When it comes to advanced heat treatment furnaces, having a reliable and high-performance heating element is crucial. The 0Cr21Al6Nb FeCrAl Wire offers unmatched performance, durability, and efficiency for industrial heating applications. DLX focuses on delivering wires that are engineered for both extreme temperatures and long-term operational stability, giving clients a competitive edge in thermal processing.

For more details, pls directly contact us

The 0Cr21Al6Nb FeCrAl Wire is a specialized alloy composed of iron, chromium, aluminum, and niobium. The 21% chromium content provides excellent oxidation resistance, forming a protective oxide layer that prevents degradation in high-temperature environments. The 6% aluminum content strengthens this layer, ensuring long-term durability. Niobium adds creep resistance and enhances stability under continuous thermal stress. Iron serves as the base metal, providing mechanical strength and structural integrity. This combination ensures that the wire performs reliably under high-temperature operations while maintaining uniform electrical and thermal properties.

Alloy Nomenclature Performance | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | ||

Chemical Compostion (%) | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

Re | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | |

Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

-- | -- | -- | -- | -- | -- | -- | ||

Max.Continuous service temp. of element | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

Resistivity at 20C(μΩ.m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

Density(g/cm) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

Thermal Conductivity(KJ/m.h) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | -- | |

Coefficient of lines expansion(αx10-6/℃) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

Melting Point Approx(degree) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

Tensile Strength(N/mm) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

Elongation at rupture(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

Variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

Repeat Bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

Hardness(H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

continuous service time(Hours/ ºC) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥80/1350 | ≥80/1350 | |

Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Shape | Size (mm) |

Wire | 0.05-7.5 |

Rod | 8-50 |

Ribbon | (0.05-0.35)*(0.5-6.0) |

Strip | (0.5-2.5)*(5-180) |

For more details, pls directly contact us

This FeCrAl wire is ideal for advanced heat treatment furnaces used in metal processing, aerospace components, automotive parts, and chemical processing. Its high-temperature stability, up to 1400°C, makes it suitable for both continuous and intermittent heating applications. The wire can be used as primary heating elements, coiled supports, or protective layers inside high-temperature furnaces, ensuring even heat distribution and consistent performance throughout thermal processes.

Parameter Comparison Table:

| Property | 0Cr21Al6Nb FeCrAl Wire | Industry Average | Notes |

|---|---|---|---|

| Chromium (Cr) | 21% | 20-22% | Enhances oxidation resistance |

| Aluminum (Al) | 6% | 5-6% | Forms strong protective oxide layer |

| Niobium (Nb) | 0.5-1% | 0.3-0.8% | Improves creep resistance and stability |

| Iron (Fe) | Balance | Balance | Core structural element |

| Maximum Operating Temp | 1400°C | 1350°C | Superior high-temp stability |

| Electrical Resistivity | 1.5 Ω·mm²/m | 1.4-1.6 Ω·mm²/m | Ensures even heating |

| Oxidation Resistance | Excellent | Good | Longer service life in harsh conditions |

| Form Availability | Coils, spools, custom | Coils & spools | DLX offers flexible forms |

