Heating applications require materials that not only withstand high temperatures but also deliver stable, reliable performance over long cycles. 0Cr21Al4 FeCrAl resistance wire is one of the most dependable alloys available, offering a combination of strength, oxidation resistance, and cost efficiency. This alloy has become a mainstay in kilns, industrial furnaces, and heating elements used across multiple industries.

At DLX, we are committed to supplying high-grade 0Cr21Al4 FeCrAl resistance wire that complies with international standards. Our customers rely on us for precision, durability, and tailored solutions that keep their heating systems running efficiently.

For more details, pls directly contact us

0Cr21Al4 belongs to the FeCrAl alloy family, with chromium and aluminum added to provide stability under high temperatures. The aluminum content forms a protective oxide layer when exposed to heat, shielding the wire from degradation and allowing for extended operation. This makes the alloy particularly well-suited for continuous use in harsh environments.

Its relatively lower density compared to NiCr wire also offers manufacturers a lighter, more flexible material, making it easier to design heating elements that balance efficiency with durability. With resistivity values that allow energy-efficient heating, 0Cr21Al4 is a material that blends technical performance with economic benefits.

Alloy Nomenclature Performance | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr27Al7Mo2 | ||||

Chemical Compostion (%) | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

Re | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | |

Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

-- | -- | -- | -- | -- | -- | -- | ||

Max.Continuous service temp. of element | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

Resistivity at 20C(μΩ.m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

Density(g/cm) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

Thermal Conductivity(KJ/m.h) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | -- | |

Coefficient of lines expansion(αx10-6/℃) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

Melting Point Approx(degree) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

Tensile Strength(N/mm) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

Elongation at rupture(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

Variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

Repeat Bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

Hardness(H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

continuous service time(Hours/ ºC) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥80/1350 | ≥80/1350 | |

Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Shape | Size (mm) |

Wire | 0.05-7.5 |

Rod | 8-50 |

Ribbon | (0.05-0.35)*(0.5-6.0) |

Strip | (0.5-2.5)*(5-180) |

For more details, pls directly contact us

The versatility of 0Cr21Al4 wire is one of the reasons it is widely adopted. In industrial contexts, it is used in kilns, ceramic firing equipment, and glass production lines where stable high temperatures are critical. It also plays a vital role in metallurgical furnaces and other heat-treatment systems that require long-term resistance performance.

In the domestic appliance market, it is found in heaters, ovens, and other household equipment, where safety, stability, and durability are non-negotiable. Because the material maintains its integrity under continuous heating cycles, it reduces maintenance costs and extends product lifespans for end users.

Comparison Table: 0Cr21Al4 FeCrAl Resistance Wire vs. NiCr Resistance Wire

| Parameter | 0Cr21Al4 FeCrAl Resistance Wire | NiCr Resistance Wire |

|---|---|---|

| Base Composition | Fe-Cr-Al | Ni-Cr |

| Max Operating Temperature | ~1250°C | ~1100°C |

| Oxidation Resistance | Excellent | Good |

| Service Life at High Temp | Longer | Moderate |

| Density (g/cm³) | ~7.2 | ~8.4 |

| Electrical Resistivity (Ω·mm²/m) | 1.35–1.45 | 1.09–1.18 |

| Cost Efficiency | More economical | Higher raw material cost |

| Applications | Kilns, furnaces, appliances | Appliances, lab devices |

Global demand for efficient heating technologies is growing, driven by both industrial expansion and the need for sustainable energy use. Industries are moving toward electrification and away from fossil fuel-based heating systems, boosting the demand for alloys like 0Cr21Al4 that provide efficient and environmentally friendly solutions.

The ceramics and glass sectors are seeing particularly strong adoption of FeCrAl alloys, thanks to their ability to handle very high temperatures without costly downtime. Appliance manufacturers are also aligning with global energy-efficiency standards, further cementing the role of this alloy.

