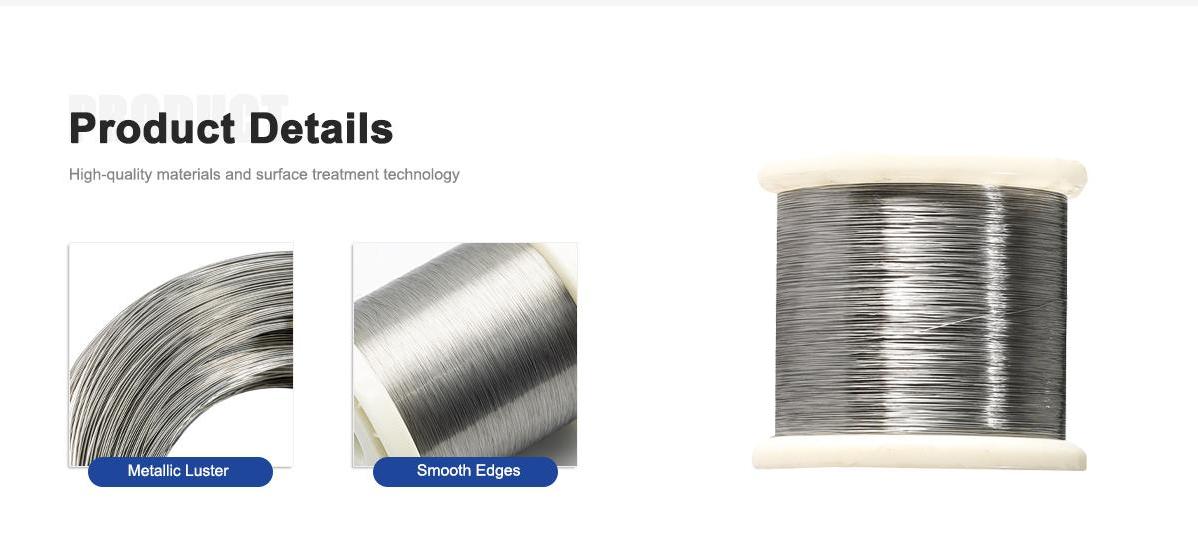

The 0Cr25Al5 high temperature resistance wire is a proven solution for industries requiring reliable performance under extreme heat. As an iron-chromium-aluminum alloy, its carefully balanced composition provides outstanding resistance to oxidation, stability in high-temperature environments, and excellent longevity compared to standard resistance materials. DLX manufactures 0Cr25Al5 wire with precision, ensuring every spool meets the highest standards for heating applications worldwide.

The alloy’s formulation—approximately 25% chromium, 5% aluminum, and the balance iron—creates a protective aluminum oxide film on the surface when exposed to heat. This oxide layer acts as a shield against scaling and environmental degradation, making the wire suitable for continuous use up to 1,300°C. This is significantly higher than the operating limits of many nickel-chromium alloys, giving it a competitive edge for demanding industries.

For more details, pls directly contact us.

In practical applications, 0Cr25Al5 wire is widely used in household appliances such as ovens, electric heaters, and hair dryers. In industrial settings, it is indispensable in high-temperature furnaces, kilns, ceramics processing, petrochemical heating, and metallurgical equipment. Its versatility and resilience make it one of the most trusted materials in both consumer and industrial heating elements.

Compared to NiCr alloys, 0Cr25Al5 offers superior oxidation resistance and cost-effectiveness. While NiCr wires provide better mechanical flexibility, they typically degrade faster when continuously exposed to very high heat. In contrast, the FeCrAl system, and specifically 0Cr25Al5, maintains stability and extends equipment lifespan, reducing replacement costs. This makes it an attractive option for large-scale industrial operations where downtime is costly.

