When it comes to reliable heating solutions, having the right material for high-temperature furnace applications is crucial. The 0Cr19Al3 FeCrAl Strip stands out as a high-performance option for industrial furnaces, offering exceptional stability, oxidation resistance, and versatility in heating applications. DLX’s approach to FeCrAl strips ensures that customers receive a product that consistently outperforms standard industry options.

For more details, pls directly contact us

0Cr19Al3 FeCrAl is an iron-chromium-aluminum alloy engineered for optimal performance at elevated temperatures. Its 19% chromium content forms a durable oxide layer that protects against oxidation and corrosion, while the 3% aluminum further reinforces this protective layer, enhancing the strip’s longevity. Iron serves as the base metal, ensuring structural integrity and consistent mechanical performance. This combination results in a strip that maintains its properties under prolonged high-temperature exposure, a crucial factor for industrial furnace applications.

|

Alloy Nomenclature Performance |

1Cr13Al4 |

0Cr25Al5 |

0Cr21Al4 |

0Cr21Al6Nb |

0Cr27Al7Mo2 |

|||

|

Chemical Compostion (%) |

Cr |

12.0-15.0 |

23.0-26.0 |

19.0-22.0 |

20.5-23.5 |

18.0-21.0 |

21.0-23.0 |

26.5-27.8 |

|

Al |

4.0-6.0 |

4.5-6.5 |

5.0-7.0 |

4.2-5.3 |

3.0-4.2 |

5.0-7.0 |

6.0-7.0 |

|

|

Re |

Opportune |

Opportune |

Opportune |

Opportune |

Opportune |

Opportune |

Opportune |

|

|

Fe |

Rest |

Rest |

Rest |

Rest |

Rest |

Rest |

Rest |

|

|

-- |

-- |

-- |

-- |

-- |

-- |

-- |

||

|

Max.Continuous service temp. of element |

950 |

1250 |

1250 |

1250 |

1100 |

1350 |

1400 |

|

|

Resistivity at 20C(μΩ.m) |

1.25 |

1.42 |

1.42 |

1.35 |

1.23 |

1.45 |

1.53 |

|

|

Density(g/cm) |

7.4 |

7.1 |

7.16 |

7.25 |

7.35 |

7.1 |

7.1 |

|

|

Thermal Conductivity(KJ/m.h) |

52.7 |

46.1 |

63.2 |

60.2 |

46.9 |

46.1 |

-- |

|

|

Coefficient of lines expansion(αx10-6/℃) |

15.4 |

16 |

14.7 |

15 |

13.5 |

16 |

16 |

|

|

Melting Point Approx(degree) |

