Nichrome alloys are recognized worldwide for their ability to withstand high temperatures, resist oxidation, and maintain stable electrical properties. Among these alloys, Cr20Ni35 stands out as a specialized grade tailored for precision resistor and circuit manufacturing. At DLX, we produce Cr20Ni35 Nichrome wire with exacting standards, offering a dependable solution for industries that demand accuracy and long-term performance.

For more details, pls directly contact us.

Cr20Ni35 Nichrome wire is composed of approximately 35% nickel, 20% chromium, and the balance iron. This balance creates a wire that is strong, durable, and capable of operating continuously at temperatures up to 1100°C. Unlike higher-nickel Nichrome grades, Cr20Ni35 provides a balance between mechanical strength and electrical stability, making it ideal for resistor applications where precision and repeatability are critical.

The alloy’s electrical resistivity is around 1.05 μΩ·m at 20°C. It maintains this resistivity with remarkable stability across a wide temperature range, ensuring consistent resistance values in precision resistor manufacturing. The wire can be drawn into fine gauges without sacrificing strength, and DLX supplies it on spools or coils to suit various production needs.

Performance / material | Cr10Ni90 | Cr20Ni80 | Cr15Ni60 | Cr20Ni35 | |||

Composition | Ni | 90 | Rest | Rest | 55.0~61.0 | 34.0~37.0 | 30.0~34.0 |

Cr | 10 | 20.0~23.0 | 28.0~31.0 | 15.0~18.0 | 18.0~21.0 | 18.0~21.0 | |

Fe | -- | ≤1.0 | ≤1.0 | Rest | Rest | Rest | |

Maximum temperature℃ | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 | |

Meltiing point ℃ | 1400 | 1400 | 1380 | 1390 | 1390 | 1390 | |

Density g/cm3 | 8.7 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

Resistivity at 20℃ (μΩ·m) | -- | 1.09±0.05 | 1.18±0.05 | 1.12±0.05 | 1.00±0.05 | 1.04±0.05 | |

Elongation at rupture | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

Specific heat (J/g.℃) | -- | 0.44 | 0.461 | 0.494 | 0.5 | 0.5 | |

Thermal conductivity (KJ/m.h℃) | -- | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

Coefficient of lines expansion a×10-6/(20~1000℃) | -- | 18 | 17 | 17 | 19 | 19 | |

Micrographic structure | -- | Austenite | Austenite | Austenite | Austenite | Austenite | |

Magnetic properties | -- | Non-magnetic | Non-magnetic | Non-magnetic | Weak magnetic | Weak magnetic | |

Shape | Size (mm) |

Wire | 0.05-7.5 |

Rod | 8-50 |

Ribbon | (0.05-0.35)*(0.5-6.0) |

Strip | (0.5-2.5)*(5-40) |

For more details, pls directly contact us.

The demand for precision resistors is growing as electronics and automation industries expand globally. With applications in consumer electronics, automotive control systems, aerospace, and medical instrumentation, the need for materials that deliver accurate and consistent resistance values is higher than ever.

Cr20Ni35 Nichrome wire fits perfectly into this market. It provides a stable resistivity profile, low temperature coefficient of resistance, and the durability to withstand mechanical processing. This makes it a reliable choice for resistor manufacturers who need consistency from batch to batch.

As industries pursue miniaturization and higher performance in electronics, the role of alloys like Cr20Ni35 becomes even more critical. The trend toward smaller, more efficient devices requires resistor wires that can maintain accuracy at fine diameters, and DLX’s manufacturing processes ensure this precision is achieved.

Applications

Precision Resistors – Stable resistance values under varying conditions.

Instrumentation – Used in sensors, control systems, and measurement devices.

Automotive Electronics – For circuit protection and stable current control.

Aerospace Electrical Systems – High reliability in demanding environments.

Industrial Electronics – Load resistors and current control applications.

Laboratory Devices – Used in controlled heating and circuit testing equipment.

Market Trends

Electronics manufacturing is shifting toward greater accuracy, efficiency, and long-term reliability. Precision resistors are central to this shift, and Cr20Ni35 Nichrome wire is playing a key role. The growth of electric vehicles, renewable energy, and smart devices has further fueled demand for resistor alloys that are dependable and cost-effective.

Sustainability is another emerging trend. Manufacturers are under pressure to produce longer-lasting components that minimize waste and extend product life cycles. Cr20Ni35, with its strength and resistance stability, contributes directly to these goals by offering durable performance.

Customization is also increasingly important. Many clients now request wires with specific diameters, resistance values, or spool sizes. At DLX, we respond to this demand with flexible production capabilities that allow us to meet a wide range of specifications.

Comparison Table

| Property | Cr20Ni35 Nichrome Wire | Cr20Ni80 Nichrome Wire | Cr15Ni60 Nichrome Wire | Cr30Ni70 Nichrome Wire |

|---|---|---|---|---|

| Nickel Content (%) | 35 | 80 | 60 | 70 |

| Chromium Content (%) | 20 | 20 | 15 | 30 |

| Iron Content (%) | Balance | Trace | Balance | Trace |

| Max Operating Temp (°C) | 1100 | 1250 | 1200 | 1150 |

| Electrical Resistivity | ~1.05 μΩ·m | ~1.09 μΩ·m | ~1.10 μΩ·m | ~1.08 μΩ·m |

| Oxidation Resistance | Moderate | High | Excellent | High |

| Mechanical Strength | High | Medium | High | Medium-High |

| Applications | Precision resistors, circuits | Heating coils, furnaces | Marine, heating coils | Heat treatment, annealing |

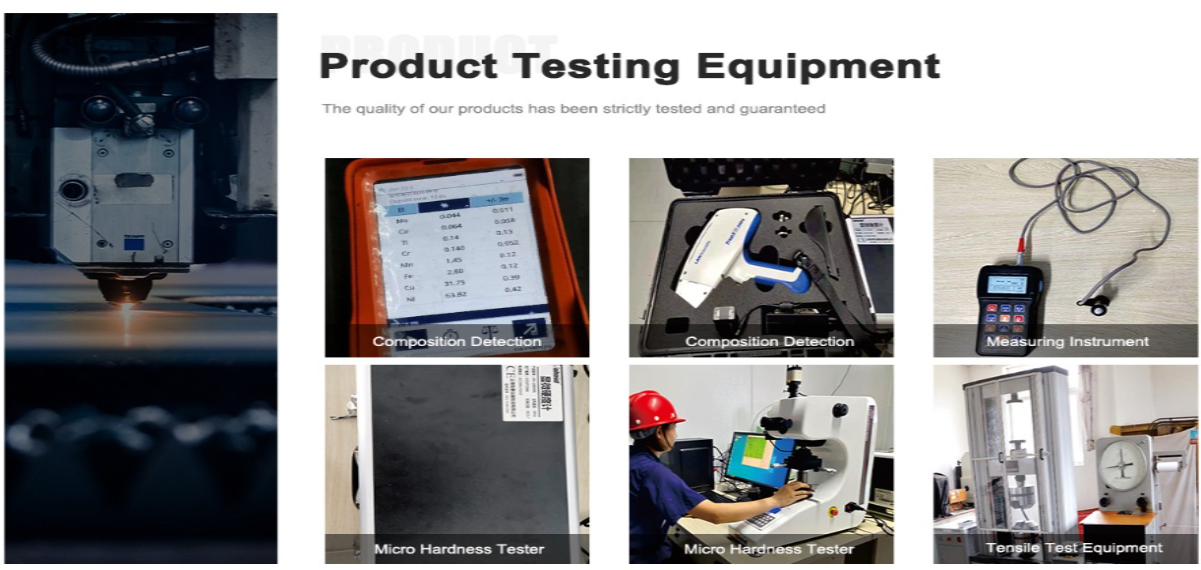

At DLX, we approach the production of Cr20Ni35 Nichrome wire with a focus on quality, customization, and customer partnership. Our advanced manufacturing processes ensure tight control of chemical composition and mechanical properties, guaranteeing that every batch meets international standards.

We understand that precision resistor manufacturing requires consistency. That’s why we provide detailed testing of each production run, including resistivity, tensile strength, and surface quality. This allows our customers to integrate our wire directly into their production lines without concerns about variability.

DLX also offers flexibility in supply. Whether clients require fine-gauge wire for miniature resistors or heavier spools for industrial electronics, we can adjust production to meet those needs. Our packaging solutions further enhance usability, making it easy for manufacturers to integrate our wire into automated processes.

Another strength is our consultative approach. We work closely with engineers and procurement teams to align material properties with end-product requirements. By doing so, we help clients optimize their designs and reduce material waste.

A Company-to-Company Comparison

While many suppliers offer general-purpose Nichrome wires, DLX distinguishes itself through specialization. Our expertise in alloys like Cr20Ni35 allows us to deliver solutions tailored to resistor manufacturing rather than generic heating applications.

Other suppliers may provide a wide mix of materials, but DLX focuses on performance consistency, technical support, and quality assurance. This dedication means that our clients gain more than just a wire—they gain a reliable partner in achieving accurate and long-lasting electrical components.

Cr20Ni35 Nichrome wire represents a perfect balance of strength, stability, and precision for resistor manufacturing. Its reliable resistivity, ability to withstand high temperatures, and ease of processing make it indispensable in electronics, automotive, aerospace, and instrumentation applications.

At DLX, we enhance these natural advantages with strict quality control, flexible supply formats, and a strong focus on customer collaboration. As industries continue to demand accuracy and durability from their resistor components, DLX is committed to being a trusted supplier of Cr20Ni35 Nichrome wire that delivers both performance and value.

By choosing DLX, manufacturers gain access to a product—and a partner—that ensures precision resistor production can keep pace with today’s rapidly evolving technological landscape.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What is the composition of Cr20Ni35 Nichrome wire?

20% chromium and 35% nickel, with balance iron and trace elements.What is the main application of Cr20Ni35?

Manufacturing precision resistors and circuit components.What is the maximum operating temperature?

Up to 1100°C in continuous service.Why is Cr20Ni35 suitable for resistors?

It has stable resistivity, low temperature coefficient, and good processability.How does Cr20Ni35 compare to Cr20Ni80?

Cr20Ni35 offers better mechanical strength but lower oxidation resistance and max temperature range.Can it be supplied in wire coils or spools?

Yes, DLX offers customized packaging for production efficiency.Is Cr20Ni35 resistant to corrosion?

It has moderate corrosion resistance, suitable for controlled environments.What industries benefit from Cr20Ni35 Nichrome wire?

Electronics, instrumentation, automotive, and aerospace electrical systems.