0Cr27Al7Mo2 alloy resistance wire is part of the FeCrAl family, designed to deliver high-temperature stability and long service life in harsh environments. By combining iron, chromium, and aluminum with molybdenum, this wire offers outstanding resistance to oxidation, creep, and corrosion. These properties make it a reliable material for industrial and household heating applications where consistent performance is essential.

The defining feature of 0Cr27Al7Mo2 is its molybdenum addition. While traditional FeCrAl alloys like 0Cr25Al5 or 0Cr21Al6Nb are excellent in resisting oxidation, they can be less durable when exposed to aggressive atmospheres such as those containing sulfur, carbon, or other reactive elements. Molybdenum strengthens the alloy against these attacks, extending its lifespan and maintaining mechanical stability under demanding thermal cycles.

For more details, pls directly contact us.

From a technical standpoint, 0Cr27Al7Mo2 achieves a maximum continuous operating temperature of about 1,400°C. This is higher than many conventional FeCrAl or NiCr alloys. The alloy forms a dense, adherent aluminum oxide layer on its surface, which prevents further oxidation and scaling even under repeated heating and cooling. This oxide layer is particularly stable and does not flake easily, which contributes to long-term durability.

|

Alloy Nomenclature Performance |

0Cr23Al5 |

0Cr21Al4 |

0Cr21Al6Nb |

0Cr27Al7Mo2 |

||||

|

Chemical Compostion (%) |

Cr |

12.0-15.0 |

23.0-26.0 |

19.0-22.0 |

20.5-23.5 |

18.0-21.0 |

21.0-23.0 |

26.5-27.8 |

|

Al |

4.0-6.0 |

4.5-6.5 |

5.0-7.0 |

4.2-5.3 |

3.0-4.2 |

5.0-7.0 |

6.0-7.0 |

|

|

Re |

Opportune |

Opportune |

Opportune |

Opportune |

Opportune |

Opportune |

Opportune |

|

|

Fe |

Rest |

Rest |

Rest |

Rest |

Rest |

Rest |

Rest |

|

|

-- |

-- |

-- |

-- |

-- |

-- |

-- |

||

|

Max.Continuous service temp. of element |

950 |

1250 |

1250 |

1250 |

1100 |

1350 |

1400 |

|

|

Resistivity at 20C(μΩ.m) |

1.25 |

1.42 |

1.42 |

1.35 |

1.23 |

1.45 |

1.53 |

|

|

Density(g/cm) |

7.4 |

7.1 |

7.16 |

7.25 |

7.35 |

7.1 |

7.1 |

|

|

Thermal Conductivity(KJ/m.h) |

52.7 |

46.1 |

63.2 |

60.2 |

46.9 |

46.1 |

-- |

|

|

Coefficient of lines expansion(αx10-6/℃) |

15.4 |

16 |

14.7 |

15 |

13.5 |

16 |

16 |

|

|

Melting Point Approx(degree) |

1450 |

1500 |

1500 |

1500 |

1500 |

1510 |

1520 |

|

|

Tensile Strength(N/mm) |

580-680 |

630-780 |

630-780 |

630-780 |

600-700 |

650-800 |

680-830 |

|

|

Elongation at rupture(%) |

>16 |

>12 |

>12 |

>12 |

>12 |

>12 |

>10 |

|

|

Variation of area(%) |

65-75 |

60-75 |

65-75 |

65-75 |

65-75 |

65-75 |

65-75 |

|

|

Repeat Bending frequency(F/R) |

>5 |

>5 |

>5 |

>5 |

>5 |

>5 |

>5 |

|

|

Hardness(H.B.) |

200-260 |

200-260 |

200-260 |

200-260 |

200-260 |

200-260 |

200-260 |

|

|

continuous service time(Hours/ ºC) |

-- |

≥80/1300 |

≥80/1300 |

≥80/1300 |

≥80/1250 |

≥80/1350 |

≥80/1350 |

|

|

Micrographic structure |

Ferrite |

Ferrite |

Ferrite |

Ferrite |

Ferrite |

Ferrite |

Ferrite |

|

|

Magnetic properties |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

|

|

Shape |

Size (mm) |

|

Wire |

0.05-7.5 |

|

Rod |

8-50 |

|

Ribbon |

(0.05-0.35)*(0.5-6.0) |

|

Strip |

(0.5-2.5)*(5-180) |

For more details, pls directly contact us.

