When it comes to gas turbines and high-performance aerospace parts, the demands on materials are extreme—intense heat, high pressure, corrosive conditions, and long-term stress cycles. That’s where our Inconel 718 spring wire comes into play.

This nickel-chromium-based superalloy is built for resilience. It’s engineered to hold its shape and strength at elevated temperatures—up to 700°C—making it an ideal material for turbine springs, retainers, and precision sealing components. Thanks to its high yield strength and excellent fatigue resistance, it delivers stable performance in both static and dynamic loading environments.

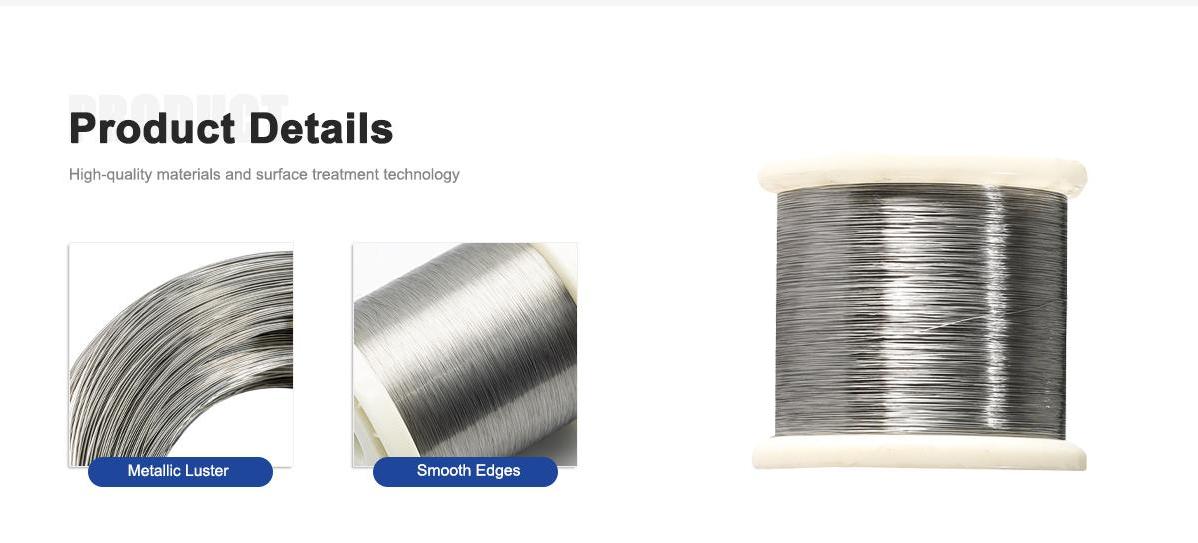

From a manufacturing standpoint, Inconel 718 can be solution heat-treated and aged to fine-tune its mechanical properties. We offer flexible customization—coil dimensions, cut lengths, surface finish—all tailored to your application requirements.

Industry Insights and Application Trends

With aerospace, defense, and energy industries pushing deeper into extreme environments, there’s a growing demand for alloys that can withstand both thermal shock and mechanical fatigue. Inconel 718 spring wire is increasingly used in:

Aerospace turbines and jet engines

Power generation turbines

Subsea valve components

Industrial high-temperature actuators

Sealing rings and snap-fit devices

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 718 | Inconel 825 | ||

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.5-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

As the aerospace sector grows, especially with increasing demand for fuel-efficient engines and next-gen turbines, the use of high-strength spring wire like Inconel 718 is expanding rapidly. Long-term reliability and resistance to failure under cyclic stress are key performance indicators driving this trend.

Part 2: Comparison Table – Inconel 718 vs Common Spring Alloys

| Property | Inconel 718 | 17-7PH Stainless Steel | Nickel Alloy X-750 |

|---|---|---|---|

| Max Service Temperature (°C) | ~700°C | ~480°C | ~650°C |

| Yield Strength (MPa) | >1100 MPa | ~960 MPa | ~880 MPa |

| Corrosion Resistance | Excellent | Good | Good |

| Creep Resistance | Excellent | Moderate | Good |

| Fatigue Resistance | High | Moderate | High |

| Heat Treatment Required | Yes (solution & age) | Yes | Yes |

| Typical Applications | Turbines, aerospace | Automotive, valves | Springs, fasteners |

What sets our company apart is our full-spectrum alloy capability. We don’t just sell material—we engineer solutions. With a dedicated R&D team, we support custom metallurgy, rapid prototyping, and flexible order fulfillment. Whether you need a few meters for development or bulk quantities for OEM production, we’ve got you covered.

We work closely with aerospace contractors, turbine manufacturers, and industrial OEMs to develop tailored spring wire solutions that meet the strictest standards. Our inventory is backed by real-time logistics tracking, robust quality control, and a commitment to quick turnaround—no matter the order size.

Let us be your reliable supplier of Inconel 718 spring wire. With unmatched technical support, global delivery capabilities, and a reputation built on trust, we're ready to power your next high-performance application.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is Inconel 718 spring wire commonly used for?

Mainly for high-temperature, high-stress components like gas turbine springs and seals.

What is the maximum operating temperature of Inconel 718 spring wire?

Around 700°C (1290°F) in long-term service.

Is Inconel 718 suitable for corrosive environments?

Yes, it offers excellent resistance to oxidation and corrosion in extreme conditions.

Can Inconel 718 wire be customized in diameter and coil shape?

Yes, we provide custom sizing and forming services.

Is heat treatment necessary after forming Inconel 718 spring wire?

Yes, solution annealing and aging treatment optimize mechanical performance.

What certifications are available for your Inconel 718 wire?

ISO 9001, CE, RoHS, and full material traceability are available.

What’s the lead time for bulk orders?

Typically 7–15 working days depending on quantity and customization.

Can you support urgent or small-batch orders?

Absolutely—we handle both trial runs and large-scale industrial orders.