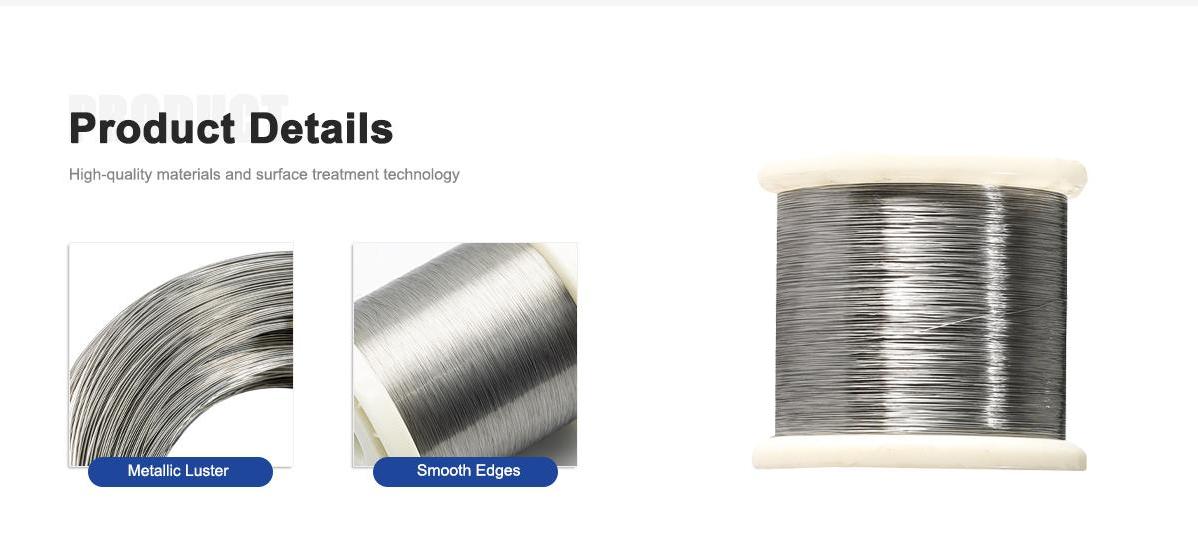

| Surface Finish | Smooth, uniform | Varies | Reduces scaling and enhances efficiency |

