Our Inconel 601 , 625, and X-750 plates are the backbone of high-strength fastener manufacturing, built to tackle the toughest conditions. These nickel-based alloys are engineered for exceptional performance—think high tensile strength, top-tier corrosion resistance, and the ability to stay tough at extreme temperatures. Inconel 601 shines with its oxidation resistance up to 2200°F (1204°C), making it perfect for furnace and chemical processing fasteners. Inconel 625 is your go-to for battling acidic and chloride-heavy environments, ideal for marine and aerospace bolts. X-750 takes it up a notch with unmatched strength for high-stress applications like turbine blades and heavy-duty screws. Available in thicknesses from 1/8″ to 2″, we tailor these plates to fit your exact fastener specs.

For more details, pls directly contact us.

The fastener industry is booming as global demand for reliable, high-performance components grows. Aerospace, oil and gas, and power generation are driving the need for fasteners that can handle extreme heat, pressure, and corrosion without failing. The global fastener market is expected to keep climbing, fueled by infrastructure projects, renewable energy, and advanced manufacturing. Materials like Inconel 601, 625, and X-750 are stealing the spotlight because they deliver durability and reduce maintenance costs in harsh environments. With industries prioritizing sustainability and efficiency, our Inconel Plate s are perfectly positioned to meet the rising demand for long-lasting, high-strength fasteners.

Parameter | Inconel 601 | Inconel 625 | Inconel X-750 | Titanium (e.g., Grade 5) |

|---|---|---|---|---|

Max Service Temperature | 2200°F (1204°C) | 1800°F (982°C) | 1300°F (704°C) | 800°F (427°C) |

Tensile Strength | ~650 MPa | ~830 MPa | ~1100 MPa | ~900 MPa |

Corrosion Resistance | Excellent oxidation resistance | Superior in acidic/chloride environments | High resistance to stress corrosion | Good, but less effective in acidic settings |

Creep Resistance | Good, resists deformation at high temps | Moderate, suitable for marine applications | Excellent, ideal for high-stress uses | Moderate, limited at high temps |

Machinability | Moderate, requires specialized tools | Moderate, requires careful handling | Moderate, high strength affects machining | Good, easier to machine |

Weight | Higher density (8.1 g/cm³) | Higher density (8.4 g/cm³) | Higher density (8.3 g/cm³) | Lower density (4.4 g/cm³) |

Cost | Moderate, cost-effective for longevity | Higher, premium for corrosion resistance | Higher, due to high-strength properties | Moderate, varies by grade |

Applications | Furnace components, chemical processing | Marine, aerospace, chemical industries | Turbine blades, high-stress fasteners | Aerospace, medical, less extreme conditions |

Our Inconel 601, 625, and X-750 plates are workhorses across multiple industries. In aerospace, they’re used for bolts and screws in jet engines and airframes, where high temperatures and stress are constant. Oil and gas operations rely on them for fasteners in offshore platforms and pipelines, resisting corrosion from seawater and chemicals. Power generation trusts these alloys for turbine fasteners and boiler components that face extreme heat and pressure. Inconel 601 is a favorite in chemical processing for equipment like reactors, while 625 thrives in marine settings, and X-750 dominates in high-stress environments like gas turbines. Whatever the challenge, our plates ensure fasteners stay strong and reliable.

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel X750 | Inconel 825 |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.02-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

