We’re proud to offer Inconel 600 wire, a top-tier solution for industries that demand reliability in the toughest conditions. This nickel-chromium alloy is a go-to for high-temperature furnace applications, and here’s why it’s a game-changer.

Inconel 600 wire is built to handle extreme heat and harsh environments. With a nickel content of at least 72%, it’s packed with resistance to oxidation and corrosion, making it perfect for furnaces operating at temperatures up to 2000°F (1093°C). Whether it’s for heating elements, thermocouple sheathing, or structural components, our Inconel 600 wire delivers unmatched durability. We offer it in various forms—round, flat, or spring wire—tailored to your exact specs. Its ability to resist thermal cycling and maintain strength under stress sets it apart from other materials.

The global push for efficiency in high-temperature industries like aerospace, power generation, and chemical processing is driving demand for Inconel 600 wire. Recent trends show a growing need for materials that can handle extreme conditions while meeting strict environmental and safety standards. According to industry insights, the nickel alloy market is expected to grow steadily through 2030, fueled by advancements in energy and aerospace technologies. Our Inconel 600 wire fits right into this trend, offering a reliable solution for manufacturers looking to optimize performance without compromising on longevity.

|

Parameter |

Inconel 600 Wire |

Stainless Steel 316 |

Hastelloy C-276 |

|---|---|---|---|

|

Nickel Content |

High (72% min) |

Moderate (10-14%) |

High (57%) |

|

Max Operating Temp |

2000°F (1093°C) |

1600°F (871°C) |

1900°F (1038°C) |

|

Oxidation Resistance |

Excellent |

Moderate |

Very Good |

|

Corrosion Resistance |

High in acidic/alkaline environments |

Good in mild environments |

Excellent in harsh chemical environments |

|

Strength at High Temp |

High |

Moderate |

High |

|

Applications |

Furnaces, chemical processing, aerospace |

General industrial, marine |

Chemical processing, pollution control |

|

Cost |

Moderate to high |

Low to moderate |

High |

|

Availability |

Wide range of forms and sizes |

Common, widely available |

Specialized, less common |

Our Inconel 600 wire is a workhorse across multiple industries:

-

Furnace Manufacturing: Used in heating elements, radiant tubes, and muffles for industrial furnaces.

-

Aerospace: Ideal for exhaust systems and turbine components exposed to high heat.

-

Chemical Processing: Perfect for equipment handling corrosive gases and liquids.

-

Power Generation: Essential for boiler components and heat exchangers in power plants.

Its versatility makes it a favorite for engineers who need a material that can take a beating and keep performing.

|

Item |

Inconel 600 |

Inconel 601 |

Inconel 625 |

Inconel 690 |

Inconel X750 |

Inconel 825 |

||

|

C |

≤0.15 |

≤0.1 |

0.05-0.15 |

≤0.08 |

≤0.05 |

≤0.08 |

≤0.08 |

≤0.05 |

|

Mn |

≤1 |

≤1.5 |

≤0.5 |

≤0.35 |

≤0.5 |

≤0.35 |

≤1 |

≤1 |

|

Fe |

6-10 |

rest |

≤3 |

rest |

7-11 |

rest |

5-9 |

≥22 |

|

P |

≤0.015 |

≤0.02 |

≤0.015 |

-- |

-- |

-- |

-- |

-- |

|

S |

≤0.015 |

≤0.015 |

≤0.015 |

≤0.015 |

≤0.015 |

≤0.01 |

≤0.01 |

≤0.03 |

|

Si |

≤0.5 |

≤0.5 |

≤0.5 |

≤0.35 |

≤0.5 |

≤0.35 |

≤0.5 |

≤0.5 |

|

Cu |

≤0.5 |

≤1 |

-- |

≤0.3 |

≤0.5 |

≤0.3 |

≤0.5 |

1.5-3 |

|

Ni |

≥72 |

58-63 |

≥44.5 |

50-55 |

≥58 |

50-55 |

≥70 |

38-46 |

|

Co |

-- |

-- |

10-15 |

≤10 |

-- |

≤1 |

≤1 |

-- |

|

Al |

-- |

1-1.7 |

0.8-1.5 |

≤0.8 |

-- |

0.2-0.8 |

0.4-1 |

≤0.2 |

|

Ti |

-- |

-- |

≤0.6 |

≤1.15 |

-- |

-- |

2.25-2.75 |

0.6-1.2 |

|

Cr |

14-17 |

21-25 |

20-24 |

17-21 |

27-31 |

17-21 |

14-17 |

19.5-23.5 |

|

Nb+Ta |

-- |

-- |

-- |

4.75-5.5 |

-- |

4.75-5.5 |

0.7-1.2 |

-- |

|

Mo |

-- |

-- |

8-10 |

2.8-3.3 |

-- |

2.8-3.3 |

-- |

2.5-3.5 |

|

B |

-- |

-- |

≤0.006 |

-- |

-- |

-- |

-- |

-- |

|

Shape |

Size (mm) |

|

Wire |

0.5-7.50 |

|

Rod/Bar |

8.0-200 |

|

Strip |

(0.5-2.5)*(5-180) |

|

Tube/Pipe |

Customized |

|

Sheet/Plate |

Customized |

For more details, pls directly contact us.

We know there are other suppliers out there, but we’re confident in what sets us apart. Our Inconel 600 wire is produced with precision, ensuring consistent quality and performance. We offer custom sizes and forms to meet your specific needs, and our rigorous quality control means you get wire that meets ASTM standards every time. Plus, our supply chain is streamlined to deliver fast, so your projects stay on track. We’re not just selling wire—we’re providing a solution you can trust for the long haul.

Why Choose Our Inconel 600 Wire?

If you’re looking for a material that can handle scorching temperatures, resist corrosion, and keep your operations running smoothly, our Inconel 600 wire is the answer. It’s built for the toughest jobs, backed by our commitment to quality and customer satisfaction. Whether you’re in aerospace, chemical processing, or furnace manufacturing, we’ve got the wire to keep your projects firing on all cylinders.

About Us:

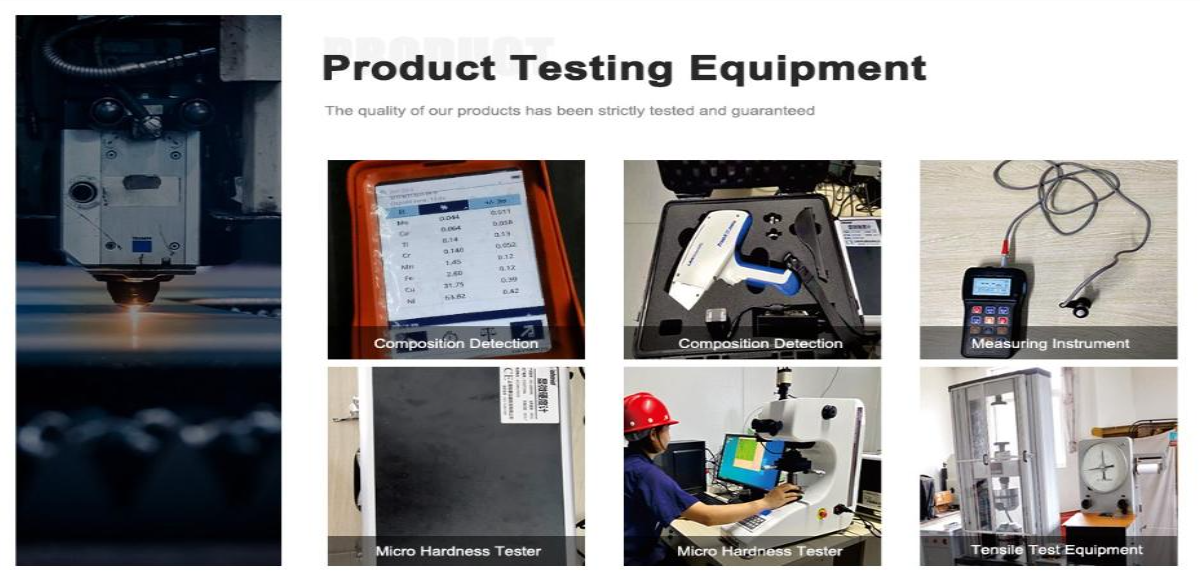

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is Inconel 600 wire?

Inconel 600 wire is a nickel-chromium alloy wire known for its high strength, corrosion resistance, and ability to withstand extreme temperatures up to 2000°F (1093°C).

What are the key properties of Inconel 600 wire?

It offers excellent oxidation and corrosion resistance, high strength, good workability, and resistance to chloride-ion stress-corrosion cracking.

What are common high-temperature furnace applications for Inconel 600 wire?

It is used in furnace components like muffles, retorts, trays, baskets, and wire belts for heat treatment processes.

Which industries use Inconel 600 wire for high-temperature applications?

Industries include chemical processing, aerospace, nuclear engineering, thermal processing, and food processing.

How does Inconel 600 wire perform in corrosive environments?

It resists corrosion from acids, alkalis, seawater, and chloride-ion stress, making it ideal for harsh chemical environments.

What are the processing requirements for Inconel 600 wire in furnaces?

Workpieces must be clean and free of contaminants like sulfur, lead, or phosphorus before and during heat treatment to prevent damage.

What are the recent trends in Inconel 600 wire applications?

Increased use in additive manufacturing (3D printing) and nuclear applications due to its high-temperature and corrosion resistance properties.

Can Inconel 600 wire be welded for furnace applications?

Yes, it can be welded using standard processes like GTAW, GMAW, and SMAW, with no need for post-weld heat treatment.