1450 |

1500 |

1500 |

1500 |

1500 |

1510 |

1520 |

|

|

Tensile Strength(N/mm) |

580-680 |

630-780 |

630-780 |

630-780 |

600-700 |

650-800 |

680-830 |

|

|

Elongation at rupture(%) |

>16 |

>12 |

>12 |

>12 |

>12 |

>12 |

>10 |

|

|

Variation of area(%) |

65-75 |

60-75 |

65-75 |

65-75 |

65-75 |

65-75 |

65-75 |

|

|

Repeat Bending frequency(F/R) |

>5 |

>5 |

>5 |

>5 |

>5 |

>5 |

>5 |

|

|

Hardness(H.B.) |

200-260 |

200-260 |

200-260 |

200-260 |

200-260 |

200-260 |

200-260 |

|

|

continuous service time(Hours/ ºC) |

-- |

≥80/1300 |

≥80/1300 |

≥80/1300 |

≥80/1250 |

≥80/1350 |

≥80/1350 |

|

|

Micrographic structure |

Ferrite |

Ferrite |

Ferrite |

Ferrite |

Ferrite |

Ferrite |

Ferrite |

|

|

Magnetic properties |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

|

|

Shape |

Size (mm) |

|

Wire |

0.05-7.5 |

|

Rod |

8-50 |

|

Ribbon |

(0.05-0.35)*(0.5-6.0) |

|

Strip |

(0.5-2.5)*(5-180) |

For more details, pls directly contact us

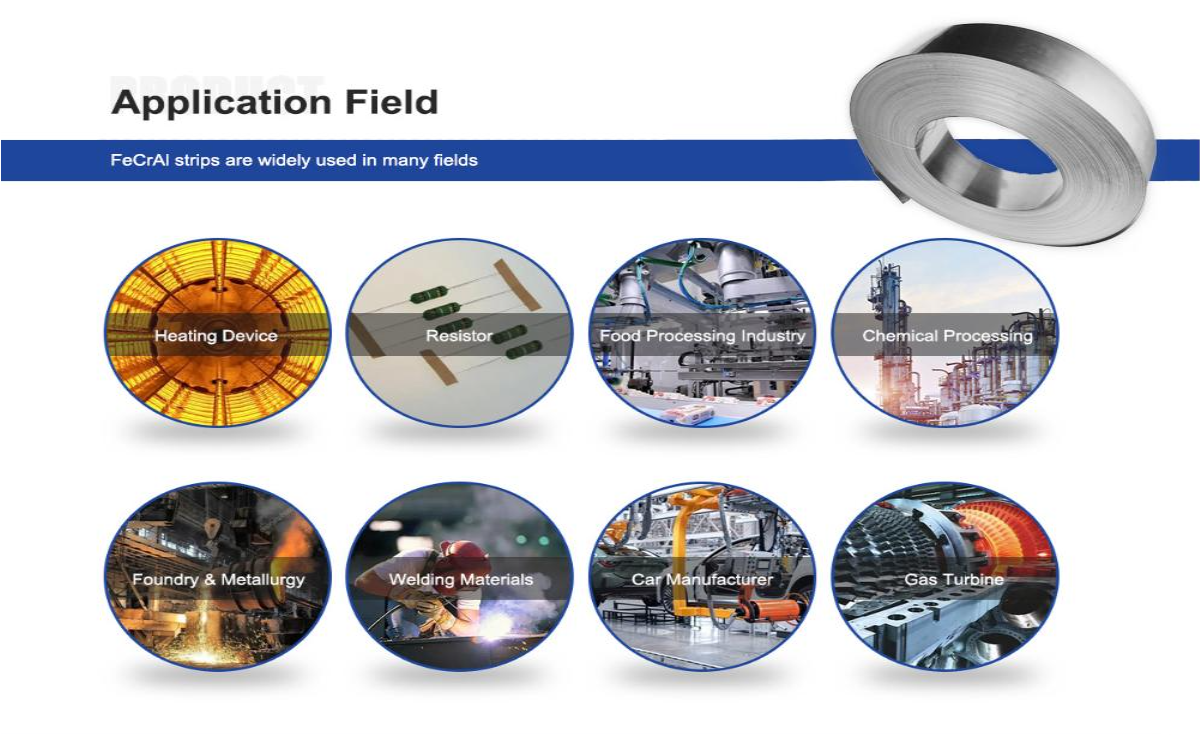

This FeCrAl strip is widely used in high-temperature furnaces, including continuous and batch processing furnaces, as well as heating systems for chemical, metallurgical, and energy industries. It can serve as heating elements, support structures, or protective layers in environments reaching up to 1250°C. The versatility of the strip means it is compatible with various furnace designs and configurations, from vertical kilns to horizontal heat treatment units.

One of the most significant advantages of 0Cr19Al3 FeCrAl strips is their oxidation resistance. In high-temperature operations, standard steel or less specialized alloys can degrade quickly, leading to frequent replacements and downtime. DLX FeCrAl strips maintain their structural and chemical stability over extended periods, reducing maintenance costs and improving furnace uptime. Additionally, its consistent electrical resistivity ensures stable heating performance, an essential factor for precise thermal processing in industrial operations.

