When it comes to extreme-temperature industrial environments, only the most advanced materials can deliver the reliability, durability, and cost-efficiency that industries demand. One such material is the 0Cr27Al7Mo2 FeCrAl strip, a specialized resistance alloy designed to withstand some of the toughest operational conditions. At DLX, we have developed a strong reputation for producing FeCrAl strips that meet and exceed the requirements of global industries, ensuring stability and long-term performance where it matters most.

For more details, pls directly contact us

The 0Cr27Al7Mo2 FeCrAl strip is a high-resistance alloy composed primarily of iron, chromium, aluminum, and molybdenum. The chromium content provides structural strength, the aluminum ensures oxidation resistance, and the molybdenum adds extra durability against corrosion and mechanical stress at elevated temperatures. This combination makes it one of the most reliable alloys for applications requiring continuous operation at temperatures up to 1450°C.

The aluminum in the alloy forms a protective aluminum oxide (Al₂O₃) layer when exposed to heat. This dense film acts as a shield against oxidation and scaling, making the alloy strip extremely stable in high-temperature environments. The molybdenum addition further enhances performance by improving creep resistance and strengthening the alloy under thermal stress.

|

Alloy Nomenclature Performance |

0Cr25Al5 |

0Cr21Al6 |

0Cr23Al5 |

0Cr21Al4 |

0Cr27Al7Mo2 |

|||

|

Chemical Compostion (%) |

Cr |

12.0-15.0 |

23.0-26.0 |

19.0-22.0 |

20.5-23.5 |

18.0-21.0 |

21.0-23.0 |

26.5-27.8 |

|

Al |

4.0-6.0 |

4.5-6.5 |

5.0-7.0 |

4.2-5.3 |

3.0-4.2 |

5.0-7.0 |

6.0-7.0 |

|

|

Re |

Opportune |

Opportune |

Opportune |

Opportune |

Opportune |

Opportune |

Opportune |

|

|

Fe |

Rest |

Rest |

Rest |

Rest |

Rest |

Rest |

Rest |

|

|

-- |

-- |

-- |

-- |

-- |

-- |

-- |

||

|

Max.Continuous service temp. of element |

950 |

1250 |

1250 |

1250 |

1100 |

1350 |

1400 |

|

|

Resistivity at 20C(μΩ.m) |

1.25 |

1.42 |

1.42 |

1.35 |

1.23 |

1.45 |

1.53 |

|

|

Density(g/cm) |

7.4 |

7.1 |

7.16 |

7.25 |

7.35 |

7.1 |

7.1 |

|

|

Thermal Conductivity(KJ/m.h) |

52.7 |

46.1 |

63.2 |

60.2 |

46.9 |

46.1 |

-- |

|

|

Coefficient of lines expansion(αx10-6/℃) |

15.4 |

16 |

14.7 |

15 |

13.5 |

16 |

16 |

|

|

Melting Point Approx(degree) |

1450 |

1500 |

1500 |

1500 |

1500 |

1510 |

1520 |

|

|

Tensile Strength(N/mm) |

580-680 |

630-780 |

630-780 |

630-780 |

600-700 |

650-800 |

680-830 |

|

|

Elongation at rupture(%) |

>16 |

>12 |

>12 |

>12 |

>12 |

>12 |

>10 |

|

|

Variation of area(%) |

65-75 |

60-75 |

65-75 |

65-75 |

65-75 |

65-75 |

65-75 |

|

|

Repeat Bending frequency(F/R) |

>5 |

>5 |

>5 |

>5 |

>5 |

>5 |

>5 |

|

|

Hardness(H.B.) |

200-260 |

200-260 |

200-260 |

200-260 |

200-260 |

200-260 |

200-260 |

|

|

continuous service time(Hours/ ºC) |

-- |

≥80/1300 |

≥80/1300 |

≥80/1300 |

≥80/1250 |

≥80/1350 |

≥80/1350 |

|

|

Micrographic structure |

Ferrite |

Ferrite |

Ferrite |

Ferrite |

Ferrite |

Ferrite |

Ferrite |

|

|

Magnetic properties |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

|

|

Shape |

Size (mm) |

|

Wire |

0.05-7.5 |

|

Rod |

8-50 |

|

Ribbon |

(0.05-0.35)*(0.5-6.0) |

|

Strip |

(0.5-2.5)*(5-180) |

For more details, pls directly contact us

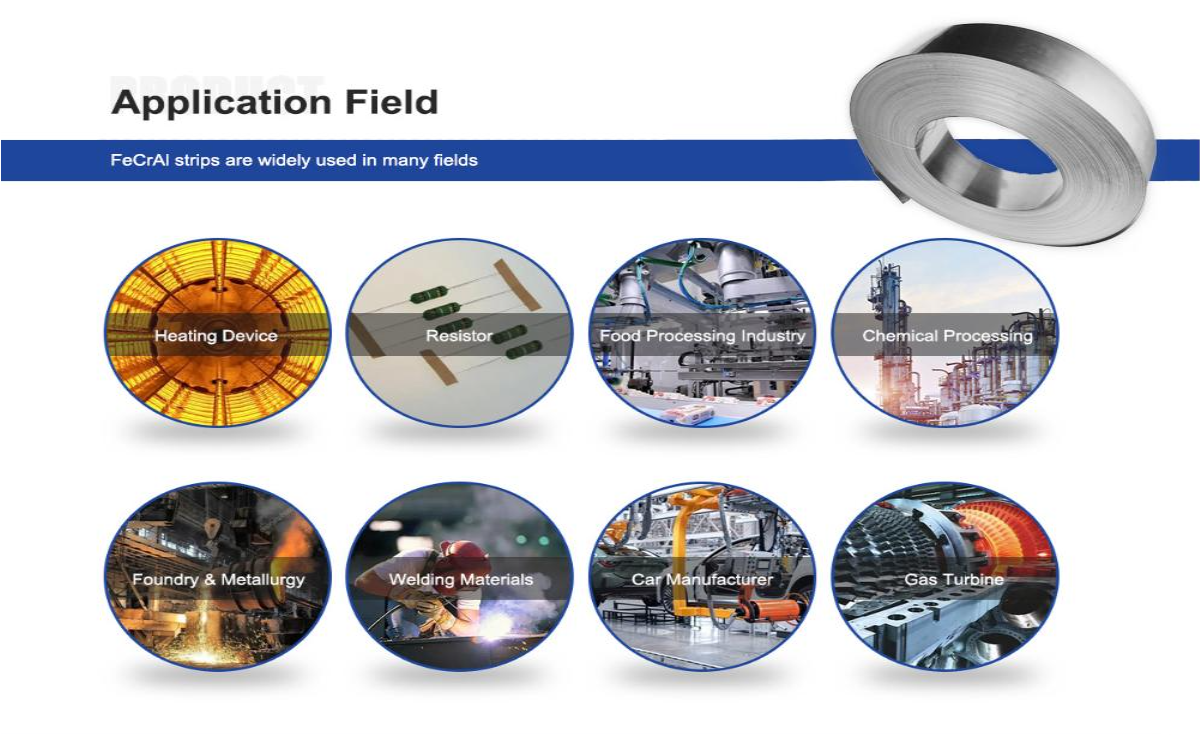

The 0Cr27Al7Mo2 FeCrAl strip is widely used in industries where extreme heat and reliability are essential. In glass manufacturing, it supports furnace systems that operate at temperatures close to the upper threshold of industrial processing. In ceramics, it plays a key role in kilns that require consistent thermal stability. The petrochemical industry also relies on this material for heating and processing equipment that must endure harsh chemical and thermal conditions. Beyond these heavy industries, the strip is also applied in precision electrical heating equipment, where stability and long service life are critical.

Global industries are increasingly demanding materials that can perform longer, reduce downtime, and minimize maintenance costs. With energy costs rising and sustainability becoming a priority, companies are seeking heating elements and furnace components that can extend service life and enhance efficiency. The 0Cr27Al7Mo2 FeCrAl strip fits perfectly into this trend, offering extreme heat resistance, reduced oxidation, and consistent performance even in the most demanding environments.

The trend toward electrification in manufacturing and energy systems is another driver for advanced alloys. As more industries transition toward electric heating and greener technologies, materials like FeCrAl are expected to play a larger role. Their long operational lifespan reduces replacement frequency, supporting sustainable production practices.

Comparative Parameters Table

| Parameter | 0Cr27Al7Mo2 FeCrAl Strip | 0Cr25Al5 FeCrAl Bar |

|---|---|---|

| Main Composition | Fe, 27% Cr, 7% Al, 2% Mo | Fe, 25% Cr, 5% Al |

| Max Continuous Temp (°C) | 1400–1450 | 1350–1400 |

| Oxidation Resistance | Excellent (strong Al₂O₃ + Mo) | Excellent (Al₂O₃ film) |

| Mechanical Strength | Higher with Mo | Moderate |

| Service Life | Longer in harsh conditions | Long under normal conditions |

| Cost Efficiency | High for extreme use | High for general use |

| Applications | Extreme furnaces, glass, petrochemicals | Heating elements, furnaces, appliances |

