When it comes to heating elements designed for furnaces and ovens, material selection plays a critical role in performance, durability, and efficiency. One alloy that has consistently proven its value in industrial and commercial applications is 0Cr19Al3 heating resistance wire. Known for its balanced chromium and aluminum content, this FeCrAl alloy delivers reliable high-temperature performance while maintaining good oxidation resistance.

For more details, pls directly contact us

0Cr19Al3 is a ferritic iron-chromium-aluminum alloy. With approximately 19% chromium and 3% aluminum, this wire offers a stable balance of heat resistance and oxidation protection. The chromium enhances corrosion resistance, while aluminum contributes to forming a dense oxide layer that protects the wire under elevated temperatures. This makes the alloy well-suited for electric furnaces, ovens, and various heating systems that demand consistent thermal output and long service life.

Alloy Nomenclature Performance | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al6Nb | |||||

Chemical Compostion (%) | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

Re | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | |

Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

-- | -- | -- | -- | -- | -- | -- | ||

Max.Continuous service temp. of element | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

Resistivity at 20C(μΩ.m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

Density(g/cm) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

Thermal Conductivity(KJ/m.h) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | -- | |

Coefficient of lines expansion(αx10-6/℃) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

Melting Point Approx(degree) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

Tensile Strength(N/mm) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

Elongation at rupture(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

Variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

Repeat Bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

Hardness(H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

continuous service time(Hours/ ºC) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥80/1350 | ≥80/1350 | |

Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Shape | Size (mm) |

Wire | 0.05-7.5 |

Rod | 8-50 |

Ribbon | (0.05-0.35)*(0.5-6.0) |

Strip | (0.5-2.5)*(5-180) |

For more details, pls directly contact us

The primary applications of 0Cr19Al3 heating resistance wire include:

Electric furnaces: Ensuring uniform heating for industrial heat treatment processes.

Baking and drying ovens: Reliable heating for commercial food equipment and drying units.

Industrial heaters: Used in air heaters, infrared heaters, and tubular heating elements.

Resistive heating systems: Suitable for both large-scale and smaller electric heating elements.

Thanks to its stability, 0Cr19Al3 is widely used where performance at around 1250°C is required without rapid degradation of the heating element.

Industry Analysis

The demand for FeCrAl resistance wires, including 0Cr19Al3, has seen steady growth due to expanding industrial applications that rely on consistent heating. Industries like metallurgy, ceramics, electronics, and household appliances increasingly require alloys that can withstand frequent heating and cooling cycles. With global initiatives focusing on energy efficiency, materials like 0Cr19Al3 are becoming even more important. They help manufacturers design furnaces and ovens that last longer, reduce downtime, and improve overall energy consumption.

Another factor driving the market is the shift toward high-performance heating solutions in renewable energy applications and advanced material processing. FeCrAl alloys are becoming the go-to choice where thermal stability and safety are essential.

Application Benefits

The advantages of using 0Cr19Al3 in heating systems include:

Durability: The alloy provides a longer operational lifespan compared to lower chromium content wires.

Oxidation resistance: Protective oxide layers minimize scaling and material loss.

Temperature tolerance: Consistent performance up to 1250°C ensures reliability.

Versatility: Applicable across industries from food processing to high-tech manufacturing.

Comparison Table: 0Cr19Al3 vs Other FeCrAl Resistance Wires

| Alloy Type | Main Composition (Fe-Cr-Al %) | Max Operating Temp (°C) | Oxidation Resistance | Typical Applications |

|---|---|---|---|---|

| 0Cr19Al3 | Fe-19Cr-3Al | ~1250°C | Good | Electric furnaces, ovens, heaters |

| 0Cr21Al4 | Fe-21Cr-4Al | ~1350°C | Excellent | Kilns, ceramic heaters, industrial |

| 1Cr13Al4 | Fe-13Cr-4Al | ~1100°C | Moderate | Appliances, small heaters |

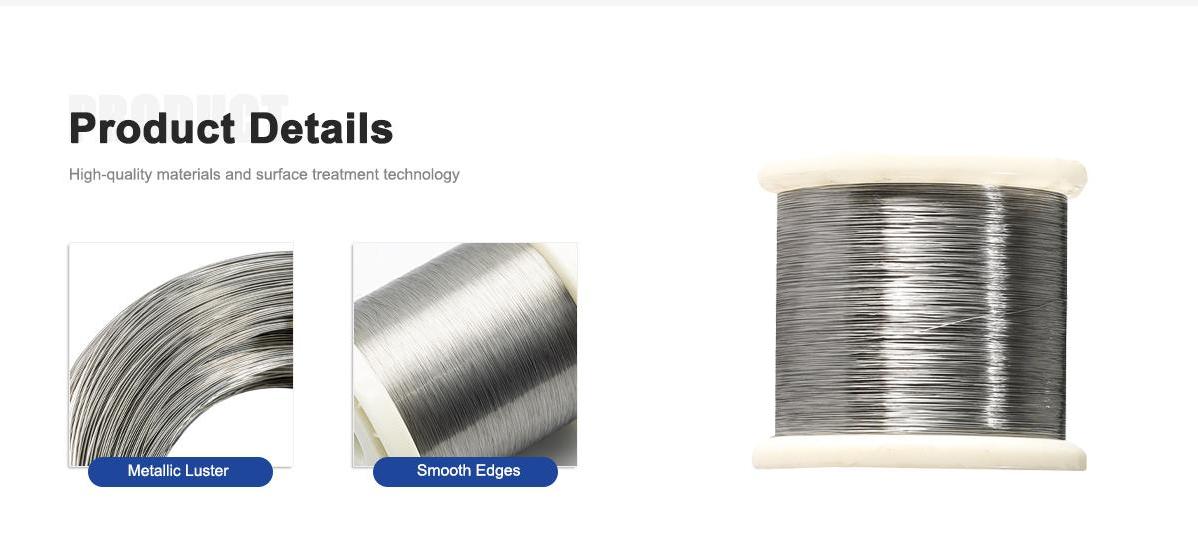

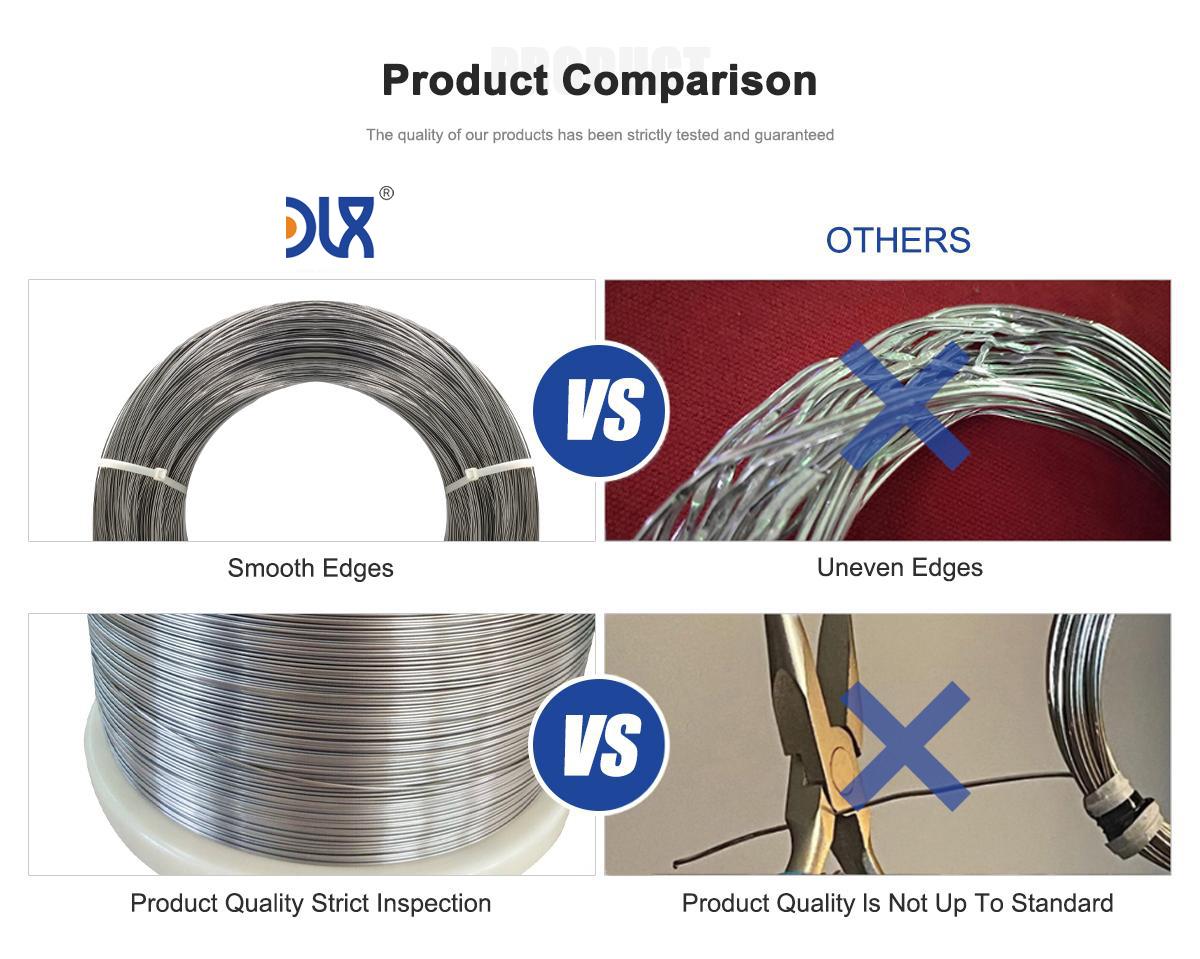

At DLX, we specialize in producing and supplying high-quality FeCrAl resistance wires, including 0Cr19Al3. Our production process ensures tight control over composition, wire diameter, and mechanical properties. This allows us to deliver consistent, internationally compliant materials that meet the needs of both industrial and commercial clients.

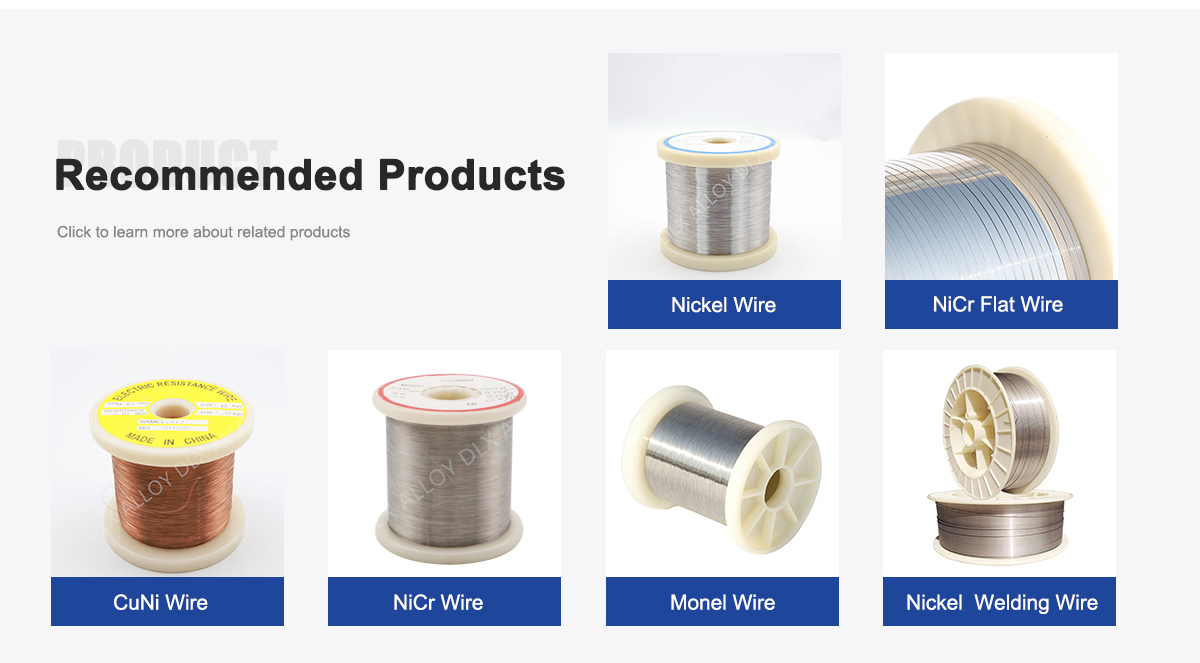

Compared with many competitors, DLX offers a unique blend of flexibility and reliability. We not only provide standard wire sizes but also custom solutions tailored to specific applications. Whether you need spooled wire, straight cut lengths, or processed heating elements, DLX delivers products with precise performance standards. Our global customer support ensures that clients can depend on DLX as a long-term partner for heating resistance materials.

