We’re proud to offer Inconel 601 and X-750 plates, two nickel-chromium superalloys engineered for the toughest aerospace challenges. These materials are built to handle extreme heat, corrosion, and mechanical stress, making them go-to choices for high-performance structural parts. Inconel 601 shines with its unbeatable oxidation resistance up to 2200°F, forming a protective oxide layer that keeps components like turbine blades and exhaust systems in top shape. Inconel X-750, on the other hand, brings incredible creep-rupture strength and flexibility, perfect for gas turbine components like blades, seals, and rotors. Both alloys deliver durability and reliability, ensuring your aerospace parts perform under pressure—literally.

Our Inconel Plate s are available in various thicknesses and sizes, tailored to meet the strict demands of aerospace manufacturing. Whether you need precision-cut plates for jet engines or robust sheets for heat exchangers, we’ve got you covered with materials that meet AS9100 standards. Our advanced manufacturing processes, like hot forming and precision machining, ensure every plate delivers consistent quality and tight tolerances.

For more details, pls directly contact us.

The aerospace industry is soaring, with global demand for fuel-efficient, lightweight, and durable materials driving innovation. Inconel 601 and X-750 are at the forefront, thanks to their ability to withstand extreme temperatures and corrosive environments. Recent trends show a shift toward additive manufacturing, allowing complex geometries for parts like turbine blades and exhaust systems. The push for sustainability is also boosting the use of high-performance alloys like Inconel, as they reduce maintenance costs and extend component lifespans, contributing to greener aviation.

Market data points to steady growth in the aerospace sector, with a focus on next-gen aircraft and space exploration. Nickel-based superalloys like Inconel are critical, with over 50% of jet engine materials relying on these alloys for their heat and corrosion resistance. As aerospace companies prioritize efficiency and performance, demand for Inconel plates is expected to climb, especially in emerging markets like space tourism and hypersonic travel.

Comparison Table: Inconel 601 vs. X-750 Plates

Parameter | Inconel 601 | Inconel X-750 |

|---|---|---|

Composition | Ni (58-63%), Cr (21-25%), Al (1-1.7%) | Ni (70%), Cr (14-17%), Ti (2.25-2.75%), Al (0.4-1%) |

Max Service Temperature | 2200°F (1200°C) | 1300°F (704°C) |

Oxidation Resistance | Outstanding at high temperatures | Good, especially in cyclic conditions |

Corrosion Resistance | Excellent in oxidizing and carburizing environments | Strong resistance to stress-corrosion cracking |

Strength | High mechanical strength, creep resistance | High tensile and creep-rupture strength |

Hardness (Brinell) | 145–220 (annealed) | 175–240 (cold-rolled) |

Key Applications | Turbine blades, heat exchangers, exhaust systems | Gas turbine blades, seals, rotors |

Weldability | Good, requires TIG or electron-beam welding | Challenging due to precipitation hardening |

Our Inconel 601 and X-750 plates are workhorses in aerospace. Inconel 601 is a top pick for jet engine components like combustion chambers, turbine blades, and exhaust systems, where it handles temperatures up to 2200°F and resists oxidation and carburization. It’s also used in heat exchangers and furnace components, ensuring reliability in high-heat environments. Inconel X-750 is a favorite for gas turbine parts, including blades, seals, and rotors, thanks to its high creep-rupture strength and performance in both high and cryogenic temperatures. Its versatility makes it ideal for structural members, bolts, and thrust reversers, where durability under stress is non-negotiable.

Beyond aerospace, these alloys find use in chemical processing, power generation, and marine applications, but their real star turn is in the skies. From commercial jets to rocket engines, our Inconel plates keep critical systems running smoothly, even in the harshest conditions.

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel X750 | Inconel 825 |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.02-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

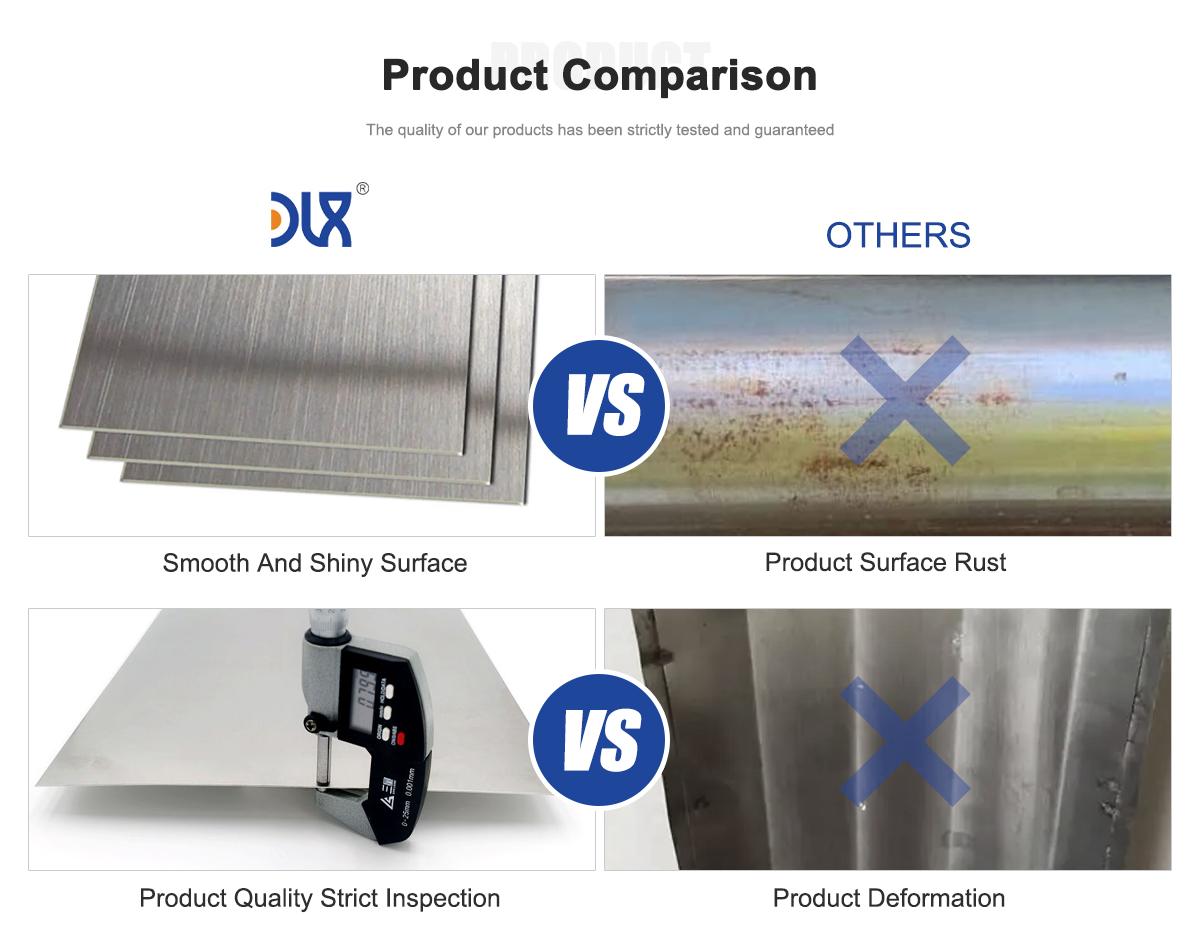

We stand out as a trusted supplier of Inconel 601 and X-750 plates, and here’s why. Our commitment to quality starts with sourcing premium raw materials, ensuring every plate meets stringent aerospace standards. Unlike others, we offer custom solutions, from tailored sizes to specialized heat treatments, giving you exactly what your project needs. Our ISO 9001 and AS9100 certifications back our promise of reliability, and our rapid delivery—often within days—keeps your production on schedule, no matter the order size.

We also invest in cutting-edge manufacturing, like precision machining and advanced welding techniques, to deliver plates with unmatched consistency. Our team of engineers provides expert guidance, helping you choose the right alloy for your specific application. While others may offer similar materials, our focus on customization, speed, and hands-on support sets us apart as the go-to partner for aerospace manufacturers.

Why Choose Our Inconel Plates?

Our Inconel 601 and X-750 plates are built for the extreme, offering unmatched strength, corrosion resistance, and heat tolerance. Whether you’re designing jet engines or spacecraft components, these alloys deliver performance you can rely on. With our industry-leading expertise, fast turnaround, and custom solutions, we’re here to help you push the boundaries of aerospace innovation. Contact us today to see how our Inconel plates can elevate your next project.

Keywords: Inconel 601, Inconel X-750, aerospace structural parts, high-temperature alloys, nickel-chromium superalloys, jet engine components, corrosion resistance, turbine blades, aerospace manufacturing, heat exchangers

About Us:

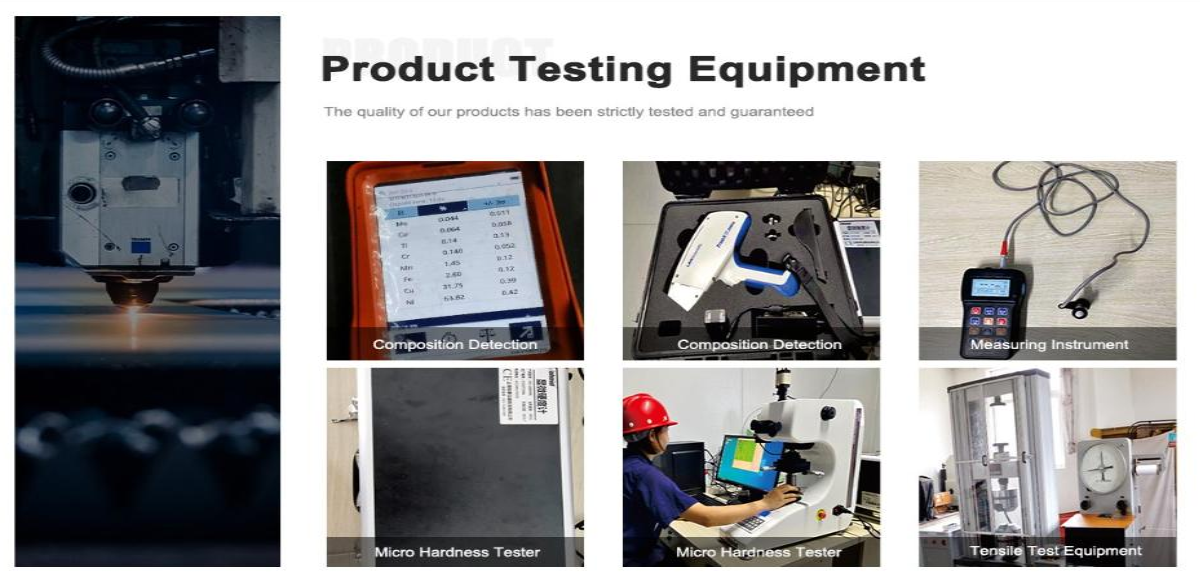

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What makes Inconel 601 plates ideal for high-temperature aerospace parts?

Inconel 601 offers excellent oxidation resistance up to 2200°F, high mechanical strength, and resistance to thermal fatigue, making it perfect for jet engine components and exhaust systems.Why choose Inconel X-750 for aerospace structural parts?

Inconel X-750 provides superior creep-rupture strength up to 1300°F, excellent corrosion resistance, and flexibility for gas turbine blades, seals, and rotors.How do Inconel 601 and X-750 compare in terms of corrosion resistance?

Inconel 601 excels in high-temperature oxidation and carburization resistance, while X-750 offers strong resistance to corrosion and stress-corrosion cracking in aerospace environments.What aerospace applications are best suited for Inconel 601 plates?

Inconel 601 is used in turbine blades, combustion chambers, and heat exchangers due to its ability to withstand extreme heat and corrosive conditions.Can Inconel X-750 handle cryogenic temperatures?

Yes, Inconel X-750 maintains excellent mechanical properties and corrosion resistance even at cryogenic temperatures, ideal for aerospace components in varied conditions.What are the key industry trends for Inconel alloys in aerospace?

Growing demand for lightweight, heat-resistant materials, advancements in additive manufacturing, and increased focus on fuel efficiency drive Inconel use in aerospace.How do Inconel 601 and X-750 plates contribute to aerospace efficiency?

Their high strength-to-weight ratio and durability in extreme environments reduce maintenance costs and improve fuel efficiency in aircraft engines.What manufacturing processes work best for Inconel 601 and X-750 plates?

Hot forming, machining, and welding (TIG or electron-beam) are ideal, with precision processes ensuring tight tolerances for aerospace-grade components.