We’re proud to offer Inconel 600, 617, and 625 welded tubes, engineered for extreme-temperature environments where strength and corrosion resistance are non-negotiable. These nickel-based superalloys are built to thrive in the harshest conditions, from scorching heat to corrosive chemicals. Our Inconel 600 tubes deliver excellent oxidation and corrosion resistance, perfect for chemical processing and furnace components. Inconel 617 steps it up with enhanced high-temperature strength, ideal for gas turbines and petrochemical systems. Meanwhile, Inconel 625 is the go-to for superior weldability and resistance to acidic environments, making it a staple in aerospace and marine applications. Each alloy is crafted with precision, ensuring our welded tubes meet rigorous industry standards like ASTM B444 and ASME SB 444 for seamless performance under pressure.

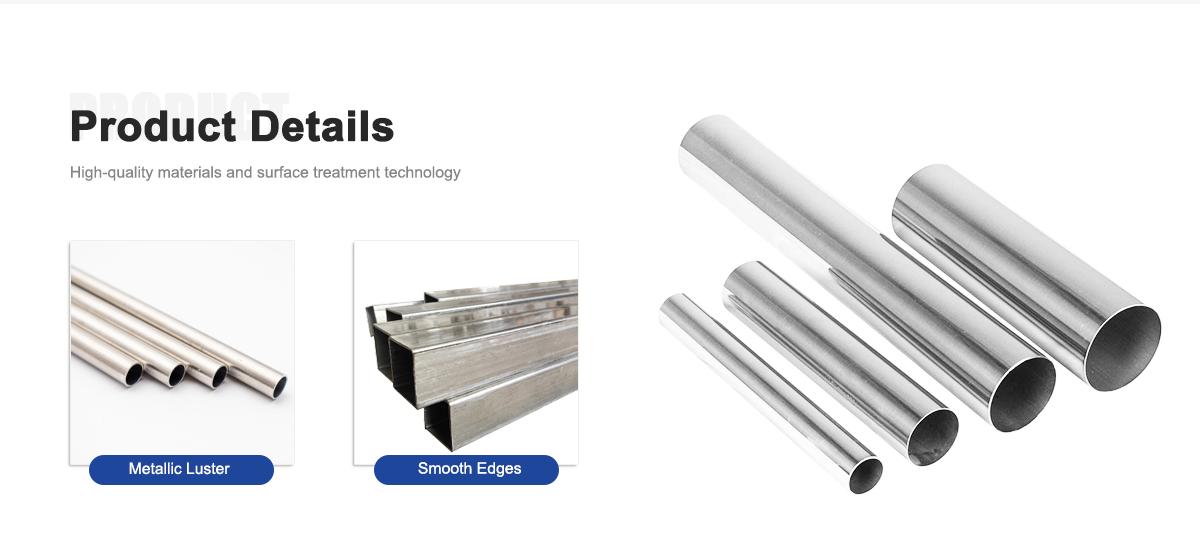

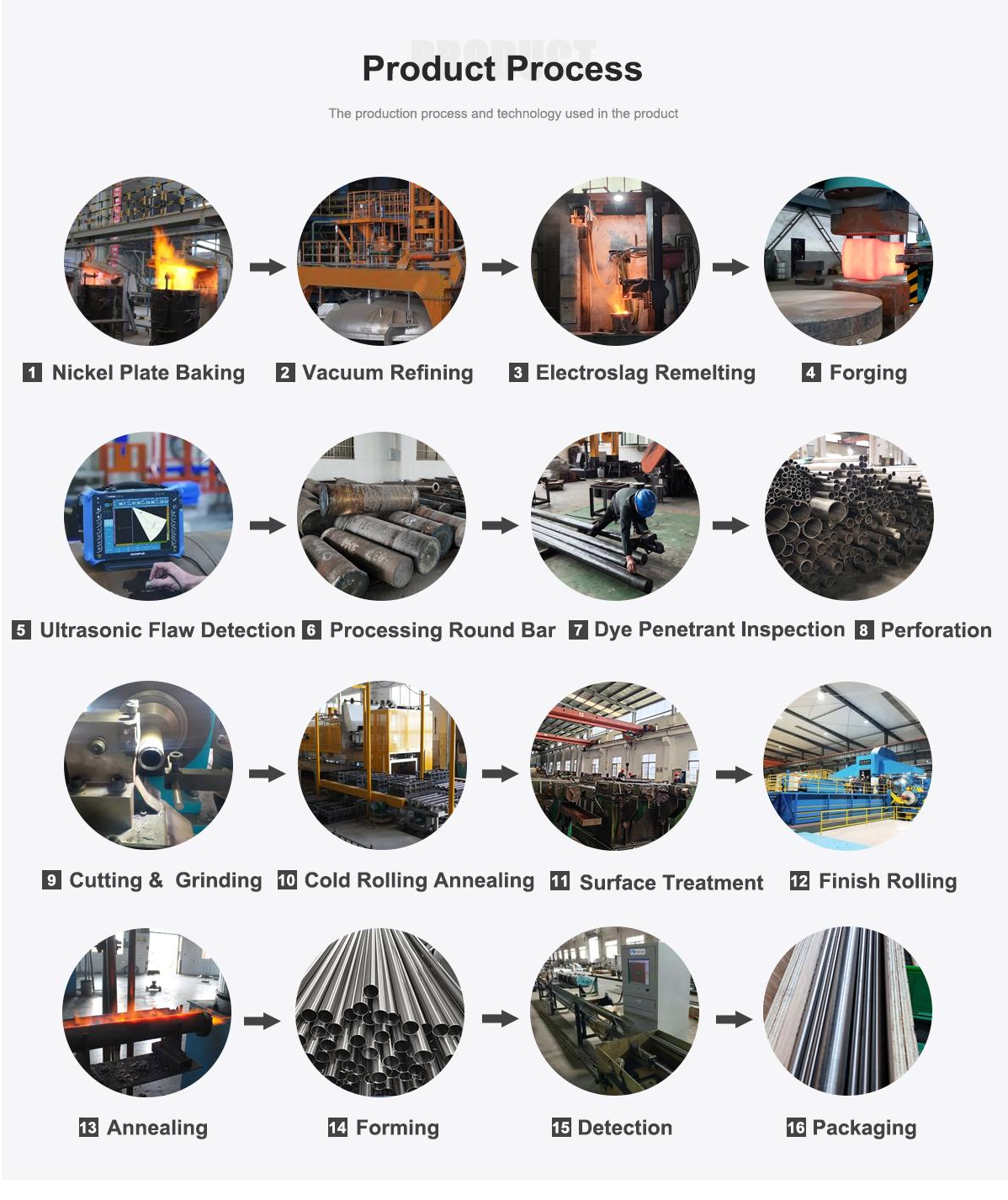

Our welded tubes are designed for reliability, offering high tensile strength, fatigue resistance, and creep resistance at temperatures up to 2000°F (1093°C). Whether it’s for heat exchangers, nuclear reactors, or offshore platforms, our Inconel tubes are versatile, durable, and ready to tackle your toughest challenges. We use advanced manufacturing processes to ensure tight tolerances, smooth welds, and consistent quality, giving you a product that performs every time.

The demand for high-performance alloys like Inconel 600, 617, and 625 is on the rise, driven by industries pushing the boundaries of temperature and corrosion resistance. Aerospace is a major player, with jet engines and turbine blades requiring materials that can handle extreme heat and stress. The chemical processing sector is also growing, as plants need reliable tubing for reactors and heat exchangers exposed to aggressive chemicals. The oil and gas industry, especially in deep-sea and sour gas environments, leans heavily on Inconel for its unmatched durability. Add to that the push for sustainable energy—think nuclear reactors and waste-to-energy plants—and the need for these alloys is only climbing.