| Customization Options | Wide | Wide |

DLX Company Strengths

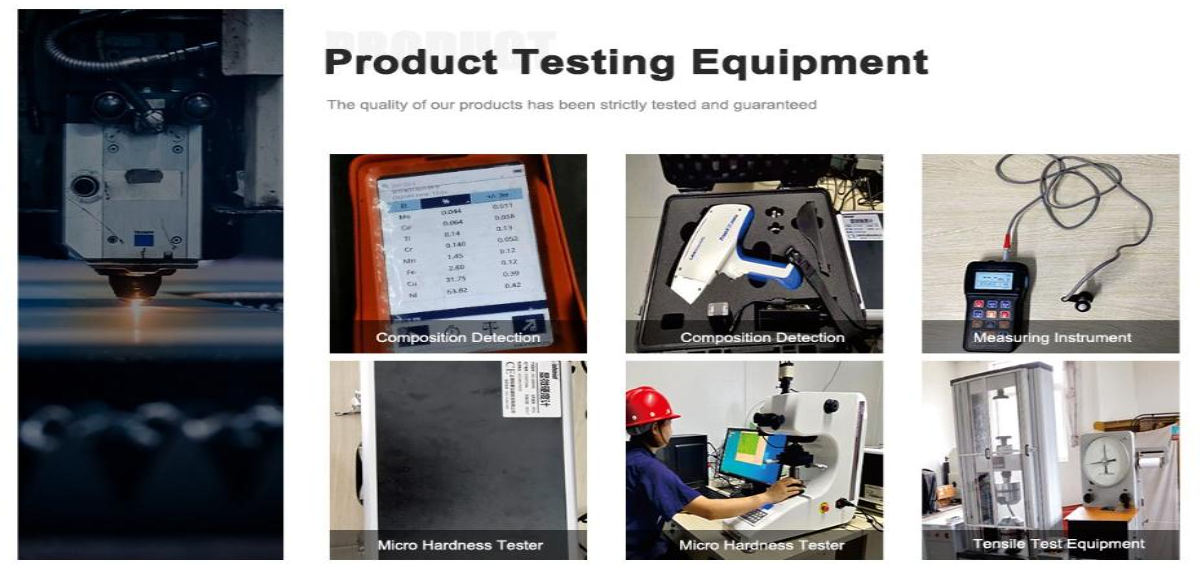

At DLX, we don’t just manufacture alloy strips—we provide solutions tailored to the real-world challenges of industrial operations. Our expertise lies in producing FeCrAl strips that are consistent in quality and performance. By controlling the chemical composition with precision and employing advanced smelting and rolling technologies, we ensure that every strip meets strict performance standards.

Our production process guarantees uniform thickness, stable resistance values, and a clean surface finish. These qualities are critical in industrial applications where even minor variations can lead to performance issues. Furthermore, DLX offers customization to meet the exact needs of our customers, from specific strip dimensions to tailored mechanical properties.

Another advantage of working with DLX is our strong technical support. We partner with clients to help them choose the right material grade, optimize their heating systems, and extend the service life of their equipment. This collaborative approach allows our customers to reduce costs, improve efficiency, and maintain uninterrupted operations.

The demand for extreme-temperature materials is expected to grow as industries expand into more advanced manufacturing and processing technologies. Electric heating solutions, high-performance furnaces, and environmentally responsible production methods will all rely on materials that can endure higher stresses and longer operational cycles. The 0Cr27Al7Mo2 FeCrAl strip is well-positioned to meet these needs, and DLX is committed to being at the forefront of this evolution.

With continuous investments in research, production capabilities, and quality systems, DLX is ready to support global industries with the most advanced FeCrAl solutions. Our focus remains on delivering value through reliable products, competitive pricing, and responsive customer service.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

-

What is 0Cr27Al7Mo2 FeCrAl strip?

It is a high-resistance iron-chromium-aluminum alloy strip with added molybdenum for extreme-temperature stability. -

What is the maximum service temperature of 0Cr27Al7Mo2 FeCrAl strip?

It can operate continuously up to 1400–1450°C. -

What industries commonly use this alloy strip?

It is widely applied in industrial furnaces, ceramics, glass production, petrochemical processing, and electrical heating equipment. -

How does the addition of molybdenum improve performance?

Molybdenum enhances corrosion resistance and improves mechanical strength at high temperatures. -

How does this strip resist oxidation?

The high aluminum content forms a dense Al₂O₃ protective layer, ensuring long-term oxidation resistance. -

Can 0Cr27Al7Mo2 FeCrAl strip be customized?

Yes, it can be produced in different thicknesses, widths, and finishes based on application needs. -

How does DLX maintain product quality?

By using advanced smelting, precise alloy composition control, and strict testing for thermal and mechanical properties. -

Why choose DLX as a supplier for FeCrAl strips?

Because DLX ensures stable quality, fast delivery, competitive pricing, and technical support tailored to extreme-temperature industries.