In terms of international recognition, 0Cr27Al7Mo2 corresponds with global equivalents in USA, Germany, France, and Russia, ensuring compatibility with international furnace and heater specifications. This makes it a versatile material for multinational manufacturers who require standardized materials across different regions.

Applications of 0Cr27Al7Mo2 cover a broad range of industries. In the petrochemical sector, it is used for heaters exposed to corrosive gases. In ceramics, it serves as a heating element in kilns operating at extreme temperatures. In metallurgy, it supports processes that require stable heat input. Household and commercial appliances also benefit from its reliability, particularly in ovens, furnaces, and heating coils that must endure long-term high-temperature service.

Compared with NiCr alloys, 0Cr27Al7Mo2 delivers higher oxidation resistance and extended life under extreme heat. While NiCr retains better ductility at lower temperatures, FeCrAl alloys like 0Cr27Al7Mo2 are more cost-effective in long-term high-temperature applications. The choice between these alloys depends on the specific needs of the application, but for most industrial furnace and petrochemical processes, 0Cr27Al7Mo2 provides superior value.

The global trend toward energy efficiency and durable heating materials has increased the demand for advanced resistance alloys. Industries are prioritizing materials that reduce downtime, extend service cycles, and provide consistent heating efficiency. 0Cr27Al7Mo2 is aligned with these trends, offering extended durability and resistance in aggressive environments.

| Property / Alloy | 0Cr27Al7Mo2 (FeCrAl-Mo) | 0Cr25Al5 (FeCrAl) | 0Cr21Al6Nb (FeCrAl-Nb) | NiCr 80/20 |

|---|---|---|---|---|

| Max Operating Temp (°C) | 1,400 | 1,300 | 1,350 | 1,150 |

| Resistivity (µΩ·m) | ~1.48 | ~1.45 | ~1.39 | ~1.09 |

| Oxidation Resistance | Excellent+ | Excellent | Excellent | Good |

| Corrosion Resistance | High (with Mo) | Medium | Medium | Medium |

| Creep Resistance | High | Medium | High | Medium |

| Service Life at High Temp | Very Long | Long | Very Long | Long |

| Main Applications | Petrochemical heaters, furnaces, kilns | Heating coils, appliances | High-stress heaters, kilns | Industrial heaters |

