The 0Cr23Al5 alloy heating wire is a high-performance FeCrAl-based resistance material designed for demanding heating applications. With a composition rich in chromium and aluminum, this alloy delivers exceptional oxidation resistance, high electrical resistivity, and excellent stability even at extreme temperatures. For industries and manufacturers seeking a balance between durability, efficiency, and cost, 0Cr23Al5 stands out as one of the most reliable solutions available.

For more details, pls directly contact us.

From an engineering perspective, the strength of 0Cr23Al5 lies in its ability to maintain structural integrity and consistent resistance even after prolonged exposure to elevated temperatures. Its maximum operating limit of 1300°C makes it suitable for environments where other alloys may fail or degrade more quickly. This advantage has established the alloy as a preferred material in electric heating elements, industrial furnaces, and household heaters.

Alloy Nomenclature Performance | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | |||||

Chemical Compostion (%) | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

Re | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | |

Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

-- | -- | -- | -- | -- | -- | -- | ||

Max.Continuous service temp. of element | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

Resistivity at 20C(μΩ.m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

Density(g/cm) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

Thermal Conductivity(KJ/m.h) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | -- | |

Coefficient of lines expansion(αx10-6/℃) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

Melting Point Approx(degree) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

Tensile Strength(N/mm) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

Elongation at rupture(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

Variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

Repeat Bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

Hardness(H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

continuous service time(Hours/ ºC) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥80/1350 | ≥80/1350 | |

Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Shape | Size (mm) |

Wire | 0.05-7.5 |

Rod | 8-50 |

Ribbon | (0.05-0.35)*(0.5-6.0) |

Strip | (0.5-2.5)*(5-180) |

For more details, pls directly contact us.

In today’s global market, the demand for heating materials is shifting toward more energy-efficient and durable alloys. As energy costs continue to rise, manufacturers and end users are searching for heating wires that extend service life, minimize replacement costs, and enhance performance. This is where 0Cr23Al5 provides clear value. Its higher aluminum content forms a dense, protective oxide layer on the surface, significantly improving resistance to scaling and corrosion, which is a critical factor in long-term operation.

