0Cr19Al3 alloy wire belongs to the FeCrAl (iron-chromium-aluminum) family, known for its strong oxidation resistance and ability to perform under elevated temperatures. With 19% chromium and 3% aluminum, it is a versatile material that balances cost, performance, and durability. This grade is widely used in heating applications where stable performance and long service life are essential.

For more details, pls directly contact us.

The standout feature of 0Cr19Al3 is its oxidation resistance at high temperatures. The aluminum in the alloy forms a dense Al₂O₃ layer on the surface when heated, protecting the wire from further oxidation and degradation. Chromium content enhances corrosion resistance and structural stability, while the iron base keeps the alloy cost-effective compared to nickel-based alternatives. The alloy maintains reliable mechanical strength up to around 1200°C, making it suitable for continuous heating operations.

Alloy Nomenclature Performance | 0Cr21Al4 | 0Cr27Al7Mo2 | ||||||

Chemical Compostion (%) | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

Re | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | |

Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

-- | -- | -- | -- | -- | -- | -- | ||

Max.Continuous service temp. of element | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

Resistivity at 20C(μΩ.m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

Density(g/cm) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

Thermal Conductivity(KJ/m.h) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | -- | |

Coefficient of lines expansion(αx10-6/℃) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

Melting Point Approx(degree) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

Tensile Strength(N/mm) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

Elongation at rupture(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

Variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

Repeat Bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

Hardness(H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

continuous service time(Hours/ ºC) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥80/1350 | ≥80/1350 | |

Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Shape | Size (mm) |

Wire | 0.05-7.5 |

Rod | 8-50 |

Ribbon | (0.05-0.35)*(0.5-6.0) |

Strip | (0.5-2.5)*(5-180) |

For more details, pls directly contact us.

The range of applications for 0Cr19Al3 alloy wire is broad. It is commonly used in:

Industrial Furnaces: As heating elements for annealing, sintering, and heat treatment.

Household Appliances: In devices like electric ovens, toasters, and dryers.

Ceramic and Glass Industries: As embedded heating elements in kilns and glass melting equipment.

Energy Sector: In heating equipment for power plants and renewable energy systems.

Resistors and Wire-Wound Components: For precision control in electronic applications.

This alloy’s high resistivity and long-term stability make it a reliable choice for industries that demand both safety and efficiency.

Market and Industry Trends

Global demand for FeCrAl alloys, including 0Cr19Al3, is increasing due to growth in clean energy, efficient heating systems, and advanced materials manufacturing. As industries shift toward sustainability and energy efficiency, alloys like 0Cr19Al3 become essential in reducing energy consumption and extending equipment life. Emerging markets in Asia, alongside steady demand from Europe and North America, are shaping a competitive environment where suppliers need to guarantee quality consistency and compliance with international standards.

International Grade Equivalents

0Cr19Al3 has equivalents across different standards:

USA: Kanthal A-1 family comparable grades (FeCrAl)

Germany: DIN FeCrAl series with similar Cr/Al ratios

France: AFNOR FeCrAl types

Russia: Х23Ю5Т (X23Yu5T) and similar FeCrAl compositions

These equivalents highlight its recognition as a trusted alloy across global markets.

Comparison Table: 0Cr19Al3 Alloy Wire vs Similar Alloys

| Alloy Grade | Composition (Cr/Al %) | Max Service Temp (°C) | Density (g/cm³) | Tensile Strength (MPa) | Typical Applications |

|---|---|---|---|---|---|

| 0Cr19Al3 (FeCrAl) | Cr 19%, Al 3% | ~1200 | 7.2 | 650–850 | Heating elements, furnaces, kilns |

| 0Cr21Al4 | Cr 21%, Al 4% | ~1250 | 7.25 | 650–850 | Industrial ovens, resistors |

| 0Cr23Al5 | Cr 23%, Al 5% | ~1300 | 7.3 | 650–900 | High-temp furnaces, metallurgy |

| Ni80Cr20 (NiCr) | Ni 80%, Cr 20% | ~1100 | 8.4 | 700–900 | Electric heating elements, resistors |

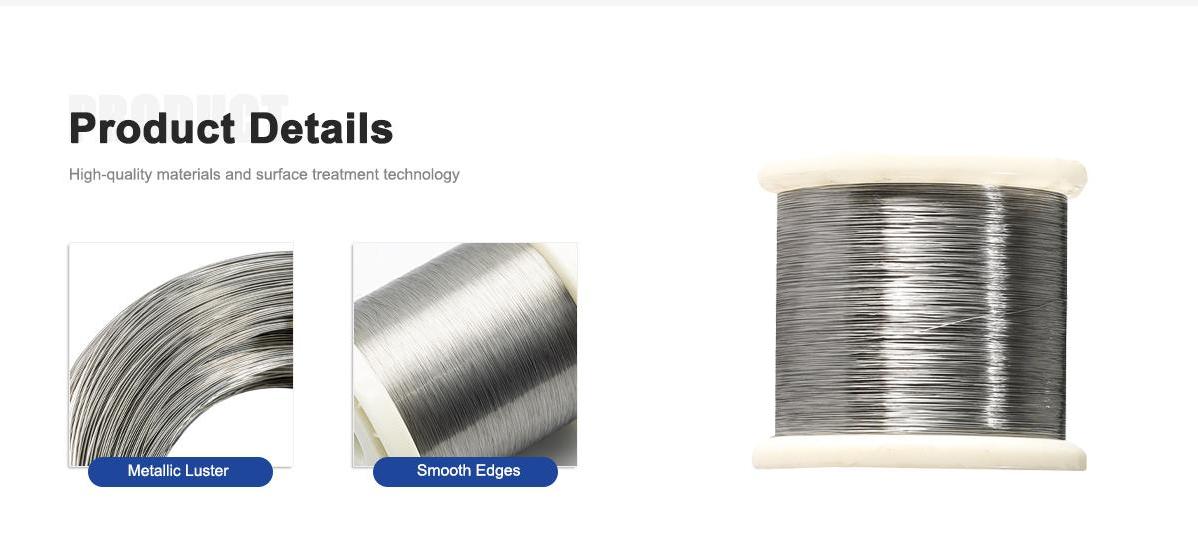

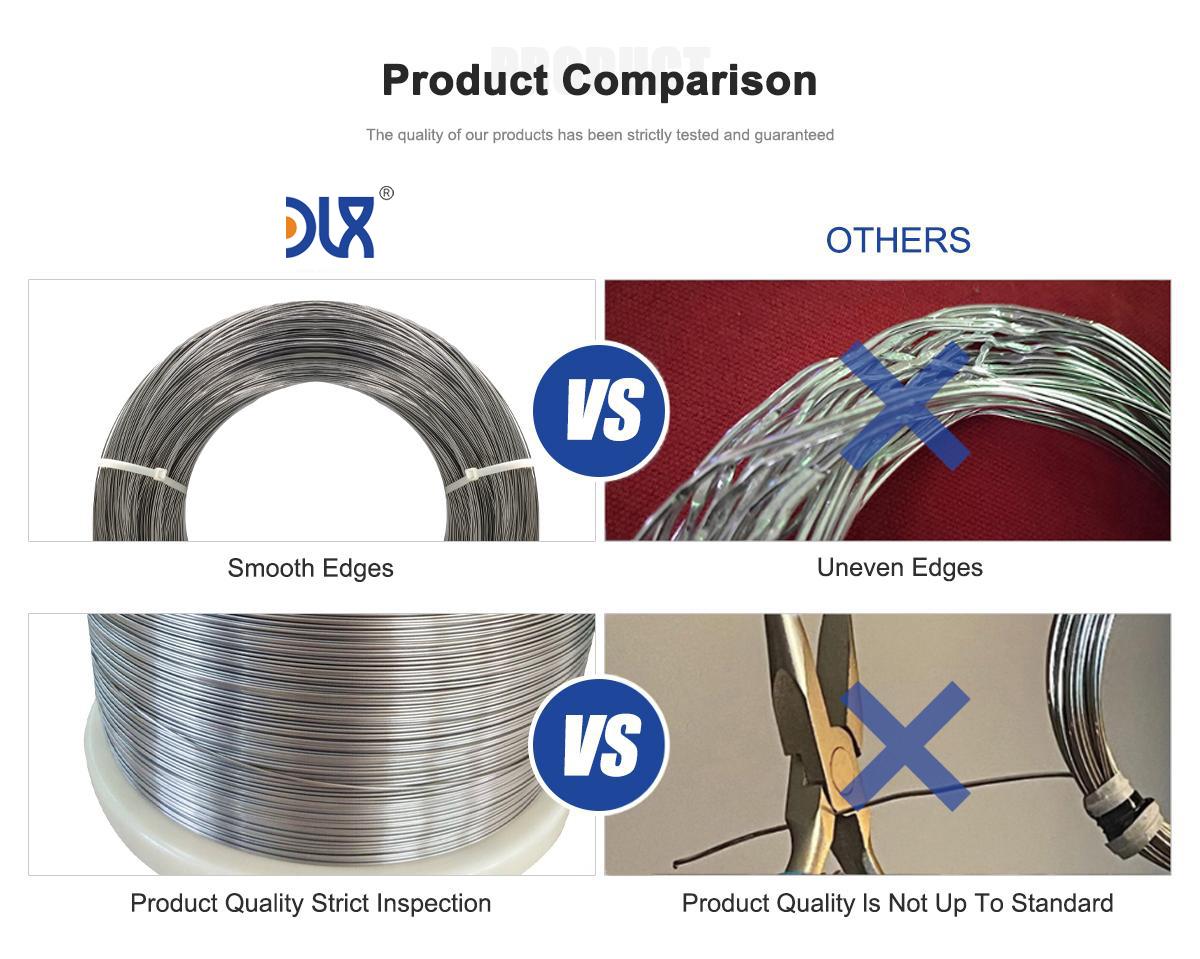

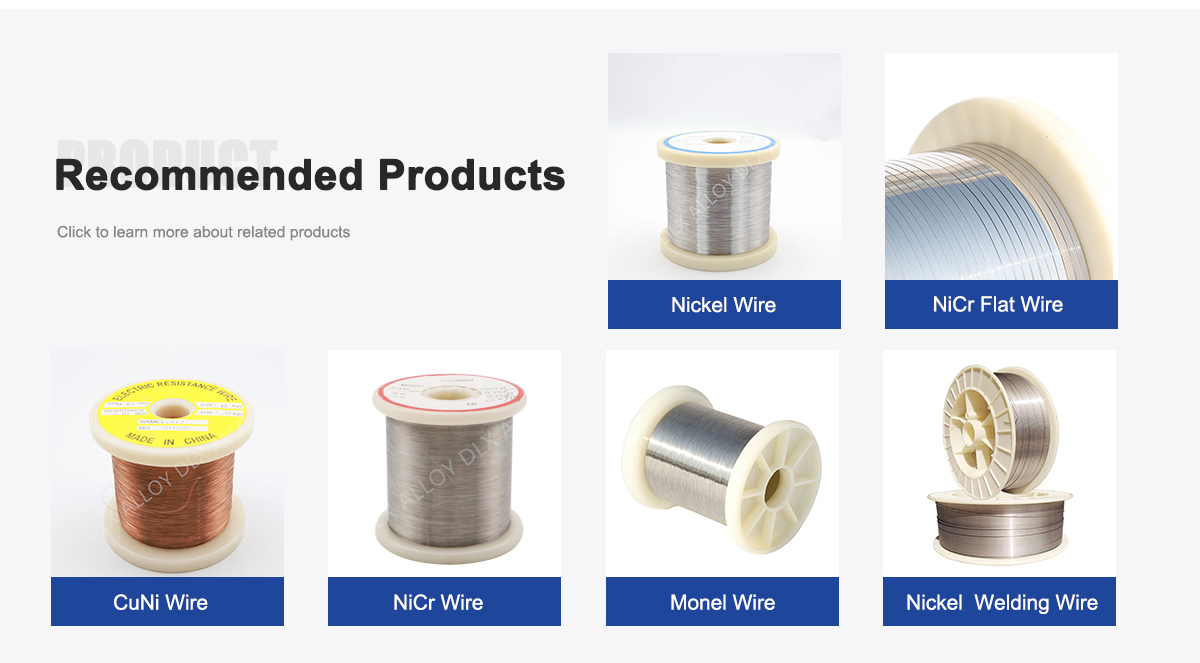

At DLX, we position ourselves as a reliable supplier of 0Cr19Al3 alloy wire by focusing on three key aspects: quality, customization, and delivery. Our production processes ensure precise chemical composition and mechanical consistency, giving customers confidence in performance under extreme conditions. We also provide flexibility in dimensions—whether fine wires, strips, or coils—catering to different industries and applications.

Another advantage we emphasize is technical support. Many buyers require guidance on choosing the right alloy grade for specific applications, especially when comparing 0Cr19Al3 to higher chromium or nickel-based alloys. DLX provides detailed consultation and data-driven recommendations, reducing trial-and-error costs for clients.

Finally, DLX maintains a strong international logistics network. With experience supplying to Europe, North America, and Asia, we ensure timely delivery and compliance with local regulations. This global reach, paired with technical expertise, sets us apart from competitors who may focus only on commodity supply.

Competitive Comparison

While nickel-based alloys like Ni80Cr20 offer good resistance and are widely used, they come with higher costs and slightly lower temperature limits. On the other hand, higher chromium FeCrAl alloys such as 0Cr23Al5 can handle hotter environments but may not be necessary for all applications. 0Cr19Al3 provides an excellent middle ground—offering affordability, durability, and performance that meets most industrial requirements. DLX leverages this balance to help clients optimize their costs without compromising reliability.

Looking ahead, 0Cr19Al3 alloy wire is set to maintain strong demand in both traditional and emerging industries. As global energy and manufacturing sectors emphasize longevity and sustainability, this alloy’s balance of properties will continue to attract attention. DLX’s strategy is to invest in R&D, continuously refining production techniques and offering customers innovative solutions tailored to evolving requirements.

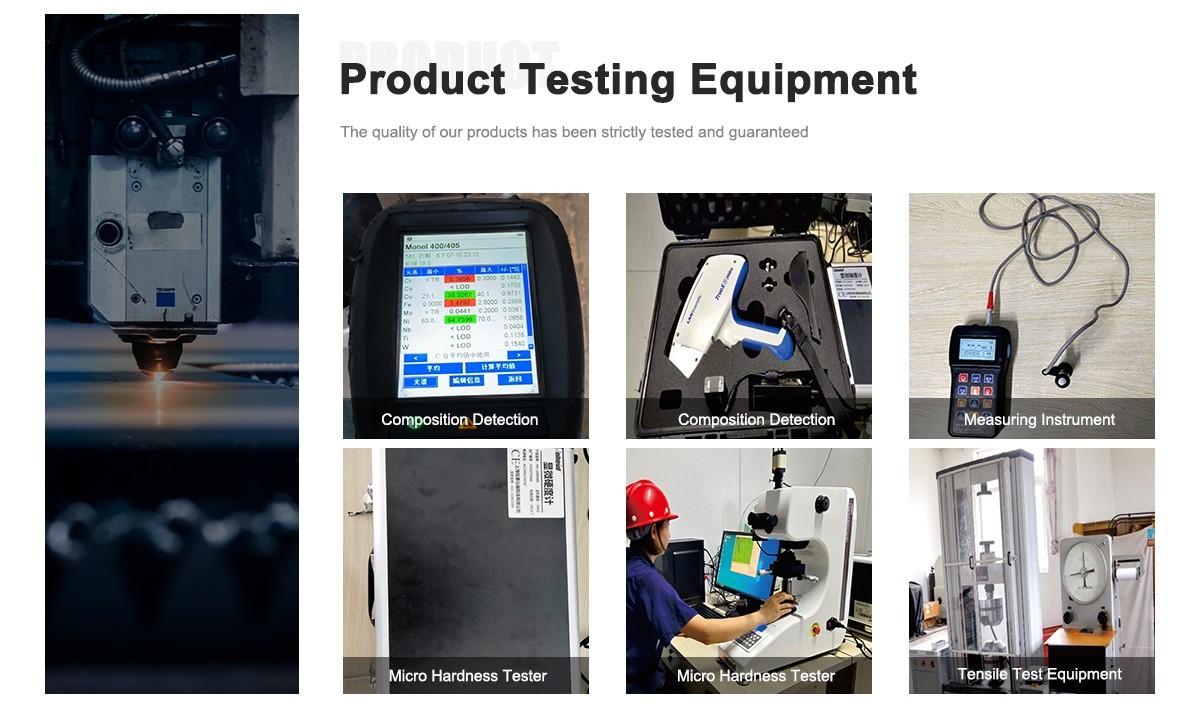

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing: