Looking for a reliable material for your resistance heating needs? Our CuNi2 copper nickel alloy strip is your go-to solution for flexible, low-voltage heating applications. Let’s dive into what makes this alloy special, explore its role in today’s industries, and see why our product stands out.

Product Introduction: What’s CuNi2 All About?

CuNi2 is a copper-nickel binary alloy with just 2% nickel, giving it a unique edge for resistance heating. It’s got low electrical resistivity—around 5 µΩ·cm—and a super-low temperature coefficient of resistance (TCR) of 0.0001/°C. This means it delivers consistent performance even as temperatures shift, up to a max of 250°C. You’ll find it in thin, flexible strips perfect for applications like electric blankets, heating cables, and low-voltage circuit breakers. Plus, it’s corrosion-resistant, shrugging off moisture, non-oxidizing acids, and salt solutions, making it a durable choice for long-term use.

Our CuNi2 strips are crafted with precision, available in various thicknesses and widths to fit your exact needs. Whether you’re building home appliances or designing thermal cutouts, this alloy offers the stability and flexibility you want without breaking the bank.

|

Properties Material |

Resistivity 200c μΩ.m |

Max working temperature (℃) |

Tensile strength (Mpa) |

Melting point (℃) |

Density (g/cm3) |

TCR *10-6/℃ (20-600℃) |

EMF vs Cu (μV/℃) (0-100℃) |

|

CuNi1 |

0.03 |

200 |

210 |

1085 |

8.9 |

<100 |

-8 |

|

CuNi2 |

0.05 |

200 |

220 |

1090 |

8.9 |

<120 |

-12 |

|

0.1 |

220 |

250 |

1095 |

8.9 |

<60 |

-18 |

|

|

0.12 |

250 |

270 |

1097 |

8.9 |

<57 |

-22 |

|

|

CuNi10 |

0.15 |

250 |

290 |

1100 |

8.9 |

<50 |

-25 |

|

0.2 |

300 |

310 |

1115 |

8.9 |

<30 |

-28 |

|

|

CuNi19 |

0.25 |

300 |

340 |

1135 |

8.9 |

<25 |

-32 |

|

CuNi23 |

0.3 |

300 |

350 |

1150 |

8.9 |

<16 |

-34 |

|

CuNi30 |

0.35 |

350 |

400 |

1170 |

8.9 |

<10 |

-37 |

|

CuNi34 |

0.4 |

350 |

400 |

1180 |

8.9 |

0 |

-39 |

|

CuNi44 |

0.5 |

400 |

420 |

1200 |

8.9 |

<-6 |

-43 |

|

Size Range |

|

|

Wire |

0.08-7.5mm |

|

Ribbon |

(0.05-0.35)*(0.5-6.0)mm |

|

Strip |

(0.50-2.5)*(5-180)mm |

|

Rod |

8-50mm |

For more other size details, pls directly contact us

The resistance heating industry is booming, driven by demand for energy-efficient, compact heating solutions. From smart home appliances to electric vehicle components, manufacturers need materials that balance performance, cost, and durability. Copper-nickel alloys like CuNi2 are stealing the spotlight thanks to their low TCR and corrosion resistance, which outshine pure copper or high-nickel alloys in specific applications.

Trends show a shift toward flexible heating elements—think wearable tech, underfloor heating, and compact circuit protection devices. The global market for resistance alloys is expected to grow steadily, with a focus on eco-friendly materials that reduce energy waste. CuNi2’s low resistivity and stable performance make it a natural fit for these innovations. Plus, its affordability compared to high-nickel alloys keeps it competitive in cost-sensitive sectors like consumer electronics and home appliances.

|

Parameter |

CuNi2 |

CuNi10 |

NiCr 80:20 |

Pure Copper |

|---|---|---|---|---|

|

Nickel Content (%) |

2 |

10 |

80 |

0 |

|

Resistivity (µΩ·cm) |

5 |

15 |

108 |

1.68 |

|

Max Operating Temp (°C) |

250 |

300 |

1200 |

200 |

|

Corrosion Resistance |

Good |

Very Good |

Excellent |

Poor |

|

Temperature Coefficient (TCR) |

Low (0.0001/°C) |

Moderate (0.00015/°C) |

High (0.00002/°C) |

High (0.004/°C) |

|

Tensile Strength (N/mm²) |

250–300 |

300–350 |

600–800 |

200–250 |

|

Cost |

Low |

Moderate |

High |

Very Low |

|

Applications |

Electric blankets, circuit breakers |

Heating cables, marine |

High-temp furnaces |

Electrical wiring |

CuNi2 is a versatile player in resistance heating. Here’s where it’s making waves:

-

Home Appliances: Electric blankets and heating pads rely on CuNi2’s flexible strips for safe, consistent warmth.

-

Circuit Protection: Low-voltage circuit breakers and thermal cutouts use CuNi2 for its stable resistance and reliability.

-

Heating Cables: Its corrosion resistance and low TCR make it ideal for underfloor heating and de-icing cables.

-

Industrial Controls: CuNi2’s durability suits low-temperature control devices in manufacturing.

Unlike pure copper, which loses stability at higher temperatures, or high-nickel alloys that spike costs, CuNi2 hits the sweet spot for low to medium-temperature applications. Its ability to resist corrosion also makes it a solid choice for environments exposed to moisture or chemicals.

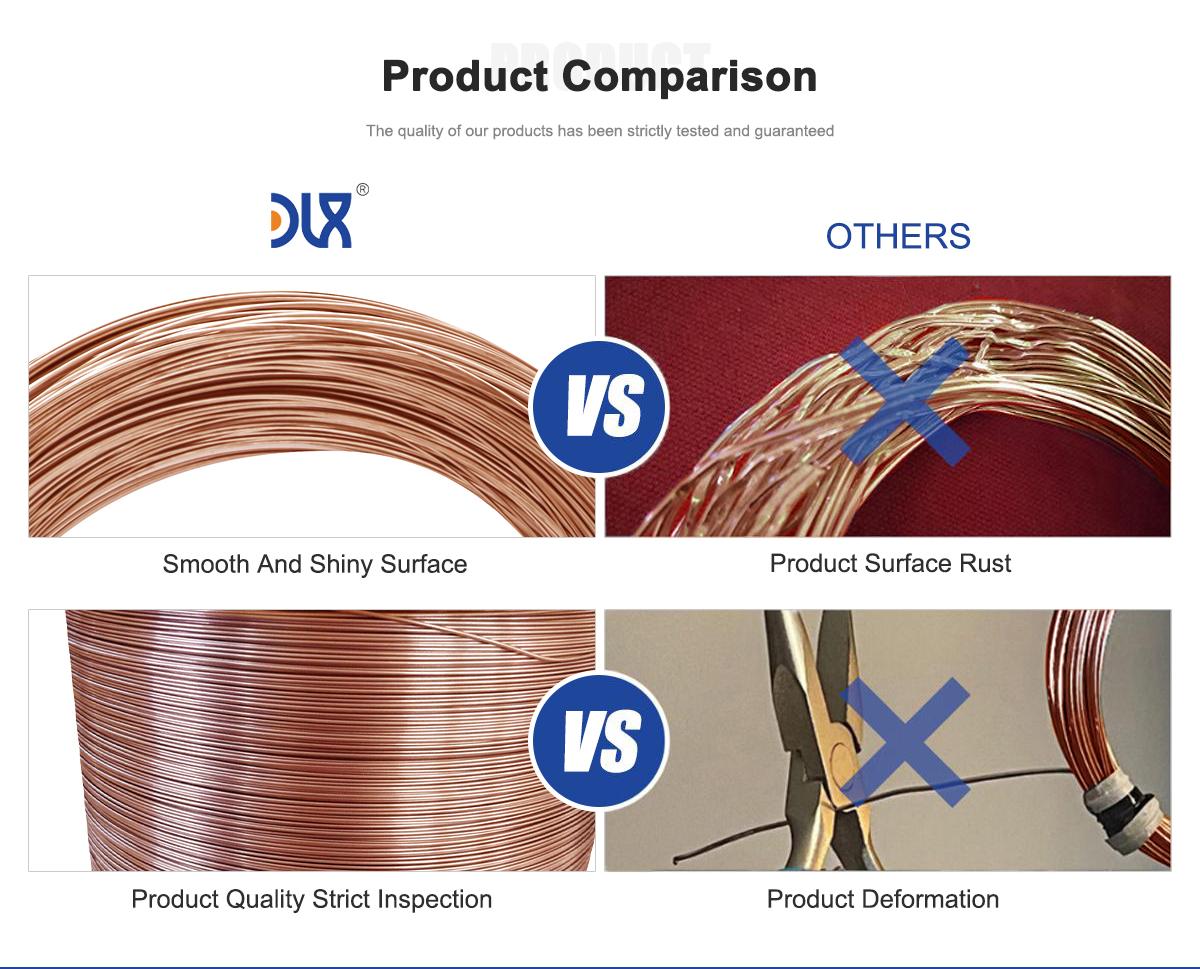

Company Comparison: Why Choose Us?

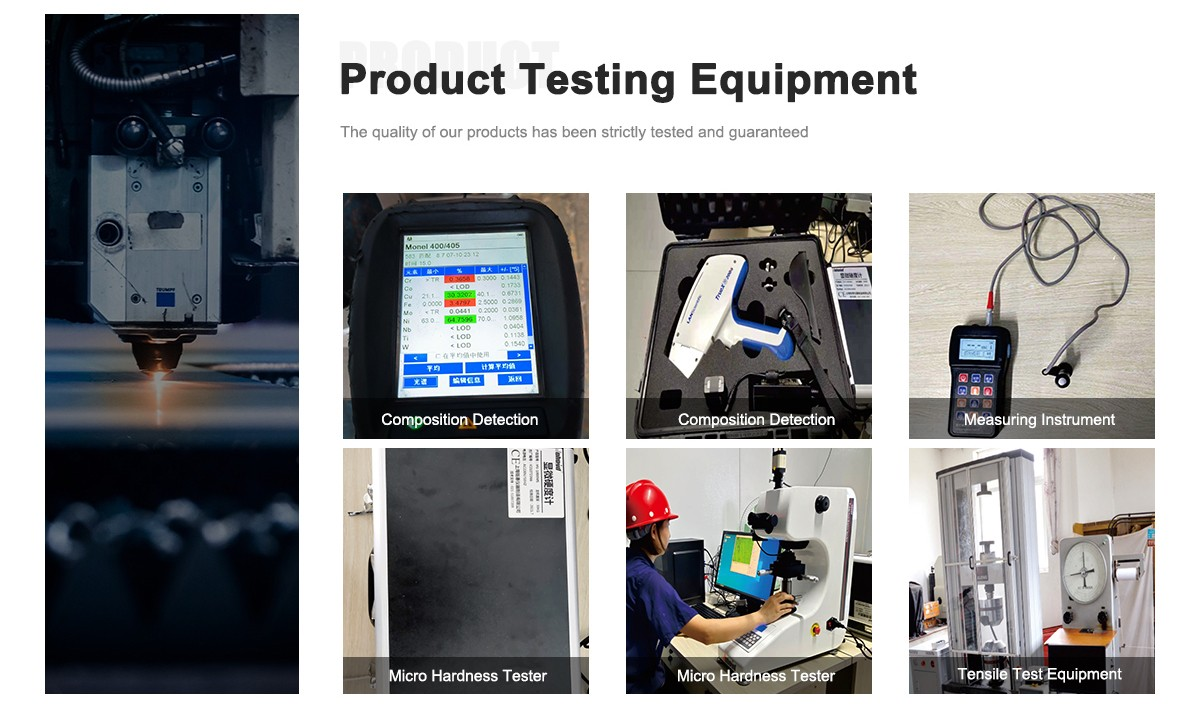

Plenty of companies offer copper-nickel alloys, but we’re a cut above. Our CuNi2 strips are produced with state-of-the-art manufacturing, ensuring tight tolerances and consistent quality. We prioritize customization, offering tailored dimensions and finishes to match your project’s specs. Our in-house testing guarantees every batch meets strict standards for resistivity, TCR, and corrosion resistance.

We also keep sustainability in mind, using efficient processes to minimize waste and energy use. Our supply chain is streamlined, so you get fast delivery without compromising quality. And while others might charge a premium for custom orders, we keep pricing competitive to support your bottom line. With decades of expertise in alloy production, we’re not just a supplier—we’re a partner in your success.

Why CuNi2? Why Us?

CuNi2 copper nickel alloy strip is a game-changer for flexible resistance heating, blending low cost, stable performance, and durability. Whether you’re crafting electric blankets or designing circuit breakers, it’s a material that delivers. And when you choose us, you’re getting top-tier quality, unmatched customization, and a team committed to your project’s success.

Ready to power up your next heating solution with CuNi2? Let’s make it happen.

Keywords: CuNi2 alloy, copper nickel strip, flexible resistance heating, low TCR alloy, corrosion-resistant alloy, electric blanket material, heating cable alloy, circuit breaker material, resistance heating industry, copper nickel alloy supplier.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

-

What is CuNi2 alloy used for?

Low-voltage heating applications like electric blankets, heating cables, and thermal cutouts. -

Why choose CuNi2 for resistance heating?

It has a low temperature coefficient of resistance, ensuring stable performance up to 250°C. -

Is CuNi2 corrosion-resistant?

Yes, it resists corrosion from moisture, non-oxidizing acids, and salt solutions. -

What forms is CuNi2 available in?

Strips, wires, and ribbons for flexible heating applications. -

How does CuNi2 compare to other alloys?

It offers lower resistivity than high-nickel alloys but better stability than pure copper. -

What industries use CuNi2?

Home appliances, electrical engineering, and low-voltage circuit protection. -

Can CuNi2 handle high temperatures?

It’s reliable up to 250°C, ideal for low to medium-temperature heating. -

Is CuNi2 cost-effective?

Yes, it balances performance and affordability for resistance heating needs.