In high-temperature applications such as kilns and ceramic furnaces, materials must withstand extreme conditions while maintaining structural integrity. Cr20Ni30 Nichrome wire has emerged as a leading solution for these demanding applications. At DLX, we produce Cr20Ni30 Nichrome wire with precision and quality control, delivering a reliable material for kiln and ceramic support systems that ensures long-term performance and operational efficiency.

For more details, pls directly contact us.

Cr20Ni30 Nichrome wire consists of approximately 20% chromium and 30% nickel, with the balance being iron. This specific alloy composition provides high mechanical strength, excellent thermal resistance, and dimensional stability under continuous high-temperature use up to 1150°C. The wire also exhibits good oxidation resistance, which is crucial for prolonged exposure to the harsh conditions inside kilns and ceramic processing environments.

Its mechanical strength allows it to serve as reliable support structures in ceramic firing systems, holding up heavy loads without deforming under thermal stress. Additionally, Cr20Ni30 maintains stable properties through repeated thermal cycles, making it an ideal choice for industrial furnaces, heat treatment setups, and other high-temperature applications.

DLX supplies Cr20Ni30 Nichrome wire in customizable diameters, lengths, and spooled forms, giving manufacturers flexibility to design supports and heating elements that meet their exact specifications.

|

Performance / material |

Cr10Ni90 |

Cr20Ni80 |

Cr15Ni60 |

Cr20Ni30 |

|||

|

Composition |

Ni |

90 |

Rest |

Rest |

55.0~61.0 |

34.0~37.0 |

30.0~34.0 |

|

Cr |

10 |

20.0~23.0 |

28.0~31.0 |

15.0~18.0 |

18.0~21.0 |

18.0~21.0 |

|

|

Fe |

--

|

≤1.0 |

≤1.0 |

Rest |

Rest |

Rest |

|

|

Maximum temperature℃ |

1300 |

1200 |

1250 |

1150 |

1100 |

1100 |

|

|

Meltiing point ℃ |

1400 |

1400 |

1380 |

1390 |

1390 |

1390 |

|

|

Density g/cm3 |

8.7 |

8.4 |

8.1 |

8.2 |

7.9 |

7.9 |

|

|

Resistivity at 20℃ (μΩ·m) |

--

|

1.09±0.05 |

1.18±0.05 |

1.12±0.05 |

1.00±0.05 |

1.04±0.05 |

|

|

Elongation at rupture |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

|

|

Specific heat (J/g.℃) |

--

|

0.44 |

0.461 |

0.494 |

0.5 |

0.5 |

|

|

Thermal conductivity (KJ/m.h℃) |

--

|

60.3 |

45.2 |

45.2 |

43.8 |

43.8 |

|

|

Coefficient of lines expansion a×10-6/(20~1000℃) |

--

|

18 |

17 |

17 |

19 |

19 |

|

|

Micrographic structure |

--

|

Austenite |

Austenite |

Austenite |

Austenite |

Austenite |

|

|

Magnetic properties |

--

|

Non-magnetic |

Non-magnetic |

Non-magnetic |

Weak magnetic |

Weak magnetic |

|

|

Shape |

Size (mm) |

|

Wire |

0.05-7.5 |

|

Rod |

8-50 |

|

Ribbon |

(0.05-0.35)*(0.5-6.0) |

|

Strip |

(0.5-2.5)*(5-40) |

For more details, pls directly contact us.

The global ceramic and kiln manufacturing industries are expanding, driven by construction, industrial materials, and advanced manufacturing applications. High-strength alloys such as Cr20Ni30 Nichrome wire are critical to supporting this growth, as they provide reliable performance in systems that must operate continuously at elevated temperatures.

Kiln and ceramic support systems require materials that combine mechanical robustness with thermal stability. Traditional iron-based or lower-grade alloys often fail under long-term thermal cycling, leading to increased maintenance costs and downtime. Cr20Ni30 offers a solution by delivering both strength and oxidation resistance, reducing replacement frequency and improving operational efficiency.

Another trend is the demand for precision in industrial processes. Modern ceramic manufacturing, advanced material sintering, and laboratory furnace operations all require supports and heating systems that do not deform or compromise the product quality during operation. Cr20Ni30 Nichrome wire meets these needs by providing consistent thermal and mechanical performance.

Applications

-

Kiln Supports – Reliable wire supports for heavy ceramic loads.

-

Ceramic Furnaces – Structural components exposed to high temperatures.

-

Laboratory Furnaces – Heating and support systems for precision experiments.

-

Metallurgy – Supports and fixtures in high-temperature treatment processes.

-

Heat Treatment Systems – Stable structural elements in industrial furnaces.

Market Trends

Industries are increasingly focusing on long-term reliability and cost-effective operation. Materials that can withstand high temperatures without frequent replacement are essential for minimizing downtime. Cr20Ni30 Nichrome wire meets this market need by combining strength, durability, and oxidation resistance.

The growth in ceramics, advanced materials, and industrial furnace manufacturing drives the demand for high-performance alloy wires. Manufacturers require materials that can support high-temperature operations without compromising the quality of the products being processed. Additionally, customization in wire diameters, lengths, and spool configurations is becoming a standard requirement, which DLX is well-positioned to provide.

