Our CuNi30, CuNi34, and CuNi44 copper-nickel wires are game-changers for high-performance heating cables. These alloys, with nickel content ranging from 30% to 44%, are designed for reliability, efficiency, and durability. Whether you need consistent heat for underfloor systems or precision resistors for industrial setups, our wires deliver. CuNi30 offers solid performance for standard heating, CuNi34 strikes a balance for versatile applications, and CuNi44 shines in high-resistivity, high-temperature environments. With excellent corrosion resistance and tensile strength, they’re built to last in tough conditions like marine or industrial settings.

Our wires stand out for their low electrical resistance, easy processing, and weldability, making them a go-to for manufacturers. Plus, they’re energy-efficient, helping you cut costs while keeping performance top-notch. Available in various forms—bare, enamelled, or litz wire—we tailor them to your needs, ensuring flexibility for any project.

Properties Material | Resistivity 200c μΩ.m | Max working temperature (℃) | Tensile strength (Mpa) | Melting point (℃) | Density (g/cm3) | TCR *10-6/℃ (20-600℃) | EMF vs Cu (μV/℃) (0-100℃) |

CuNi1 | 0.03 | 200 | 210 | 1085 | 8.9 | <100 | -8 |

CuNi2 | 0.05 | 200 | 220 | 1090 | 8.9 | <120 | -12 |

CuNi6 | 0.1 | 220 | 250 | 1095 | 8.9 | <60 | -18 |

CuNi8 | 0.12 | 250 | 270 | 1097 | 8.9 | <57 | -22 |

CuNi10 | 0.15 | 250 | 290 | 1100 | 8.9 | <50 | -25 |

CuNi14 | 0.2 | 300 | 310 | 1115 | 8.9 | <30 | -28 |

CuNi19 | 0.25 | 300 | 340 | 1135 | 8.9 | <25 | -32 |

CuNi23 | 0.3 | 300 | 350 | 1150 | 8.9 | <16 | -34 |

CuNi30 | 0.35 | 350 | 400 | 1170 | 8.9 | <10 | -37 |

CuNi34 | 0.4 | 350 | 400 | 1180 | 8.9 | 0 | -39 |

CuNi44 | 0.5 | 400 | 420 | 1200 | 8.9 | <-6 | -43 |

Size Range | |

Wire | 0.08-7.5mm |

Ribbon | (0.05-0.35)*(0.5-6.0)mm |

Strip | (0.50-2.5)*(5-180)mm |

Rod | 8-50mm |

For more other size details, pls directly contact us

The copper-nickel wire market is heating up, driven by demand for energy-efficient and eco-friendly heating solutions. With global pushes for sustainability, industries like aerospace, automotive, and marine are leaning into CuNi alloys for their durability and green credentials. The rise of smart homes and IoT devices is also fueling growth, as these wires power advanced underfloor heating and thermal management systems. Market trends show a shift toward lightweight, high-performance materials, with CuNi Wire s fitting the bill perfectly.

Challenges? Sure, raw material price fluctuations can be a hurdle, but the long-term benefits—like lower maintenance and energy savings—make these wires a smart investment. The market’s expected to grow steadily through 2030, with Asia-Pacific and North America leading the charge due to industrial expansion and green tech adoption.

Comparison Table: CuNi30, CuNi34, CuNi44 Copper Nickel Wires

Parameter | CuNi30 | CuNi34 | CuNi44 |

|---|---|---|---|

Nickel Content | 30% | 34% | 44% |

Resistivity (μΩ·m) | 0.30 ± 5% | 0.35 ± 5% | 0.49 ± 2% |

Max Operating Temp (°C) | 300 | 300 | 400 |

Tensile Strength (MPa) | >400 | >380 | >350 |

Density (g/cm³) | 8.9 | 8.9 | 8.9 |

Corrosion Resistance | High (seawater, acids) | High (seawater, acids) | Very High (precision use) |

Elongation (%) | >25 | >20 | >15 |

Typical Applications | Heating cables, resistors | Heating cables, thermocouples | Precision resistors, rheostats |

Our CuNi wires are incredibly versatile. Here’s where they shine:

Heating Cables: Perfect for underfloor heating, thermal blankets, and industrial heat tracing, ensuring consistent warmth.

Resistors and Rheostats: CuNi44’s high resistivity makes it ideal for precision resistors in electronics.

Thermocouples: CuNi34’s balance of properties supports accurate temperature sensing in harsh environments.

Marine Systems: Corrosion resistance makes these wires a staple in seawater-exposed equipment.

Aerospace and Automotive: Lightweight and durable, they’re used in sensors and heating elements for high-performance vehicles.