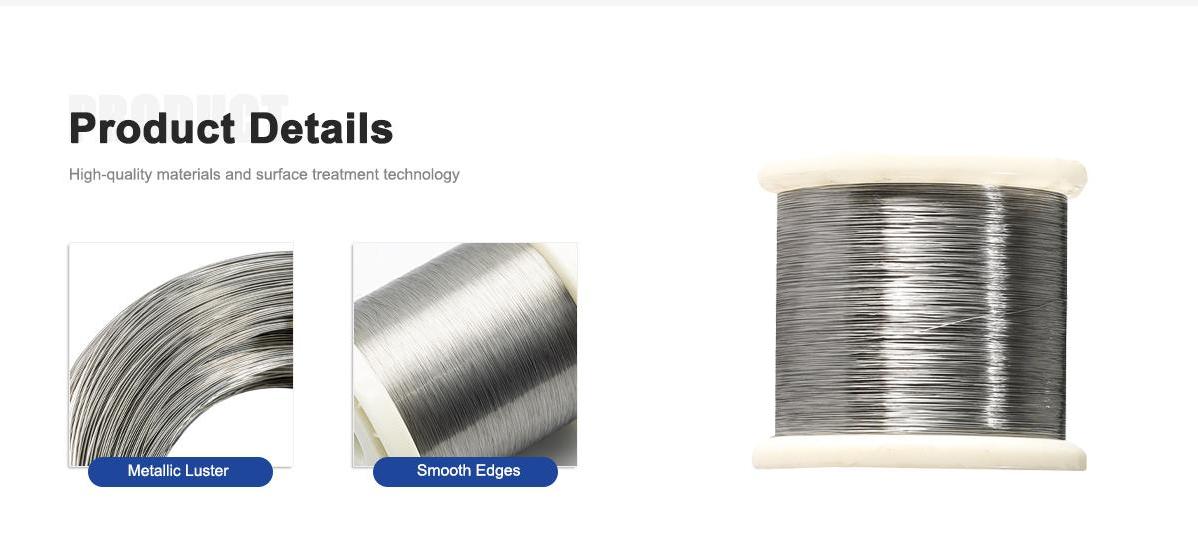

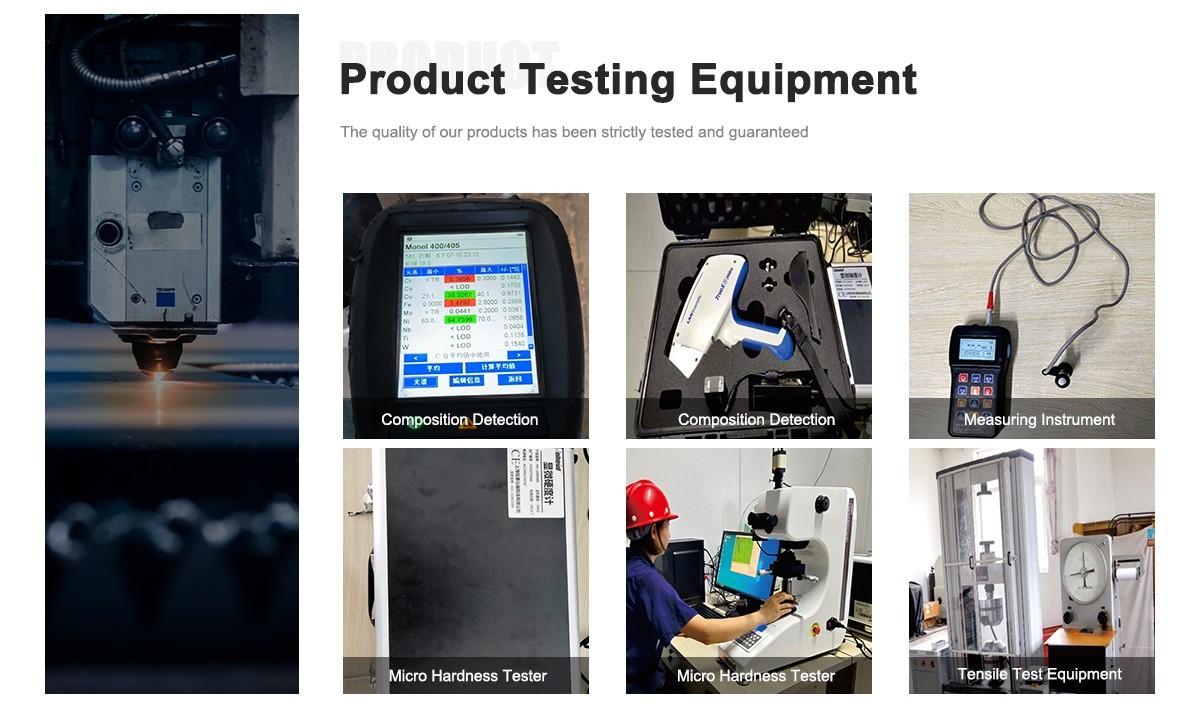

DLX plays a key role in supplying 0Cr27Al7Mo2 alloy resistance wire. Our production process emphasizes precise chemical balance, ensuring that each batch maintains the correct molybdenum, chromium, and aluminum ratios for reliable performance. By employing advanced drawing techniques, we achieve accurate diameters and uniform resistivity across wire lengths, which is critical for heating element manufacturers.

