CuNi1 wire, a copper-nickel alloy with about 1% nickel, is one of our flagship products designed for low-voltage electrical applications. Known for its low resistivity and excellent stability, this alloy shines in environments where precision and reliability are non-negotiable. It’s got a knack for handling temperatures up to 200°C without breaking a sweat, making it a go-to for low-voltage circuit breakers, thermal overload relays, and even electric blankets. Our CuNi1 wire is crafted with top-notch consistency, ensuring every strand delivers predictable performance for your critical systems. Plus, it’s corrosion-resistant and easy to work with, whether you’re soldering or welding it into place.

The copper-nickel wire market is buzzing, with demand spiking thanks to growing needs in electrical, automotive, and marine industries. By 2034, the copper alloy wire market is expected to hit USD 25.85 billion, driven by urbanization and infrastructure projects. CuNi1, in particular, is carving out a niche in low-voltage applications due to its affordability and performance balance. Trends show a shift toward lightweight, corrosion-resistant materials in industries like construction and electronics, where our wire fits like a glove. Sustainability is also a big deal—our production process minimizes waste, aligning with the industry’s push for greener solutions.

|

Properties Material |

Resistivity 200c μΩ.m |

Max working temperature (℃) |

Tensile strength (Mpa) |

Melting point (℃) |

Density (g/cm3) |

TCR *10-6/℃ (20-600℃) |

EMF vs Cu (μV/℃) (0-100℃) |

|

CuNi1 |

0.03 |

200 |

210 |

1085 |

8.9 |

<100 |

-8 |

|

CuNi2 |

0.05 |

200 |

220 |

1090 |

8.9 |

<120 |

-12 |

|

CuNi6 |

0.1 |

220 |

250 |

1095 |

8.9 |

<60 |

-18 |

|

CuNi8 |

0.12 |

250 |

270 |

1097 |

8.9 |

<57 |

-22 |

|

0.15 |

250 |

290 |

1100 |

8.9 |

<50 |

-25 |

|

|

0.2 |

300 |

310 |

1115 |

8.9 |

<30 |

-28 |

|

|

CuNi19 |

0.25 |

300 |

340 |

1135 |

8.9 |

<25 |

-32 |

|

CuNi23 |

0.3 |

300 |

350 |

1150 |

8.9 |

<16 |

-34 |

|

CuNi30 |

0.35 |

350 |

400 |

1170 |

8.9 |

<10 |

-37 |

|

CuNi34 |

0.4 |

350 |

400 |

1180 |

8.9 |

0 |

-39 |

|

CuNi44 |

0.5 |

400 |

420 |

1200 |

8.9 |

<-6 |

-43 |

|

Size Range |

|

|

Wire |

0.08-7.5mm |

|

Ribbon |

(0.05-0.35)*(0.5-6.0)mm |

|

Strip |

(0.50-2.5)*(5-180)mm |

|

Rod |

8-50mm |

For more other size details, pls directly contact us

Our CuNi1 wire is a rockstar in low-voltage circuit breakers, where its low resistivity ensures efficient power flow without overheating. It’s also a favorite in thermal overload relays, protecting equipment by sensing temperature spikes. Beyond that, you’ll find it in electric blankets, heating mats, and even some automotive wiring systems where reliability is critical. Its corrosion resistance makes it a solid pick for environments exposed to moisture or chemicals, ensuring longevity in tough conditions.

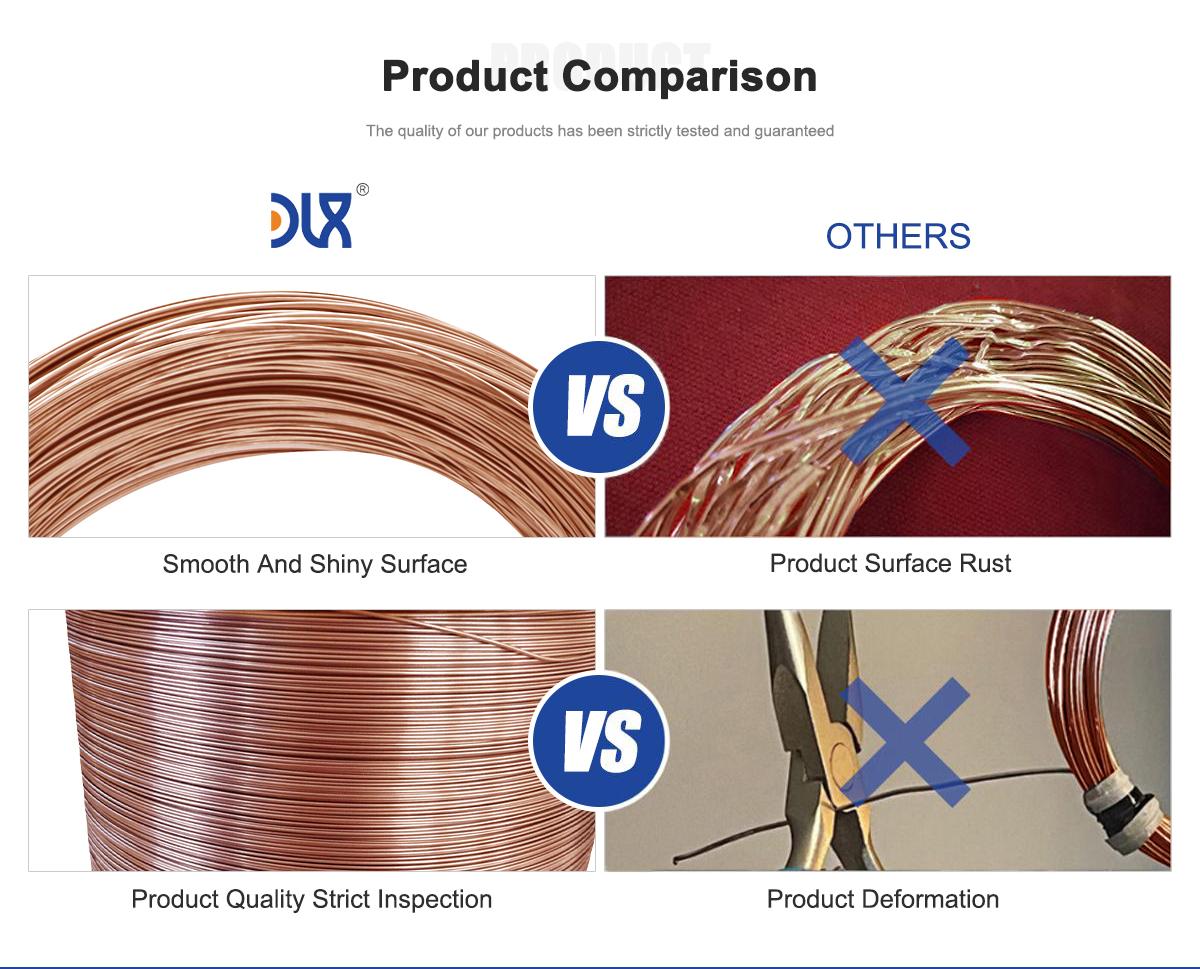

Why Our CuNi1 Wire Stands Out

Compared to others in the market, our CuNi1 wire offers unmatched consistency in resistance, which is critical for precise circuit breaker performance. We’ve fine-tuned our manufacturing to deliver wires with uniform resistivity and superior stability, reducing the risk of failures in your systems. Our wire’s ductility makes it a breeze to fabricate, saving you time and costs during production. Plus, we offer it in a range of sizes—0.1mm to 10mm for round wires and custom dimensions for ribbons and strips—to fit your exact needs. We also prioritize quick lead times and competitive pricing, ensuring you get top-quality wire without breaking the bank.

