Looking for reliable, high-performance wires for your precision resistance needs? Our CuNi23, CuNi30, CuNi34, and CuNi44 wires—part of the constantan family—are engineered to deliver unmatched stability, durability, and versatility. Whether you’re building thermocouples, resistors, or heating systems, these copper-nickel alloys are your go-to solution. Let’s dive into what makes our products stand out, explore their applications, and check out the industry trends driving demand.

Product Introduction: Why Choose Our CuNi Wire s?

Our CuNi wires are copper-nickel alloys with nickel content ranging from 23% to 44%, offering a spectrum of resistivity and performance characteristics. Here’s what you get with our lineup:

-

CuNi23: A cost-effective option with 0.30 μΩ·m resistivity, perfect for heating cables and low-cost resistors.

-

CuNi30: Balances performance and price with 0.35 μΩ·m resistivity, ideal for precision resistors.

-

CuNi34: Steps up with 0.40 μΩ·m resistivity and excellent corrosion resistance for strain gauges.

-

CuNi44: The premium choice with 0.49 μΩ·m resistivity, used in high-precision thermocouples and resistors, stable up to 400°C.

What sets us apart? We prioritize quality and customization. Our wires come in diameters from 0.05mm to 40mm, available as bare wire, enameled, or in ribbon/foil forms. With a low temperature coefficient of resistance (TCR), our constantan wires ensure consistent performance across temperature swings. Plus, they’re ductile, corrosion-resistant, and easy to solder or weld, making them a favorite for demanding applications.

Industry Analysis: What’s Driving the CuNi Wire Market?

The copper-nickel alloy market is buzzing, and for good reason. These wires are critical in industries pushing for precision and reliability. Here’s what’s fueling growth:

-

Electronics Boom: With smart devices and IoT on the rise, demand for compact, stable resistors is skyrocketing.

-

Renewable Energy: Solar and wind systems need lightweight, corrosion-resistant wires for efficient energy transfer.

-

Electric Vehicles (EVs): CuNi wires are used in battery management systems and thermal controls, supporting the EV revolution.

-

Aerospace and Medical: These sectors require materials that withstand harsh conditions without compromising performance.

Recent trends show a shift toward eco-friendly manufacturing and lightweight materials. Our production processes align with these demands, using sustainable practices to deliver high-quality alloys. The global market for resistance alloys is expected to grow steadily, with CuNi wires playing a starring role due to their versatility and reliability.

|

Properties Material |

Resistivity 200c μΩ.m |

Max working temperature (℃) |

Tensile strength (Mpa) |

Melting point (℃) |

Density (g/cm3) |

TCR *10-6/℃ (20-600℃) |

EMF vs Cu (μV/℃) (0-100℃) |

|

CuNi1 |

0.03 |

200 |

210 |

1085 |

8.9 |

<100 |

-8 |

|

CuNi2 |

0.05 |

200 |

220 |

1090 |

8.9 |

<120 |

-12 |

|

CuNi6 |

0.1 |

220 |

250 |

1095 |

8.9 |

<60 |

-18 |

|

CuNi8 |

0.12 |

250 |

270 |

1097 |

8.9 |

<57 |

-22 |

|

CuNi10 |

0.15 |

250 |

290 |

1100 |

8.9 |

<50 |

-25 |

|

CuNi14 |

0.2 |

300 |

310 |

1115 |

8.9 |

<30 |

-28 |

|

CuNi19 |

0.25 |

300 |

340 |

1135 |

8.9 |

<25 |

-32 |

|

CuNi23 |

0.3 |

300 |

350 |

1150 |

8.9 |

<16 |

-34 |

|

CuNi30 |

0.35 |

350 |

400 |

1170 |

8.9 |

<10 |

-37 |

|

CuNi34 |

0.4 |

350 |

400 |

1180 |

8.9 |

0 |

-39 |

|

CuNi44 |

0.5 |

400 |

420 |

1200 |

8.9 |

<-6 |

-43 |

|

Size Range |

|

|

Wire |

0.08-7.5mm |

|

Ribbon |

(0.05-0.35)*(0.5-6.0)mm |

|

Strip |

(0.50-2.5)*(5-180)mm |

|

Rod |

8-50mm |

For more other size details, pls directly contact us

Our CuNi wires are incredibly versatile, serving a range of industries with tailored solutions:

-

Precision Resistors: CuNi30 and CuNi34 are perfect for industrial rheostats and potentiometers, offering stable resistance.

-

Thermocouples: CuNi44 is a staple in type J and type T thermocouples, used in heat treatment and cryogenic applications.

-

Heating Systems: CuNi23 excels in low-temperature heating cables for electric blankets and underfloor heating.

-

Strain Gauges: CuNi34’s corrosion resistance makes it ideal for strain gauges in aerospace and automotive testing.

-

Medical Devices: Our wires ensure reliable performance in diagnostic equipment and surgical tools.