From smart home gadgets to heavy-duty industrial systems, our wires keep things running smoothly and efficiently.

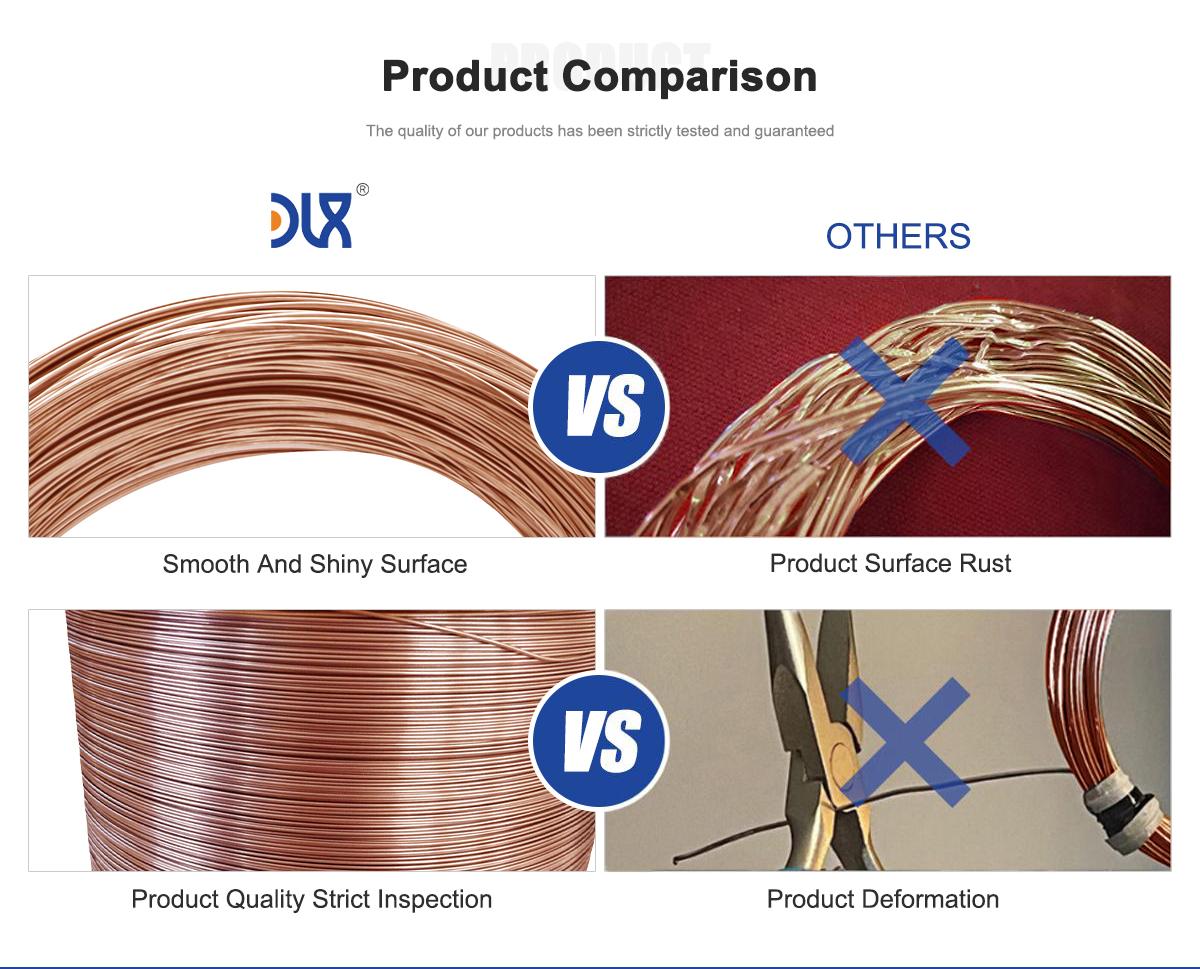

Competitor Comparison

Some companies in the market produce similar copper-nickel wires, but our focus on quality and customization sets us apart. While others may offer standard alloys, we fine-tune our CuNi30, CuNi34, and CuNi44 wires to meet specific resistivity and temperature needs. Our in-house testing ensures every batch meets strict standards for tensile strength and corrosion resistance, giving you peace of mind. We also prioritize fast delivery and scalable production, so whether you need a small sample or bulk orders, we’ve got you covered.

Unlike competitors who might cut corners on insulation or packaging, we offer a range of enamelled and litz wire options, plus argon-sealed packaging for sensitive applications. Our commitment to sustainability means we optimize production to reduce waste, aligning with the industry’s green push. Simply put, our wires aren’t just products—they’re solutions tailored to your success.