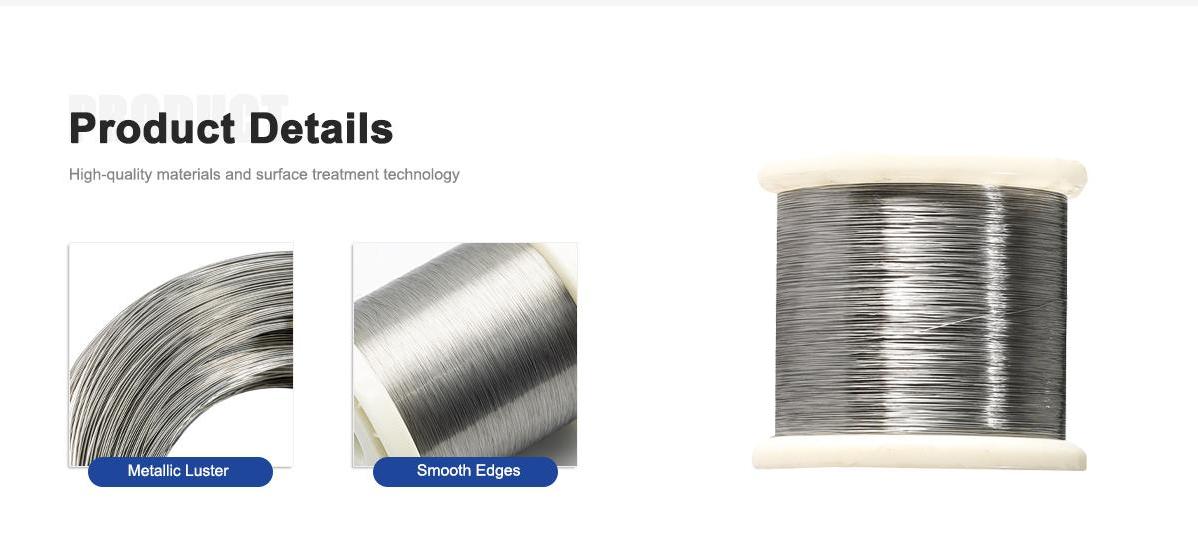

What sets DLX apart is not only the quality of the material we deliver but also the level of support and customization we provide. Every spool and coil of 0Cr21Al4 resistance wire from DLX undergoes strict quality inspection to guarantee consistent resistivity and tolerance.

We understand that different projects require different specifications. That’s why we offer flexibility in diameter, coil length, and resistance values, helping our customers optimize their heating element designs. For manufacturers who operate in high-demand industries, our tailored solutions save time and costs.

Company Comparison

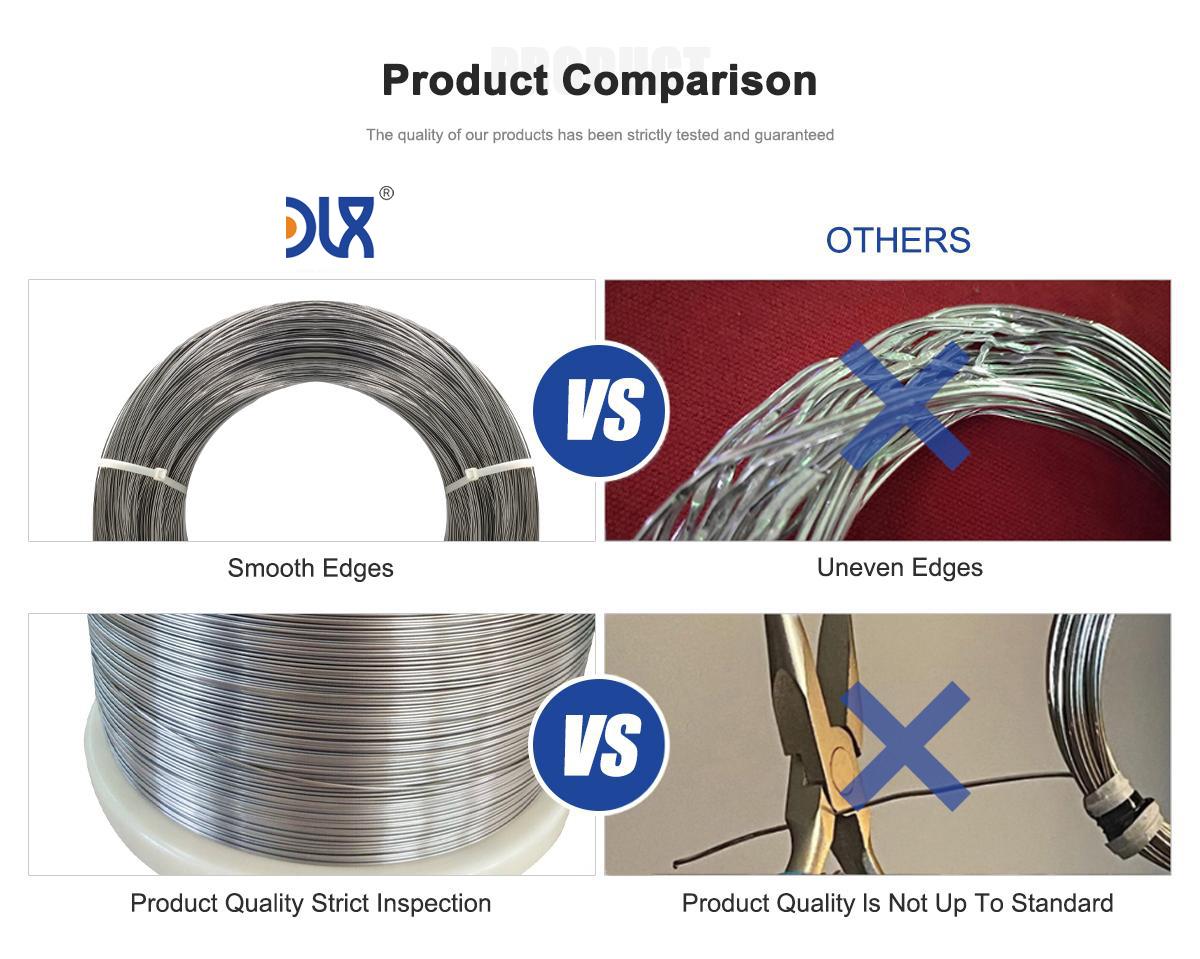

Compared to general suppliers, DLX offers three distinct advantages:

Consistency: Our wire quality is monitored across every batch, ensuring reliability.

Customization: Clients can request tailored formats, diameters, and resistances.

Logistics: With a robust global supply chain, DLX delivers quickly and securely.

This combination allows our partners to minimize downtime, improve efficiency, and stay competitive in their markets.

As the heating industry moves toward more efficient, long-lasting materials, 0Cr21Al4 FeCrAl resistance wire is expected to maintain a strong position. DLX is committed to supporting this growth by delivering resistance wires that exceed expectations and adapt to evolving industry needs.

Our focus is not just on meeting current demands, but also on anticipating the future—providing materials and expertise that help our clients succeed in a world that increasingly values efficiency, sustainability, and reliability.

Conclusion

0Cr21Al4 FeCrAl resistance wire has proven itself as a leading material for kilns, furnaces, and heating elements. Its balance of high-temperature resistance, oxidation protection, and efficiency makes it indispensable for industries and appliances alike.

DLX goes further by combining international quality standards with customer-focused services, ensuring our partners benefit from consistent performance, flexibility, and reliable delivery. By choosing DLX, manufacturers gain more than a supplier—they gain a trusted partner for long-term success.

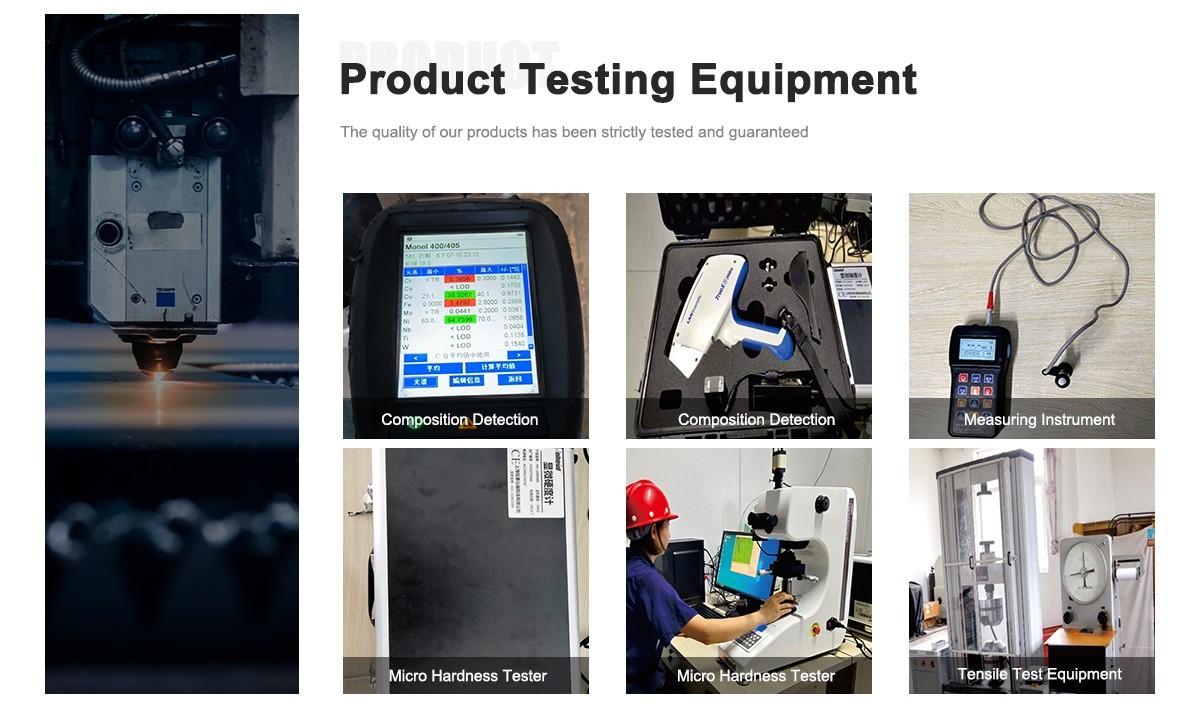

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What is 0Cr21Al4 resistance wire made of?

It is an iron-chromium-aluminum alloy designed for high resistance and superior oxidation protection.What is the maximum working temperature of 0Cr21Al4 wire?

It can operate stably at temperatures up to about 1250°C.Which industries commonly use 0Cr21Al4 FeCrAl resistance wire?

It is used in kilns, industrial furnaces, metallurgy, ceramics, glass production, and household appliances.How does it compare to nickel-chromium resistance wire?

It has higher temperature capacity, better oxidation resistance, and often provides a longer service life.Can 0Cr21Al4 wire be supplied in customized formats?

Yes, it is available in spools, coils, straight rods, and cut-to-length formats.Is this wire suitable for continuous heating?

Yes, it is stable in long-term high-temperature environments and resists creep.What is its density?

Approximately 7.2 g/cm³, lighter than NiCr wires, offering more design flexibility.Why choose DLX for 0Cr21Al4 resistance wire?

Because DLX delivers reliable quality, precise tolerances, competitive pricing, and fast global logistics.