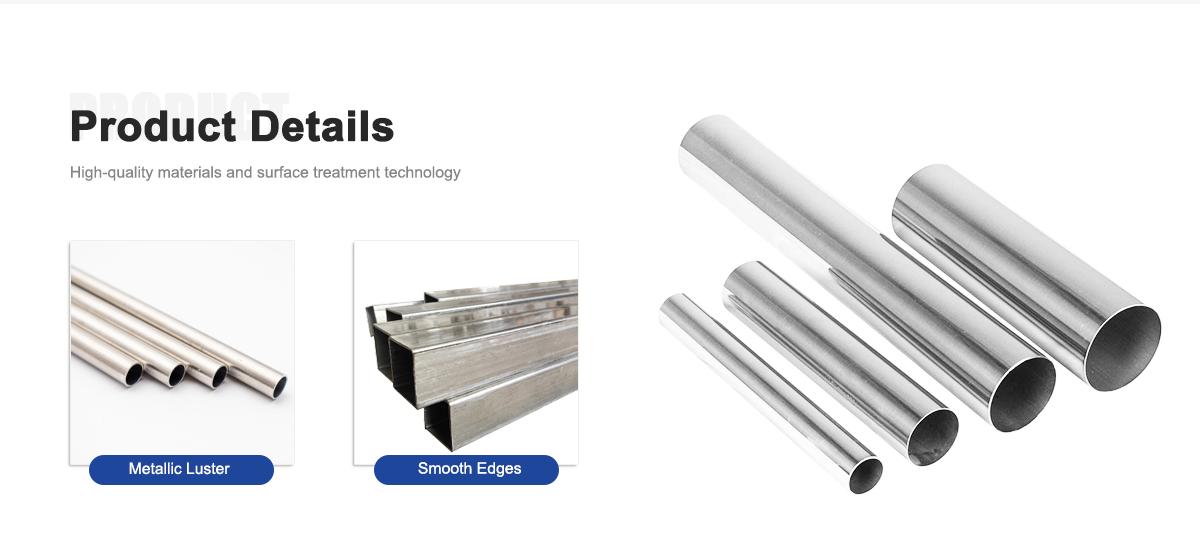

Our Inconel 625, 718, and X-750 seamless tubes are built to withstand the toughest marine and subsea environments, where corrosion, pressure, and extreme conditions demand top-tier performance. These nickel-based superalloys are engineered for durability, offering unmatched strength and resistance to harsh seawater and acidic conditions. Inconel 625 excels in corrosion resistance, perfect for subsea pipelines and heat exchangers. Inconel 718 brings high tensile strength and fatigue resistance, ideal for marine fasteners and turbine components. Inconel X-750, with its excellent spring properties, shines in high-stress applications like valve springs and subsea connectors. Every tube is crafted to meet stringent ASTM B444 and ASME SB 704 standards, ensuring flawless performance in critical systems.

Our seamless tubes are designed for precision, with smooth surfaces and tight tolerances to handle pressures up to 15,000 psi and temperatures from cryogenic to 1300°F (704°C). Whether it’s offshore platforms, subsea equipment, or marine propulsion systems, our Inconel tubes deliver reliability and longevity, keeping your operations running smoothly in the harshest conditions.

Industry Analysis

The marine and subsea sectors are booming, driven by growing demand for offshore oil and gas exploration, renewable energy projects like offshore wind, and deep-sea mining. Inconel alloys are critical here, as they resist pitting, crevice corrosion, and stress-corrosion cracking in seawater. The global push for sustainable energy is increasing investments in subsea infrastructure, with projects like carbon capture and storage relying on durable materials. Meanwhile, advancements in manufacturing, like cold-drawn seamless tubing, are improving performance while reducing costs. Supply chain disruptions and nickel price volatility pose challenges, but the long-term outlook is strong, with the marine alloy market projected to grow steadily through 2030. Our seamless tubes are positioned to meet these needs, offering high performance and cost efficiency.

Comparison Table

Parameter | Inconel 625 | Inconel 718 | Inconel X-750 |

|---|---|---|---|

Nickel Content | ~58% | ~52% | ~70% |

Chromium Content | 20-23% | 17-21% | 14-17% |

Molybdenum Content | 8-10% | 2.8-3.3% | - |

Key Alloying Elements | Niobium, Tantalum | Niobium, Titanium, Aluminum | Titanium, Aluminum, Niobium |

Max Service Temperature | 980°C | 704°C | 704°C |

Corrosion Resistance | Outstanding in seawater and acidic media | High in oxidizing environments | Good in corrosive environments |

Tensile Strength | ~120 ksi | ~185 ksi (age-hardened) | ~165 ksi (age-hardened) |

Weldability | Excellent, resists post-weld cracking | Good, requires post-weld heat treatment | Moderate, sensitive to cracking |

Key Applications | Subsea pipelines, heat exchangers | Marine fasteners, turbine blades | Valve springs, subsea connectors |