Comparison Table

| Property | Cr20Ni30 Nichrome Wire | Cr20Ni35 Nichrome Wire | Cr20Ni80 Nichrome Wire | Cr30Ni70 Nichrome Wire |

|---|---|---|---|---|

| Nickel Content (%) | 30 | 35 | 80 | 70 |

| Chromium Content (%) | 20 | 20 | 20 | 30 |

| Iron Content (%) | Balance | Balance | Trace | Trace |

| Max Operating Temp (°C) | 1150 | 1100 | 1250 | 1150 |

| Mechanical Strength | High | High | Medium | Medium-High |

| Oxidation Resistance | Good | Moderate | High | High |

| Applications | Kilns, ceramic supports | Precision resistors | Heating elements | Industrial annealing |

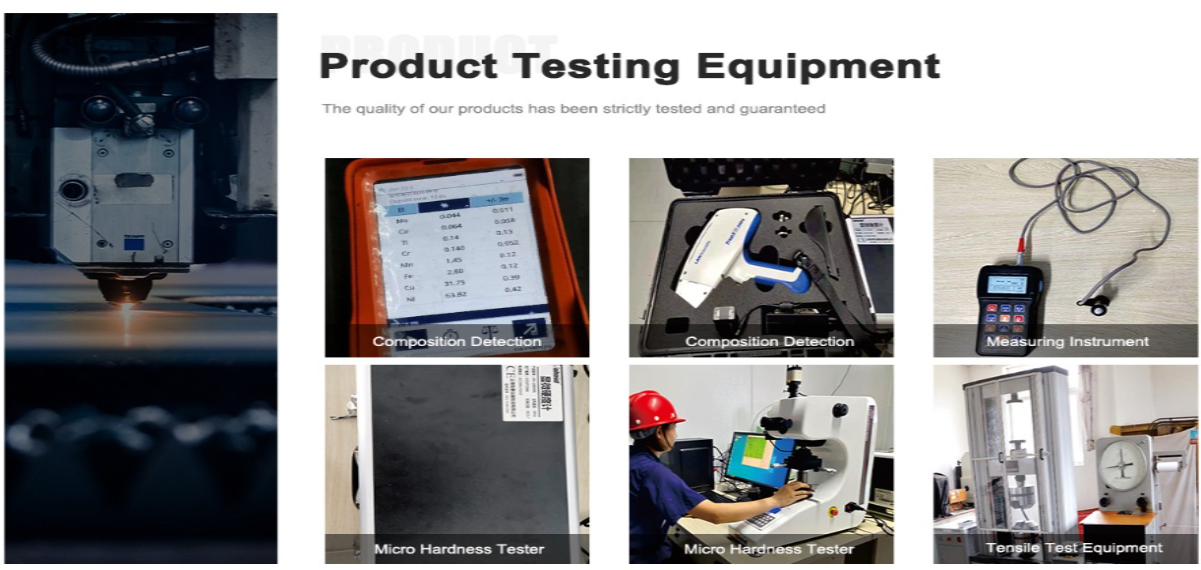

DLX stands out in supplying Cr20Ni30 Nichrome wire due to its focus on precision, quality, and customization. Every wire batch undergoes strict quality control, ensuring consistent composition, mechanical strength, and surface finish. This enables manufacturers to integrate the wire into high-temperature systems with confidence.

We offer a variety of diameters and spooled lengths to suit different kiln designs and ceramic support structures. Our technical team collaborates with clients to optimize wire dimensions and performance, ensuring minimal deformation and maximum efficiency during use.

Unlike general suppliers, DLX emphasizes customer-specific solutions. Whether the project requires a delicate laboratory furnace wire or heavy-duty kiln supports, we can tailor the Cr20Ni30 Nichrome wire to meet operational demands. The result is enhanced reliability, reduced maintenance, and consistent performance in high-temperature environments.

A Company-to-Company Comparison

While other suppliers may provide generic Nichrome wires, DLX focuses on high-strength and application-specific grades. Our Cr20Ni30 Nichrome wire is optimized for mechanical robustness in kiln and ceramic support applications, rather than just electrical or general heating purposes.

DLX’s combination of precise manufacturing, strict quality control, and customization support gives clients an advantage in both efficiency and operational reliability. Our expertise ensures that Cr20Ni30 wire performs consistently under high temperatures and mechanical stress, setting it apart from standard alloy wire options.

Cr20Ni30 Nichrome wire is an essential material for kiln and ceramic support systems, providing the strength, thermal resistance, and oxidation stability required in high-temperature industrial and laboratory applications. Its ability to maintain performance under repeated thermal cycles makes it a reliable choice for manufacturers and engineers seeking long-term operational efficiency.

DLX enhances these benefits by offering precision manufacturing, customization options, and expert technical support. With Cr20Ni30 Nichrome wire from DLX, clients receive not just a product but a reliable partner in achieving high-strength, high-performance kiln and ceramic systems.

By choosing DLX, industries gain confidence in consistent results, reduced maintenance, and a material solution that aligns with the evolving demands of modern high-temperature applications.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

-

What is the composition of Cr20Ni30 Nichrome wire?

20% chromium, 30% nickel, balance iron and trace elements. -

What is the maximum operating temperature?

Up to 1150°C for continuous use. -

Why is Cr20Ni30 suitable for kiln and ceramic support?

It offers high mechanical strength, dimensional stability, and thermal resistance. -

Can Cr20Ni30 wire be supplied in customized diameters and lengths?

Yes, DLX provides tailored spools and coils to meet specific project requirements. -

How does Cr20Ni30 compare to Cr20Ni80 Nichrome wire?

Cr20Ni30 has higher mechanical strength but lower oxidation resistance than Cr20Ni80. -

Is Cr20Ni30 resistant to oxidation and scaling?

Yes, it maintains good oxidation resistance under high-temperature environments. -

Which industries use Cr20Ni30 Nichrome wire?

Ceramics, metallurgy, kiln manufacturing, laboratory furnaces, and heat treatment systems. -

What are the benefits of choosing DLX for Cr20Ni30 Nichrome wire?

Precision manufacturing, consistent quality, customization, and technical support for high-temperature applications.