When it comes to demanding environments where both strength and corrosion resistance are critical, Cr15Ni60 Nichrome wire stands out as a trusted material. Known for its unique combination of high nickel and chromium, this alloy has earned its place across industries that operate under extreme heat, corrosive environments, and continuous stress. At DLX, we take pride in manufacturing Cr15Ni60 Nichrome wire that not only meets but often exceeds industry expectations.

For more details, pls directly contact us.

Cr15Ni60 is composed of approximately 60% nickel and 15% chromium, with the remainder being iron and minor stabilizing elements. This specific balance gives the wire its dual advantages: superior resistance to oxidation at elevated temperatures and remarkable stability against marine corrosion. Unlike standard resistance wires, Cr15Ni60 is tailored for durability in aggressive conditions where seawater, humidity, and chemical exposure often lead to premature failures.

Its electrical resistivity, around 1.1 μΩ·m at room temperature, makes it highly suitable for heating elements, resistors, and specialized circuits. More importantly, it maintains consistent performance at operating temperatures reaching up to 1200°C, making it versatile across industries that demand reliable long-term heating.

|

Performance / material |

Cr10Ni90 |

Cr30Ni70 |

Cr15Ni60 |

Cr20Ni35 |

|||

|

Composition |

Ni |

90 |

Rest |

Rest |

55.0~61.0 |

34.0~37.0 |

30.0~34.0 |

|

Cr |

10 |

20.0~23.0 |

28.0~31.0 |

15.0~18.0 |

18.0~21.0 |

18.0~21.0 |

|

|

Fe |

--

|

≤1.0 |

≤1.0 |

Rest |

Rest |

Rest |

|

|

Maximum temperature℃ |

1300 |

1200 |

1250 |

1150 |

1100 |

1100 |

|

|

Meltiing point ℃ |

1400 |

1400 |

1380 |

1390 |

1390 |

1390 |

|

|

Density g/cm3 |

8.7 |

8.4 |

8.1 |

8.2 |

7.9 |

7.9 |

|

|

Resistivity at 20℃ (μΩ·m) |

--

|

1.09±0.05 |

1.18±0.05 |

1.12±0.05 |

1.00±0.05 |

1.04±0.05 |

|

|

Elongation at rupture |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

|

|

Specific heat (J/g.℃) |

--

|

0.44 |

0.461 |

0.494 |

0.5 |

0.5 |

|

|

Thermal conductivity (KJ/m.h℃) |

--

|

60.3 |

45.2 |

45.2 |

43.8 |

43.8 |

|

|

Coefficient of lines expansion a×10-6/(20~1000℃) |

--

|

18 |

17 |

17 |

19 |

19 |

|

|

Micrographic structure |

--

|

Austenite |

Austenite |

Austenite |

Austenite |

Austenite |

|

|

Magnetic properties |

--

|

Non-magnetic |

Non-magnetic |

Non-magnetic |

Weak magnetic |

Weak magnetic |

|

|

Shape |

Size (mm) |

|

Wire |

0.05-7.5 |

|

Rod |

8-50 |

|

Ribbon |

(0.05-0.35)*(0.5-6.0) |

|

Strip |

(0.5-2.5)*(5-40) |

For more details, pls directly contact us.

The global demand for corrosion-resistant alloys has surged due to the expansion of marine industries, offshore energy exploration, and chemical processing. Nichrome alloys, particularly Cr15Ni60, are at the forefront of this growth. This is largely because industries now prioritize longevity and reduced maintenance costs, which are only achievable through materials with superior mechanical and environmental stability.

In marine applications, traditional metals often fail due to chloride-induced stress corrosion cracking. Cr15Ni60 has proven to be more resilient, reducing downtime for shipbuilders, desalination plants, and coastal power facilities. In addition, the energy sector relies on these alloys for heaters in oil refineries and chemical plants, where stable resistivity and corrosion protection are vital.

Furthermore, the rise of electric heating systems in laboratories and manufacturing facilities highlights another growth sector. Consistent resistivity, coupled with the ability to handle repeated heating and cooling cycles, ensures Cr15Ni60 remains a material of choice.

Applications

-

Marine Engineering – Used in heaters, pumps, and components exposed to seawater.

-

Electrical Heating Elements – Found in toasters, furnaces, dryers, and industrial heating units.

-

Chemical Processing Equipment – For heating coils that face acidic or alkaline environments.

-

Laboratory Equipment – Provides stable heating for controlled experimental setups.

-

Resistors and Circuitry – Utilized in precision resistors and load banks requiring stable performance.

Market Trends

The demand for high-performance alloys like Cr15Ni60 is expected to grow as industries transition toward more sustainable and energy-efficient processes. Offshore renewable energy projects, such as tidal and wind power, are creating new use cases for marine-grade alloys. At the same time, laboratory and industrial heating markets continue to expand, driven by advancements in electronics, renewable energy, and materials science.

Another key trend is customization. End-users increasingly seek specific wire diameters, coil shapes, and surface treatments to optimize performance for unique applications. As a result, suppliers with flexible production capabilities have a competitive edge.

