When it comes to heating applications that demand long-term stability at elevated temperatures, 0Cr21Al4 alloy wire is one of the most trusted materials. As part of the FeCrAl family, this alloy balances durability, oxidation resistance, and cost efficiency, making it a preferred choice for heating elements, kilns, and industrial furnaces.

At DLX, we supply high-quality 0Cr21Al4 alloy wire that not only meets but exceeds international standards. Our goal is to provide customers with dependable materials that drive performance, reliability, and efficiency in their heating systems.

For more details, pls directly contact us

0Cr21Al4 is composed primarily of iron with chromium and aluminum additions. The chromium enhances corrosion resistance, while aluminum provides oxidation resistance by forming a protective layer of alumina on the surface during high-temperature exposure. This protective layer significantly extends the service life of heating elements, especially under continuous operation.

Its relatively lower density compared to NiCr wires gives engineers flexibility in designing lighter and more efficient heating systems. The alloy also provides stable resistivity, making it well-suited for applications where consistent heating output is critical.

Alloy Nomenclature Performance | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr27Al7Mo2 | ||||

Chemical Compostion (%) | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

Re | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | |

Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

-- | -- | -- | -- | -- | -- | -- | ||

Max.Continuous service temp. of element | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

Resistivity at 20C(μΩ.m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

Density(g/cm) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

Thermal Conductivity(KJ/m.h) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | -- | |

Coefficient of lines expansion(αx10-6/℃) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

Melting Point Approx(degree) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

Tensile Strength(N/mm) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

Elongation at rupture(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

Variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

Repeat Bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

Hardness(H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

continuous service time(Hours/ ºC) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥80/1350 | ≥80/1350 | |

Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Shape | Size (mm) |

Wire | 0.05-7.5 |

Rod | 8-50 |

Ribbon | (0.05-0.35)*(0.5-6.0) |

Strip | (0.5-2.5)*(5-180) |

For more details, pls directly contact us

The versatility of 0Cr21Al4 alloy wire allows it to serve both industrial and household sectors. It is used extensively in kilns for ceramics, industrial furnaces for metallurgy, and glass production processes where sustained high temperatures are essential. In household appliances, it powers ovens, heaters, and toasters, delivering reliable and safe performance.

Because of its ability to resist creep and maintain mechanical strength at elevated temperatures, 0Cr21Al4 is especially valued in continuous-heating environments. This reduces replacement frequency, minimizes downtime, and increases cost savings for manufacturers.

Comparison Table: 0Cr21Al4 Alloy Wire vs. NiCr Alloy Wire

| Parameter | 0Cr21Al4 Alloy Wire | NiCr Alloy Wire |

|---|---|---|

| Composition | Fe-Cr-Al | Ni-Cr |

| Max Operating Temperature | ~1250°C | ~1100°C |

| Oxidation Resistance | Excellent | Good |

| Service Life | Longer | Moderate |

| Density (g/cm³) | ~7.2 | ~8.4 |

| Electrical Resistivity (Ω·mm²/m) | 1.35–1.45 | 1.09–1.18 |

| Cost Efficiency | More economical | Higher material cost |

| Applications | Kilns, heaters, furnaces | Appliances, lab devices |

The global shift toward energy-efficient and sustainable heating solutions has reinforced the importance of FeCrAl alloys like 0Cr21Al4. Industries are steadily moving away from fossil-fuel-based heating systems and adopting electrically powered solutions. This change highlights the need for alloys that combine high performance with long service life.

In industrial manufacturing, particularly in ceramics and glass, demand for alloys that can endure higher working temperatures without frequent maintenance is on the rise. Appliance makers also prefer 0Cr21Al4 because it allows them to design compact, efficient, and durable heating systems that comply with international safety and performance standards.

DLX Advantage

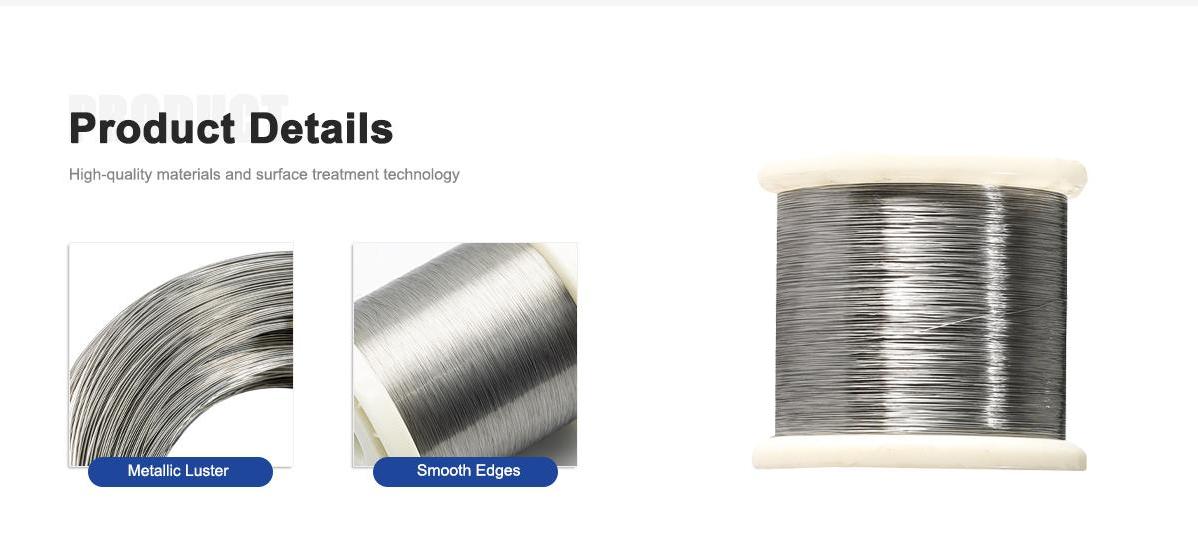

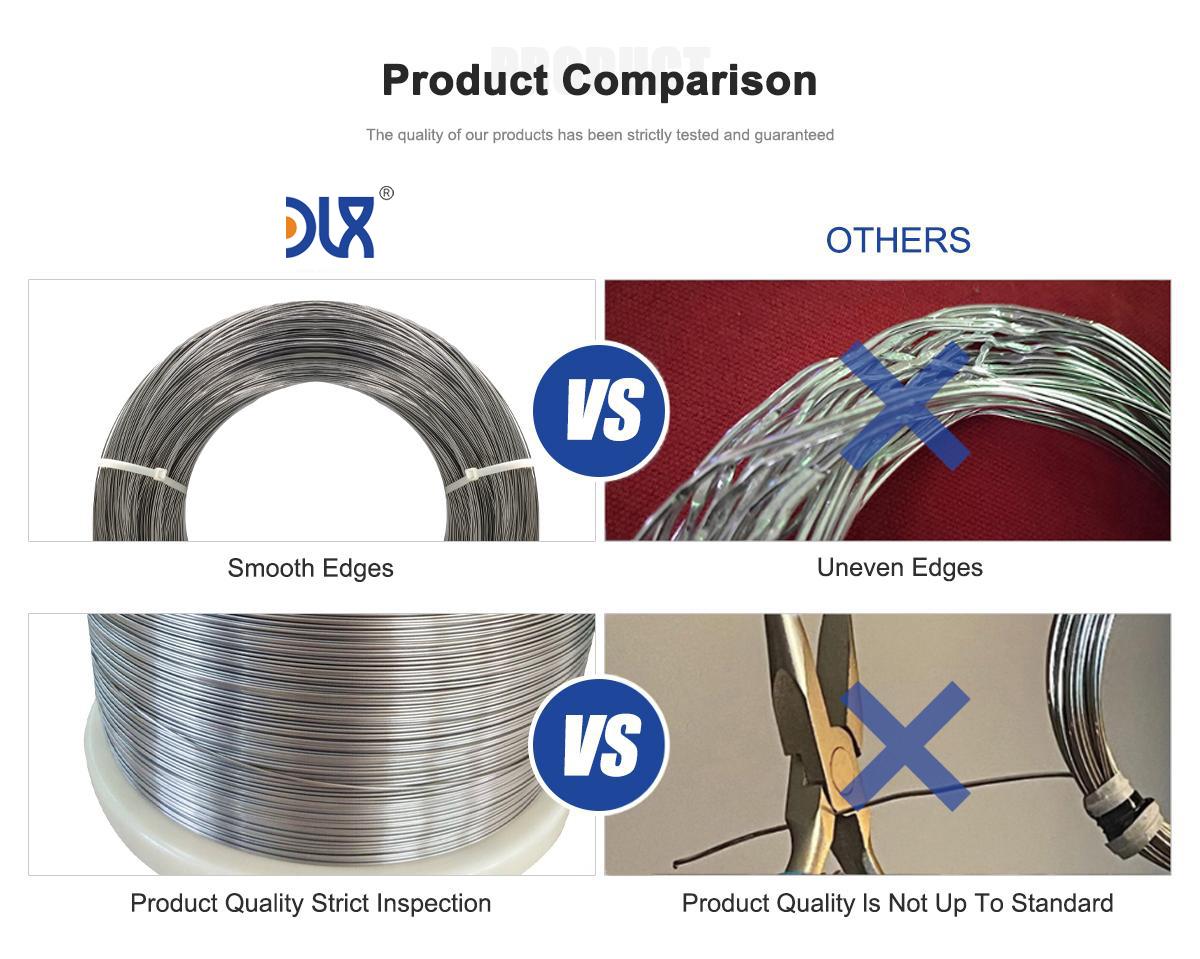

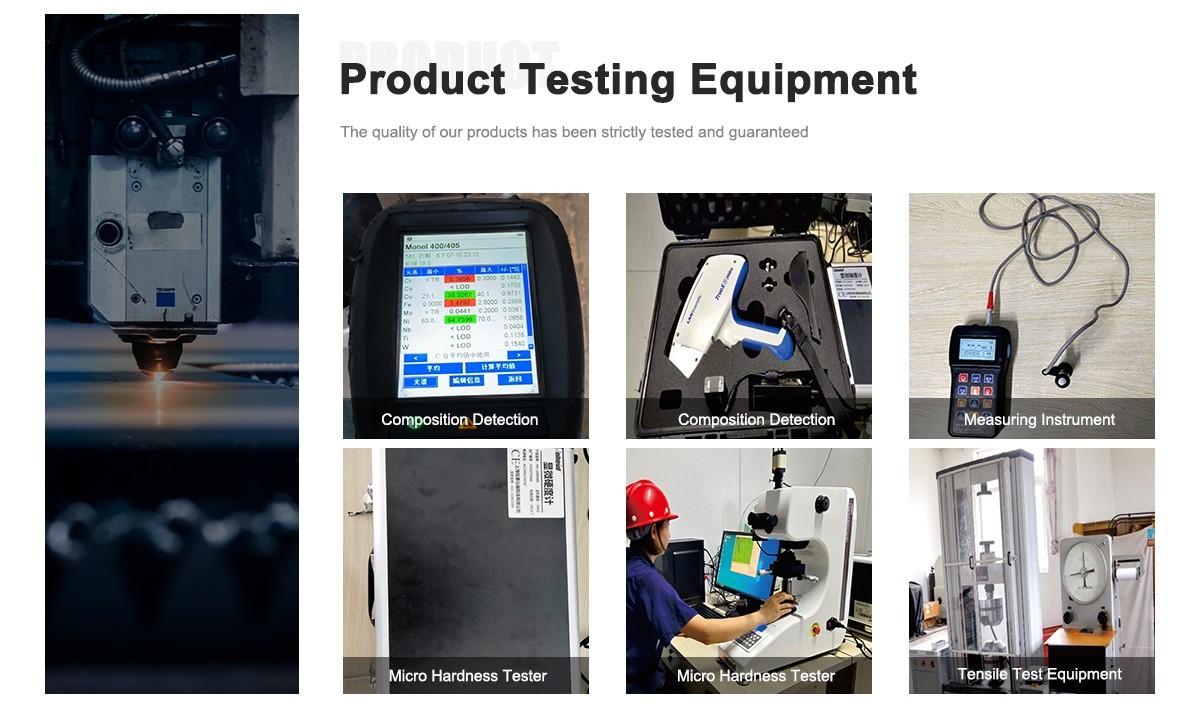

DLX distinguishes itself by offering not only superior-quality 0Cr21Al4 alloy wire but also comprehensive support that helps customers optimize their operations. Every batch we produce is tested rigorously for resistivity and tolerance accuracy, ensuring consistency across global markets.

We provide flexibility in supply formats — from large spools for mass production to custom lengths for specific heating applications. Our technical team works closely with clients to recommend the best diameter and resistance specifications for their needs, giving them a competitive edge in design and production.

While other suppliers may provide FeCrAl wire, DLX offers a more complete package:

Consistency: Our production and testing systems ensure reliable performance in every shipment.

Customization: We adapt our supply to match exact customer requirements.

Global Delivery: Our international logistics network provides fast and dependable delivery.

These factors make DLX a trusted partner for companies across industries that require both quality and efficiency.

