Our Cr20Ni80 Nichrome wire is the top pick for high-temperature industrial heating elements that need to perform under pressure. This nickel-chromium alloy, with 20% chromium and 80% nickel, is built to handle scorching temperatures up to 2192°F (1200°C) without breaking a sweat. Its high electrical resistivity makes it perfect for generating consistent heat, while its oxidation resistance keeps it from degrading in harsh environments. Whether you’re designing furnaces, ovens, or custom heating systems, our Cr20Ni80 wire comes in diameters from 0.01″ to 0.2″, tailored to your exact specs. It’s formable, weldable, and ready to deliver reliable performance.

The industrial heating market is on fire, driven by growing demand in aerospace, chemical processing, and metallurgy. As industries push for equipment that can handle higher temperatures and tougher conditions, materials like Cr20Ni80 Nichrome wire are in high demand. The global market for heating elements is expanding, with a focus on energy efficiency and durability to reduce downtime and maintenance costs. Nichrome’s ability to withstand extreme heat and corrosion makes it a go-to for modern industrial applications. With sustainability and performance at the forefront, our Cr20Ni80 wire is perfectly positioned to meet the needs of today’s high-tech industries.

Applications

Our Cr20Ni80 Nichrome wire shines in a range of high-temperature applications. In aerospace, it’s used in heating elements for jet engine testing and component processing, where consistent heat and durability are critical. Chemical processing plants rely on it for reactors and furnaces exposed to corrosive gases. Metallurgy uses it in heat treatment furnaces and annealing systems, where its oxidation resistance ensures long-term performance. It’s also a staple in appliance manufacturing for toasters, ovens, and industrial dryers, delivering reliable heat in compact designs. From heavy industry to precision applications, our Nichrome wire keeps things hot and steady.

Comparison Table

|

Parameter |

Cr20Ni80 Nichrome Wire |

Copper Wire |

|---|---|---|

|

Max Service Temperature |

2192°F (1200°C) |

500°F (260°C) |

|

Corrosion Resistance |

Excellent in oxidizing environments |

Moderate, prone to oxidation |

|

Tensile Strength |

~650 MPa, stable at high temps |

~210 MPa, weakens significantly at high temps |

|

Oxidation Resistance |

Outstanding, forms protective oxide layer |

Poor, oxidizes quickly at elevated temps |

|

Electrical Resistivity |

High (~1.09 µΩ·m), ideal for heating |

Low (~0.017 µΩ·m), less suited for heating |

|

Formability |

Excellent, easily shaped for custom designs |

Good, but softer and less durable |

|

Cost |

Moderate, long-term savings |

Lower, but higher maintenance costs |

|

Applications |

Industrial furnaces, appliances, aerospace |

General electrical, low-heat applications |

We set the standard for Cr20Ni80 Nichrome wire in industrial heating applications. Our state-of-the-art manufacturing ensures every spool meets strict quality standards, delivering consistent performance every time. We offer unmatched customization, with a range of diameters and lengths to fit your specific heating element designs. Our wire is optimized for formability and weldability, making fabrication a breeze and saving you time on the production line. Unlike others, we prioritize durability, producing wire that resists oxidation and corrosion to minimize maintenance costs. With our robust supply chain and fast delivery, we keep your projects on track, no matter the scale.

|

Performance / material |

Cr10Ni90 |

Cr20Ni80 |

Cr30Ni70 |

Cr20Ni30 |

|||

|

Composition |

Ni |

90 |

Rest |

Rest |

55.0~61.0 |

34.0~37.0 |

30.0~34.0 |

|

Cr |

10 |

20.0~23.0 |

28.0~31.0 |

15.0~18.0 |

18.0~21.0 |

18.0~21.0 |

|

|

Fe |

--

|

≤1.0 |

≤1.0 |

Rest |

Rest |

Rest |

|

|

Maximum temperature℃ |

1300 |

1200 |

1250 |

1150 |

1100 |

1100 |

|

|

Meltiing point ℃ |

1400 |

1400 |

1380 |

1390 |

1390 |

1390 |

|

|

Density g/cm3 |

8.7 |

8.4 |

8.1 |

8.2 |

7.9 |

7.9 |

|

|

Resistivity at 20℃ (μΩ·m) |

--

|

1.09±0.05 |

1.18±0.05 |

1.12±0.05 |

1.00±0.05 |

1.04±0.05 |

|

|

Elongation at rupture |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

|

|

Specific heat (J/g.℃) |

--

|

0.44 |

0.461 |

0.494 |

0.5 |

0.5 |

|

|

Thermal conductivity (KJ/m.h℃) |

--

|

60.3 |

45.2 |

45.2 |

43.8 |

43.8 |

|

|

Coefficient of lines expansion a×10-6/(20~1000℃) |

--

|

18 |

17 |

17 |

19 |

19 |

|

|

Micrographic structure |

--

|

Austenite |

Austenite |

Austenite |

Austenite |

Austenite |

|

|

Magnetic properties |

--

|

Non-magnetic |

Non-magnetic |

Non-magnetic |

Weak magnetic |

Weak magnetic |

|

|

Shape |

Size (mm) |

|

Wire |

0.05-7.5 |

|

Rod |

8-50 |

|

Ribbon |

(0.05-0.35)*(0.5-6.0) |

|

Strip |

(0.5-2.5)*(5-40) |

For more details, pls directly contact us.