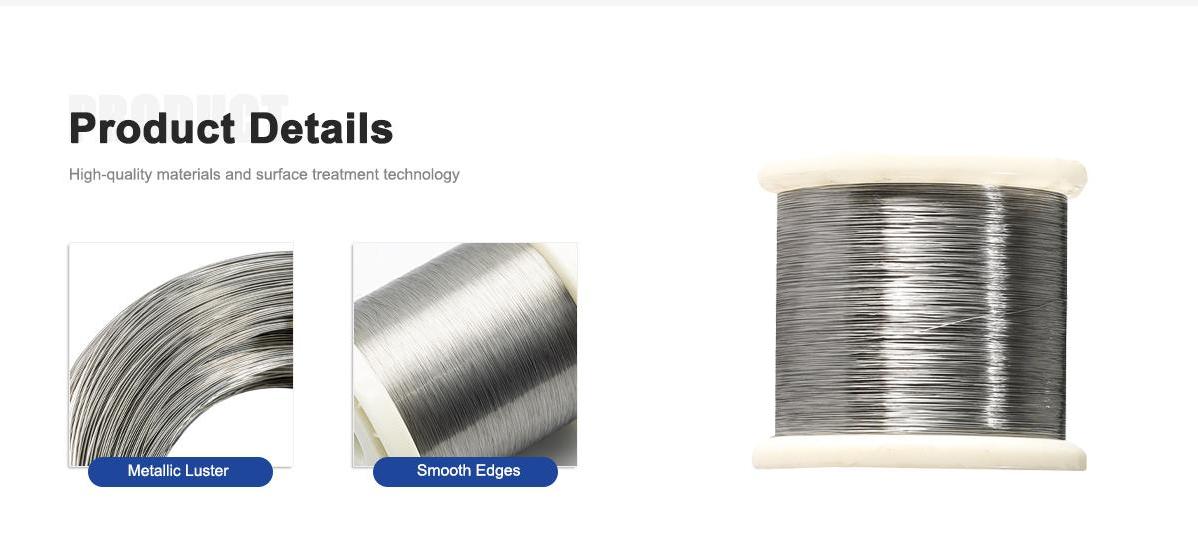

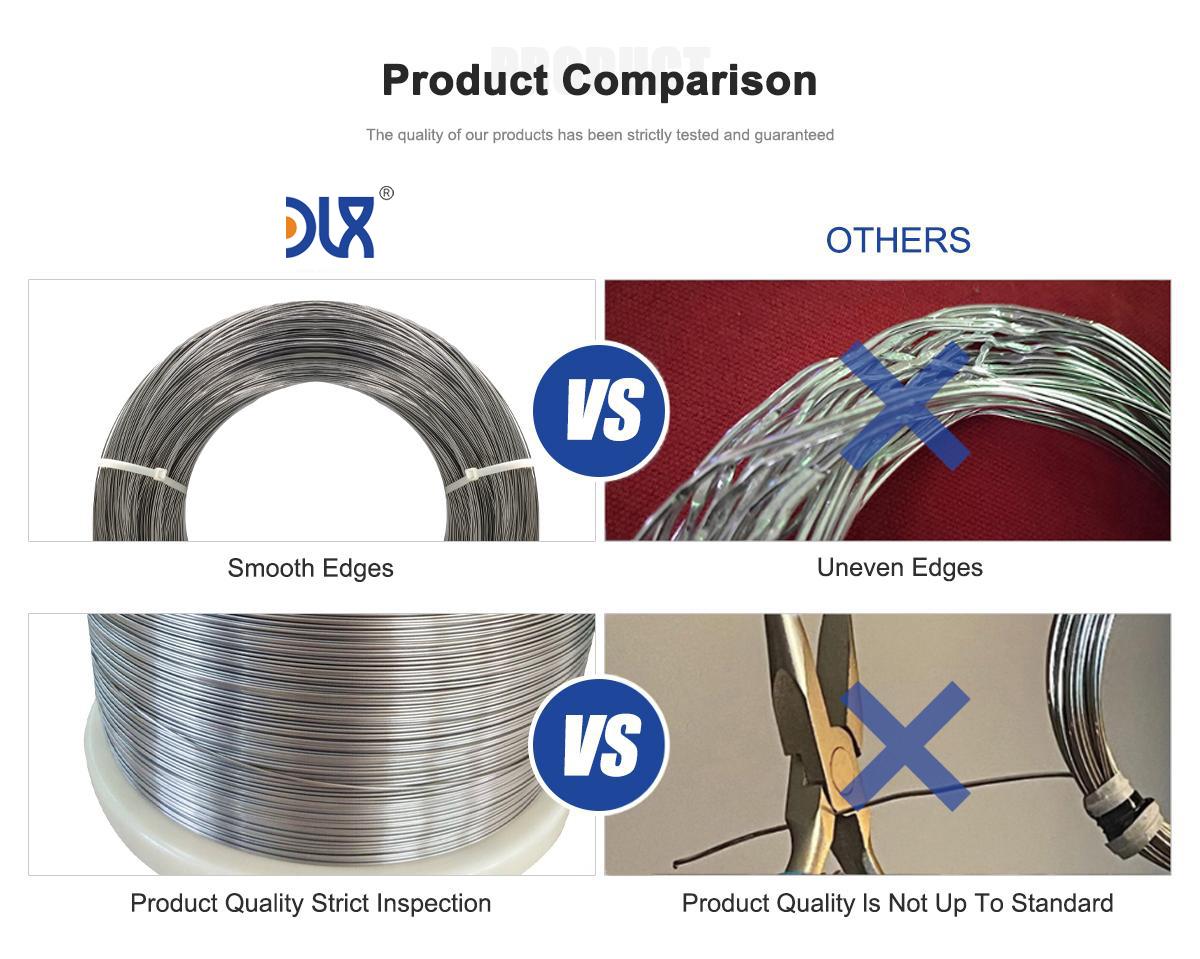

DLX has positioned itself as a leading supplier of 0Cr23Al5 alloy heating wire by combining advanced production technology with rigorous quality control. Unlike general suppliers that focus solely on mass production, DLX emphasizes material precision, surface uniformity, and consistency across batches. For customers, this translates into fewer performance deviations and a more reliable heating element that performs consistently in demanding conditions.

Comparison Table

| Property | 0Cr23Al5 (FeCrAl) | 0Cr21Al6 (FeCrAl) | NiCr 80/20 Alloy |

|---|---|---|---|

| Max Operating Temp (°C) | 1300 | 1250 | 1200 |

| Oxidation Resistance | Excellent | Very Good | Good |

| Electrical Resistivity | High | High | Medium |

| Service Life | Long | Long | Moderate |

| Cost Efficiency | High | High | Medium |

| Common Applications | Industrial & household heaters, furnaces, resistors | Heating elements, resistors, appliances | Heating coils, toasters, furnaces |

Another key factor driving the adoption of 0Cr23Al5 is its versatility across industries. In household appliances, such as ovens, water heaters, and space heaters, it ensures quick and efficient heating with minimal energy loss. In industrial settings, such as metallurgy, ceramics, and petrochemical processing, it endures the thermal cycles of high-temperature furnaces without significant degradation. This adaptability makes it a truly global product, with equivalents recognized in Europe, the USA, Russia, and other major industrial markets.

