Our Inconel 600, 625, and 718 plates are game-changers for industries tackling extreme heat and corrosion. These nickel-based superalloys are built to thrive where other materials fail, delivering top-notch performance in high-temperature furnace cladding. Let’s dive into what makes our products stand out, explore their applications, analyze industry trends, and see how we stack up against the competition.

For more details, pls directly contact us.

Product Introduction: Why Our Inconel Plate s Rock

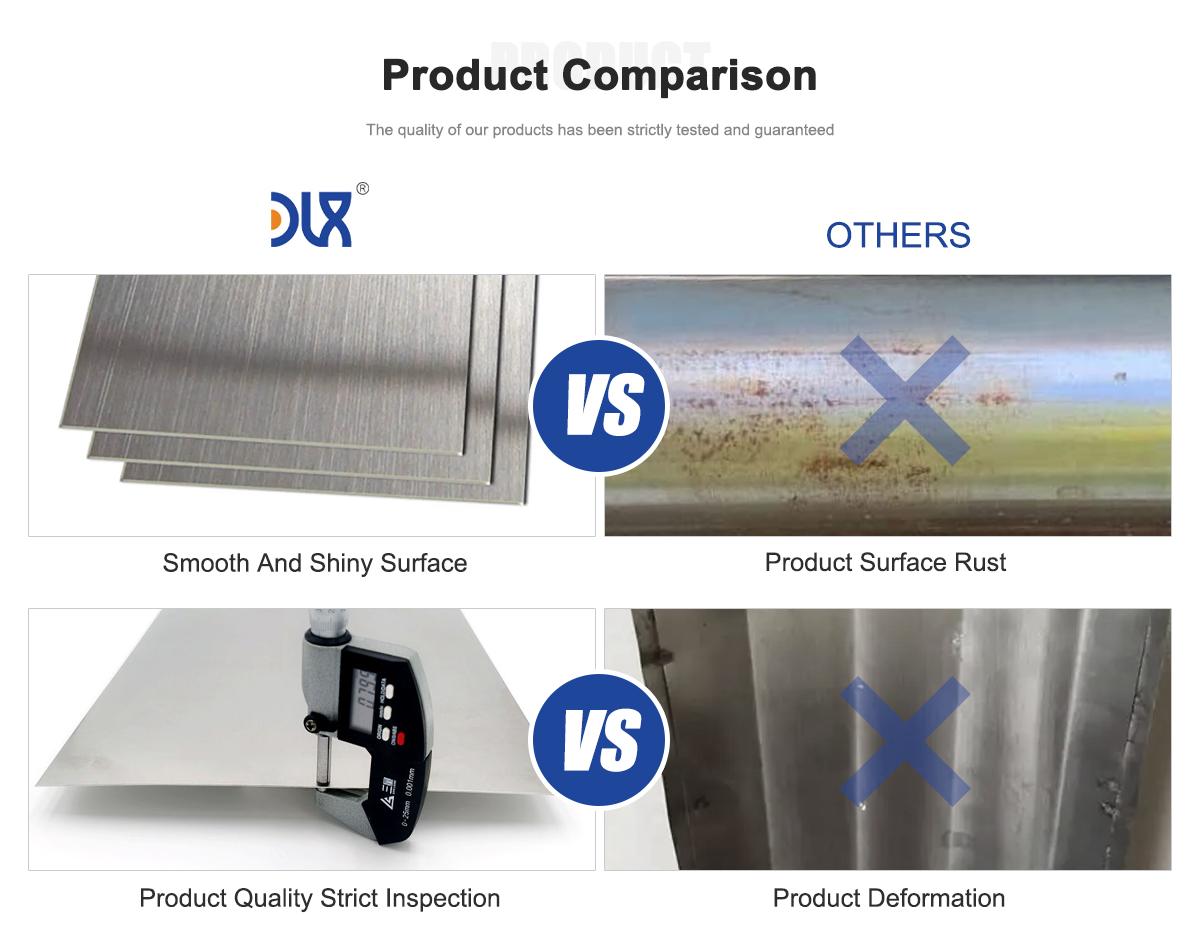

Our Inconel plates are engineered for durability and reliability in the toughest conditions. Here’s the lowdown:

Inconel 600: With over 72% nickel and 14–17% chromium, this alloy laughs in the face of oxidation and carburization. It’s your go-to for furnace components, heat exchangers, and chemical processing equipment, holding strong up to 2000°F.

Inconel 625: Packing 61% nickel, plus molybdenum and niobium, this alloy is a corrosion-fighting champ. It’s perfect for marine, aerospace, and nuclear applications, with excellent weldability and strength up to 1800°F.

Inconel 718: The heavyweight of the group, with 52% nickel and precipitation-hardening elements like niobium and titanium. It boasts a tensile strength of 1375 MPa, making it ideal for jet engines and gas turbines where high stress and heat are the norm.

Each plate is crafted with precision, adhering to ASTM standards, and available in various forms like sheets, bars, and custom cuts. Whether you need robust cladding for furnaces or high-strength components for aerospace, our Inconel plates deliver.

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel X750 | Inconel 825 |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.02-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

The demand for high-temperature alloys like Inconel is skyrocketing, driven by industries pushing the limits of performance. Aerospace is a major player, with Inconel 718 dominating jet engine components due to its unmatched strength at 1300°F. Chemical processing leans on Inconel 600 and 625 for their corrosion resistance in harsh acidic environments. The nuclear sector loves Inconel 625 for reactor cores and heat exchangers, while oil and gas rely on it for subsea equipment facing seawater corrosion.

Recent trends show additive manufacturing (like Direct Energy Deposition) revolutionizing Inconel fabrication, allowing for complex geometries and reduced waste. The push for green energy, like hydrogen production, is also boosting demand for Inconel in high-temperature reactors. Market reports suggest the global superalloy market will grow steadily through 2030, with aerospace and energy sectors leading the charge.

Comparison Table: Inconel 600, 625, and 718 Plates

Parameter | Inconel 600 | Inconel 625 | Inconel 718 |

|---|---|---|---|

Nickel Content | >72% | ~61% | ~52% |

Chromium Content | 14–17% | 20–23% | 17–21% |

Key Alloying Elements | Iron, Manganese | Molybdenum, Niobium | Niobium, Titanium, Aluminum |

Tensile Strength (MPa) | ~930 | ~827–965 | ~1375 |

Yield Strength (MPa) | ~310–413 | ~414–517 | ~1100 |

Max Service Temp (°F) | ~2000 | ~1800 | ~1300 |

Corrosion Resistance | Excellent in oxidizing environments | Superior in acidic and marine conditions | High in high-stress environments |

Weldability | Moderate, prone to cracking | Excellent, resistant to sensitization | Good with specialized techniques |

Primary Strengthening | Solid solution | Solid solution | Precipitation hardening |

Applications | Furnace components, chemical processing | Marine, aerospace, nuclear reactors | Jet engines, gas turbines, aerospace |

About Us:

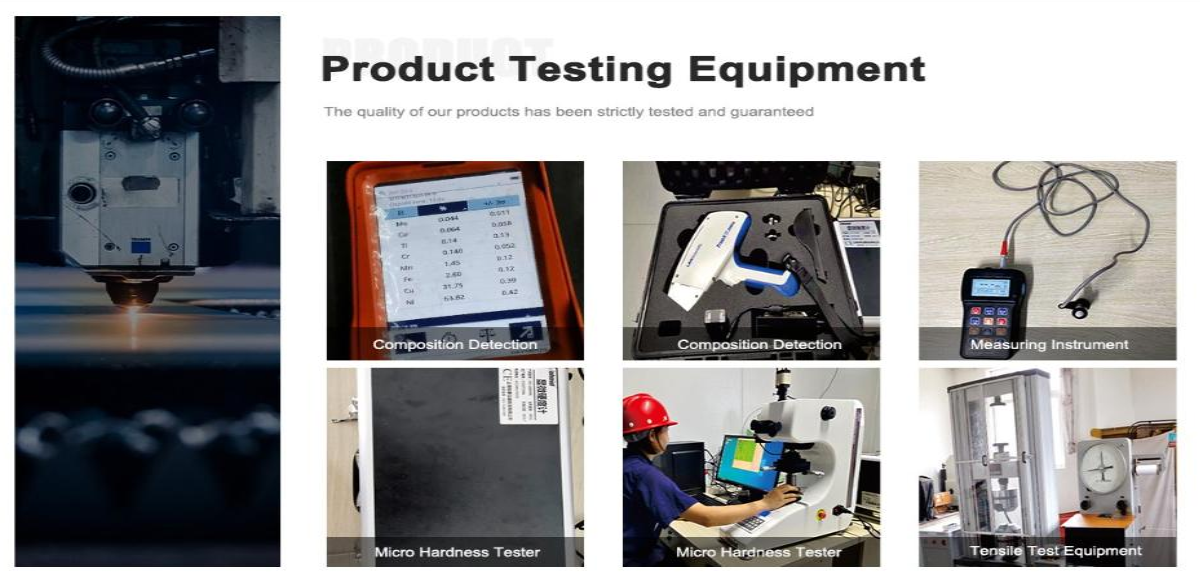

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

1. What are the key properties of Inconel 600, 625, and 718 plates?

Inconel 600 offers excellent corrosion and oxidation resistance up to 2000°F. Inconel 625 provides superior strength and weldability in extreme environments. Inconel 718 delivers high tensile strength and creep resistance, ideal for high-stress applications.

2. What industries use Inconel plates for furnace cladding?

Aerospace, chemical processing, nuclear, and oil and gas industries rely on Inconel plates for their high-temperature and corrosion-resistant properties.

3. Why choose Inconel 600 for furnace cladding?

Its resistance to oxidation and carburization makes it perfect for furnace components exposed to high heat and corrosive gases.

4. How does Inconel 625 perform in harsh environments?

It excels in resisting corrosion from seawater, acids, and high temperatures, making it ideal for marine and chemical processing applications.

5. What makes Inconel 718 stand out for high-temperature applications?

Its precipitation-hardened structure provides exceptional strength and fatigue resistance, even at temperatures up to 1300°F.

6. Are Inconel plates easy to work with?

Inconel 625 is highly weldable, while 600 and 718 require careful machining due to work-hardening tendencies, but all can be fabricated with proper techniques.

7. What are the latest trends in Inconel use for furnace cladding?

Additive manufacturing and advanced welding techniques are improving fabrication efficiency, while demand grows in aerospace and green energy sectors.

8. How do Inconel plates compare to other materials for furnace cladding?

Inconel outperforms stainless steel in high-temperature strength and corrosion resistance, making it a top choice for extreme environments.