Our CuNi2, CuNi19, CuNi23, and CuNi30 wires, with nickel contents of ~2%, ~19%, ~23%, and ~30% respectively, are designed for low-resistivity heating applications where efficiency and durability are key. These copper-nickel alloys offer a range of resistivities to suit different heating needs, from low-power systems to high-performance setups. CuNi2 is perfect for minimal resistance, while CuNi30 delivers higher resistivity for specialized applications. We produce these wires with top-tier precision, ensuring consistent performance, excellent corrosion resistance, and easy workability for heating cables, resistors, and more.

The copper-nickel wire market is heating up, with the global copper alloy sector expected to reach USD 25.85 billion by 2034. Demand is soaring in industries like electronics, automotive, and renewable energy, driven by the need for efficient, corrosion-resistant materials. Low-resistivity wires like CuNi2, CuNi19, CuNi23, and CuNi30 are in high demand for heating systems in smart homes, electric vehicles, and industrial setups. The industry’s also leaning toward sustainable production, and our eco-friendly manufacturing process—minimizing waste and energy use—keeps us ahead of the game.

|

Properties Material |

Resistivity 200c μΩ.m |

Max working temperature (℃) |

Tensile strength (Mpa) |

Melting point (℃) |

Density (g/cm3) |

TCR *10-6/℃ (20-600℃) |

EMF vs Cu (μV/℃) (0-100℃) |

|

CuNi1 |

0.03 |

200 |

210 |

1085 |

8.9 |

<100 |

-8 |

|

CuNi2 |

0.05 |

200 |

220 |

1090 |

8.9 |

<120 |

-12 |

|

CuNi6 |

0.1 |

220 |

250 |

1095 |

8.9 |

<60 |

-18 |

|

CuNi8 |

0.12 |

250 |

270 |

1097 |

8.9 |

<57 |

-22 |

|

CuNi10 |

0.15 |

250 |

290 |

1100 |

8.9 |

<50 |

-25 |

|

CuNi14 |

0.2 |

300 |

310 |

1115 |

8.9 |

<30 |

-28 |

|

CuNi19 |

0.25 |

300 |

340 |

1135 |

8.9 |

<25 |

-32 |

|

CuNi23 |

0.3 |

300 |

350 |

1150 |

8.9 |

<16 |

-34 |

|

CuNi30 |

0.35 |

350 |

400 |

1170 |

8.9 |

<10 |

-37 |

|

CuNi34 |

0.4 |

350 |

400 |

1180 |

8.9 |

0 |

-39 |

|

CuNi44 |

0.5 |

400 |

420 |

1200 |

8.9 |

<-6 |

-43 |

|

Size Range |

|

|

Wire |

0.08-7.5mm |

|

Ribbon |

(0.05-0.35)*(0.5-6.0)mm |

|

Strip |

(0.50-2.5)*(5-180)mm |

|

Rod |

8-50mm |

For more other size details, pls directly contact us

Our CuNi2, CuNi19, CuNi23, and CuNi30 wires shine in low-resistivity heating applications. CuNi2 is ideal for low-power heating cables in electric blankets and floor heating. CuNi19 and CuNi23 work great in automotive heating elements and industrial resistors, offering a balance of efficiency and durability. CuNi30 is perfect for high-performance heating systems where higher resistivity is needed. These wires are also corrosion-resistant, making them a solid choice for marine and humid environments, ensuring long-lasting performance in tough conditions.

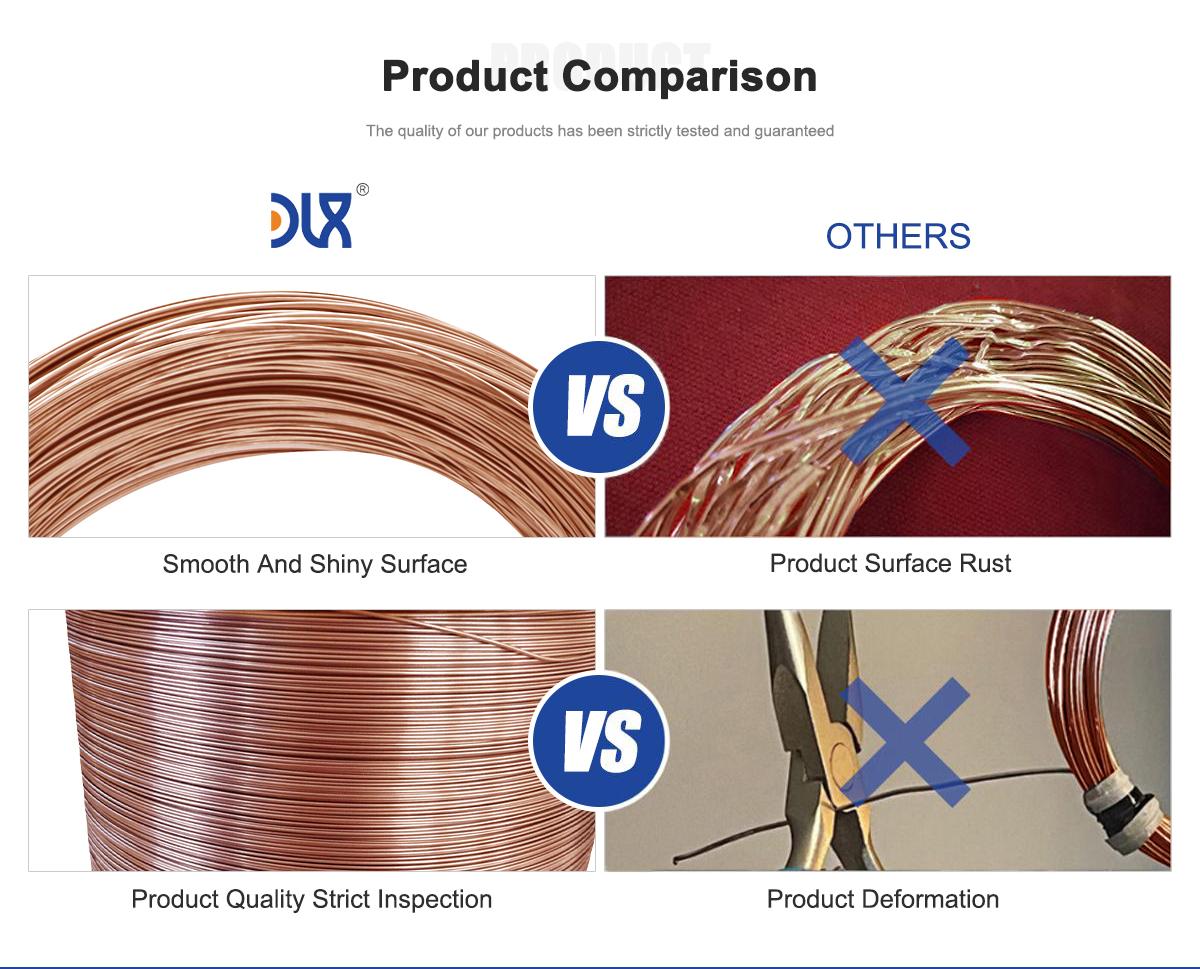

Why Our CuNi Wire s Stand Out

Our CuNi2, CuNi19, CuNi23, and CuNi30 wires outshine others with their superior resistivity consistency and durability. We’ve optimized our production to deliver wires with excellent ductility, making them easy to shape and install. Compared to others, our wires offer better corrosion resistance and thermal stability, with operating temperatures up to 350°C for CuNi30. We provide a wide range of sizes—0.1mm to 8mm for round wires and custom flat profiles—along with fast lead times and competitive pricing, ensuring you get premium quality without the wait or high costs.

Comparison Table

|

Parameter |

Our CuNi2 Wire |

Our CuNi19 Wire |

Our CuNi23 Wire |

Our CuNi30 Wire |

Competitor A |

Competitor B |

|---|---|---|---|---|---|---|

|

Nickel Content |

~2% |

~19% |

~23% |

~30% |

~2-30% |

~2-30% |

|

Resistivity (μΩ·cm) |

0.05 |

0.25 |

0.30 |

0.35 |

0.06-0.37 |

0.07-0.36 |

|

Max Operating Temp (°C) |

200 |

300 |

300 |

350 |

190-340 |

200-330 |

|

Corrosion Resistance |

High |

Excellent |

Excellent |

Excellent |

Moderate |

High |

|

Ductility |

Excellent |

High |

High |

High |

Good |

Moderate |

|

Tensile Strength (N/mm²) |

~280 |

~380 |

~400 |

~420 |

~260-400 |

~270-410 |

|

Weldability |

Excellent |

Excellent |

High |

High |

Good |

Good |

|

Availability (Sizes) |

0.1-8mm (custom) |

0.1-8mm (custom) |

0.1-8mm (custom) |

0.1-8mm (custom) |

0.2-7mm |

0.3-7mm |

About Us:

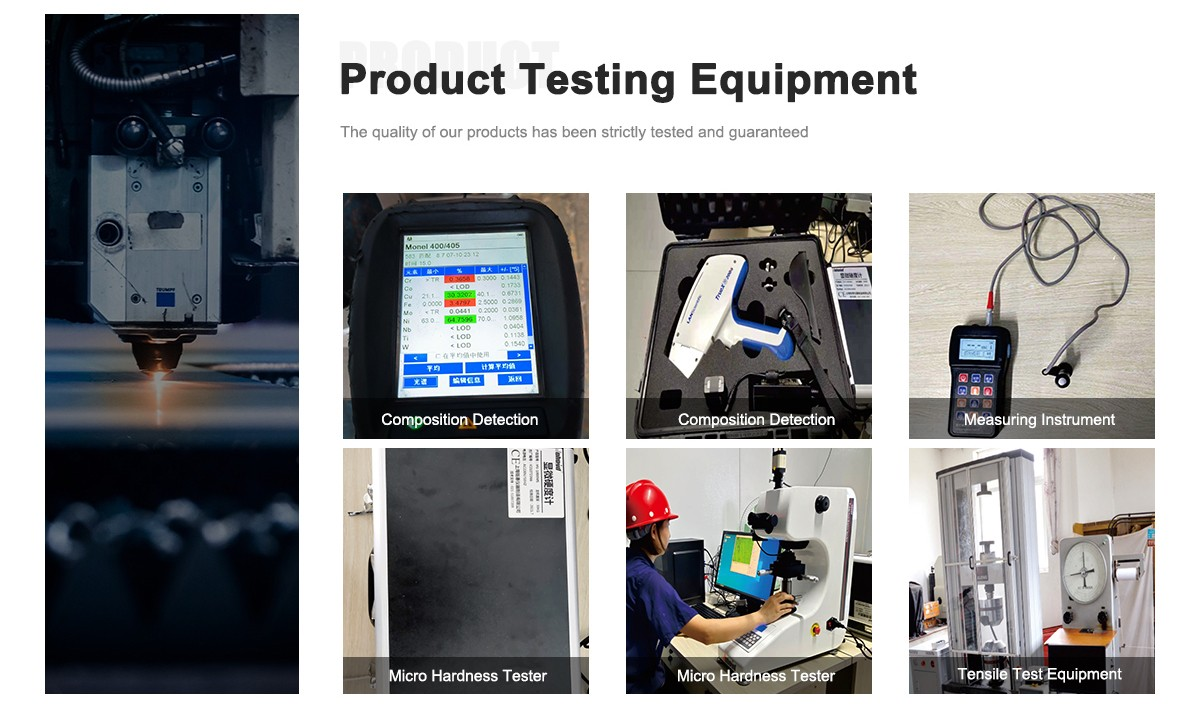

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

-

Why are CuNi2, CuNi19, CuNi23, and CuNi30 ideal for heating applications?

Their low to moderate resistivities (0.05-0.35 μΩ·cm) ensure efficient heat generation with reliable performance. -

How do these wires differ in use?

CuNi2 is great for low-power heating, CuNi19 and CuNi23 suit balanced systems, and CuNi30 handles high-resistivity needs. -

Can these wires handle high temperatures?

Absolutely—CuNi2 up to 200°C, CuNi19 and CuNi23 to 300°C, and CuNi30 to 350°C. -

Are these wires corrosion-resistant?

Yep, they’re built to resist moisture and chemicals, ideal for marine or humid environments. -

What industries use these CuNi wires?

They’re popular in electronics, automotive, and renewable energy for heating cables and resistors. -

Can you customize these wire sizes?

Totally, we offer round wires from 0.1mm to 8mm and custom flat profiles to fit your specs. -

How fast is your delivery for these wires?

We’re quick—most orders ship within 1-2 weeks, depending on customization and volume. -

Are these wires cost-effective?

Definitely, they deliver top performance and durability at prices that won’t break the bank.