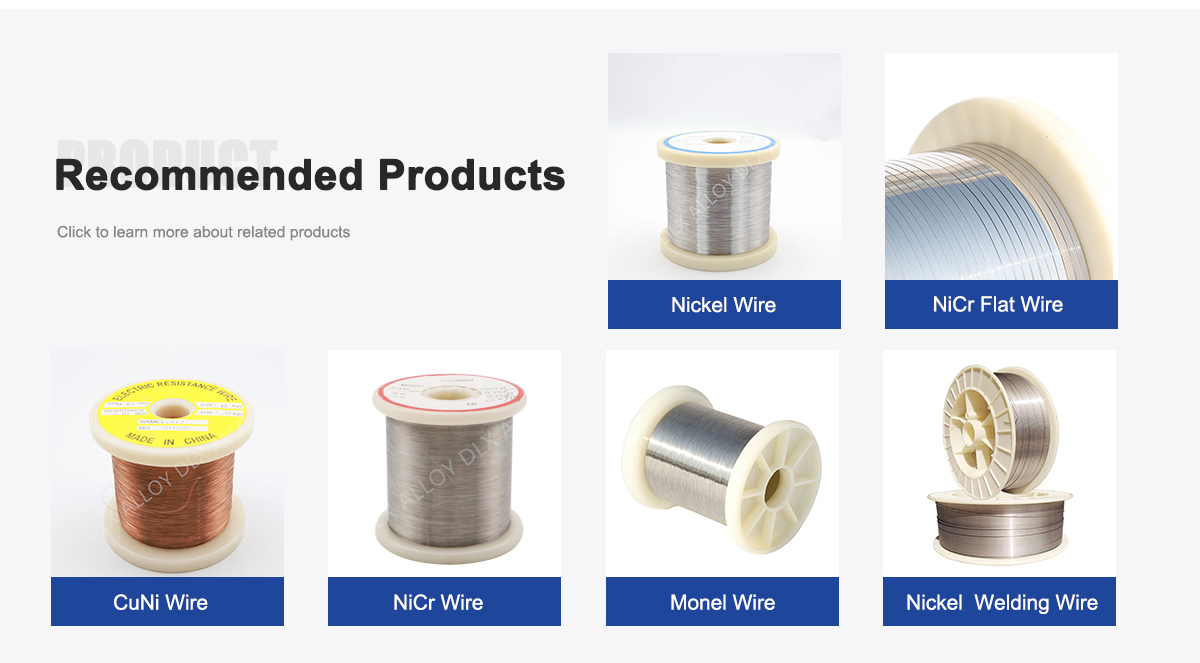

Another major advantage of working with DLX is flexibility. We offer resistance wire in a wide range of sizes and formats, from straight-cut lengths to coils and spools. This customization supports customers in various industries who have specific requirements for heating coil designs or furnace elements. Our engineering team works closely with clients to recommend the best alloy grade and wire configuration for their application.

