Our CuNi1 0 flat wire, a copper-nickel alloy with about 10% nickel, is built for durability in resistance applications. This wire’s got a perfect balance of moderate resistivity and toughness, making it a solid pick for demanding setups. It can handle temperatures up to 250°C without losing its cool, ideal for heating elements, resistors, and automotive wiring. We produce our CuNi10 flat wire with precision, ensuring consistent performance across every batch. Its flat shape boosts surface contact for better heat dissipation, and its corrosion resistance makes it a reliable choice in harsh environments.

The copper-nickel alloy market is growing fast, with the global copper alloy wire sector expected to reach USD 25.85 billion by 2034. Industries like automotive, electronics, and renewable energy are driving demand for durable, corrosion-resistant materials like CuNi10. Trends show a push for compact, efficient components in electric vehicles and smart devices, where our flat wire’s design shines. Sustainability is also key—our production process cuts waste and uses eco-friendly methods, aligning with the industry’s green shift.

|

Properties Material |

Resistivity 200c μΩ.m |

Max working temperature (℃) |

Tensile strength (Mpa) |

Melting point (℃) |

Density (g/cm3) |

TCR *10-6/℃ (20-600℃) |

EMF vs Cu (μV/℃) (0-100℃) |

|

CuNi1 |

0.03 |

200 |

210 |

1085 |

8.9 |

<100 |

-8 |

|

CuNi2 |

0.05 |

200 |

220 |

1090 |

8.9 |

<120 |

-12 |

|

CuNi6 |

0.1 |

220 |

250 |

1095 |

8.9 |

<60 |

-18 |

|

CuNi8 |

0.12 |

250 |

270 |

1097 |

8.9 |

<57 |

-22 |

|

CuNi10 |

0.15 |

250 |

290 |

1100 |

8.9 |

<50 |

-25 |

|

CuNi14 |

0.2 |

300 |

310 |

1115 |

8.9 |

<30 |

-28 |

|

CuNi19 |

0.25 |

300 |

340 |

1135 |

8.9 |

<25 |

-32 |

|

CuNi23 |

0.3 |

300 |

350 |

1150 |

8.9 |

<16 |

-34 |

|

CuNi30 |

0.35 |

350 |

400 |

1170 |

8.9 |

<10 |

-37 |

|

0.4 |

350 |

400 |

1180 |

8.9 |

0 |

-39 |

|

|

0.5 |

400 |

420 |

1200 |

8.9 |

<-6 |

-43 |

|

Size Range |

|

|

Wire |

0.08-7.5mm |

|

Ribbon |

(0.05-0.35)*(0.5-6.0)mm |

|

Strip |

(0.50-2.5)*(5-180)mm |

|

Rod |

8-50mm |

For more other size details, pls directly contact us

CuNi10 flat wire is a workhorse in durable resistance applications. It’s perfect for heating elements in appliances like electric heaters and toasters, thanks to its stable resistivity and heat tolerance. You’ll also find it in automotive wiring harnesses, where its durability and corrosion resistance ensure long-term performance. It’s a go-to for industrial resistors and marine applications, standing up to moisture and chemicals without breaking down. The flat profile makes it ideal for applications needing efficient heat transfer.

Why Our CuNi10 Flat Wire Stands Out

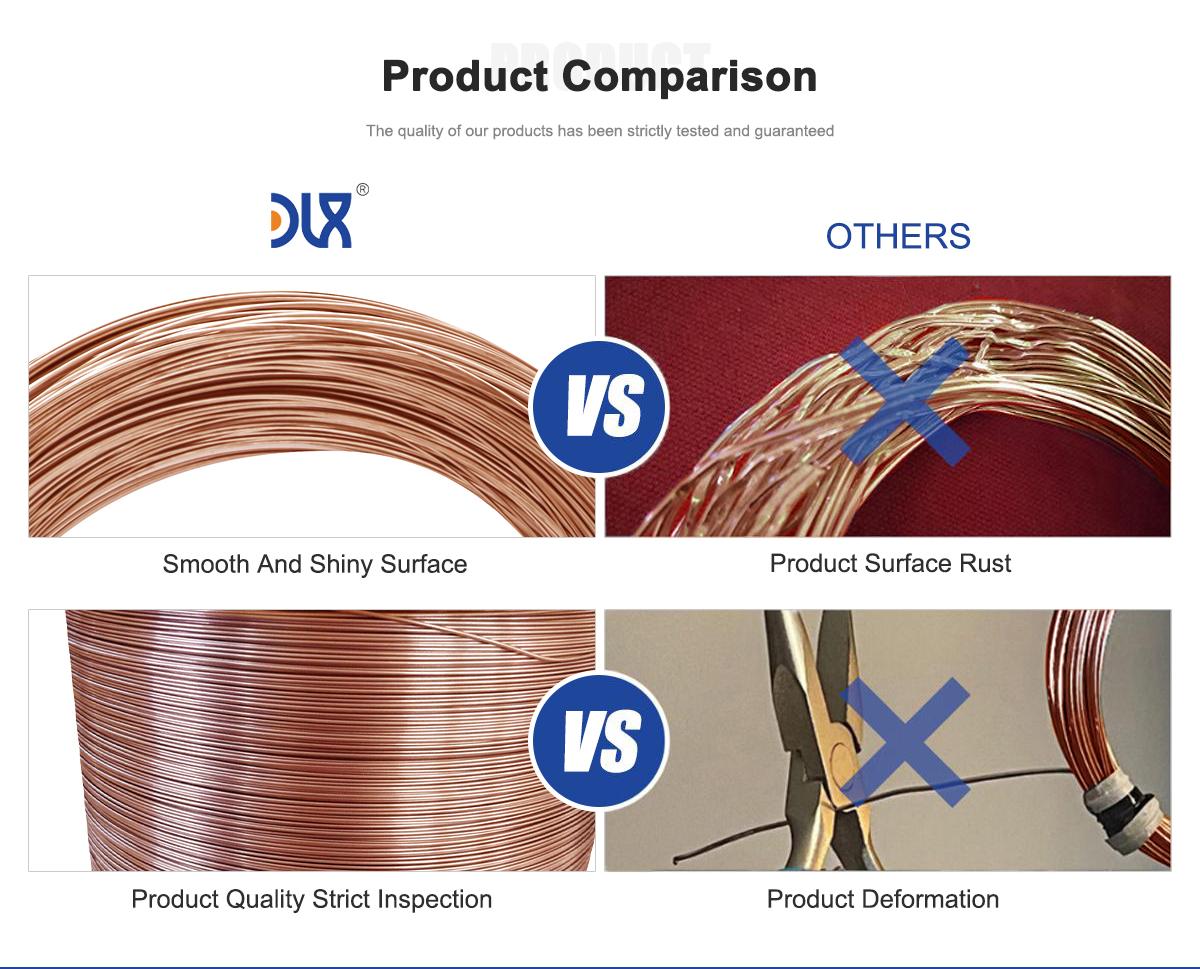

Our CuNi10 flat wire outshines others with its superior consistency in resistivity and enhanced durability. We’ve optimized our manufacturing to deliver wire with excellent tensile strength and flexibility, making it easy to form into complex shapes. Compared to others, our wire offers better corrosion resistance and a wider range of sizes—0.05mm to 5mm in thickness and custom widths for flat profiles. We keep lead times tight and prices competitive, giving you top-quality wire without the hassle or high costs.

Comparison Table

|

Parameter |

Our CuNi10 Flat Wire |

Competitor A |

Competitor B |

|---|---|---|---|

|

Nickel Content |

~10% |

~10% |

~10% |

|

Resistivity (μΩ·cm) |

0.15 |

0.16 |

0.17 |

|

Max Operating Temp (°C) |

250 |

230 |

240 |

|

Corrosion Resistance |

Excellent |

Good |

High |

|

Ductility |

High |

Moderate |

Good |

|

Tensile Strength (N/mm²) |

~350 |

~320 |

~330 |

|

Weldability |

Excellent |

Good |

Good |

|

Availability (Sizes) |

0.05-5mm thick, custom widths |

0.1-4mm thick |

0.08-4.5mm thick |

About Us:

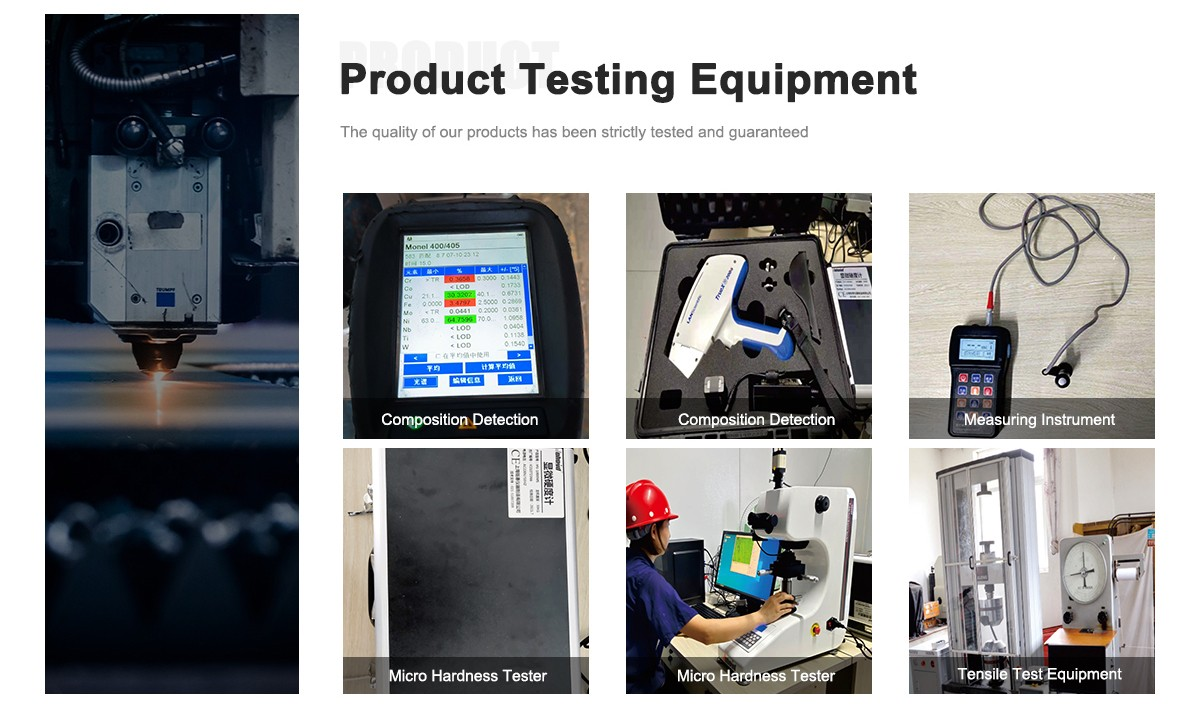

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

-

Why is CuNi10 flat wire good for heating elements?

Its moderate resistivity (0.15 μΩ·cm) and high heat tolerance up to 250°C ensure efficient, reliable performance. -

Can CuNi10 flat wire resist corrosion?

You bet—it’s built to withstand moisture and chemicals, perfect for marine or industrial settings. -

What industries use CuNi10 flat wire?

It’s big in automotive, electronics, and renewable energy for resistors and heating applications. -

How does your CuNi10 flat wire compare to others?

Ours has better resistivity consistency, higher durability, and more size options for flexibility. -

Can you customize CuNi10 flat wire dimensions?

Absolutely, we offer thicknesses from 0.05mm to 5mm and custom widths to fit your needs. -

Is CuNi10 flat wire easy to work with?

Totally, its high ductility and weldability make it a breeze to shape and install. -

How fast can you deliver CuNi10 flat wire?

We’re speedy—most orders ship within 1-2 weeks, depending on specs and volume. -

Is CuNi10 flat wire cost-effective?