Our Cr20Ni80 Nichrome wire is built to power industrial heating elements through the toughest conditions. With its high-temperature strength, corrosion resistance, and reliable electrical performance, it’s the perfect choice for furnaces, reactors, and appliances. Whether you’re in aerospace, chemical processing, or metallurgy, our wire delivers the heat and durability you need. Backed by our commitment to quality, customization, and timely delivery, we’re here to help you build heating systems that stand the test of time. Choose our Cr20Ni80 Nichrome wire for solutions that keep the heat on and the downtime off.

About Us:

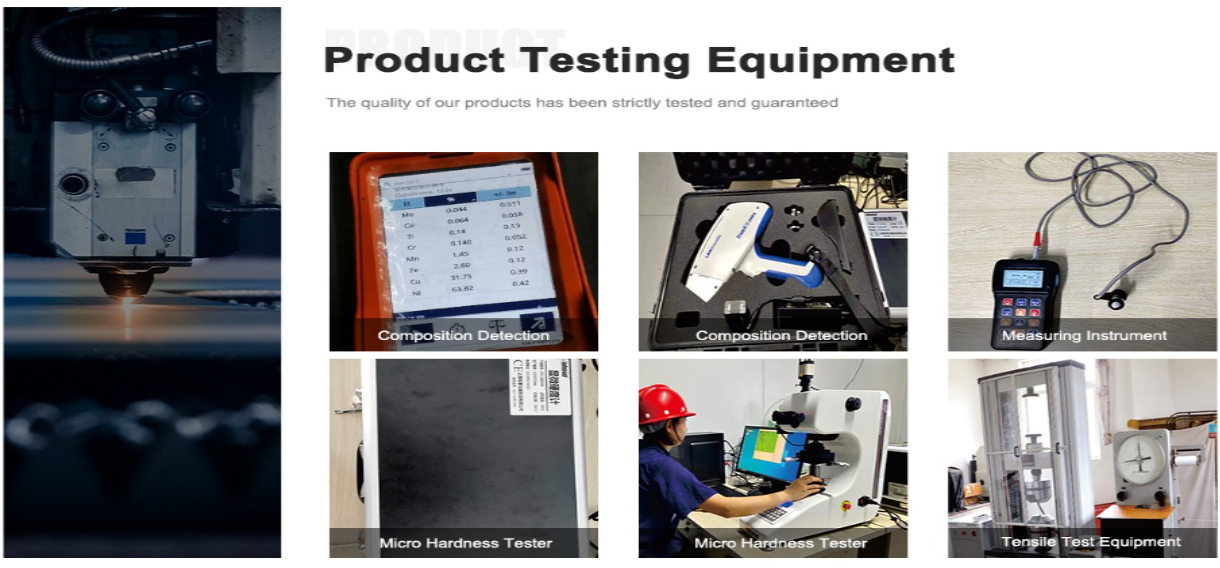

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What makes Cr20Ni80 Nichrome wire ideal for industrial heating elements?

Its high nickel content ensures excellent resistance to oxidation and corrosion, with stable performance up to 2192°F (1200°C). -

What industries use Cr20Ni80 Nichrome wire?

It’s widely used in aerospace, chemical processing, metallurgy, and appliance manufacturing for heating elements. -

How does Cr20Ni80 handle high temperatures?

It maintains strength and resists scaling at temperatures up to 2192°F (1200°C), perfect for extreme heat applications. -

Is Cr20Ni80 Nichrome wire corrosion-resistant?

Yes, it offers superior resistance to oxidation and chemical corrosion, even in harsh industrial environments. -

Can Cr20Ni80 Nichrome wire be easily shaped or welded?

It’s highly formable and weldable using standard techniques, making it ideal for custom heating element designs. -

How does Cr20Ni80 compare to copper for heating elements?

Cr20Ni80 outperforms copper with better high-temperature stability and corrosion resistance in industrial settings. -

What sizes are available for Cr20Ni80 Nichrome wire?

We offer diameters from 0.01″ to 0.2″, customizable to suit specific heating element requirements. -

Is Cr20Ni80 Nichrome wire cost-effective for industrial use?

Its durability and low maintenance in high-heat conditions make it a cost-effective choice despite a higher initial cost.