Global Equivalents

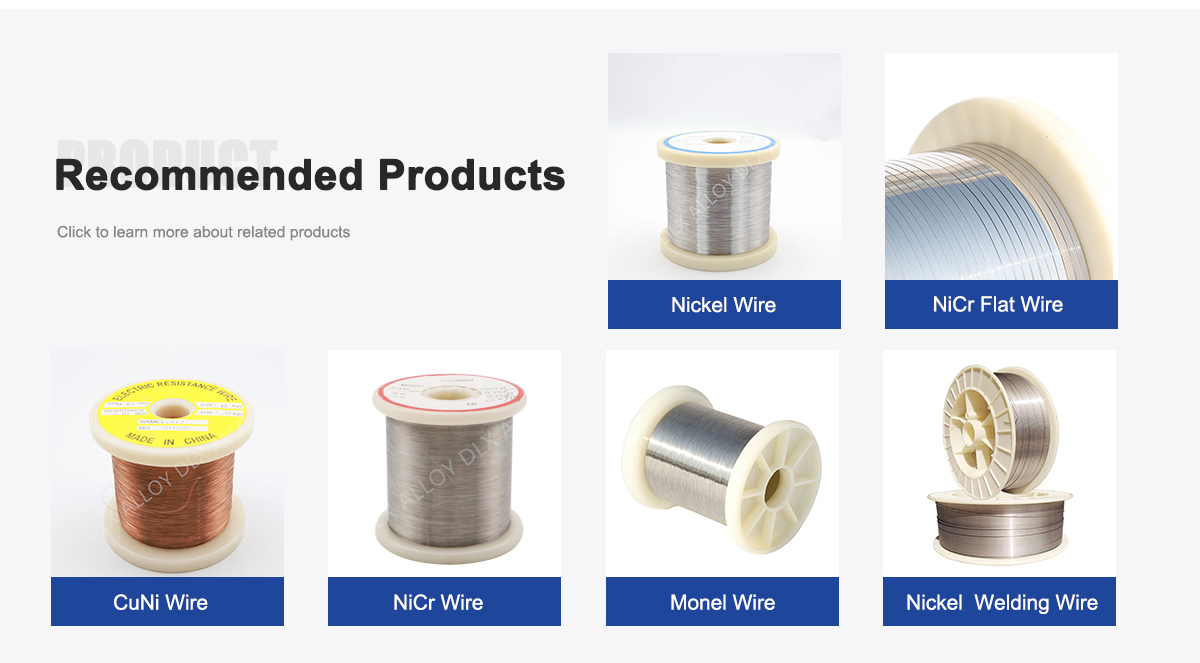

0Cr21Al4 alloy wire is recognized globally under different equivalent standards. Its properties align closely with other FeCrAl grades used worldwide, ensuring compatibility with international applications. DLX ensures compliance with these equivalents, giving customers confidence that our wire integrates seamlessly into their production systems, no matter where they operate.

As industries evolve toward higher efficiency and sustainability, 0Cr21Al4 alloy wire will continue to be a material of choice. Its ability to withstand high temperatures, resist oxidation, and deliver cost-effective performance makes it indispensable for heating technologies of the future.

At DLX, we remain dedicated to delivering solutions that support this evolution. With our focus on precision, customization, and customer partnership, we provide more than just materials — we deliver reliability that keeps production moving forward.

0Cr21Al4 alloy wire offers unmatched value for high-temperature heating applications. Its superior oxidation resistance, long service life, and adaptability across industries ensure it remains a leading material in global markets.

By choosing DLX, customers gain more than a supplier — they gain a partner committed to delivering international-standard materials with consistent quality, tailored solutions, and dependable global logistics. This is why DLX continues to be a trusted name for 0Cr21Al4 alloy wire worldwide.

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What is 0Cr21Al4 alloy wire made of?

It is an iron-chromium-aluminum alloy engineered for resistance and high-temperature stability.What is the maximum operating temperature of 0Cr21Al4 wire?

It can perform reliably at temperatures up to around 1250°C.Which industries commonly use 0Cr21Al4 alloy wire?

It is widely used in kilns, furnaces, ceramics, glass production, metallurgy, and household appliances.How does 0Cr21Al4 compare to NiCr alloy wire?

It offers higher oxidation resistance, better high-temperature performance, and longer service life.Can 0Cr21Al4 wire be produced in different forms?

Yes, it is available in spools, coils, rods, and cut-to-length options.Is this wire suitable for continuous heating applications?

Yes, it resists creep and maintains integrity in long-term high-temperature environments.What is its density?

Around 7.2 g/cm³, lighter than NiCr alternatives, providing more design flexibility.Why choose DLX for 0Cr21Al4 alloy wire?

Because DLX ensures strict quality, customized supply options, and global delivery support.