Fatigue Resistance | High, suitable for cyclic loading | Excellent, ideal for dynamic stress | Superior, perfect for spring applications |

Our Inconel 625, 718, and X-750 seamless tubes are go-to solutions for marine and subsea challenges. Inconel 625 is a star in subsea pipelines, umbilical tubes, and heat exchangers, thanks to its resistance to chloride-induced corrosion. Inconel 718 is perfect for high-strength components like marine fasteners, pump shafts, and turbine blades, handling extreme mechanical stress. Inconel X-750 is a favorite for springs, seals, and connectors in subsea valves and risers, offering excellent fatigue resistance. From offshore drilling rigs to underwater robotics and renewable energy platforms, our tubes ensure durability and performance in corrosive, high-pressure environments.

Item | Inconel 600 | Inconel 625 | Inconel 718 | Inconel X750 | Inconel 825 | |||

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.02-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

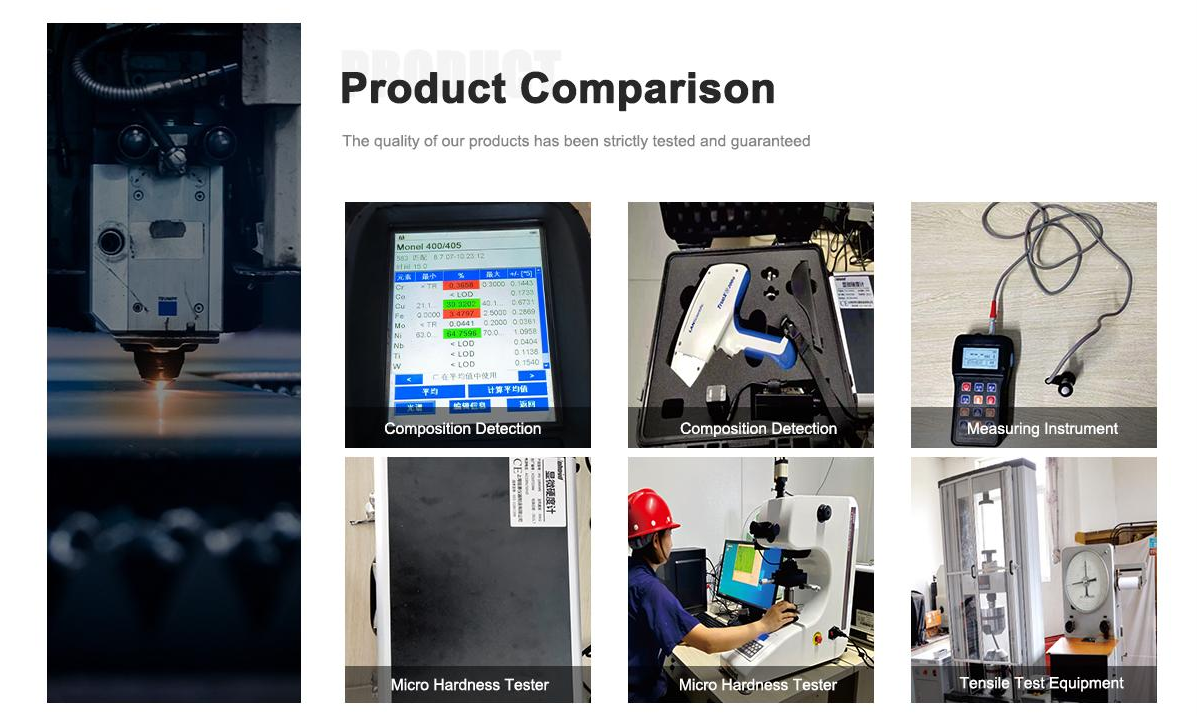

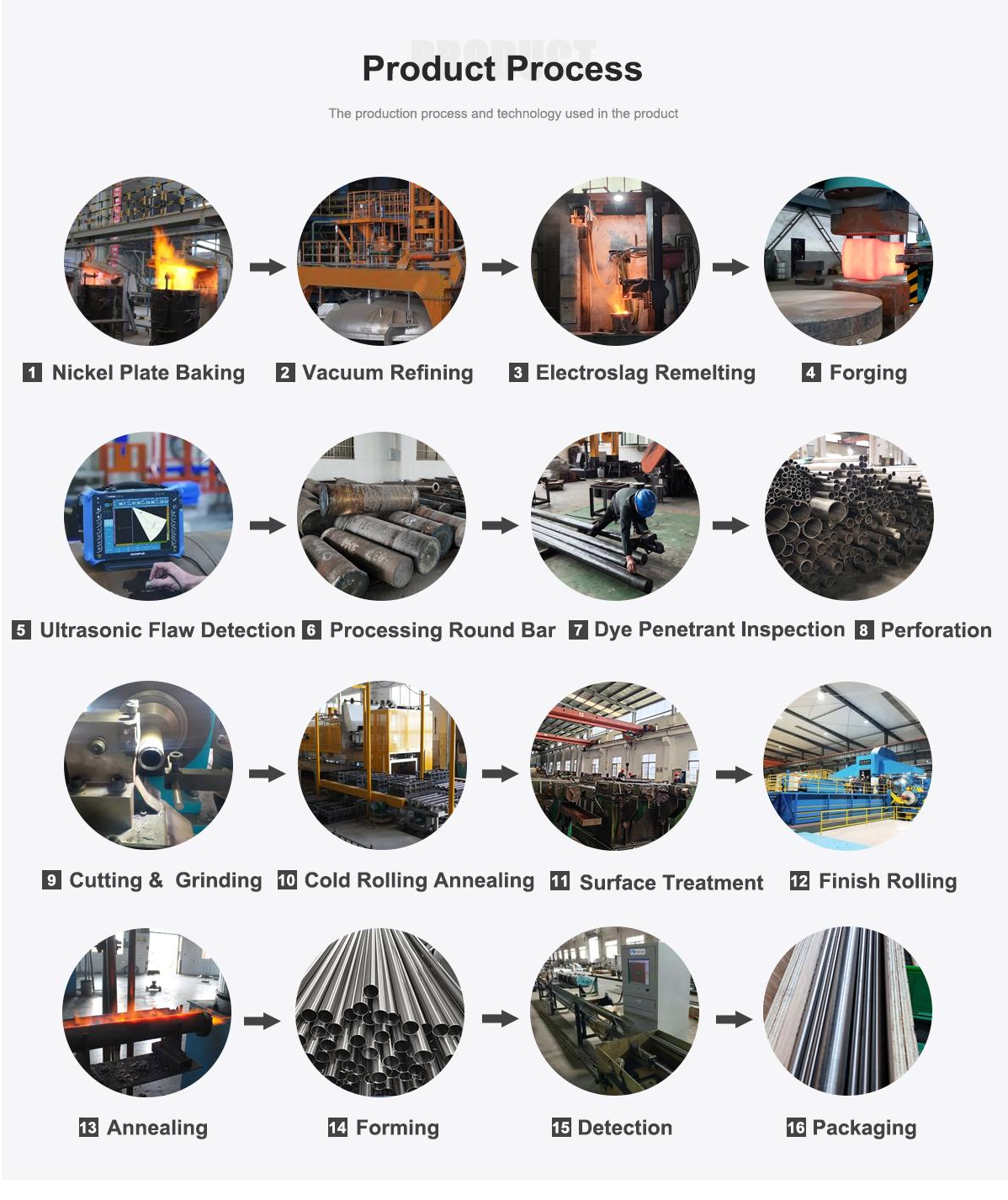

Our Inconel seamless tubes stand out in a crowded market. We prioritize quality with advanced cold-drawing techniques, ensuring defect-free surfaces and superior mechanical properties. Every batch undergoes rigorous testing for corrosion resistance and tensile strength, meeting or exceeding industry standards. Unlike some competitors, we offer flexible customization in dimensions and finishes, so you get exactly what your project needs. Our focus on sustainable manufacturing—minimizing waste and optimizing energy use—gives you a high-quality product with a smaller environmental footprint. Plus, our streamlined supply chain keeps costs competitive, delivering premium Inconel tubes without the premium price tag.

Why Choose Us?