Comparison Table

|

Parameter |

Our CuNi1 Wire |

Competitor A |

Competitor B |

|---|---|---|---|

|

Nickel Content |

~1% |

~1% |

~1% |

|

Resistivity (μΩ·cm) |

0.03 |

0.032 |

0.035 |

|

Max Operating Temp (°C) |

200 |

180 |

190 |

|

Corrosion Resistance |

High |

Moderate |

High |

|

Ductility |

Excellent |

Good |

Moderate |

|

Tensile Strength (N/mm²) |

~250 |

~230 |

~240 |

|

Weldability |

Excellent |

Good |

Good |

|

Availability (Sizes) |

0.1-10mm (customizable) |

0.2-8mm |

0.3-7mm |

About Us:

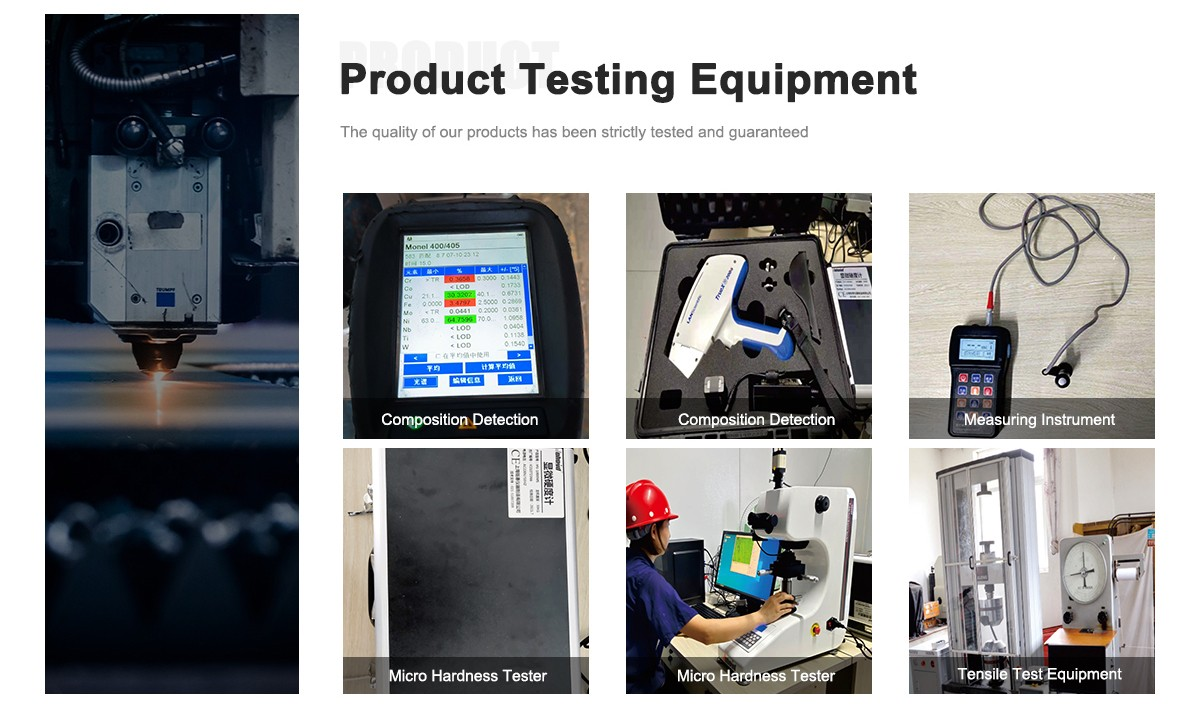

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

-

What makes CuNi1 wire ideal for circuit breakers?

Its low resistivity (0.03 μΩ·cm) ensures efficient power flow, and its stability prevents overheating in low-voltage systems. -

Can CuNi1 wire handle high temperatures?

Yep, it’s good up to 200°C, perfect for thermal overload relays and heating applications. -

Is CuNi1 wire corrosion-resistant?

Absolutely, it holds up well against moisture and chemicals, making it great for tough environments. -

What industries use CuNi1 wire?

It’s big in electrical, automotive, and even marine applications due to its reliability and corrosion resistance. -

How does your CuNi1 wire compare to others?

Our wire has better resistivity consistency, higher ductility, and a wider range of sizes for more flexibility. -

Can CuNi1 wire be customized?

Totally! We offer round wires from 0.1mm to 10mm and custom ribbons or strips to match your specs. -

What’s the lead time for CuNi1 wire orders?

We pride ourselves on fast delivery—typically within 1-2 weeks, depending on order size and customization. -

Is CuNi1 wire cost-effective?

You bet! It balances performance and price, giving you top-notch quality without burning a hole in your budget.