The automotive industry is under constant pressure to improve efficiency, reduce emissions, and enhance durability. Materials used in exhaust systems play a key role in achieving these goals. One of the most reliable solutions is the 0Cr15Al5 FeCrAl Strip , a high-resistivity alloy designed to perform under the harsh thermal and chemical conditions of modern automotive exhaust systems. At DLX, we specialize in producing FeCrAl strips that combine technical reliability with cost efficiency, making them a top choice for global automotive manufacturers.

For more details, pls directly contact us

The 0Cr15Al5 FeCrAl strip is composed of iron, chromium, and aluminum. With 15% chromium and 5% aluminum, the alloy achieves a balance between resistivity, oxidation resistance, and cost. The aluminum ensures that, under high temperatures, a dense aluminum oxide (Al₂O₃) protective film forms on the surface. This layer prevents scaling and oxidation, even during rapid heating and cooling cycles that are typical in exhaust systems.

In addition to its oxidation resistance, the high resistivity of 0Cr15Al5 makes it suitable for electrical heating applications within the automotive sector. This combination of electrical and thermal stability makes it a versatile alloy strip for exhaust gas treatment and other high-temperature automotive parts.

Alloy Nomenclature Performance | 1Cr13Al4 | 0Cr25Al5 | 0Cr23Al5 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |||

Chemical Compostion (%) | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

Re | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | |

Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

-- | -- | -- | -- | -- | -- | -- | ||

Max.Continuous service temp. of element | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

Resistivity at 20C(μΩ.m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

Density(g/cm) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

Thermal Conductivity(KJ/m.h) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | -- | |

Coefficient of lines expansion(αx10-6/℃) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

Melting Point Approx(degree) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

Tensile Strength(N/mm) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

Elongation at rupture(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

Variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

Repeat Bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

Hardness(H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

continuous service time(Hours/ ºC) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥80/1350 | ≥80/1350 | |

Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Shape | Size (mm) |

Wire | 0.05-7.5 |

Rod | 8-50 |

Ribbon | (0.05-0.35)*(0.5-6.0) |

Strip | (0.5-2.5)*(5-180) |

For more details, pls directly contact us

Automotive exhaust systems face some of the harshest operating environments. Components are exposed to constant fluctuations in temperature, corrosive gases, and mechanical vibrations. The 0Cr15Al5 FeCrAl strip addresses these challenges with its ability to maintain structural integrity and resist oxidation.

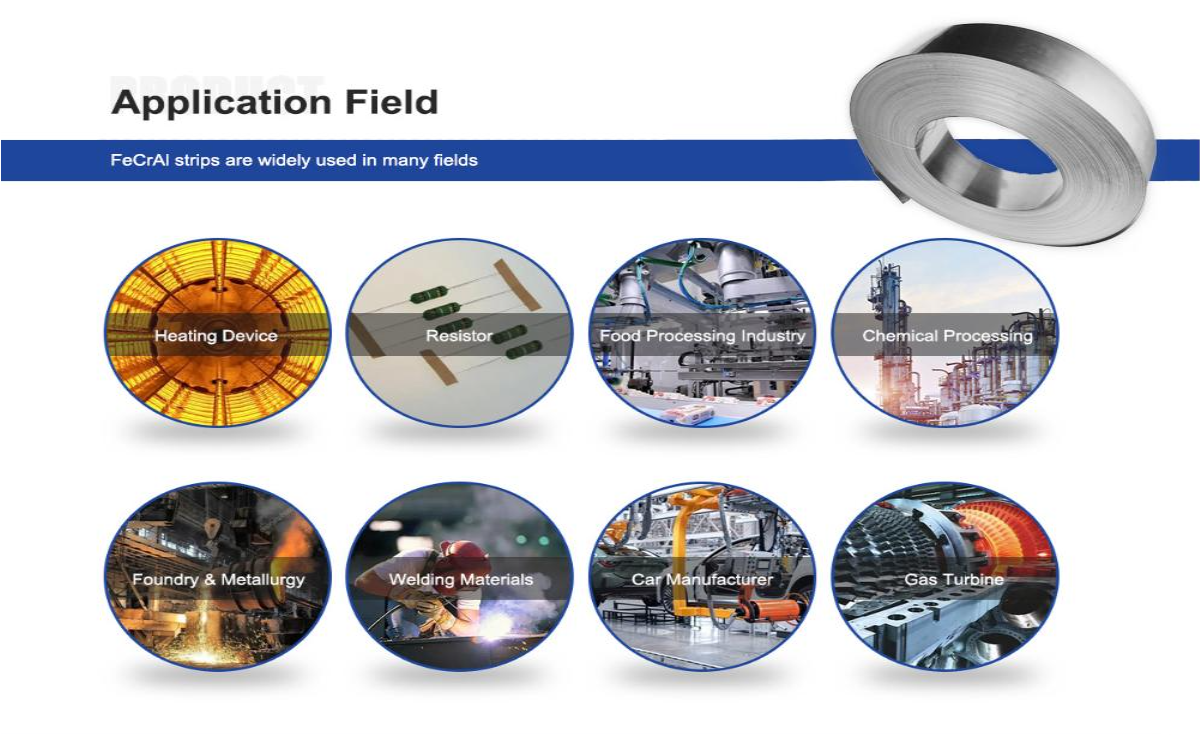

It is commonly used in:

Catalytic converter substrates, where stable heating supports emissions reduction.

Exhaust gas sensors, ensuring accurate monitoring even under thermal stress.

Diesel particulate filters, where regeneration cycles demand high-temperature stability.

Heating elements in after-treatment systems, supporting efficient emission control.

By integrating 0Cr15Al5 FeCrAl strips, automotive manufacturers can achieve longer service life, improved fuel efficiency, and compliance with increasingly strict environmental regulations.