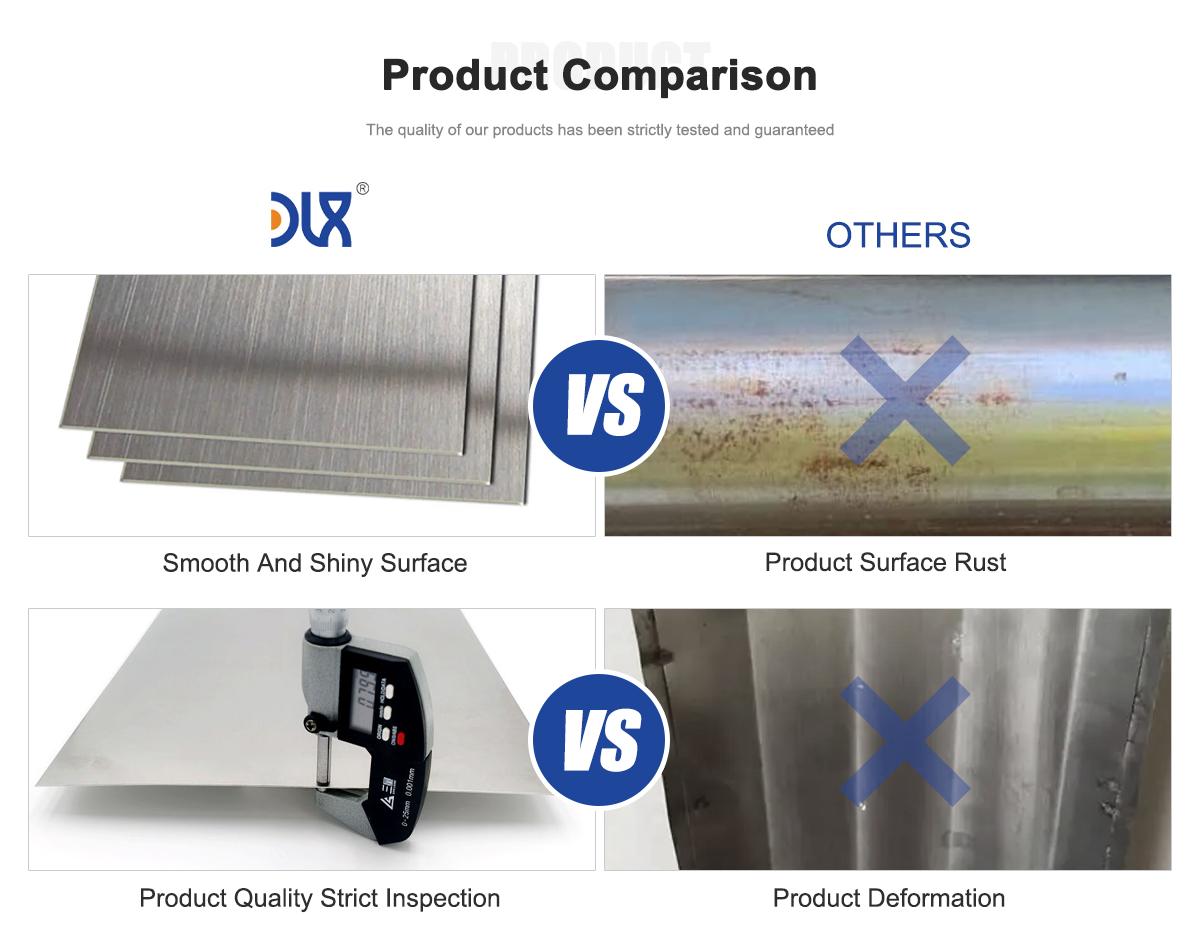

We set the bar high when it comes to Inconel 601, 625, and X-750 plates for fastener manufacturing. Our state-of-the-art production processes deliver plates that meet the strictest industry standards, ensuring every piece is flawless. We offer unmatched customization, providing a range of thicknesses and sizes to match your exact fastener designs. Our plates are optimized for machinability, making it easier to craft precise bolts, screws, and other components. Unlike others, we prioritize quality control at every step, from raw material to final product, guaranteeing consistency and performance. Our robust supply chain and fast delivery keep your projects on schedule, while the durability of our Inconel plates minimizes downtime and maintenance costs.

Why Choose Our Inconel Plates?

