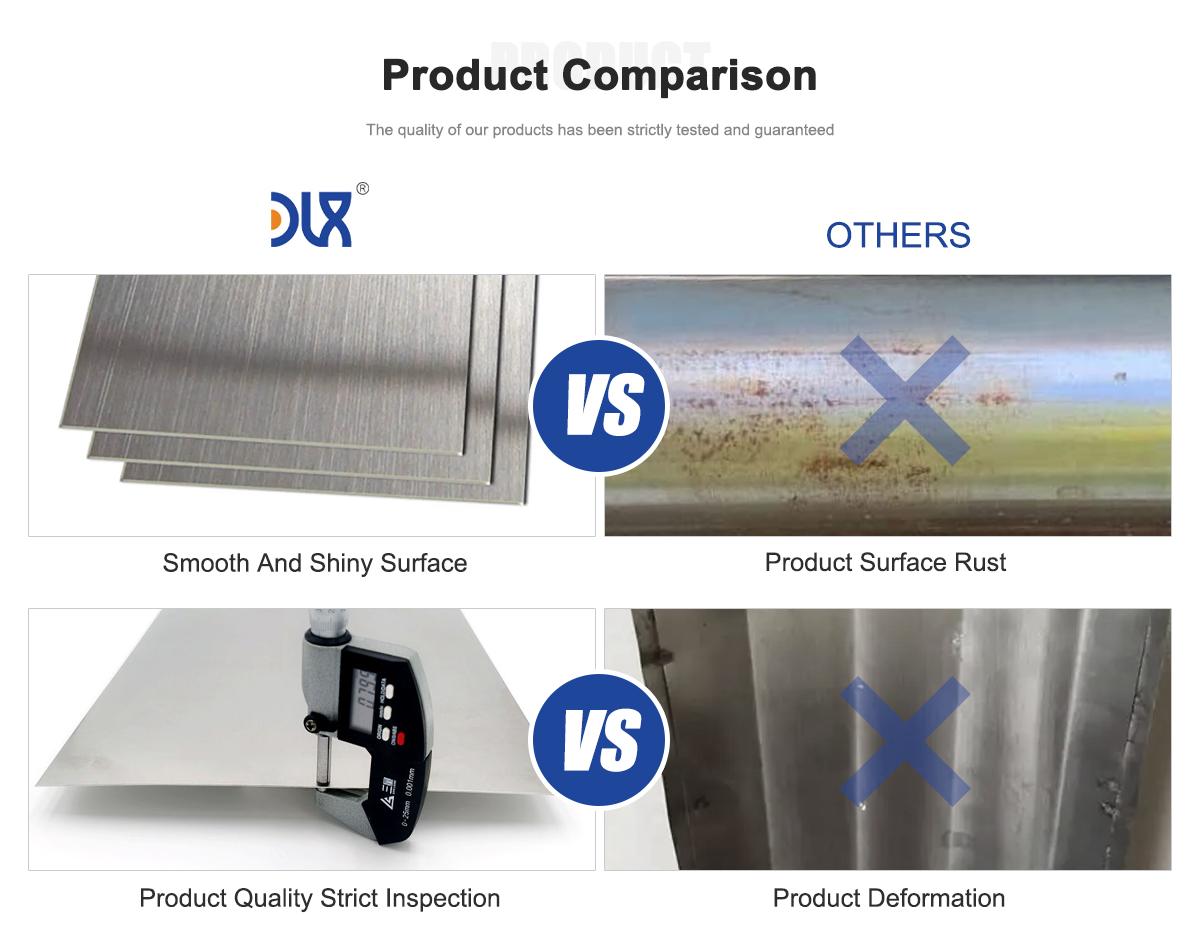

We lead the pack when it comes to Inconel 625, 617, and 690 plates for power plant components. Our cutting-edge manufacturing delivers plates that meet the toughest industry standards, with rigorous quality checks ensuring zero defects. We offer unmatched customization, tailoring plate sizes and thicknesses to your specific designs. Our plates are optimized for weldability and formability, streamlining fabrication and reducing downtime. Unlike others, we focus on delivering materials that maximize longevity and minimize maintenance, even in the harshest power plant environments. With our reliable supply chain and fast delivery, we keep your projects on schedule, no matter the scope.