No matter the application, our wires deliver consistent results, thanks to their high tensile strength and low TCR.

|

Alloy |

Nickel Content (%) |

Resistivity (μΩ·m) |

Max Operating Temp (°C) |

Corrosion Resistance |

Key Applications |

|---|---|---|---|---|---|

|

CuNi23 |

23 |

0.30 |

300 |

Good |

Heating cables, low-cost resistors |

|

CuNi30 |

30 |

0.35 |

350 |

Very Good |

Precision resistors, thermocouples |

|

CuNi34 |

34 |

0.40 |

375 |

Excellent |

Strain gauges, industrial resistors |

|

CuNi44 |

44 |

0.49 |

400 |

Superior |

Thermocouples, high-precision resistors |

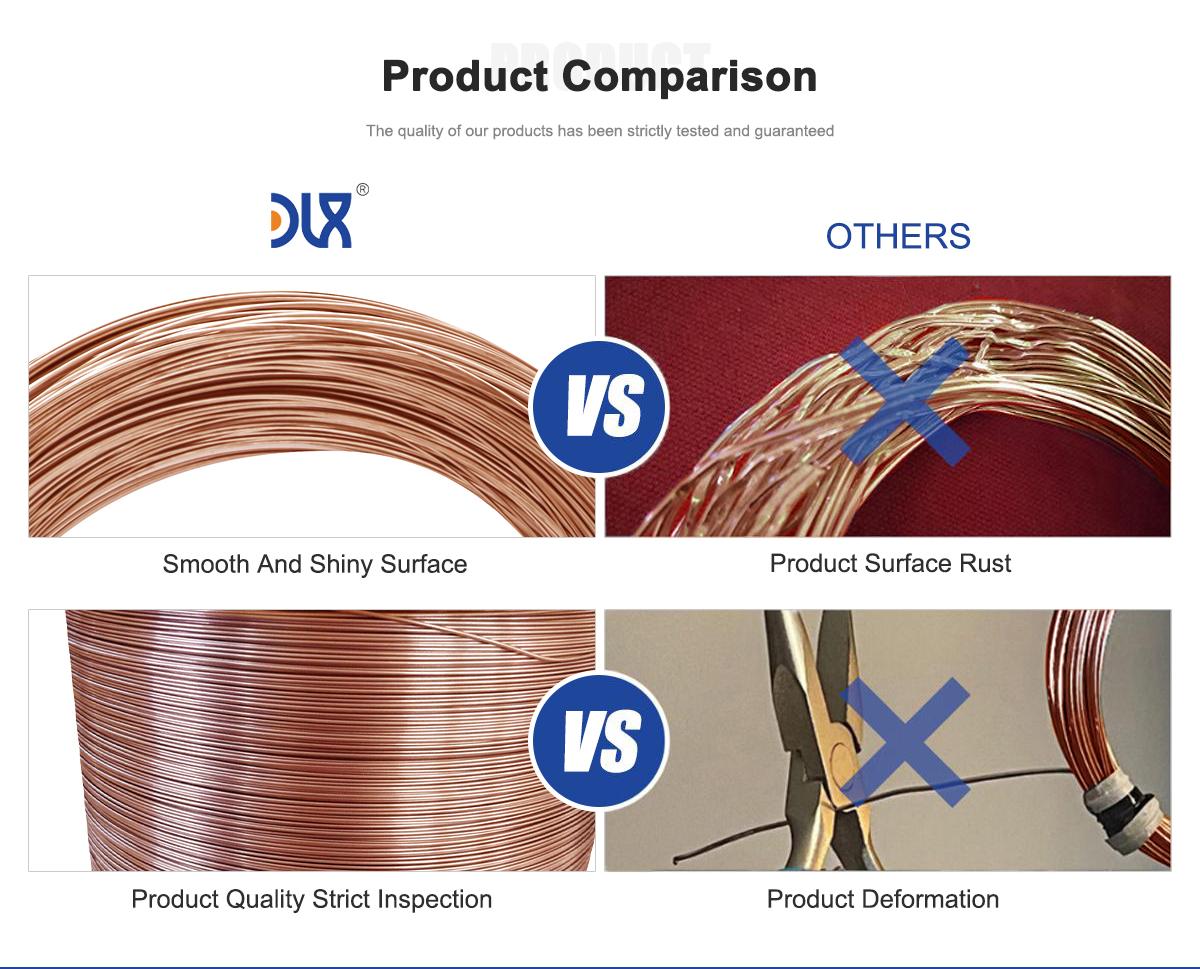

When it comes to CuNi wires, we know you have options. But here’s why we stand out from the crowd. Unlike some companies that cut corners, we’re all about quality and innovation. Our state-of-the-art manufacturing facility ensures every wire meets strict ISO 9001 standards. We’ve been in the game for over 20 years, perfecting our alloys to offer superior resistivity and durability.

Customization is our superpower. Need a specific diameter, coating, or form? We’ve got you covered with fast turnaround times and small order flexibility. Our competitors often stick to standard sizes, but we tailor solutions to your exact specs. Plus, our in-house R&D team keeps us ahead of industry trends, ensuring you get cutting-edge materials for your projects.

Another big win? Our customer support. We don’t just sell wires—we partner with you to solve challenges. From technical advice to rapid delivery, we make your job easier. And with competitive pricing, you get premium quality without breaking the bank.

Why Our CuNi Wires Are the Future

Our CuNi23, CuNi30, CuNi34, and CuNi44 wires are more than just materials—they’re solutions built for precision, reliability, and innovation. Whether you’re in electronics, aerospace, or renewable energy, these constantan wires deliver the performance you need. With a growing market and endless applications, now’s the time to tap into the power of copper-nickel alloys.

Ready to elevate your projects? Contact us today to explore our CuNi wire range and see how we can customize solutions for you. Let’s build something great together.

About Us:

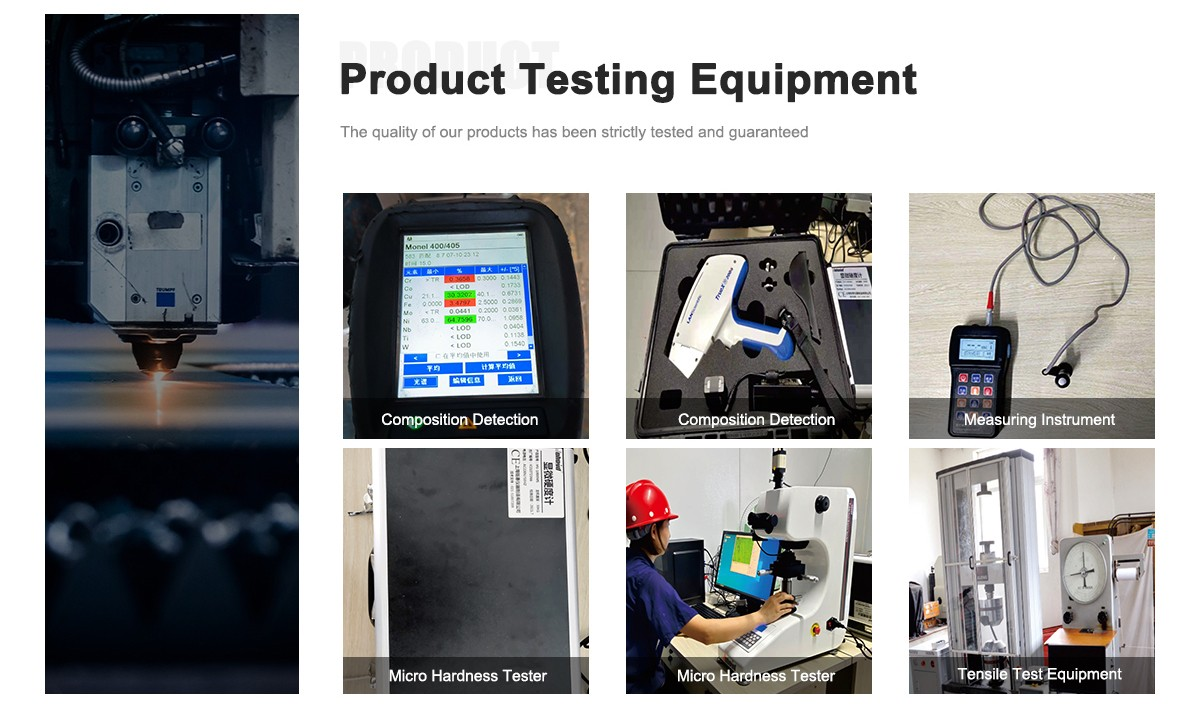

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

-

What are CuNi23, CuNi30, CuNi34, and CuNi44 wires made of?

-

They’re copper-nickel alloys with varying nickel content, designed for precise electrical resistance and stability.

-

What’s the main use of these CuNi wires?

They’re used in precision resistors, thermocouples, heating cables, and strain gauges due to their stable resistance. -

How do these alloys differ in performance?

Higher nickel content (e.g., CuNi44) offers higher resistivity and better corrosion resistance, while lower nickel (e.g., CuNi23) suits cost-sensitive applications. -

What industries rely on these wires?

Electronics, aerospace, automotive, and medical industries use them for reliable resistance and temperature control. -

Are these wires suitable for high-temperature environments?

Yes, they can handle temperatures up to 400°C, with CuNi44 being the most heat-resistant. -

What’s the advantage of using constantan in these wires?

Constantan provides low temperature coefficient of resistance, ensuring consistent performance across temperature changes. -

Can these wires be customized?

Absolutely, we offer various diameters (0.05-40mm), forms (wire, ribbon, foil), coatings, and tempers to meet specific needs. -

What’s the latest trend in CuNi wire applications?

Demand is growing in renewable energy and EVs for lightweight, corrosion-resistant resistance solutions.