We’re thrilled to supply Inconel 617, 625, and 690 plates, nickel-based superalloys designed to tackle the extreme conditions of nuclear reactors. These alloys are built to handle high temperatures, intense radiation, and corrosive environments, making them perfect for shielding components and critical reactor parts. Inconel 617 stands out with its high-temperature strength and creep resistance up to 1000°C, ideal for heat exchangers and hot gas ducts. Inconel 625 brings top-notch corrosion resistance and weldability, making it a go-to for reactor cores and fuel cladding. Inconel 690, with its low cobalt content, shines in resisting stress-corrosion cracking, perfect for fuel elements and steam generators.

Our plates come in custom sizes and thicknesses, meeting stringent nuclear industry standards like ASME Boiler and Pressure Vessel Code. With advanced manufacturing techniques like hot rolling and precision welding, we ensure every plate delivers the durability and performance your reactor demands.

For more details, pls directly contact us.

The nuclear power industry is on the rise as the world pushes for clean, sustainable energy. Inconel 617, 625, and 690 are critical to this growth, thanks to their ability to withstand the harsh conditions of next-generation reactors like Very High Temperature Reactors (VHTRs). Industry trends show a surge in demand for radiation-resistant materials, driven by stricter safety regulations and the need for long-lasting components. Additive manufacturing is also gaining traction, allowing for complex reactor parts with enhanced precision, reducing waste and costs.

Global nuclear capacity is expanding, with new reactors and upgrades to existing plants increasing the need for high-performance alloys. Inconel’s role in ensuring reactor safety and efficiency makes it a cornerstone of the industry, especially as clean energy goals intensify. Emerging applications, like small modular reactors (SMRs), are further boosting demand for these alloys.

Comparison Table: Inconel 617 vs. 625 vs. 690 Plates

|

Parameter |

Inconel 617 |

Inconel 625 |

Inconel 690 |

|---|---|---|---|

|

Composition |

Ni (44-56%), Cr (20-24%), Co (10-15%), Mo (8-10%) |

Ni (58% min), Cr (20-23%), Mo (8-10%), Nb (3.15-4.15%) |

Ni (58% min), Cr (27-31%), Fe (7-11%) |

|

Max Service Temperature |

1000°C (1832°F) |

980°C (1800°F) |

700°C (1292°F) |

|

Corrosion Resistance |

Excellent in oxidizing and carburizing environments |

Superior in acidic, chloride-rich environments |

Outstanding resistance to stress-corrosion cracking |

|

Radiation Resistance |

Good, suitable for reactor internals |

Excellent, ideal for fuel cladding |

Excellent, low cobalt for nuclear safety |

|

Tensile Strength |

~671 MPa (solution annealed) |

~690 MPa |

~671 MPa |

|

Hardness (Brinell) |

145–220 (annealed) |

145–240 (annealed) |

150–240 (annealed) |

|

Key Applications |

Heat exchangers, hot gas ducts, control rods |

Reactor cores, fuel cladding, pressure vessels |

Fuel elements, reactor internals, steam generators |

|

Weldability |

Good, requires TIG or electron-beam welding |

Excellent, no cracking post-welding |

Good, designed for nuclear-grade welding |

Our Inconel 617, 625, and690 plates are engineered for the toughest nuclear reactor challenges. Inconel 617 is used in heat exchangers, hot gas ducts, and control rods, where its high-temperature strength and oxidation resistance shine. Inconel 625 is a staple in reactor cores, fuel cladding, and pressure vessels, thanks to its ability to resist corrosion in acidic and chloride-rich environments, as well as its radiation resistance. Inconel 690, with its low cobalt content, is ideal for fuel elements, reactor internals, and steam generators, offering unmatched protection against stress-corrosion cracking in nuclear settings.

These alloys also find use in chemical processing and marine applications, but their primary role is in nuclear power, ensuring safe, efficient operation under extreme conditions. From boiling water reactors (BWRs) to advanced VHTRs, our Inconel Plate s keep critical systems running smoothly.

|

Item |

Inconel 600 |

Inconel 601 |

Inconel 617 |

Inconel 625 |

Inconel 690 |

Inconel 718 |

Inconel X750 |

Inconel 825 |

|

C |

≤0.15 |

≤0.1 |

0.05-0.15 |

≤0.08 |

≤0.05 |

≤0.08 |

≤0.08 |

≤0.05 |

|

Mn |

≤1 |

≤1.5 |

≤0.5 |

≤0.35 |

≤0.5 |

≤0.35 |

≤1 |

≤1 |

|

Fe |

6-10 |

rest |

≤3 |

rest |

7-11 |

rest |

5-9 |

≥22 |

|

P |

≤0.015 |

≤0.02 |

≤0.015 |

-- |

-- |

-- |

-- |

-- |

|

S |

≤0.015 |

≤0.015 |

≤0.015 |

≤0.015 |

≤0.015 |

≤0.01 |

≤0.01 |

≤0.03 |

|

Si |

≤0.5 |

≤0.5 |

≤0.5 |

≤0.35 |

≤0.5 |

≤0.35 |

≤0.5 |

≤0.5 |

|

Cu |

≤0.5 |

≤1 |

-- |

≤0.3 |

≤0.5 |

≤0.3 |

≤0.5 |

1.5-3 |

|

Ni |

≥72 |

58-63 |

≥44.5 |

50-55 |

≥58 |

50-55 |

≥70 |

38-46 |

|

Co |

-- |

-- |

10-15 |

≤10 |

-- |

≤1 |

≤1 |

-- |

|

Al |

-- |

1-1.7 |

0.8-1.5 |

≤0.8 |

-- |

0.2-0.8 |

0.4-1 |

≤0.2 |

|

Ti |

-- |

-- |

≤0.6 |

≤1.15 |

-- |

-- |

2.25-2.75 |

0.6-1.2 |

|

Cr |

14-17 |

21-25 |

20-24 |

17-21 |

27-31 |

17-21 |

14-17 |

19.5-23.5 |

|

Nb+Ta |

-- |

-- |

-- |

4.75-5.5 |

-- |

4.75-5.5 |

0.7-1.2 |

-- |

|

Mo |

-- |

-- |

8-10 |

2.8-3.3 |

-- |

2.8-3.3 |

-- |

2.5-3.5 |

|

B |

-- |

-- |

≤0.006 |

-- |

-- |

-- |

-- |

-- |

|

Shape |

Size (mm) |

|

Wire |

0.02-7.50 |

|

Rod/Bar |

8.0-200 |

|

Strip |

(0.5-2.5)*(5-180) |

|

Tube/Pipe |

Customized |

|

Sheet/Plate |

Customized |

For more details, pls directly contact us.

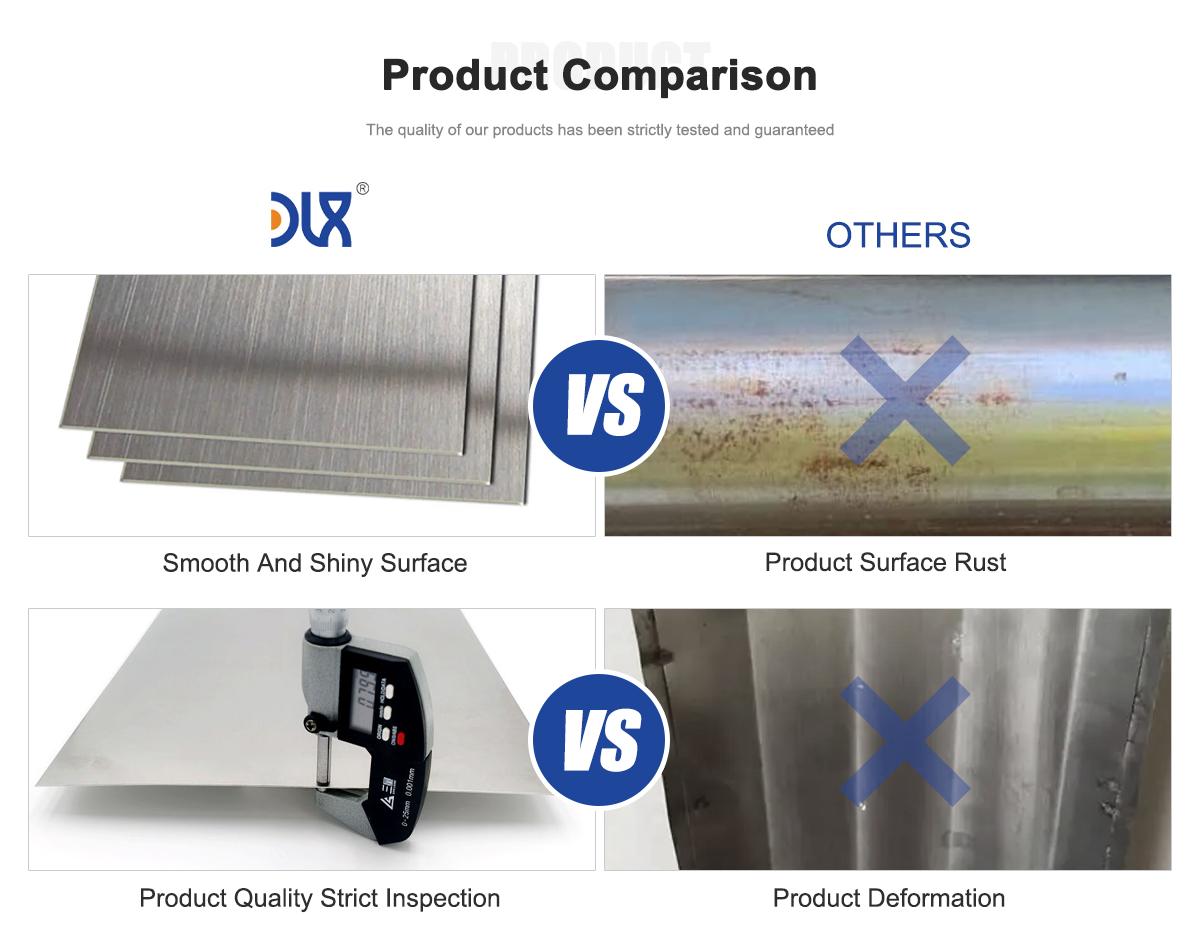

We’re a leading supplier of Inconel 617, 625, and 690 plates, and our edge comes from our commitment to quality and customization. We source only the highest-grade materials, ensuring every plate meets nuclear industry standards like ASME and ASTM. Our advanced manufacturing capabilities, including precision machining and specialized heat treatments, deliver plates with exceptional consistency and performance. Unlike others, we offer tailored solutions—custom sizes, thicknesses, and finishes—to meet your exact specifications.

Our ISO 9001 and AS9100 certifications guarantee reliability, and our fast delivery—often within days—keeps your projects on track. With a dedicated team of experts, we provide hands-on support to help you select the right alloy for your reactor components. Our focus on innovation, quality, and speed makes us the preferred partner for nuclear manufacturers worldwide.

Why Choose Our Inconel Plates?

Our Inconel 617, 625, and 690 plates are built to power the future of nuclear energy. With unmatched strength, corrosion resistance, and radiation tolerance, they ensure your reactor components perform reliably in the harshest conditions. Backed by our expertise, custom solutions, and rapid delivery, we’re here to support your nuclear projects with materials you can trust. Reach out today to learn how our Inconel plates can drive your next reactor build.

About Us:

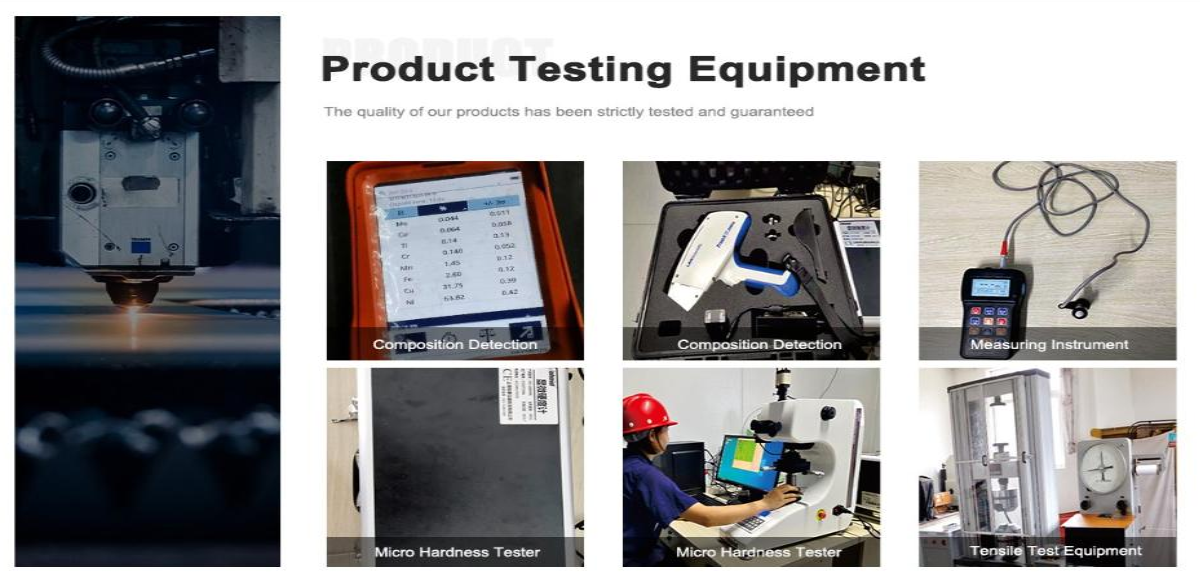

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What makes Inconel 617 plates suitable for nuclear reactor shielding?

Inconel 617 offers exceptional high-temperature strength, oxidation resistance, and creep resistance up to 1000°C, ideal for reactor components like heat exchangers and ducts. -

Why is Inconel 625 a top choice for nuclear applications?

Inconel 625 provides excellent corrosion resistance, high tensile strength, and weldability, making it perfect for reactor cores, fuel cladding, and pressure vessels. -

How does Inconel 690 perform in nuclear environments?

Inconel 690 has low cobalt content and superior resistance to stress-corrosion cracking, making it ideal for nuclear fuel elements and reactor internals. -

What are the key applications of Inconel 617 in nuclear reactors?

Inconel 617 is used in heat exchangers, hot gas ducts, and control rods due to its ability to withstand high temperatures and corrosive conditions. -

How does Inconel 625 contribute to nuclear reactor safety?

Its resistance to radiation, corrosion, and high temperatures ensures reliable performance in fuel cladding and containment structures, enhancing reactor safety. -

What industry trends are driving Inconel use in nuclear power?

Increased focus on clean energy, advancements in additive manufacturing, and demand for radiation-resistant materials are boosting Inconel adoption in nuclear reactors. -

How do Inconel 625 and 690 compare for corrosion resistance?

Inconel 625 excels in acidic and chloride-rich environments, while Inconel 690 is optimized for stress-corrosion cracking resistance in nuclear settings. -

What manufacturing processes are best for Inconel 617, 625, and 690 plates?

Precision machining, hot rolling, and TIG welding ensure high-quality plates with tight tolerances for nuclear-grade components.