Why Choose Our Inconel Plate s?

Our Inconel 625, 617, and 690 plates are built to keep power plants running smoothly, no matter the challenge. With top-notch corrosion resistance, high-temperature strength, and durability, they’re perfect for boiler tubes, superheaters, nuclear reactors, and more. Whether you’re tackling fossil fuel emissions or nuclear stresses, our plates deliver performance you can rely on. Backed by our commitment to quality, customization, and timely delivery, we’re here to help

About Us:

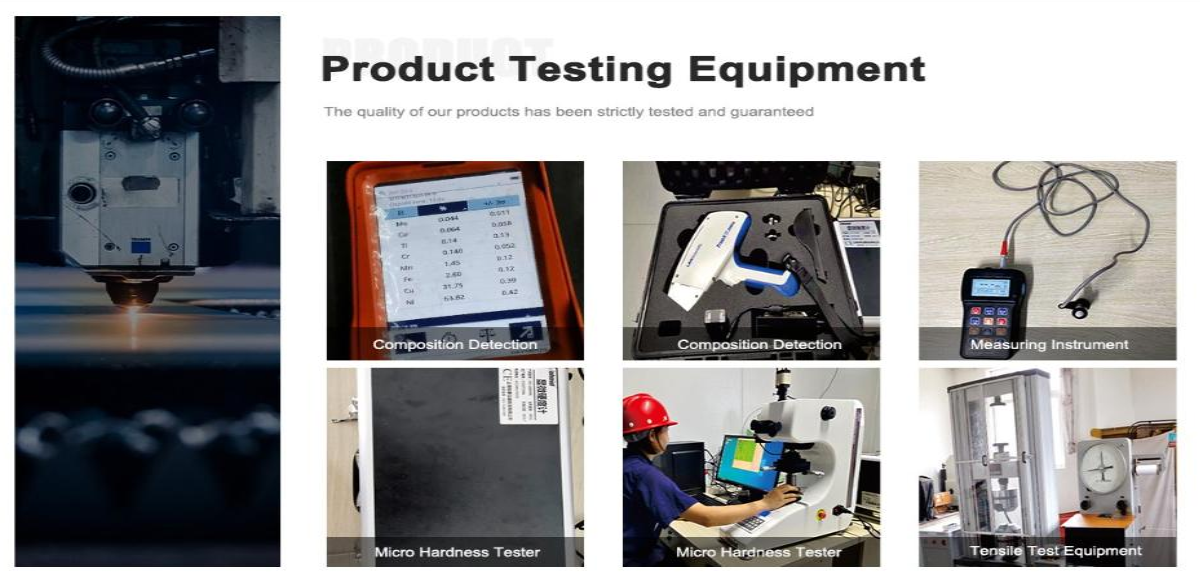

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

Why are Inconel 625, 617, and 690 plates ideal for power plant components?

They provide exceptional corrosion resistance, high-temperature strength, and durability in aggressive power plant environments.What power plant applications use these plates?

They’re used in boiler tubes, superheaters, turbine components, and flue gas desulfurization systems.How do these alloys perform in high-temperature conditions?

Inconel 625 operates up to 1800°F (982°C), 617 up to 2000°F (1093°C), and 690 up to 1900°F (1038°C) with excellent stability.Are these plates resistant to corrosive environments?

Yes, 625 excels in acidic and chloride settings, 617 resists oxidation, and 690 is outstanding against stress corrosion cracking.Can these Inconel plates be welded for power plant fabrication?

All three are easily weldable using standard methods like TIG or MIG, requiring no post-weld heat treatment.How do these plates compare to stainless steel for power plants?

Inconel 625, 617, and 690 offer superior corrosion resistance and strength at higher temperatures than stainless steel.What sizes are available for these Inconel plates?

We offer customizable thicknesses from 1/8″ to 2″, tailored for specific power plant component designs.Are these plates cost-effective for power plant use?

Their durability and low maintenance in harsh conditions make them a cost-effective choice despite higher initial costs.