Why Choose Our CuNi Wires?

We’re not just selling wires; we’re delivering performance you can trust. Our CuNi30, CuNi34, and CuNi44 wires combine cutting-edge alloy tech with decades of expertise. They’re corrosion-resistant, energy-efficient, and built for the toughest jobs. Whether you’re wiring a smart home or a marine vessel, our wires keep things running smoothly. Ready to power up your next project? Let’s talk about how our copper-nickel wires can make it happen.

Keywords: CuNi30 wire, CuNi34 wire, CuNi44 wire, copper nickel wire, high-performance heating cables, resistance

About Us:

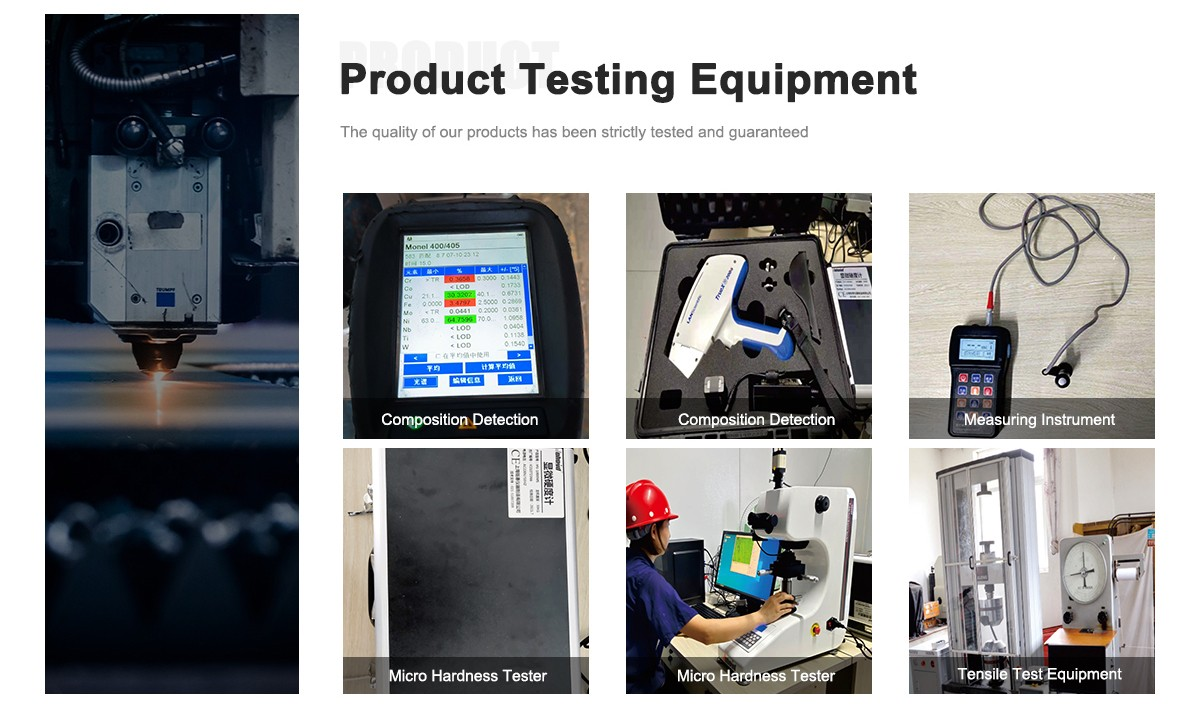

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What are CuNi30, CuNi34, and CuNi44 wires made of?

Copper-nickel alloys with 30%, 34%, and 44% nickel content, respectively, offering varying resistivity and strength.What are the main applications for these wires?

Heating cables, resistors, thermocouples, and industrial heating systems like underfloor heating and thermal blankets.How do CuNi30, CuNi34, and CuNi44 differ in performance?

CuNi30 has lower resistivity, CuNi34 offers a balance of resistance and durability, and CuNi44 provides high resistivity for precision applications.Are these wires corrosion-resistant?

Yes, they resist corrosion from moisture, seawater, and mild acids, ideal for harsh environments.What’s the maximum operating temperature for these wires?

CuNi30 and CuNi34 up to 300°C, CuNi44 up to 400°C, depending on the application.How do these wires perform in high-performance heating cables?

They deliver consistent heat, high tensile strength, and energy efficiency for reliable heating systems.What industries use CuNi alloy wires the most?

Aerospace, automotive, marine, and industrial manufacturing, especially for heating and sensing solutions.What’s the trend in the copper-nickel wire market?

Growing demand for energy-efficient heating and eco-friendly materials, driven by green tech and smart home innovations.