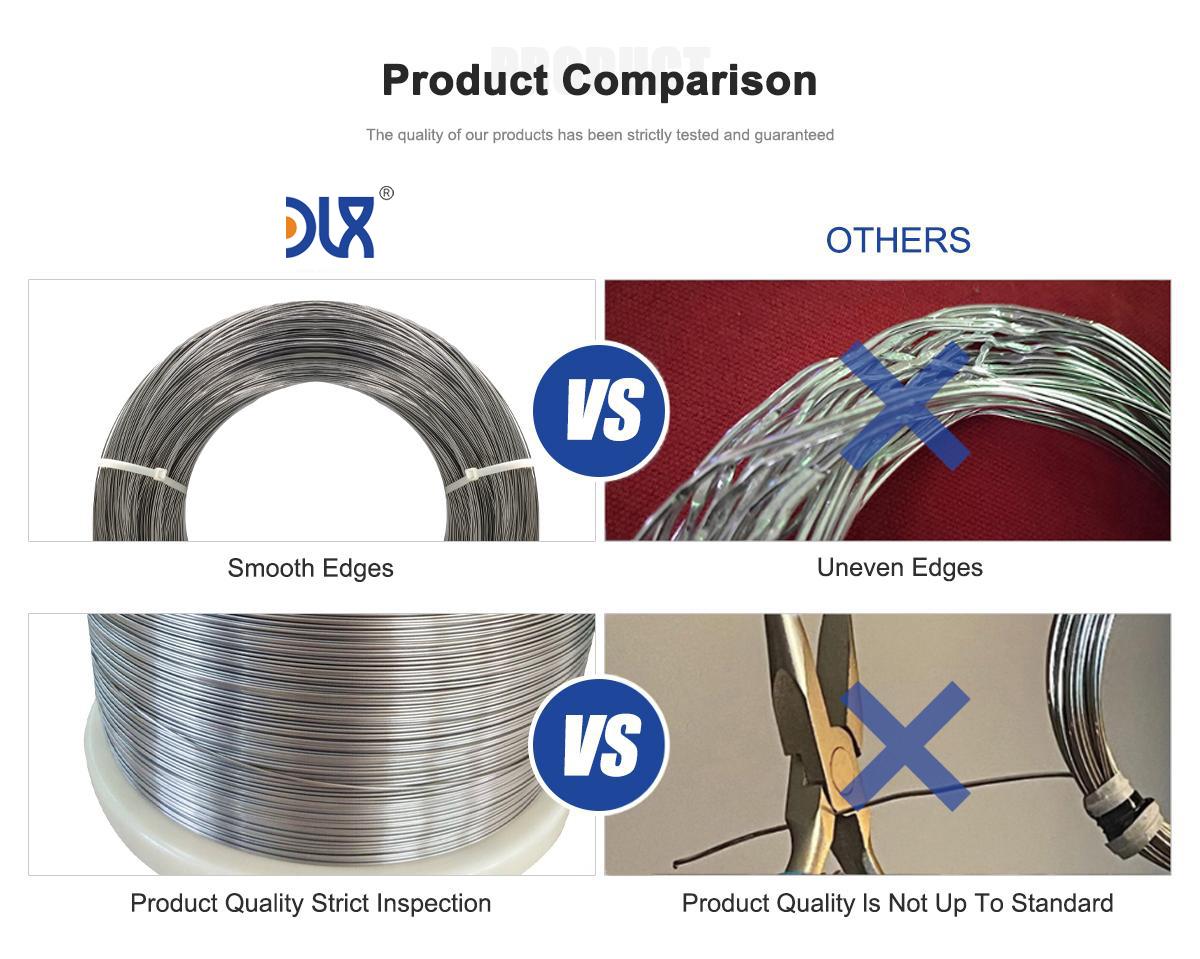

When comparing DLX’s FeCrAl-Mo wire with alternatives, the key difference lies in quality assurance and longevity. Inferior wires may suffer from premature failure, uneven resistivity, or scaling under prolonged heating cycles. In contrast, DLX wires are tested for resistivity, tensile strength, and oxidation resistance to ensure long-lasting service in the harshest conditions.

Looking forward, the adoption of 0Cr27Al7Mo2 will expand as industries shift toward advanced electric heating solutions. Its combination of heat tolerance, corrosion resistance, and compatibility with global standards makes it an essential material in the next generation of high-efficiency heating systems.

DLX is committed to remaining a leader in FeCrAl alloy supply by maintaining consistent quality, expanding production capabilities, and providing tailored solutions for both industrial and household clients. With our extensive experience and technical expertise, customers can rely on us to deliver not just materials, but solutions that improve efficiency, extend service life, and reduce operational costs.

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

-

What is 0Cr27Al7Mo2 alloy wire?

0Cr27Al7Mo2 is a high-performance FeCrAl-based resistance wire alloyed with chromium, aluminum, and molybdenum for enhanced oxidation and corrosion resistance at high temperatures. -

What makes 0Cr27Al7Mo2 different from other FeCrAl alloys?

The addition of molybdenum improves resistance to corrosive environments, especially under sulfur or carbon-rich atmospheres, making it more durable than standard FeCrAl wires. -

What is the maximum operating temperature of 0Cr27Al7Mo2?

It can be used continuously at temperatures up to 1,400°C depending on the application and atmosphere. -

What are its international grade equivalents?

Equivalent grades exist in USA, Germany, France, and Russia under their respective FeCrAl standards, making it compatible with global heating equipment requirements. -

What applications use 0Cr27Al7Mo2?

It is applied in industrial furnaces, petrochemical heating systems, kilns, electric heaters, and other high-temperature resistance heating elements. -

How does molybdenum improve the alloy’s performance?

Molybdenum increases creep resistance and helps the alloy resist attack from aggressive gases, extending service life in demanding industrial environments. -

How does 0Cr27Al7Mo2 compare with NiCr alloys?

While NiCr alloys offer ductility, 0Cr27Al7Mo2 provides higher oxidation resistance and longer life in extreme heat, making it ideal for heavy-duty heating applications. -

What advantages does DLX provide for customers?

DLX ensures consistent chemical composition, precision wire drawing, customizable coil dimensions, and reliable supply tailored to industrial and household heating requirements.