Comparison Table

| Property | Cr15Ni60 Nichrome Wire | Cr20Ni80 Nichrome Wire | Cr20Ni35 Nichrome Wire | Cr10Ni90 Nichrome Wire |

|---|---|---|---|---|

| Nickel Content (%) | 60 | 80 | 35 | 90 |

| Chromium Content (%) | 15 | 20 | 20 | 10 |

| Max Operating Temp (°C) | 1200 | 1250 | 1100 | 1250 |

| Corrosion Resistance | Excellent (marine-grade) | Very High | Moderate | High |

| Mechanical Strength | High | Medium | High | Medium |

| Applications | Marine, chemical, coils | Furnaces, kilns, coils | Resistors, circuits | Labs, heating systems |

At DLX, we recognize that no two clients’ needs are the same. Our ability to offer tailor-made Cr15Ni60 Nichrome wire solutions sets us apart. We work closely with customers to deliver the exact diameter, resistance values, and spool sizes required for their applications.

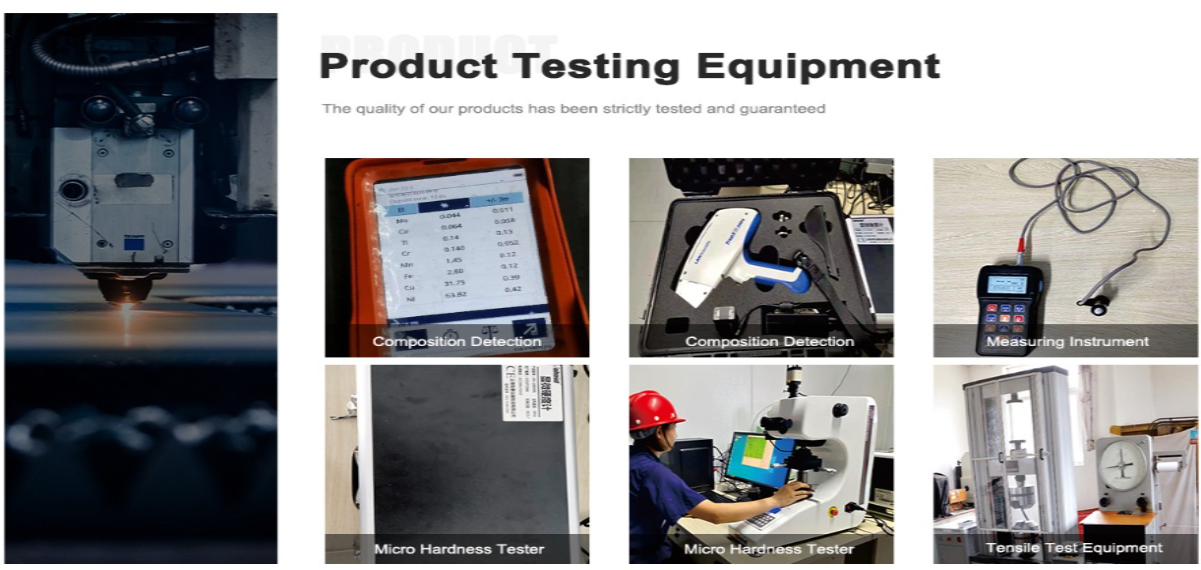

Our production process emphasizes precision and consistency. Every batch of wire undergoes strict quality control, including chemical composition verification, resistivity testing, and mechanical strength evaluation. This ensures that our clients receive products they can rely on, even in the most demanding environments.

What makes DLX stand out is not just the quality of our wire but also the way we integrate customer feedback into product innovation. We understand that marine industries demand wire that resists pitting corrosion, while laboratories prioritize stable resistivity. By tailoring solutions, we enable clients to maximize efficiency and minimize maintenance costs.

While some suppliers focus on standard-grade nichrome wires, DLX dedicates resources to ensuring marine-grade corrosion resistance. This means our Cr15Ni60 Nichrome wire is not only strong but also capable of enduring harsh seawater and humid conditions without significant degradation.

We also provide unmatched after-sales support. Our technical experts assist clients in designing custom heating systems, choosing the right wire gauges, and planning for long-term performance. This level of engagement ensures clients don’t just buy a product but invest in a solution that directly supports their operational goals.

Conclusion

Cr15Ni60 Nichrome wire continues to play a critical role in industries where heat, corrosion, and mechanical stress converge. From marine engineering to laboratory heating, its versatility and durability make it indispensable. With global industries pushing toward efficiency and sustainability, the importance of reliable materials like Cr15Ni60 has never been higher.

At DLX, our commitment to quality, customization, and customer satisfaction ensures that we remain a trusted partner in this evolving market. By choosing DLX, clients gain not just a supplier but a long-term ally in achieving excellence across their heating and corrosion-resistant applications.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

-

What is the main composition of Cr15Ni60 Nichrome wire?

Nickel 60%, Chromium 15%, balance Iron and minor elements. -

What industries typically use Cr15Ni60 Nichrome wire?

Marine, chemical processing, electrical heating, and aerospace. -

What temperature can Cr15Ni60 Nichrome wire withstand?

Up to 1200°C in continuous operation. -

Why is Cr15Ni60 preferred for marine applications?

It offers excellent corrosion resistance against seawater and humid environments. -

Can this wire be customized in different diameters?

Yes, DLX offers tailored diameters and spool lengths based on project needs. -

How does Cr15Ni60 differ from Cr20Ni80 Nichrome wire?

Cr15Ni60 provides better mechanical strength and corrosion resistance, while Cr20Ni80 has higher temperature stability. -

What electrical resistivity does Cr15Ni60 Nichrome wire have?

Around 1.1 μΩ·m at 20°C. -

Is Cr15Ni60 suitable for resistor and heating coil manufacturing?

Yes, it is widely used for resistors, heating elements, and laboratory heating systems.