|

Alloy Nomenclature Performance |

1Cr13Al4 |

0Cr23Al5 |

0Cr21Al6Nb |

0Cr27Al7Mo2 |

||||

|

Chemical Compostion (%) |

Cr |

12.0-15.0 |

23.0-26.0 |

19.0-22.0 |

20.5-23.5 |

18.0-21.0 |

21.0-23.0 |

26.5-27.8 |

|

Al |

4.0-6.0 |

4.5-6.5 |

5.0-7.0 |

4.2-5.3 |

3.0-4.2 |

5.0-7.0 |

6.0-7.0 |

|

|

Re |

Opportune |

Opportune |

Opportune |

Opportune |

Opportune |

Opportune |

Opportune |

|

|

Fe |

Rest |

Rest |

Rest |

Rest |

Rest |

Rest |

Rest |

|

|

-- |

-- |

-- |

-- |

-- |

-- |

-- |

||

|

Max.Continuous service temp. of element |

950 |

1250 |

1250 |

1250 |

1100 |

1350 |

1400 |

|

|

Resistivity at 20C(μΩ.m) |

1.25 |

1.42 |

1.42 |

1.35 |

1.23 |

1.45 |

1.53 |

|

|

Density(g/cm) |

7.4 |

7.1 |

7.16 |

7.25 |

7.35 |

7.1 |

7.1 |

|

|

Thermal Conductivity(KJ/m.h) |

52.7 |

46.1 |

63.2 |

60.2 |

46.9 |

46.1 |

-- |

|

|

Coefficient of lines expansion(αx10-6/℃) |

15.4 |

16 |

14.7 |

15 |

13.5 |

16 |

16 |

|

|

Melting Point Approx(degree) |

1450 |

1500 |

1500 |

1500 |

1500 |

1510 |

1520 |

|

|

Tensile Strength(N/mm) |

580-680 |

630-780 |

630-780 |

630-780 |

600-700 |

650-800 |

680-830 |

|

|

Elongation at rupture(%) |

>16 |

>12 |

>12 |

>12 |

>12 |

>12 |

>10 |

|

|

Variation of area(%) |

65-75 |

60-75 |

65-75 |

65-75 |

65-75 |

65-75 |

65-75 |

|

|

Repeat Bending frequency(F/R) |

>5 |

>5 |

>5 |

>5 |

>5 |

>5 |

>5 |

|

|

Hardness(H.B.) |

200-260 |

200-260 |

200-260 |

200-260 |

200-260 |

200-260 |

200-260 |

|

|

continuous service time(Hours/ ºC) |

-- |

≥80/1300 |

≥80/1300 |

≥80/1300 |

≥80/1250 |

≥80/1350 |

≥80/1350 |

|

|

Micrographic structure |

Ferrite |

Ferrite |

Ferrite |

Ferrite |

Ferrite |

Ferrite |

Ferrite |

|

|

Magnetic properties |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

|

|

Shape |

Size (mm) |

|

Wire |

0.05-7.5 |

|

Rod |

8-50 |

|

Ribbon |

(0.05-0.35)*(0.5-6.0) |

|

Strip |

(0.5-2.5)*(5-180) |

For more details, pls directly contact us.

Industry trends show a growing demand for energy-efficient and durable heating solutions. As industries shift toward higher productivity and longer service cycles, resistance wire alloys like 0Cr25Al5 are gaining recognition. Its ability to withstand extreme conditions while maintaining consistent electrical performance aligns with the requirements of modern manufacturing and processing facilities.

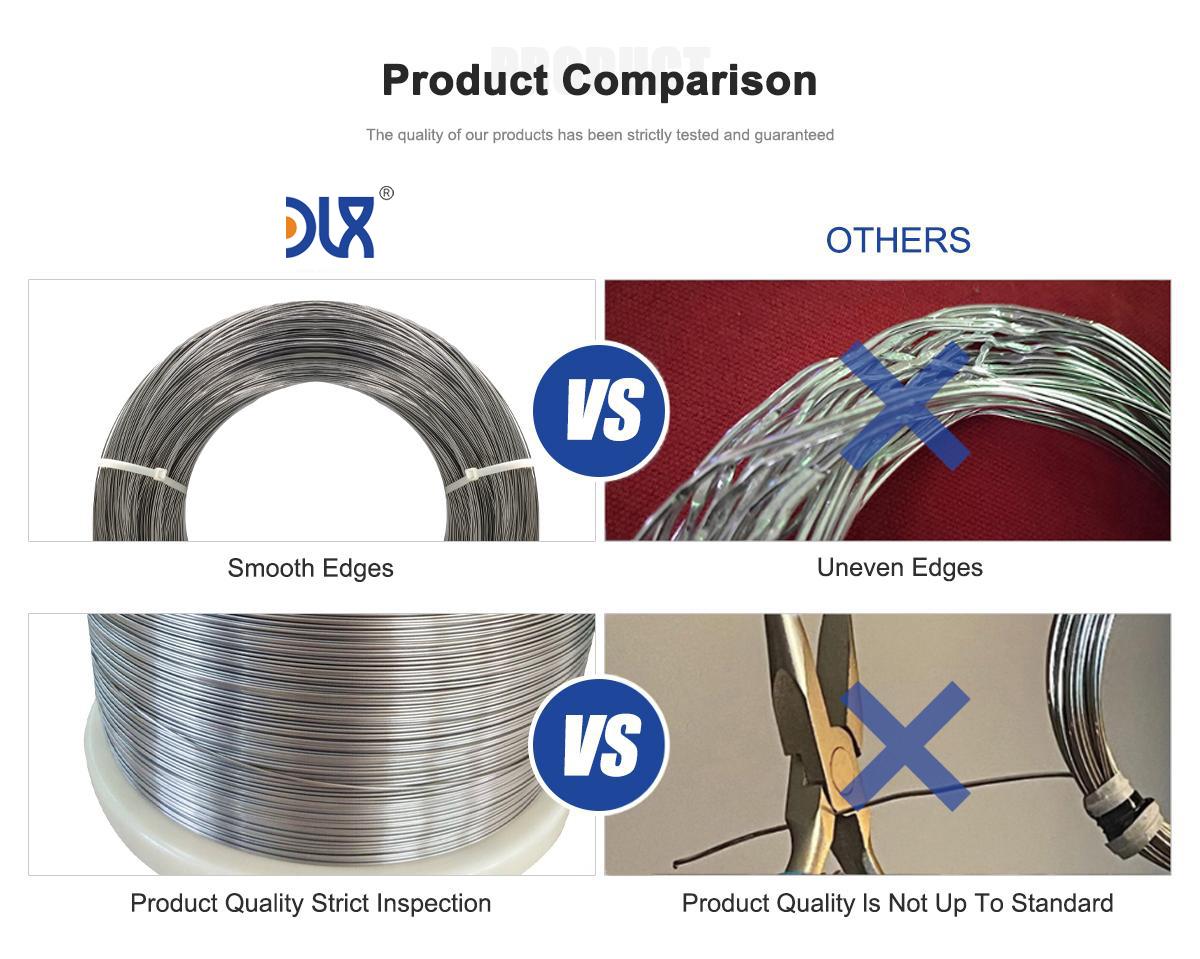

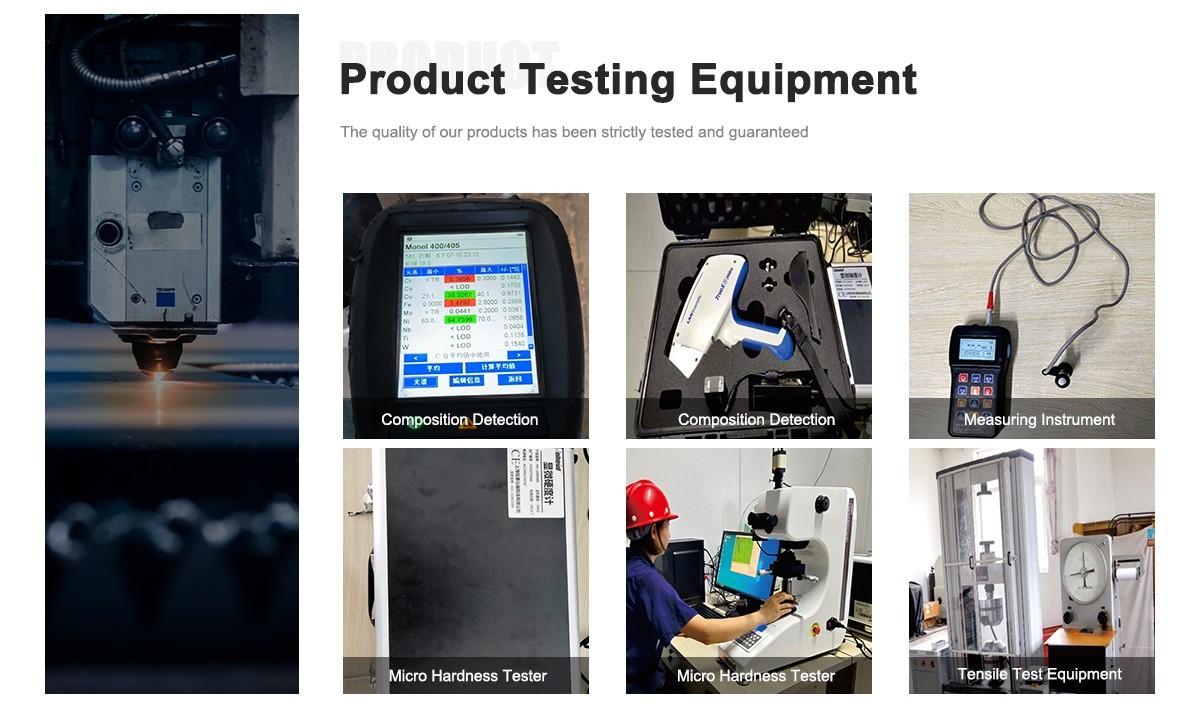

At DLX, we emphasize not just the production of 0Cr25Al5 wire, but also the added value we provide to our clients. Our production facilities utilize advanced smelting and wire drawing technologies to maintain precise control over alloy composition and microstructure. Each batch undergoes stringent quality checks, including resistivity measurement, tensile testing, and high-temperature performance validation. This ensures that the wire we deliver performs consistently across different applications.

Another advantage DLX offers is customization. Clients can request wire in a variety of diameters, spool sizes, and even pre-coiled elements for direct installation into heating systems. This flexibility helps reduce processing time for manufacturers and ensures that our wire integrates seamlessly into their production lines.

In comparison to cheaper resistance wires, 0Cr25Al5 provides significant long-term savings. Cheaper materials may initially reduce costs but often lead to early failures, increased maintenance, and unscheduled downtime. By investing in a high-performance material like 0Cr25Al5, companies secure both operational efficiency and cost stability over time.

Looking ahead, the adoption of renewable energy systems and advanced electric heating technologies will further increase the role of high-performance resistance wires. From sustainable heating in residential buildings to large-scale industrial furnaces powered by electricity, the demand for reliable, high-temperature materials will continue to rise. 0Cr25Al5, with its robust performance profile, is well positioned to meet these future demands.

| Property / Alloy | 0Cr25Al5 (FeCrAl) | NiCr 80/20 | NiCr 60/15 | Pure Iron Wire |

|---|---|---|---|---|

| Max Operating Temp (°C) | 1,300 | 1,150 | 1,050 | 500 |

| Resistivity (µΩ·m) | ~1.45 | ~1.09 | ~1.11 | ~0.10 |

| Oxidation Resistance | Excellent | Good | Good | Poor |

| Service Life at High Temp | Very Long | Long | Medium | Very Short |

| Mechanical Strength | High | Medium | Medium | Low |

| Applications | Heating coils, industrial furnaces, kilns, home appliances | Heating elements, industrial heaters | Toasters, dryers, small appliances | Low-temp resistors |