Compared with NiCr alloys, which have been widely used in the past, 0Cr23Al5 offers higher temperature capability and superior oxidation resistance at a lower cost. While NiCr alloys remain useful for specific applications requiring flexibility and ductility, the FeCrAl family, particularly 0Cr23Al5, dominates in heavy-duty heating environments where long-term durability is a priority.

Looking at market trends, the heating wire industry is experiencing a gradual shift from nickel-based alloys toward FeCrAl-based materials. This change is largely driven by rising nickel prices and the demand for more cost-efficient alternatives. At the same time, industries are emphasizing sustainability, pushing for products that extend service cycles and reduce energy waste. 0Cr23Al5 aligns perfectly with these expectations, and its adoption is expected to expand further in the coming years.

DLX continues to lead in this transformation by offering not only standard grades of 0Cr23Al5 wire but also customized solutions tailored to client requirements. Whether customers need fine diameters for compact heating devices or larger wires for heavy-duty furnaces, DLX ensures precision manufacturing and reliable supply. The company’s global distribution network also ensures timely delivery, making it easier for manufacturers in different regions to adopt and integrate 0Cr23Al5 into their production lines.

In conclusion, the 0Cr23Al5 alloy heating wire represents a balance of high strength, durability, and cost efficiency. It meets the demands of both industrial and household applications while addressing global trends in energy efficiency and sustainability. With DLX’s technical expertise, manufacturing quality, and customer-focused approach, clients gain not just a material, but a long-term solution for reliable heating performance.

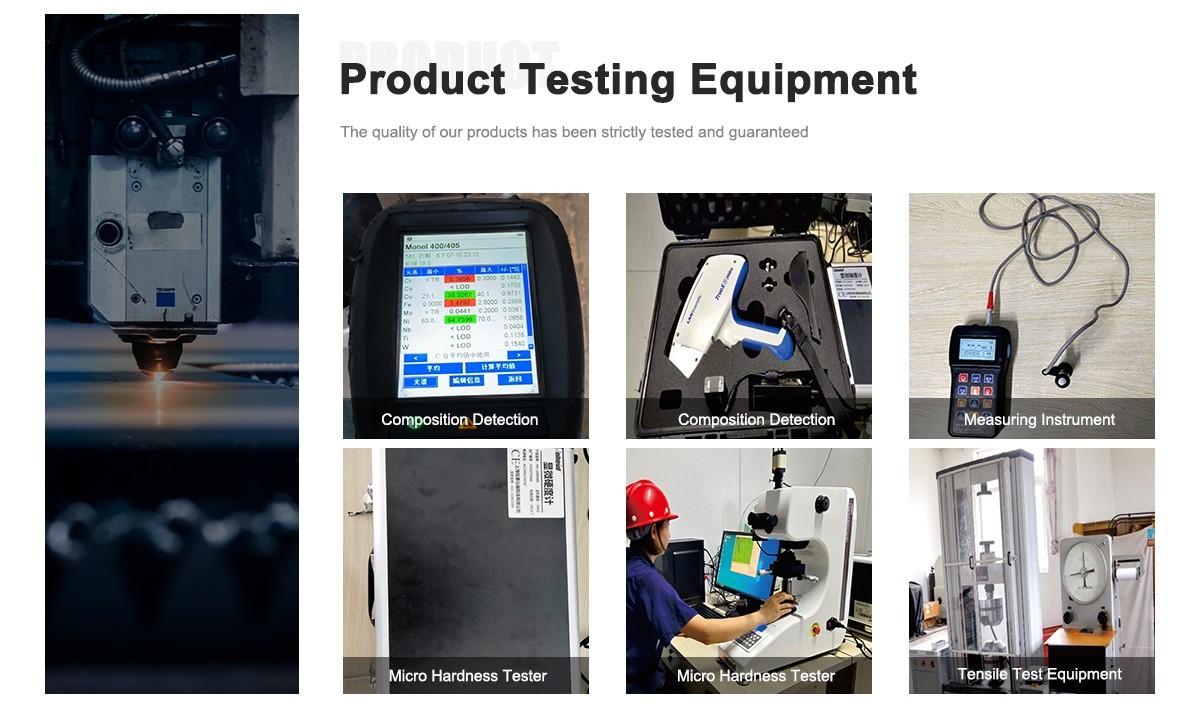

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing: