In today’s world, household appliances demand materials that not only perform consistently but also endure constant exposure to heat, moisture, and chemicals. The 1Cr13Al4 FeCrAl strip has emerged as one of the most reliable solutions for manufacturers in this space. Designed for stability, corrosion resistance, and energy efficiency, it plays a crucial role in ensuring that modern appliances meet consumer expectations for longevity and performance.

For more details, pls directly contact us

The 1Cr13Al4 FeCrAl strip is a specialized alloy composed primarily of iron, chromium, and aluminum. Its unique composition—around 13% chromium and 4% aluminum—gives it enhanced resistance against oxidation and chemical corrosion. Unlike standard stainless steels, this material is engineered for consistent heating performance, making it especially suitable for appliances that operate under frequent heating and cooling cycles.

What sets this strip apart is its balance between mechanical strength and resistivity. It doesn’t simply resist rust or degradation; it maintains electrical efficiency over time, reducing energy waste. For applications like electric stoves, water Heaters , hair dryers, and other home appliances, this strip delivers both reliability and cost savings.

Alloy Nomenclature Performance | 1Cr13Al4 | 0Cr25Al5 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | |||

Chemical Compostion (%) | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

Re | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | |

Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

-- | -- | -- | -- | -- | -- | -- | ||

Max.Continuous service temp. of element | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

Resistivity at 20C(μΩ.m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

Density(g/cm) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

Thermal Conductivity(KJ/m.h) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | -- | |

Coefficient of lines expansion(αx10-6/℃) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

Melting Point Approx(degree) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

Tensile Strength(N/mm) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

Elongation at rupture(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

Variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

Repeat Bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

Hardness(H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

continuous service time(Hours/ ºC) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥80/1350 | ≥80/1350 | |

Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Shape | Size (mm) |

Wire | 0.05-7.5 |

Rod | 8-50 |

Ribbon | (0.05-0.35)*(0.5-6.0) |

Strip | (0.5-2.5)*(5-180) |

For more details, pls directly contact us

The household appliance industry has shifted significantly over the past decade. With consumers prioritizing energy-efficient, durable, and safe products, manufacturers are under pressure to adopt materials that go beyond traditional solutions. Regulations around energy consumption and product sustainability have also driven this change, making high-performance alloys like 1Cr13Al4 FeCrAl a natural choice.

Globally, the demand for FeCrAl materials is rising due to their ability to withstand demanding operating conditions. In regions with strict energy and environmental regulations, manufacturers are increasingly turning to corrosion-resistant alloys to ensure compliance. The household appliance sector, in particular, has become a major driver for this growth, with heating elements accounting for a large share of material demand.

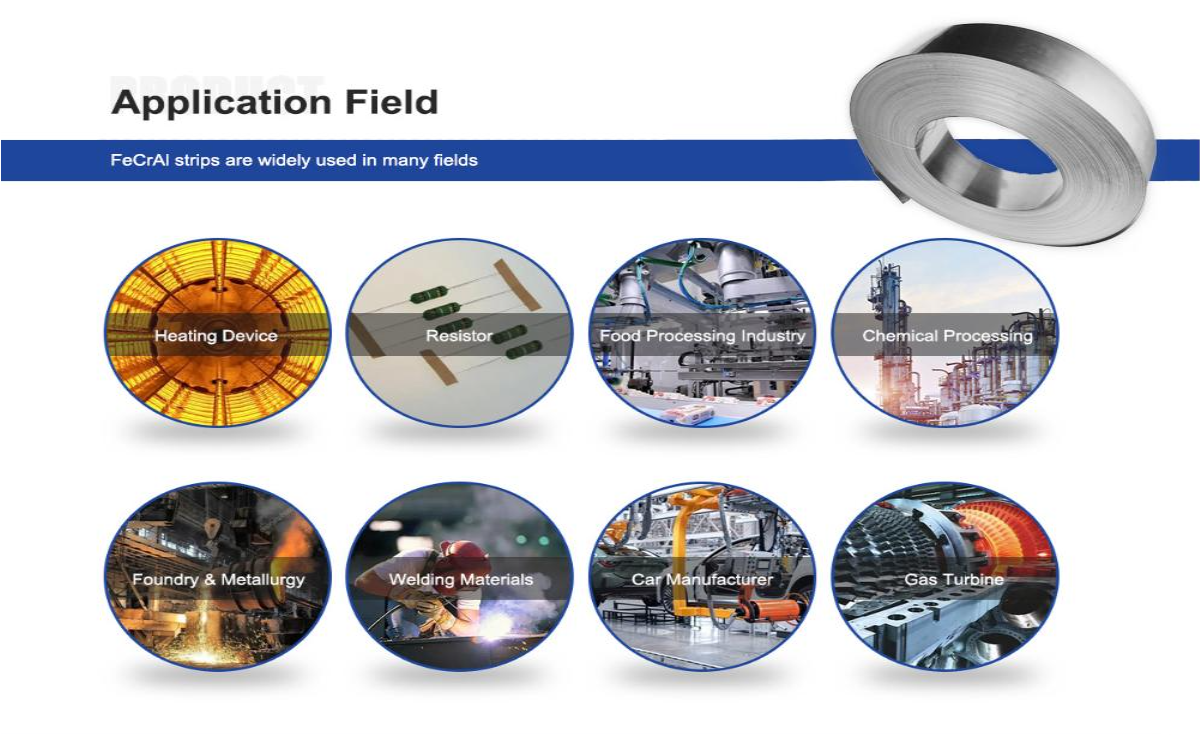

Applications

The versatility of 1Cr13Al4 FeCrAl strip lies in its ability to serve multiple applications within household appliances:

Electric Water Heaters: Ensures long-term performance even in contact with water and minerals.

Electric Stoves and Ovens: Provides stable heating and resists repeated thermal cycling.

Toasters and Coffee Machines: Offers quick and efficient heating while maintaining durability.

Hair Dryers and Irons: Delivers controlled heating without risk of oxidation damage.

Washing Machines and Dishwashers: Handles moisture exposure and cleaning chemicals effectively.

Each of these applications benefits from the alloy’s core strengths: corrosion resistance, stable resistivity, and consistent performance under thermal stress.

Comparison Table

| Property | 1Cr13Al4 FeCrAl Strip | 0Cr19Al3 FeCrAl Bar | 0Cr25Al5 FeCrAl Bar | 0Cr27Al7Mo2 FeCrAl Strip |

|---|---|---|---|---|

| Chromium Content (%) | ~13 | ~19 | ~25 | ~27 |

| Aluminum Content (%) | ~4 | ~3 | ~5 | ~7 |

| Added Elements | None | None | None | Mo (2%) |

| Max Operating Temp (°C) | 1200 | 1250 | 1350 | 1400+ |

| Key Feature | Corrosion resistance | Stable furnace use | Long-lasting heating | Extreme high-temp stability |

| Main Application | Household appliances | Industrial furnaces | Electrical heaters | Harsh industrial systems |

Several trends are shaping the future of materials used in household appliances:

Energy Efficiency: Consumers and governments demand lower energy consumption, making high-resistivity alloys essential.

Durability and Longevity: Appliances are expected to last longer, requiring components that do not fail under stress.

Miniaturization of Components: With appliances becoming more compact, materials must deliver performance in smaller dimensions.

Sustainability: Eco-friendly designs require recyclable, long-lasting materials like FeCrAl.

Global Expansion: Emerging markets are fueling demand for affordable yet high-performance appliances, boosting alloy adoption.

These trends highlight the strategic importance of 1Cr13Al4 FeCrAl strip for appliance manufacturers seeking to stay competitive.

When selecting a supplier for FeCrAl strips, consistency and quality control are everything. Many suppliers can offer alloy products, but few can guarantee the precision, customization, and reliability required by appliance manufacturers. This is where DLX stands apart.

At DLX, we combine advanced production techniques with strict quality management. Every strip undergoes thorough inspection to ensure uniform thickness, precise resistivity, and surface quality. Unlike competitors that may compromise on tolerances, we maintain a strict focus on precision, which directly translates into better appliance performance and fewer failures in the field.

Additionally, DLX provides tailored solutions for each customer. Whether the requirement is specific strip widths for compact heating elements or large-scale supply for global production, we deliver with efficiency and flexibility. Our global logistics capabilities further ensure that customers receive their materials on time, minimizing supply chain disruptions.

Why DLX?

The real advantage of choosing DLX for 1Cr13Al4 FeCrAl strip lies in our commitment to long-term partnerships. We don’t just supply materials; we provide solutions that improve product performance and reduce total costs for manufacturers. By investing in state-of-the-art production equipment and continuously refining our processes, we ensure that our materials meet the evolving demands of the household appliance industry.

For customers, this means fewer concerns about product recalls, energy inefficiencies, or premature failures. Instead, it means appliances that last longer, operate safely, and deliver real value to end users.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What is the primary advantage of 1Cr13Al4 FeCrAl strip in appliance applications?

It offers excellent corrosion resistance and durability under frequent heating cycles.Can this strip handle direct contact with moisture and cleaning agents?

Yes, it resists corrosion and maintains performance in humid and chemically exposed environments.What temperature range can 1Cr13Al4 FeCrAl strip withstand?

It typically works reliably up to 1200°C depending on the application.Is it suitable for long-term use in household appliances?

Yes, it provides a stable and long-lasting heating performance.How does its resistivity compare to other FeCrAl grades?

It has a balanced resistivity level suitable for energy-efficient heating.Can this strip be customized for different thicknesses and widths?

Yes, customization is available to meet appliance design requirements.Does it improve the energy efficiency of appliances?

Yes, it minimizes energy loss while maintaining effective heating.Why choose DLX for 1Cr13Al4 FeCrAl strip supply?

DLX ensures consistent quality, precision processing, and reliable global delivery.