DLX understands that no two industrial processes are exactly alike. The 0Cr19Al3 FeCrAl strips can be customized in width, thickness, and length to meet specific furnace requirements. Whether clients need narrow precision strips for tight-fitting heating elements or broader rolls for large-scale installations, DLX offers tailored solutions. Surface finishing is another area of focus, with smooth, uniform finishes reducing the risk of scale formation and improving overall heat transfer efficiency.

Parameter Comparison Table:

| Property | 0Cr19Al3 FeCrAl Strip | Industry Average | Notes |

|---|---|---|---|

| Chromium (Cr) | 19% | 18-20% | Enhances oxidation resistance |

| Aluminum (Al) | 3% | 2.5-3.5% | Provides protective oxide layer |

| Iron (Fe) | Balance | Balance | Core structural element |

| Maximum Operating Temp | 1250°C | 1200°C | Higher stability at extreme heat |

| Electrical Resistivity | 1.2 Ω·mm²/m | 1.1-1.3 Ω·mm²/m | Ensures consistent heating |

| Oxidation Resistance | Excellent | Good | Superior for long-term performance |

| Form Availability | Strips, sheets, rolls | Strips & sheets | DLX offers wider variety |

| Surface Finish | Smooth, uniform | Varies | Reduces scale formation |

As industrial furnaces evolve, there is an increasing demand for materials that combine high-temperature resistance with longer service life. Industries are moving towards energy-efficient solutions that minimize downtime and reduce maintenance costs. The 0Cr19Al3 FeCrAl strip aligns perfectly with these trends, offering superior performance that supports higher furnace operating efficiency. Environmental concerns also play a role: by reducing the need for frequent replacements, these strips contribute to lower material consumption and waste, fitting modern sustainability goals.

DLX Company Advantages

DLX’s FeCrAl strips stand out in the market for several reasons:

-

Strict Quality Control: Each batch undergoes rigorous testing for chemical composition, dimensional accuracy, and surface quality.

-

Consistent Performance: The combination of alloy composition and precise manufacturing ensures long-term oxidation resistance and mechanical stability.

-

Flexible Supply: DLX provides multiple forms, including rolls, sheets, and precision-cut strips, catering to a wide range of industrial applications.

-

Tailored Solutions: Customers can request specific dimensions, tolerances, and surface finishes to meet their exact requirements.

-

Technical Support: DLX offers guidance on installation, optimal operating conditions, and maintenance to maximize the strip’s performance.

Comparison with Standard Options

While other FeCrAl strips may offer similar nominal chemical compositions, DLX strips differentiate themselves through uniformity, stability, and quality assurance. Many suppliers face variability in surface finish and electrical resistivity, which can lead to uneven heating or premature oxidation. DLX’s strict manufacturing protocols and focus on precision ensure that each strip delivers predictable performance in demanding furnace environments.

In a high-temperature processing plant, DLX 0Cr19Al3 FeCrAl strips were implemented as heating elements in a continuous furnace operating at 1200°C. Over six months, the strips maintained uniform performance without any visible scaling or oxidation issues. This resulted in a significant reduction in downtime compared to previous elements, illustrating the real-world benefits of choosing high-quality FeCrAl materials.

For industries that require stable, reliable, and high-performance heating solutions, the 0Cr19Al3 FeCrAl strip from DLX provides an optimal choice. Its combination of material properties, durability, and customization options ensures that industrial furnaces operate efficiently and safely, even under the most demanding conditions. By choosing DLX, customers benefit from a product that is engineered to meet modern industry demands, offering both economic and operational advantages.

With the growing emphasis on energy efficiency, longevity, and maintenance reduction, investing in high-quality FeCrAl strips is no longer optional—it’s a necessity. DLX’s 0Cr19Al3 strips deliver on all fronts, making them a trusted solution for high-temperature furnace performance.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs