At DLX, we pride ourselves on delivering premium Cr30Ni70 Nichrome wire designed for the toughest industrial heat treatment challenges. This nickel-chromium alloy is engineered with 70% nickel and 30% chromium, giving it a perfect balance of high-temperature strength, durability, and oxidation resistance. Whether you’re running an industrial furnace, building resistance heating elements, or designing custom high-temp equipment, our Cr30Ni70 wire is built to perform consistently.

For more details, pls directly contact us.

The 70/30 ratio of nickel to chromium makes this wire extremely stable at temperatures up to 1,200°C. The chromium content ensures a protective oxide layer forms on the surface, which prevents further oxidation and extends service life. Meanwhile, the high nickel content gives it excellent ductility, making it easy to bend, coil, or form into custom heating elements. This combination of properties makes Cr30Ni70 ideal for long-term industrial operations, where downtime is costly.

|

Performance / material |

Cr10Ni90 |

Cr20Ni80 |

Cr30Ni70 |

Cr20Ni35 |

|||

|

Composition |

Ni |

90 |

Rest |

Rest |

55.0~61.0 |

34.0~37.0 |

30.0~34.0 |

|

Cr |

10 |

20.0~23.0 |

28.0~31.0 |

15.0~18.0 |

18.0~21.0 |

18.0~21.0 |

|

|

Fe |

--

|

≤1.0 |

≤1.0 |

Rest |

Rest |

Rest |

|

|

Maximum temperature℃ |

1300 |

1200 |

1250 |

1150 |

1100 |

1100 |

|

|

Meltiing point ℃ |

1400 |

1400 |

1380 |

1390 |

1390 |

1390 |

|

|

Density g/cm3 |

8.7 |

8.4 |

8.1 |

8.2 |

7.9 |

7.9 |

|

|

Resistivity at 20℃ (μΩ·m) |

--

|

1.09±0.05 |

1.18±0.05 |

1.12±0.05 |

1.00±0.05 |

1.04±0.05 |

|

|

Elongation at rupture |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

|

|

Specific heat (J/g.℃) |

--

|

0.44 |

0.461 |

0.494 |

0.5 |

0.5 |

|

|

Thermal conductivity (KJ/m.h℃) |

--

|

60.3 |

45.2 |

45.2 |

43.8 |

43.8 |

|

|

Coefficient of lines expansion a×10-6/(20~1000℃) |

--

|

18 |

17 |

17 |

19 |

19 |

|

|

Micrographic structure |

--

|

Austenite |

Austenite |

Austenite |

Austenite |

Austenite |

|

|

Magnetic properties |

--

|

Non-magnetic |

Non-magnetic |

Non-magnetic |

Weak magnetic |

Weak magnetic |

|

|

Shape |

Size (mm) |

|

Wire |

0.05-7.5 |

|

Rod |

8-50 |

|

Ribbon |

(0.05-0.35)*(0.5-6.0) |

|

Strip |

(0.5-2.5)*(5-40) |

For more details, pls directly contact us.

Cr30Ni70 wire is widely used in industrial heat treatment furnaces, including annealing, tempering, and hardening processes. It’s also essential in the production of resistance heating coils, laboratory heating equipment, and automotive component heat treatments. Aerospace manufacturers rely on it for precise thermal processing of metal parts, while chemical processing plants utilize its corrosion resistance to maintain consistent heat performance in aggressive environments.

Industry Trends and Demand

The industrial heat treatment sector is evolving rapidly, with increasing demand for high-efficiency, long-lasting heating elements. With energy costs rising, materials like Cr30Ni70, which maintain performance at extreme temperatures while minimizing degradation, are becoming critical. Additionally, industries are moving toward customized wire forms to meet unique furnace designs, requiring a reliable supplier with engineering expertise. DLX is positioned perfectly to support these trends, offering tailored solutions, fast delivery, and precise material specifications.

Comparison Table: Cr-Ni Nichrome Wire Series

| Alloy | Ni % | Cr % | Max Temp (°C) | Resistivity (Ω·mm²/m) | Tensile Strength (MPa) | Typical Application |

|---|---|---|---|---|---|---|

| Cr20Ni80 | 80 | 20 | 1,100 | 1.10 | 750 | Heating elements, small lab furnaces |

| Cr30Ni70 | 70 | 30 | 1,200 | 1.10 | 750 | Industrial heat treatment, high-temp coils |

| Cr15Ni85 | 85 | 15 | 1,100 | 1.05 | 780 | High-resistance wire, lab instruments |

| Cr40Ni60 | 60 | 40 | 1,250 | 1.15 | 730 | Specialty furnaces, oxidation-prone environments |

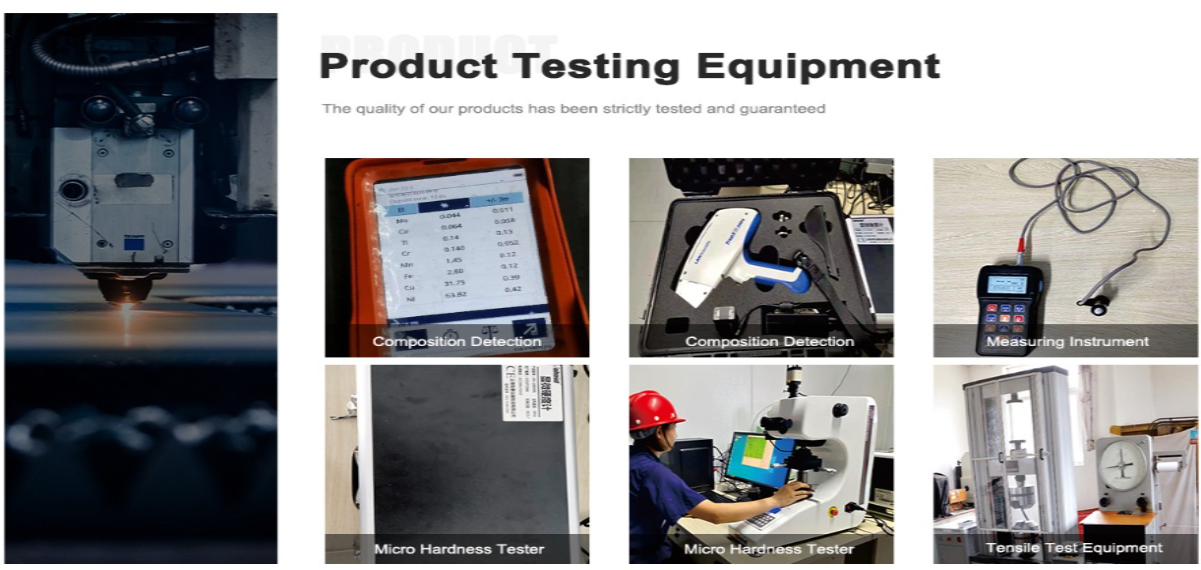

Unlike other suppliers, DLX combines strict quality control with advanced production techniques. Every batch of Cr30Ni70 wire undergoes careful inspection for composition, resistivity, and tensile strength. Our team can provide custom wire diameters, pre-formed coils, or straight lengths to match your exact industrial requirements. We also maintain a robust inventory to support urgent projects and large-scale production schedules.

When using DLX Cr30Ni70 Nichrome wire, clients benefit from exceptional longevity and consistent performance. The alloy’s resistance to oxidation prevents premature failure in high-temperature environments, while its mechanical strength allows it to withstand thermal cycling without deformation. These qualities reduce maintenance downtime and replacement costs, helping facilities maintain operational efficiency.

DLX understands that industrial heat treatment applications can vary significantly, from small lab furnaces to large-scale production lines. That’s why we provide technical support for wire selection, forming, and installation, ensuring optimal performance for your application. Our engineers work closely with clients to determine the ideal wire specifications based on operating temperatures, furnace designs, and electrical requirements.

In a world where precision, durability, and reliability matter, DLX’s Cr30Ni70 Nichrome wire delivers unmatched performance for industrial heat treatment applications. With a perfect balance of nickel and chromium, excellent oxidation resistance, and flexibility for forming, it’s the material of choice for industrial furnaces, resistance heating, aerospace, automotive, and laboratory equipment. Choosing DLX means choosing a partner committed to high-quality materials, customized solutions, and dependable delivery.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

-

What is Cr30Ni70 Nichrome Wire made of?

Chromium 30%, Nickel 70% alloy. -

What are its main industrial applications?

Heat treatment furnaces, electric heating elements, and resistance wire applications. -

What is its maximum operating temperature?

Up to 1,200°C (2,192°F). -

Is Cr30Ni70 wire corrosion-resistant?

Yes, it offers excellent oxidation and high-temperature corrosion resistance. -

Can it be bent or shaped for custom heating elements?

Yes, it has good ductility for forming and coiling. -

Is the wire compatible with welding or soldering?

Yes, it can be welded or joined using specialized techniques. -

What forms does DLX provide?

Coils, straight wires, and custom-cut lengths. -

What industries benefit most from this wire?

Industrial furnaces, aerospace heat treatment, automotive components, and laboratory heating equipment.