Industry Trends

Growing demand for energy-efficient furnaces: The push for lower energy consumption makes alloys like 0Cr19Al3 more relevant.

Expansion in electronics and renewable energy: Heating wires are increasingly used in precision thermal management systems.

Global standardization: Customers prefer materials compliant with international benchmarks, and DLX ensures adherence to these requirements.

Customization requests: End-users are asking for specific wire designs to improve performance in niche applications.

Conclusion

0Cr19Al3 heating resistance wire is a dependable choice for electric furnaces, ovens, and industrial heaters. With its balance of heat resistance, oxidation protection, and durability, it supports industries aiming for efficiency and longevity. As market demand for high-performance heating solutions grows, DLX continues to lead by providing premium-quality alloys with a customer-first approach. Choosing DLX means partnering with a supplier committed to innovation, quality, and reliable global delivery.

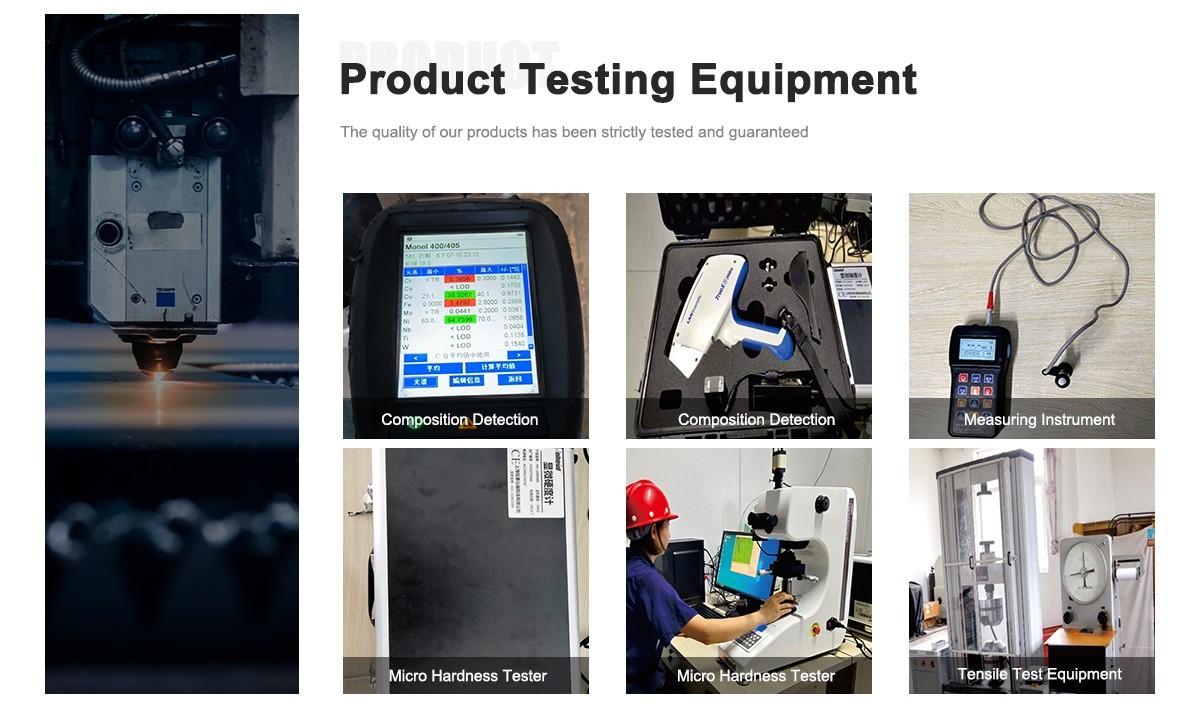

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing: