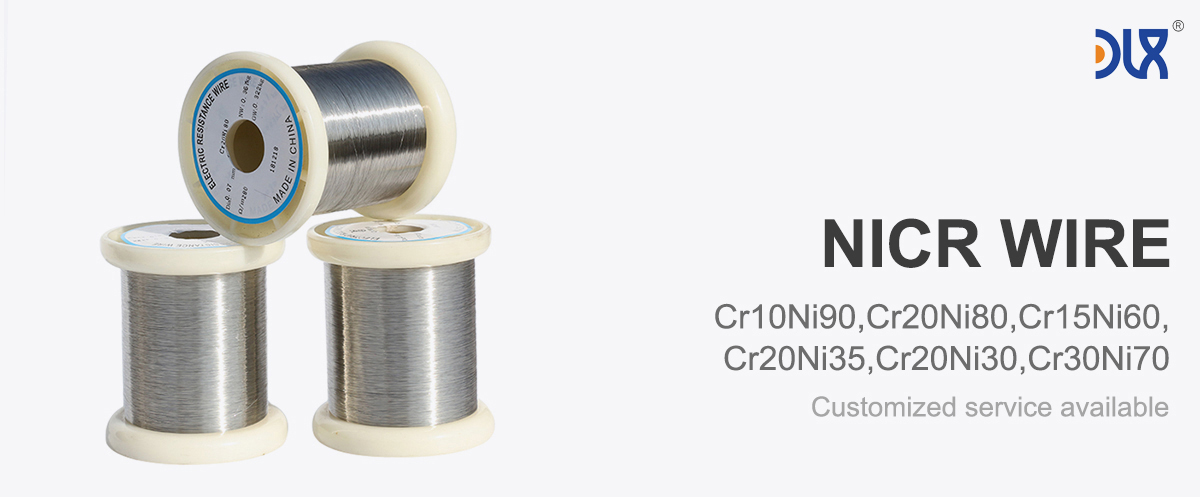

In industries where precision heating, stable resistance, and durability under high temperatures are essential, Cr20Ni80 Nichrome wire has established itself as a go-to material. Its high nickel content combined with chromium makes it one of the most stable heating alloys available today. At DLX, we specialize in producing Cr20Ni80 Nichrome wire spools designed for custom heating element applications, ensuring that every client gets a solution tailored to their exact requirements.

For more details, pls directly contact us.

Cr20Ni80 consists of approximately 80% nickel and 20% chromium. This composition gives the wire a unique balance of properties: outstanding electrical stability, excellent resistance to oxidation, and the ability to perform at temperatures up to 1250°C. With an electrical resistivity of about 1.09 μΩ·m at room temperature, it offers precise heating performance, making it ideal for designing heating elements of varying shapes and capacities.

Supplied on spools, our Cr20Ni80 Nichrome wire is easy to handle, transport, and integrate into custom heating systems. The spool format allows engineers and manufacturers to cut and wind the wire according to their exact design needs, whether that’s for large-scale industrial furnaces or compact electronic devices.

|

Performance / material |

Cr20Ni80 |

Cr30Ni70 |

Cr20Ni35 |

Cr20Ni30 |

|||

|

Composition |

Ni |

90 |

Rest |

Rest |

55.0~61.0 |

34.0~37.0 |

30.0~34.0 |

|

Cr |

10 |

20.0~23.0 |

28.0~31.0 |

15.0~18.0 |

18.0~21.0 |

18.0~21.0 |

|

|

Fe |

--

|

≤1.0 |

≤1.0 |

Rest |

Rest |

Rest |

|

|

Maximum temperature℃ |

1300 |

1200 |

1250 |

1150 |

1100 |

1100 |

|

|

Meltiing point ℃ |

1400 |

1400 |

1380 |

1390 |

1390 |

1390 |

|

|

Density g/cm3 |

8.7 |

8.4 |

8.1 |

8.2 |

7.9 |

7.9 |

|

|

Resistivity at 20℃ (μΩ·m) |

--

|

1.09±0.05 |

1.18±0.05 |

1.12±0.05 |

1.00±0.05 |

1.04±0.05 |

|

|

Elongation at rupture |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

|

|

Specific heat (J/g.℃) |

--

|

0.44 |

0.461 |

0.494 |

0.5 |

0.5 |

|

|

Thermal conductivity (KJ/m.h℃) |

--

|

60.3 |

45.2 |

45.2 |

43.8 |

43.8 |

|

|

Coefficient of lines expansion a×10-6/(20~1000℃) |

--

|

18 |

17 |

17 |

19 |

19 |

|

|

Micrographic structure |

--

|

Austenite |

Austenite |

Austenite |

Austenite |

Austenite |

|

|

Magnetic properties |

--

|

Non-magnetic |

Non-magnetic |

Non-magnetic |

Weak magnetic |

Weak magnetic |

|

|

Shape |

Size (mm) |

|

Wire |

0.05-7.5 |

|

Rod |

8-50 |

|

Ribbon |

(0.05-0.35)*(0.5-6.0) |

|

Strip |

(0.5-2.5)*(5-40) |

For more details, pls directly contact us.

The global heating element market is expanding rapidly, fueled by industries ranging from household appliances to advanced manufacturing. With growing demand for energy efficiency and reliability, materials like Cr20Ni80 Nichrome wire are becoming increasingly critical.

Appliance manufacturers depend on this wire for components in toasters, dryers, ovens, and electric stoves. Laboratories rely on it for precise heating systems in furnaces and analytical devices. Meanwhile, industrial sectors such as metallurgy, ceramics, and glass processing need Cr20Ni80 for its ability to withstand repeated thermal cycling without performance degradation.

Another driver is customization. The shift toward specialized applications, including medical devices and renewable energy systems, has increased demand for wire supplied on spools that can be easily configured. This flexibility makes Cr20Ni80 especially attractive in markets where design versatility is a competitive advantage.

Applications

-

Household Appliances – Heating coils in ovens, toasters, and dryers.

-

Industrial Furnaces – Coiled or straight elements for continuous high-temperature operation.

-

Laboratory Equipment – Precise heating elements for kilns, furnaces, and controlled experiments.

-

Resistors and Load Banks – Stable resistivity makes it suitable for precision resistors.

-

Medical Equipment – Applied in sterilization devices and heating systems requiring stable output.

-

Renewable Energy Systems – Used in specialized heating for battery testing and energy storage applications.

Market Trends

The growth of energy-efficient heating solutions is pushing innovation in heating wire design. Clients now require materials that not only perform under high temperatures but also contribute to longer product life cycles and reduced maintenance. Cr20Ni80 fits these needs, offering stability and reliability over thousands of heating cycles.

Additionally, sustainability goals are influencing material choices. Many industries seek alloys that reduce downtime, minimize waste, and enhance operational efficiency. Nichrome wires like Cr20Ni80 align perfectly with these objectives, as they provide long-lasting performance without frequent replacement.

Another trend is the growing reliance on digital and automated manufacturing. As more companies adopt custom-designed heating systems, the demand for spooled Nichrome wire that can be precisely wound and integrated into automated assembly lines is rising.

Comparison Table

| Property | Cr20Ni80 Nichrome Wire | Cr15Ni60 Nichrome Wire | Cr20Ni35 Nichrome Wire | Cr30Ni70 Nichrome Wire |

|---|---|---|---|---|

| Nickel Content (%) | 80 | 60 | 35 | 70 |

| Chromium Content (%) | 20 | 15 | 20 | 30 |

| Max Operating Temp (°C) | 1250 | 1200 | 1100 | 1150 |

| Electrical Resistivity | 1.09 μΩ·m | 1.1 μΩ·m | 1.05 μΩ·m | 1.08 μΩ·m |

| Corrosion Resistance | High | Excellent (marine-grade) | Moderate | High |

| Mechanical Strength | Medium | High | High | Medium-High |

| Applications | Heating coils, furnaces | Marine, chemical, coils | Resistors, circuits | Heat treatment, annealing |

At DLX, we understand that clients often face challenges when sourcing heating materials that meet exact specifications. That’s why we emphasize flexibility in our production process. Our Cr20Ni80 Nichrome wire spools are available in a wide range of diameters and spool sizes, allowing us to cater to everything from large industrial projects to compact electronic applications.

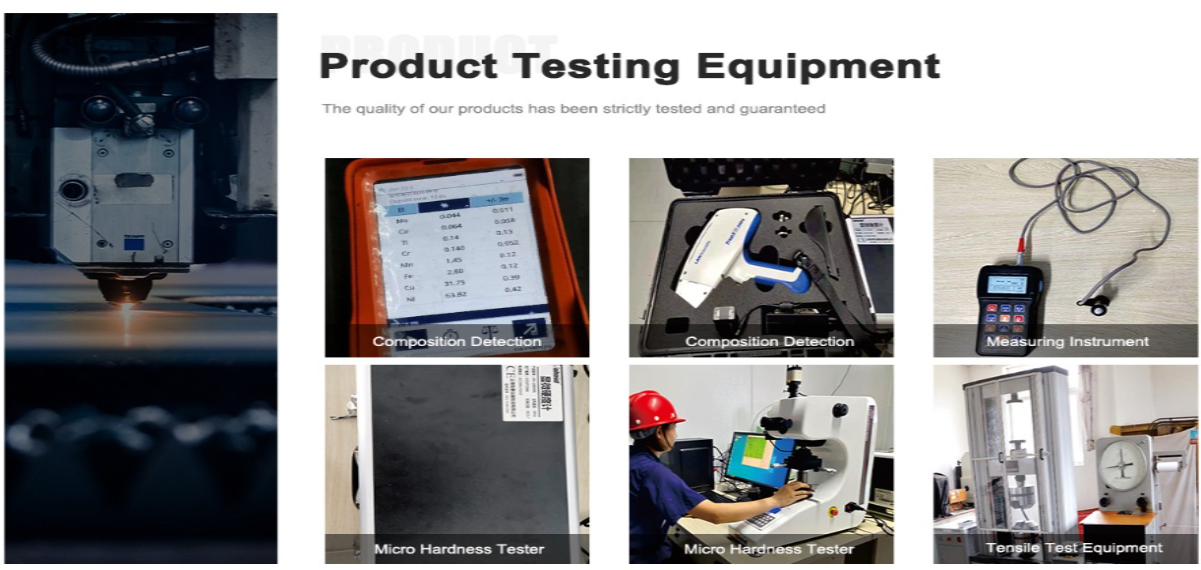

We take quality control seriously. Every spool is tested for resistivity, mechanical strength, and surface finish to ensure consistent performance. By maintaining strict production standards, we give our clients confidence that their heating elements will perform reliably under demanding conditions.

Another advantage lies in our customer support. We work closely with engineers and designers to understand their project needs, offering technical advice and customized solutions. This consultative approach helps our clients optimize their heating systems while reducing costs associated with trial-and-error design.

A Company-to-Company Comparison

While some suppliers may offer general-purpose Nichrome wires, DLX focuses on delivering tailored solutions. Our specialization in providing Cr20Ni80 on spools ensures ease of handling, efficiency in production, and precise customization for heating element design.

What sets us apart is our ability to adapt. Whether the requirement is for a high-resistivity wire for lab equipment or heavy-duty coils for an industrial furnace, we can adjust specifications to meet performance goals. By choosing DLX, clients benefit from a supplier that not only provides the wire but also actively supports innovation and application development.

Cr20Ni80 Nichrome wire remains one of the most reliable materials for custom heating element designs. Its stability, oxidation resistance, and ability to withstand high temperatures make it a cornerstone in industries ranging from household appliances to advanced laboratory equipment.

At DLX, we ensure that every spool of Cr20Ni80 Nichrome wire delivers quality, precision, and adaptability. As the global demand for efficient heating solutions grows, our focus on customization and customer partnership positions us as a trusted supplier for clients worldwide. By working with DLX, industries gain more than just a product—they gain a partner dedicated to helping them succeed in creating heating systems that perform at the highest level.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

-

What is the composition of Cr20Ni80 Nichrome wire?

20% chromium, 80% nickel. -

What is the maximum operating temperature?

Up to 1250°C. -

Why is Cr20Ni80 popular for heating elements?

It has stable resistivity, oxidation resistance, and long service life. -

Can it be supplied on spools for custom designs?

Yes, DLX provides wire on spools in customized lengths and diameters. -

What electrical resistivity does it have?

About 1.09 μΩ·m at 20°C. -

What industries typically use Cr20Ni80 Nichrome wire?

Electronics, household appliances, laboratory heating, and industrial furnaces. -

How does Cr20Ni80 differ from Cr15Ni60 Nichrome wire?

Cr20Ni80 has higher nickel content, better stability at high temperatures, but slightly less mechanical strength. -

Is Cr20Ni80 suitable for precision resistor manufacturing?

Yes, it is widely used for resistors and precision electrical applications.