Our Inconel 625, 718, and X-750 seamless tubes are engineered for the toughest marine and subsea applications. We combine cutting-edge manufacturing, strict quality control, and sustainable practices to deliver tubes that perform under pressure—literally. From offshore platforms to deep-sea pipelines, our products offer unmatched durability, corrosion resistance, and strength. Choose us for reliable, high-performance solutions that keep your operations running smoothly, no matter how harsh the environment.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

Why are Inconel 625, 718, and X-750 seamless tubes ideal for marine use?

Their high nickel and chromium content provides exceptional resistance to seawater corrosion and high-pressure conditions.What are the main applications for Inconel 625 seamless tubes?

Subsea pipelines, umbilical tubes, and heat exchangers due to superior corrosion resistance in chloride environments.How does Inconel 718 perform in marine environments?

It offers high tensile strength and fatigue resistance, perfect for marine fasteners and turbine components.What makes Inconel X-750 suitable for subsea equipment?

Its excellent spring properties and fatigue resistance make it ideal for valve springs and subsea connectors.How do your seamless tubes compare to competitors?

We offer superior quality control, customizable options, and competitive pricing through efficient manufacturing.What standards do your Inconel tubes meet?

Our tubes comply with ASTM B444 and ASME SB 704 for reliable performance in extreme conditions.Can Inconel tubes handle cryogenic temperatures?

Yes, all three alloys maintain strength and toughness from cryogenic to high temperatures up to 1300°F.How do you ensure sustainability in production?

We use optimized manufacturing processes to reduce material waste and energy consumption.