DLX stands out in this competitive market by combining high-quality production with tailored solutions. Our technical team works closely with customers to understand their requirements and provide the most effective heating wire solutions. By ensuring that every detail—from alloy consistency to delivery logistics—is optimized, we help our clients maintain efficiency, safety, and reliability in their heating systems.

To summarize, 0Cr25Al5 high temperature resistance wire represents the perfect balance of durability, oxidation resistance, and cost-effectiveness. It is a proven solution for both household and industrial heating applications, and DLX’s manufacturing expertise ensures that clients receive wire that meets the strictest performance demands. With its exceptional properties and our commitment to quality, 0Cr25Al5 continues to be the preferred choice for industries worldwide.

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

-

What is 0Cr25Al5 resistance wire?

0Cr25Al5 is an iron-chromium-aluminum alloy wire with about 25% chromium and 5% aluminum, designed for high-temperature resistance applications. -

What temperature can 0Cr25Al5 wire withstand?

It can operate continuously up to around 1,300°C, making it suitable for demanding heating environments. -

How does 0Cr25Al5 compare to nickel-chromium alloys?

While NiCr wires have higher ductility and conductivity, 0Cr25Al5 offers superior oxidation resistance and longer service life at higher temperatures. -

What industries use 0Cr25Al5 heating wire?

Industries include household appliances, metallurgy, ceramics, industrial furnaces, and chemical processing. -

Can 0Cr25Al5 wire be customized?

Yes, it can be manufactured in various diameters, spool sizes, and coil forms depending on application requirements. -

Does 0Cr25Al5 have good oxidation resistance?

Yes, its aluminum content forms a stable oxide film, protecting the wire from scaling and extending its lifespan. -

How does DLX ensure quality in 0Cr25Al5 wire production?

DLX follows strict metallurgical standards, advanced furnace control, and surface treatments to ensure uniform composition, high-temperature performance, and durability. -

Why choose 0Cr25Al5 over cheaper resistance wires?

Because it provides higher reliability, reduced maintenance, and long-term cost efficiency in high-heat applications.