Our Inconel 601, 625, and X-750 plates are built for the long haul, offering the strength, corrosion resistance, and high-temperature performance needed for top-tier fasteners. Whether you’re fastening turbine blades, offshore rigs, or chemical reactors, our plates deliver reliability you can trust. With our focus on quality, customization, and efficient delivery, we’re here to help you build fasteners that stand up to the toughest challenges in aerospace, oil and gas, power generation, and beyond. Choose our Inconel plates for fasteners that don’t just hold—they dominate.

About Us:

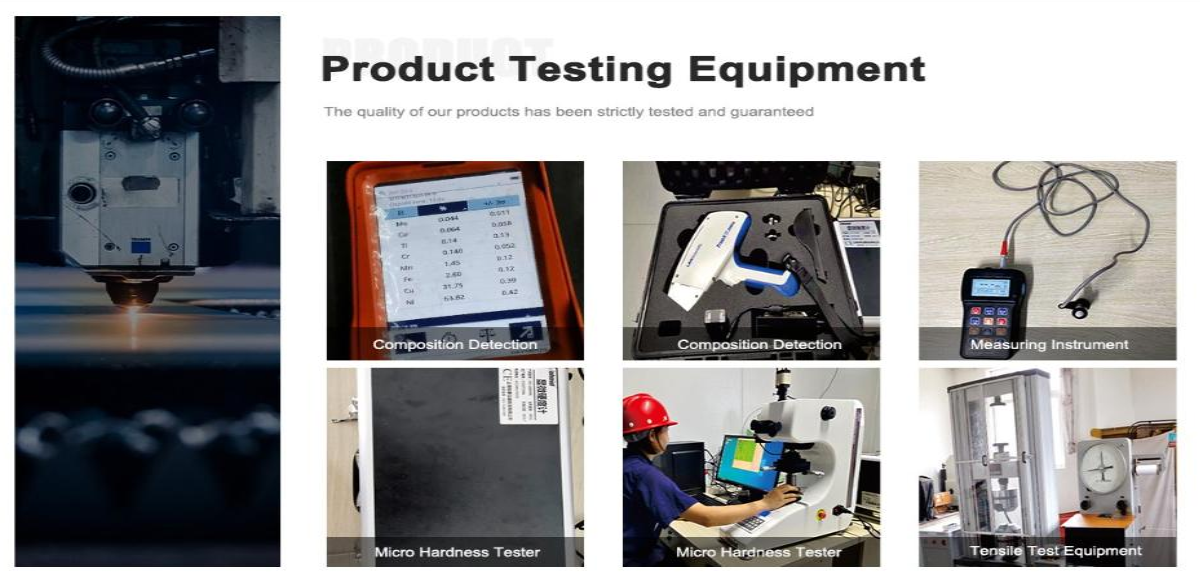

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What makes Inconel 601, 625, and X-750 plates suitable for fasteners?

These alloys offer high strength, excellent corrosion resistance, and stability at elevated temperatures, ideal for durable, reliable fasteners in extreme conditions.Which industries rely on these Inconel plates for fasteners?

Aerospace, oil and gas, power generation, and marine industries use them for their ability to withstand harsh environments and high stress.How do these alloys perform in high-temperature settings?

Inconel 601 excels up to 2200°F (1204°C), 625 up to 1800°F (982°C), and X-750 up to 1300°F (704°C) with superior creep resistance.Are these plates resistant to corrosion?

Yes, 601 resists oxidation, 625 handles acidic and chloride environments, and X-750 offers excellent resistance to stress corrosion cracking.Can these Inconel plates be easily machined for fasteners?

They’re machinable with proper tools and techniques, allowing precise shaping for bolts, screws, and other fasteners.What’s the advantage of using X-750 for fasteners over 601 or 625?

X-750 provides higher tensile strength and better performance in high-stress, high-temperature applications like turbine blades.How do these plates compare to titanium for fastener manufacturing?

Inconel plates offer better high-temperature strength and corrosion resistance in aggressive chemical environments compared to titanium.What sizes are available for these Inconel plates?

We provide customizable thicknesses from 1/8″ to 2″, tailored to meet specific fastener manufacturing needs.