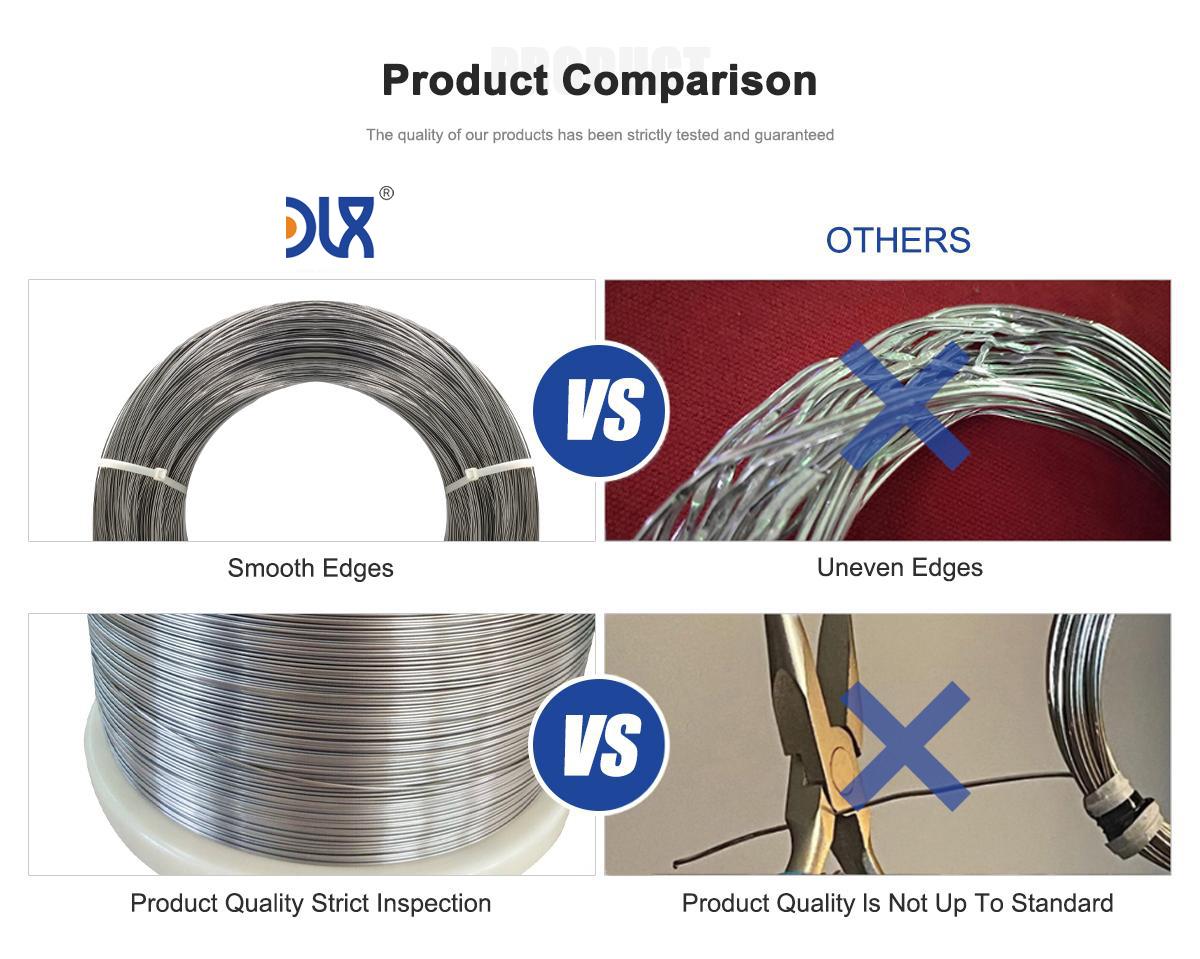

The 0Cr21Al6Nb wire excels in oxidation resistance and structural stability. Many standard wires degrade quickly at high temperatures, leading to increased maintenance and operational interruptions. DLX’s wire maintains its integrity over long-term use, reducing downtime and lowering replacement costs. Its controlled electrical resistivity guarantees even heating, critical for precise heat treatment operations where consistent temperature profiles are essential.

Durability and Long-Term Benefits

The inclusion of niobium enhances creep resistance, allowing the wire to maintain its shape and performance even under prolonged thermal cycling. This durability extends the service life of the heating elements, providing cost savings over time. The smooth, uniform surface finish minimizes scaling and facilitates better heat transfer, further improving the efficiency and longevity of the furnace. DLX’s strict manufacturing standards ensure each wire batch meets rigorous quality requirements, guaranteeing reliability for industrial operations.

In modern industrial heating, efficiency, precision, and longevity are key. Manufacturers are seeking materials that support high temperatures, reduce maintenance, and minimize energy consumption. Advanced FeCrAl wires, like 0Cr21Al6Nb, are increasingly favored for their ability to maintain stable performance in demanding environments. Sustainability is also driving demand for materials that reduce waste and extend service life, aligning with eco-friendly operational goals. DLX’s wire addresses these trends, providing a high-performance, durable, and environmentally conscious solution.

DLX stands out in the FeCrAl wire market through quality, precision, and service:

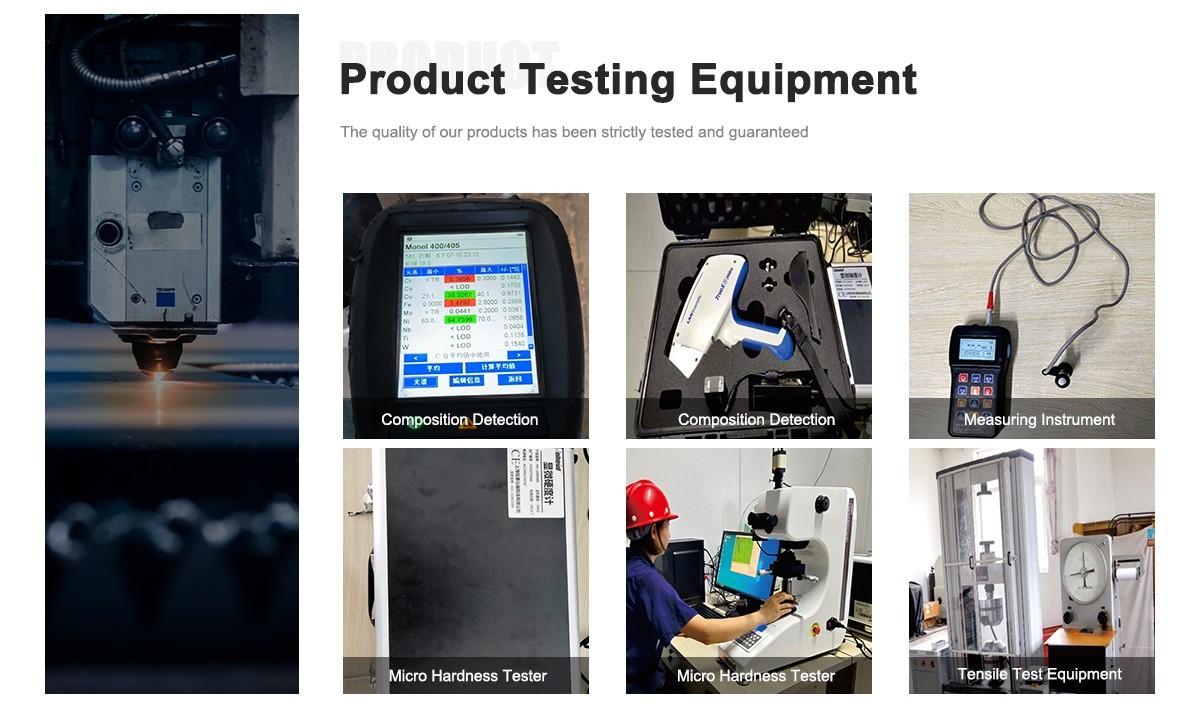

Quality Assurance: Each wire undergoes strict testing for chemical composition, diameter, and surface uniformity.

Consistent Performance: Controlled manufacturing ensures stable electrical resistivity and high oxidation resistance.

Flexible Supply: Available in coils, spools, and custom lengths to meet diverse industrial requirements.

Custom Solutions: DLX can adjust wire diameter, length, and surface finish to meet client specifications.

Technical Support: Guidance on installation, operation, and maintenance helps maximize the wire’s lifespan and efficiency.

Comparison with Standard Options

While other FeCrAl wires may have similar compositions, DLX wires excel in surface uniformity, thermal stability, and long-term reliability. Many alternative wires show variability that can lead to uneven heating, premature oxidation, or deformation. DLX’s manufacturing precision ensures predictable performance and minimizes operational risk, giving industrial operators confidence in their heating solutions.

A high-tech metal processing plant installed DLX 0Cr21Al6Nb wires as heating elements in an advanced continuous furnace operating at 1380°C. Over a year of operation, the wires demonstrated minimal scaling, maintained structural integrity, and provided consistent heating performance. This reduced maintenance frequency, lowered energy consumption, and enhanced overall operational efficiency, illustrating the practical benefits of investing in high-quality FeCrAl wires.

For industries that require advanced, high-temperature heat treatment solutions, the 0Cr21Al6Nb FeCrAl Wire from DLX is a superior choice. Its material composition, durability, and adaptability make it ideal for demanding applications in heat treatment furnaces, industrial heaters, and chemical processing equipment. By selecting DLX, clients gain reliable, long-lasting, and energy-efficient heating solutions that reduce downtime and operational costs.

The combination of chromium, aluminum, and niobium ensures high oxidation resistance, structural stability, and thermal efficiency. DLX’s precision manufacturing and strict quality controls make the 0Cr21Al6Nb wire a trusted component for advanced heat treatment furnaces, providing both performance and peace of mind for industrial operators.

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What is 0Cr21Al6Nb FeCrAl Wire made of?

Iron, chromium, aluminum, and niobium.

What applications is this wire suitable for?

Advanced heat treatment furnaces, industrial heaters, and high-temperature heating elements.

What is its maximum operating temperature?

Up to 1400°C continuous use.

How does it perform in oxidation resistance?

Excellent resistance even under prolonged high-temperature exposure.

What forms are available for this wire?

Coils, spools, and custom lengths.

Is it suitable for both continuous and intermittent heating?

Yes, designed for reliable performance in both conditions.

Can DLX customize the wire for specific industrial requirements?

Yes, diameter, length, and surface finish can be tailored.

How does this wire improve furnace efficiency?

Provides uniform heating, reduces maintenance, and extends element lifespan.