Market trends show a shift toward additive manufacturing and sustainable production methods, reducing material waste while maintaining performance. Wire arc additive manufacturing (WAAM) is gaining traction, cutting energy use and waste compared to traditional machining. Meanwhile, global supply chain challenges and fluctuating nickel prices are influencing costs, but the long-term outlook is strong as industries prioritize durability and efficiency. Our Inconel welded tubes are positioned to meet these evolving demands, offering both performance and cost-effectiveness.

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel 825 | |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.02-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

Our Inconel 600, 617, and 625 welded tubes shine in applications where failure isn’t an option. Inconel 600 is a workhorse for chemical processing equipment, heat exchangers, and furnace components, thanks to its resistance to oxidation and carburization up to 1200°C. Inconel 617 is a powerhouse in gas turbines, petrochemical processing, and nuclear reactors, with its cobalt and molybdenum content boosting strength at high temperatures. Inconel 625, with its niobium-enhanced weldability, is a favorite for aerospace components like turbine blades, exhaust systems, and marine applications like seawater heat exchangers. These tubes are also critical in oil and gas for sour gas pipelines and in nuclear plants for reactor cores and control rods. Whatever the industry, our tubes deliver reliability and longevity in extreme conditions.

Comparison Table

Parameter | Inconel 600 | Inconel 617 | Inconel 625 |

|---|---|---|---|

Nickel Content | ~76% | ~52% | ~58% |

Chromium Content | 14-17% | 20-24% | 20-23% |

Molybdenum Content | - | 8-10% | 8-10% |

Key Alloying Elements | Iron | Cobalt, Aluminum | Niobium, Tantalum |

Max Service Temperature | 1200°C | 1100°C | 980°C |

Corrosion Resistance | Excellent in oxidizing environments | High in reducing/oxidizing media | Superior in acidic and marine environments |

Weldability | Good, but prone to sensitization | Excellent, high workability | Outstanding, resists post-weld cracking |

Tensile Strength | ~93 ksi | ~100 ksi | ~120 ksi |

Key Applications | Furnace components, chemical processing | Gas turbines, nuclear reactors | Aerospace, marine, oil & gas |

Creep Resistance | Moderate | High, due to cobalt and molybdenum | Excellent, enhanced by niobium |