Industry Trends

The automotive industry is rapidly evolving toward electrification and stricter emission standards. Even as electric vehicles gain popularity, internal combustion engines continue to dominate in many regions, making exhaust system optimization essential. Advanced materials like 0Cr15Al5 are key to meeting stricter regulations while maintaining performance.

There is also a clear trend toward lightweight and long-lasting materials that reduce maintenance needs. By using FeCrAl strips, manufacturers minimize downtime and replacement costs, while supporting sustainable production goals. Additionally, as hybrid vehicles combine electric and combustion systems, materials with dual advantages in resistivity and heat resistance—like 0Cr15Al5—are becoming increasingly important.

Comparative Parameters Table

| Parameter | 0Cr15Al5 FeCrAl Strip | 0Cr25Al5 FeCrAl Strip |

|---|---|---|

| Main Composition | Fe, 15% Cr, 5% Al | Fe, 25% Cr, 5% Al |

| Max Continuous Temp (°C) | 1200–1250 | 1350–1400 |

| Oxidation Resistance | Good (Al₂O₃ layer) | Excellent (higher Al₂O₃) |

| Resistivity | High | Moderate to high |

| Service Life | Long in exhaust systems | Longer in extreme furnaces |

| Cost Efficiency | High | High |

| Applications | Automotive exhaust, heaters | Furnaces, heating appliances |

| Customization Options | Wide | Wide |

When compared to nickel-chromium alloys, 0Cr15Al5 FeCrAl demonstrates better oxidation resistance at high temperatures and longer durability under thermal cycling. While nickel-chromium alloys may offer higher ductility, FeCrAl strips are superior in exhaust applications that prioritize oxidation resistance and service life. Compared to higher-grade FeCrAl alloys like 0Cr25Al5, 0Cr15Al5 offers a more cost-effective solution for applications that do not require the highest temperature resistance, making it well-suited for automotive use.

DLX Company Strengths

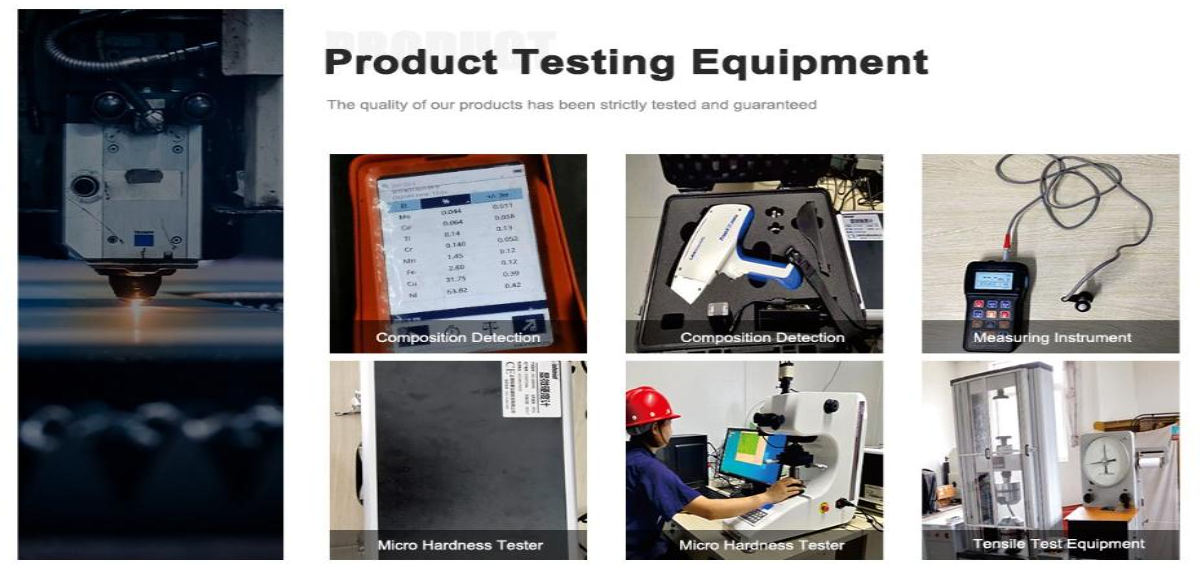

At DLX, we understand that automotive clients demand more than just materials—they require reliability, precision, and long-term partnerships. Our production process is designed to deliver FeCrAl strips with uniform thickness, stable resistance values, and excellent surface finish. Every batch is carefully monitored, from alloy smelting to final rolling, ensuring consistent quality that meets strict automotive standards.

We also provide tailored customization for automotive applications. Whether it’s specific strip dimensions for exhaust sensors or unique surface treatments for catalytic converter components, DLX works closely with customers to deliver exactly what they need. This flexibility helps automotive manufacturers streamline production and reduce integration challenges.

Another core strength of DLX is our technical support. Our engineers assist clients in selecting the right alloy grade, optimizing system performance, and ensuring compliance with international emission standards. This hands-on support allows our clients to remain competitive in a rapidly changing industry.

As emission standards tighten and hybrid vehicle technologies expand, the role of FeCrAl strips in automotive exhaust systems will continue to grow. Advanced alloys like 0Cr15Al5 will play a crucial role in balancing cost, performance, and sustainability. At DLX, we are committed to supporting this growth by investing in new manufacturing technologies, improving alloy performance, and helping customers stay ahead of industry changes.

The 0Cr15Al5 FeCrAl strip offers a powerful combination of high resistivity, oxidation resistance, and cost efficiency—making it ideal for automotive exhaust systems. Its performance under extreme thermal cycling ensures long service life and supports compliance with global environmental standards. At DLX, we combine this advanced material with precision manufacturing, strict quality control, and customer-focused technical support, making us the trusted choice for automotive manufacturers worldwide.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing: