Our Cr15Ni60 Nichrome wire is a high-quality nickel-chromium alloy crafted for top-notch performance in oven heating coils and other high-temperature applications. With a composition of 15% chromium and 60% nickel, balanced with iron, this wire offers excellent corrosion resistance and thermal stability. It’s built to handle temperatures up to 1150°C (2102°F) with a melting point around 1390°C (2534°F), making it perfect for demanding environments like industrial and commercial ovens. Its reliable electrical resistivity ensures consistent heating, while its durability means fewer replacements and less downtime.

Available in diameters from 0.02’’ to 0.3’’, our Cr15Ni60 wire comes in coils, spools, or custom configurations to suit your needs. Its flexibility and weldability make it a breeze to work with, whether you’re designing heating elements or precision components. We’ve engineered this wire to deliver long-lasting performance, giving you peace of mind for your heating projects.

Industry Analysis

The nichrome wire market is buzzing, fueled by rising demand for efficient heating solutions in industries like food processing, manufacturing, and electronics. As businesses prioritize energy efficiency and durability, alloys like Cr15Ni60 are gaining traction for their ability to withstand corrosion and high temperatures. The shift toward automated and smart heating systems is driving innovation, with a focus on materials that offer consistent performance and lower maintenance costs. Market projections show steady growth through 2030, particularly in regions with expanding industrial and commercial sectors.

Sustainability is also a big player in today’s market, with companies seeking eco-friendly materials that reduce energy waste. Our Cr15Ni60 Nichrome wire fits the bill, offering high efficiency and a long service life, which aligns with the industry’s push for greener, cost-effective solutions.

Comparison Table

|

Parameter |

Cr15Ni60 Nichrome Wire |

Other Nichrome Alloys |

|---|---|---|

|

Composition |

60% Ni, 15% Cr, Fe |

Varies (e.g., 80% Ni, 20% Cr) |

|

Max Operating Temperature |

1150°C (2102°F) |

1100–1200°C (2012–2190°F) |

|

Melting Point |

1390°C (2534°F) |

1350–1400°C (2462–2552°F) |

|

Resistivity |

1.12 μΩ·m |

1.08–1.20 μΩ·m |

|

Corrosion Resistance |

Excellent (oxide layer) |

Moderate to good |

|

Service Life |

Up to 5-7 years |

3-6 years |

|

Weldability |

Excellent |

Moderate |

|

Customization Options |

Wide range (coils, spools) |

Limited |

Our Cr15Ni60 Nichrome wire shines in a range of applications:

-

Commercial and Industrial Ovens: Ideal for heating coils, ensuring uniform heat and corrosion resistance.

-

Electronics: Used in resistors and circuit components for stable electrical performance.

-

Food Processing: Powers heating elements in equipment like baking ovens and dehydrators.

-

Automotive: Supports heating systems in exhaust and sensor applications.

-

Medical Equipment: Perfect for sterilization units due to its non-magnetic and corrosion-resistant properties.

-

Home Appliances: Found in toasters, air fryers, and electric heaters for reliable, long-term use.

Its ability to resist corrosion in humid or chemical-heavy environments makes it a standout choice across these industries.

|

Performance / material |

Cr30Ni70 |

Cr15Ni60 |

Cr20Ni35 |

Cr20Ni30 |

|||

|

Composition |

Ni |

90 |

Rest |

Rest |

55.0~61.0 |

34.0~37.0 |

30.0~34.0 |

|

Cr |

10 |

20.0~23.0 |

28.0~31.0 |

15.0~18.0 |

18.0~21.0 |

18.0~21.0 |

|

|

Fe |

--

|

≤1.0 |

≤1.0 |

Rest |

Rest |

Rest |

|

|

Maximum temperature℃ |

1300 |

1200 |

1250 |

1150 |

1100 |

1100 |

|

|

Meltiing point ℃ |

1400 |

1400 |

1380 |

1390 |

1390 |

1390 |

|

|

Density g/cm3 |

8.7 |

8.4 |

8.1 |

8.2 |

7.9 |

7.9 |

|

|

Resistivity at 20℃ (μΩ·m) |

--

|

1.09±0.05 |

1.18±0.05 |

1.12±0.05 |

1.00±0.05 |

1.04±0.05 |

|

|

Elongation at rupture |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

|

|

Specific heat (J/g.℃) |

--

|

0.44 |

0.461 |

0.494 |

0.5 |

0.5 |

|

|

Thermal conductivity (KJ/m.h℃) |

--

|

60.3 |

45.2 |

45.2 |

43.8 |

43.8 |

|

|

Coefficient of lines expansion a×10-6/(20~1000℃) |

--

|

18 |

17 |

17 |

19 |

19 |

|

|

Micrographic structure |

--

|

Austenite |

Austenite |

Austenite |

Austenite |

Austenite |

|

|

Magnetic properties |

--

|

Non-magnetic |

Non-magnetic |

Non-magnetic |

Weak magnetic |

Weak magnetic |

|

|

Shape |

Size (mm) |

|

Wire |

0.05-7.5 |

|

Rod |

8-50 |

|

Ribbon |

(0.05-0.35)*(0.5-6.0) |

|

Strip |

(0.5-2.5)*(5-40) |

For more details, pls directly contact us.

Our Cr15Ni60 Nichrome wire sets the bar high. While other alloys may struggle with corrosion or lose efficiency over time, our wire boasts superior resistance to oxidation and chemical degradation, lasting up to 5-7 years in oven applications. Its excellent weldability and flexibility make it easier to shape and install compared to alternatives, saving you time and effort. We also offer a range of diameters and finishes—bright or oxidized—to meet your specific requirements, a level of customization not always available elsewhere.

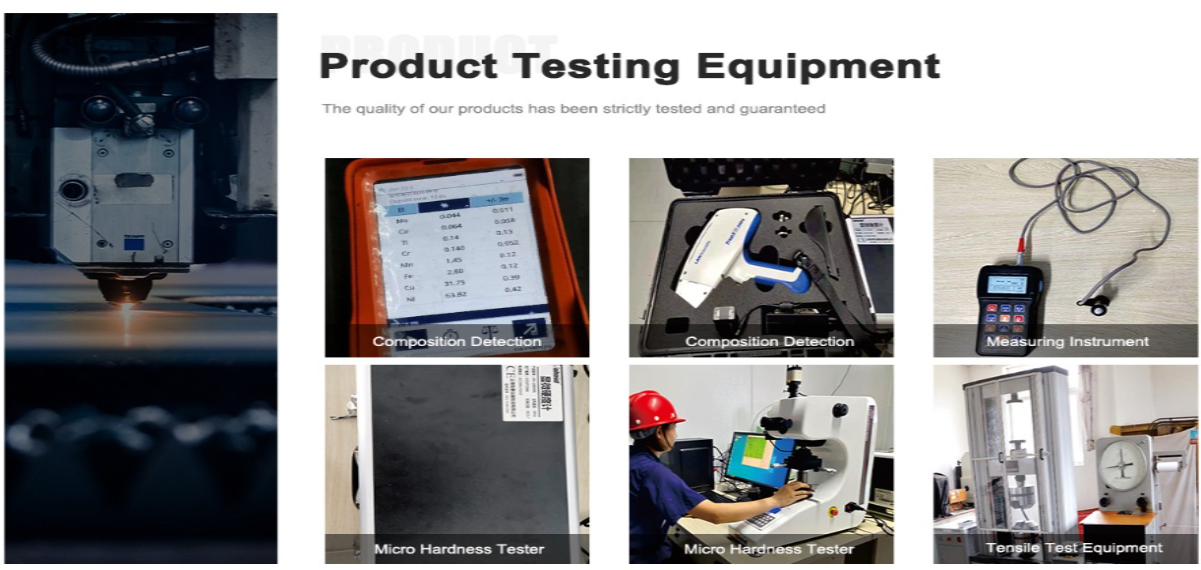

Our rigorous quality control ensures every batch meets ASTM B344 standards, delivering consistent performance you can count on. By optimizing our production process, we keep costs competitive while maintaining top-tier quality, making our wire a smart choice for businesses looking to maximize value.

Why Choose Our Cr15Ni60 Nichrome Wire?

We’ve designed our Cr15Ni60 Nichrome wire to excel in tough conditions. Its corrosion resistance and high-temperature stability mean you get reliable performance with minimal maintenance. The wire’s non-magnetic properties make it ideal for sensitive applications, like medical or precision electronics. With our focus on customization and quality, you’re getting a product tailored to your project’s needs, backed by a service life that outpaces many alternatives. Whether you’re building oven coils or high-tech components, our wire delivers the durability and efficiency you need to stay ahead.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is Cr15Ni60 Nichrome wire made of?

It’s a nickel-chromium alloy with 60% nickel, 15% chromium, and iron for added strength and corrosion resistance. -

What are the main applications of Cr15Ni60 Nichrome wire?

It’s used in oven heating coils, resistors, food processing equipment, automotive systems, medical devices, and appliances. -

What temperatures can Cr15Ni60 Nichrome wire handle?

It performs reliably up to 1150°C (2102°F) with a melting point of about 1390°C (2534°F). -

Is Cr15Ni60 Nichrome wire corrosion-resistant?

Yes, its high chromium content forms a protective oxide layer, resisting corrosion in harsh environments. -

Can the wire be customized?

Absolutely, we offer diameters from 0.02’’ to 0.3’’, plus coils, spools, or custom shapes to fit your needs. -

How long does Cr15Ni60 Nichrome wire last?

In oven applications, it can last 5-7 years, depending on usage and conditions. -

Is Cr15Ni60 Nichrome wire non-magnetic?

Yes, its non-magnetic nature makes it suitable for sensitive applications like medical equipment. -

What industries benefit most from Cr15Ni60 Nichrome wire?

Food processing, electronics, automotive, medical, and appliance manufacturing rely on its performance.