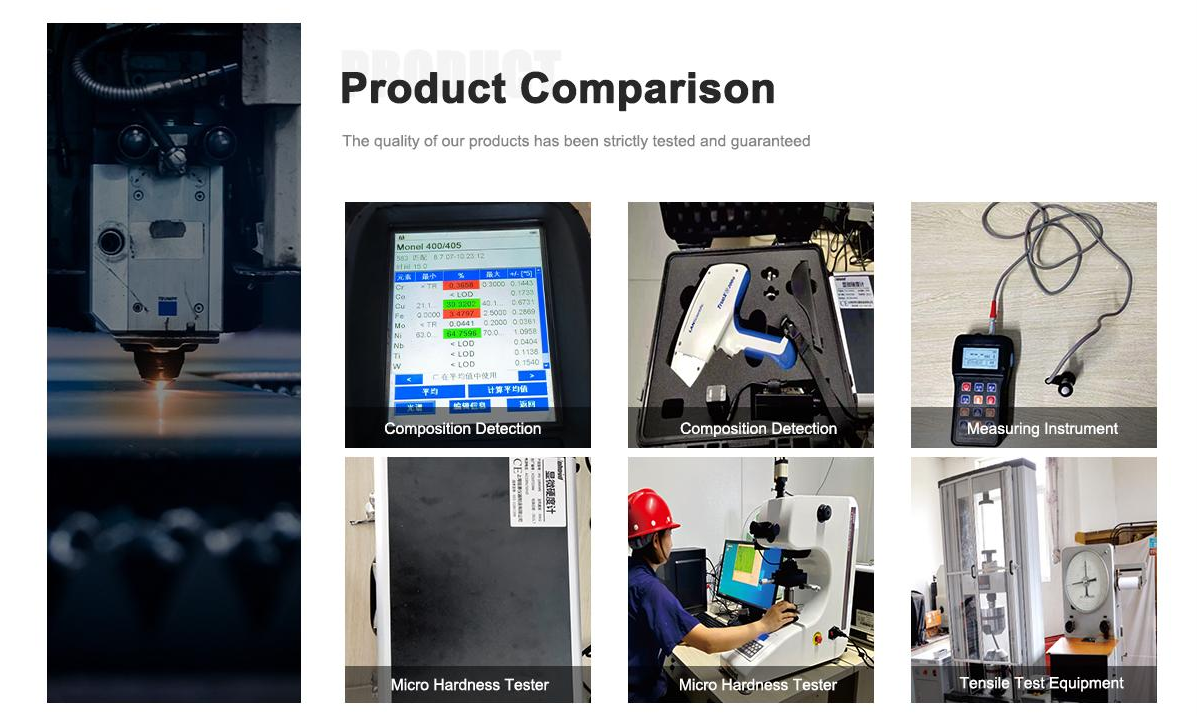

When stacking up against competitors, our Inconel welded tubes stand out for a few key reasons. First, our manufacturing process emphasizes precision and quality control, ensuring every tube meets or exceeds ASTM and ASME standards. We use advanced welding techniques, like gas tungsten arc welding, to produce seamless, crack-free joints that hold up under stress. Our competitors might cut corners on quality checks, but we test every batch for mechanical properties and corrosion resistance, so you get consistent performance. We also offer customizable dimensions and finishes, giving you flexibility that others might not. Plus, our focus on sustainable production—optimizing material use and minimizing waste—means you’re getting a high-performance product with a lower environmental footprint. Price-wise, we keep things competitive by streamlining our supply chain, so you get top-tier Inconel tubes without breaking the bank.

Why Choose Us?

Our Inconel 600, 617, and 625 welded tubes are built to outperform, with a focus on quality, durability, and versatility. We know industries like aerospace, chemical processing, and oil and gas need materials they can trust, and we deliver every time. Our advanced manufacturing, rigorous testing, and commitment to sustainability set us apart, ensuring you get tubes that handle extreme temperatures and corrosive environments with ease. Whether you’re building jet engines, reactors, or offshore platforms, our Inconel tubes are your go-to solution for long-lasting performance.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What makes Inconel 600, 617, and 625 welded tubes suitable for extreme temperatures?

Their high nickel, chromium, and molybdenum content ensures excellent strength, oxidation resistance, and stability at temperatures up to 2000°F.Which industries use Inconel 600 welded tubes?

Chemical processing, nuclear reactors, and furnace manufacturing rely on Inconel 600 for its corrosion and heat resistance.What are the key applications for Inconel 617 tubes?

Inconel 617 is used in gas turbines, petrochemical processing, and high-temperature nuclear applications due to its enhanced strength.Why is Inconel 625 preferred for marine environments?

Its niobium content boosts weldability and resistance to pitting and crevice corrosion in seawater and acidic conditions.How do your Inconel tubes compare to competitors?

Our tubes offer superior quality control, advanced welding techniques, and customizable options, all at competitive prices.Can Inconel welded tubes be used in aerospace?

Absolutely, Inconel 625 is widely used for turbine blades and exhaust systems due to its high strength and corrosion resistance.What manufacturing standards do your Inconel tubes meet?

Our tubes comply with ASTM B444 and ASME SB 444, ensuring top performance in high-pressure and high-temperature applications.How does your company ensure sustainability in production?

We optimize material use and employ efficient manufacturing processes to reduce waste and energy consumption.