0Cr21Al6 FeCrAl wire is a high-performance iron-chromium-aluminum alloy designed for demanding heating applications. With 21% chromium and 6% aluminum, it combines excellent oxidation resistance with durability under prolonged high-temperature use. Its mechanical strength and ability to withstand continuous service at temperatures up to 1350°C make it one of the most reliable alloys for electric heating equipment and precision resistors.

For more details, pls directly contact us.

The defining advantage of 0Cr21Al6 is its protective aluminum oxide layer, which forms on the surface at elevated temperatures. This layer acts as a barrier, preventing further oxidation and extending the service life of the wire even under continuous heating cycles. Compared with lower chromium or aluminum FeCrAl alloys, 0Cr21Al6 offers improved performance in harsher thermal environments.

Other key properties include:

High Resistivity: Stable electrical performance for resistive heating.

Oxidation Resistance: Long-term operation without significant degradation.

Mechanical Strength: Resistance to creep and deformation at elevated temperatures.

Cost Efficiency: More affordable than nickel-based alloys with similar heating performance.

Alloy Nomenclature Performance | 1Cr13Al4 | 0Cr21Al4 | ||||||

Chemical Compostion (%) | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

Re | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | |

Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

-- | -- | -- | -- | -- | -- | -- | ||

Max.Continuous service temp. of element | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

Resistivity at 20C(μΩ.m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

Density(g/cm) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

Thermal Conductivity(KJ/m.h) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | -- | |

Coefficient of lines expansion(αx10-6/℃) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

Melting Point Approx(degree) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

Tensile Strength(N/mm) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

Elongation at rupture(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

Variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

Repeat Bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

Hardness(H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

continuous service time(Hours/ ºC) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥80/1350 | ≥80/1350 | |

Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Shape | Size (mm) |

Wire | 0.05-7.5 |

Rod | 8-50 |

Ribbon | (0.05-0.35)*(0.5-6.0) |

Strip | (0.5-2.5)*(5-180) |

For more details, pls directly contact us.

0Cr21Al6 is used widely in industries where heating efficiency and durability are critical:

Electric Heating Equipment: Heating coils in industrial furnaces, ovens, and kilns.

Resistors: Wire-wound resistors and precision components in electronics.

Ceramic and Glass Production: Kiln elements and heating systems for stable, uniform heat.

Household Appliances: Electric stoves, ovens, and dryers requiring consistent heat.

Energy Industry: Heating elements in power generation and renewable energy equipment.

This versatility makes 0Cr21Al6 a go-to choice for manufacturers balancing long service life and cost-effectiveness.

Industry Trends

As industries move toward more energy-efficient technologies, demand for alloys like 0Cr21Al6 continues to rise. High-performance heating materials are essential in new-generation equipment designed to reduce power consumption while maintaining reliability. The global market shows growth in electric heating systems for renewable energy, advanced ceramics, and industrial processing—fields where FeCrAl wires like 0Cr21Al6 have a strong role.

In comparison to nickel-based alloys, FeCrAl alloys are becoming increasingly attractive due to their lower cost and higher temperature capability. This makes 0Cr21Al6 a preferred choice for both established and emerging markets.

Comparison Table: 0Cr21Al6 vs Similar FeCrAl and NiCr Alloys

| Alloy Grade | Composition (Cr/Al %) | Max Service Temp (°C) | Density (g/cm³) | Tensile Strength (MPa) | Applications |

|---|---|---|---|---|---|

| 0Cr19Al3 | Cr 19%, Al 3% | ~1200 | 7.2 | 650–850 | Heating coils, furnaces, household ovens |

| 0Cr21Al6 | Cr 21%, Al 6% | ~1350 | 7.25 | 650–900 | Electric heating equipment, resistors, kilns |

| 0Cr23Al5 | Cr 23%, Al 5% | ~1400 | 7.3 | 650–900 | High-temp furnaces, metallurgy |

| Ni80Cr20 | Ni 80%, Cr 20% | ~1100 | 8.4 | 700–900 | Electric heaters, resistors, lab equipment |

0Cr21Al6 has counterparts across multiple international standards:

USA: FeCrAl alloys with similar chromium and aluminum levels.

Germany: DIN-standard FeCrAl compositions.

France: AFNOR FeCrAl series.

Russia: Х23Ю5Т and related FeCrAl materials.

These equivalents demonstrate the global acceptance of this alloy for industrial applications.

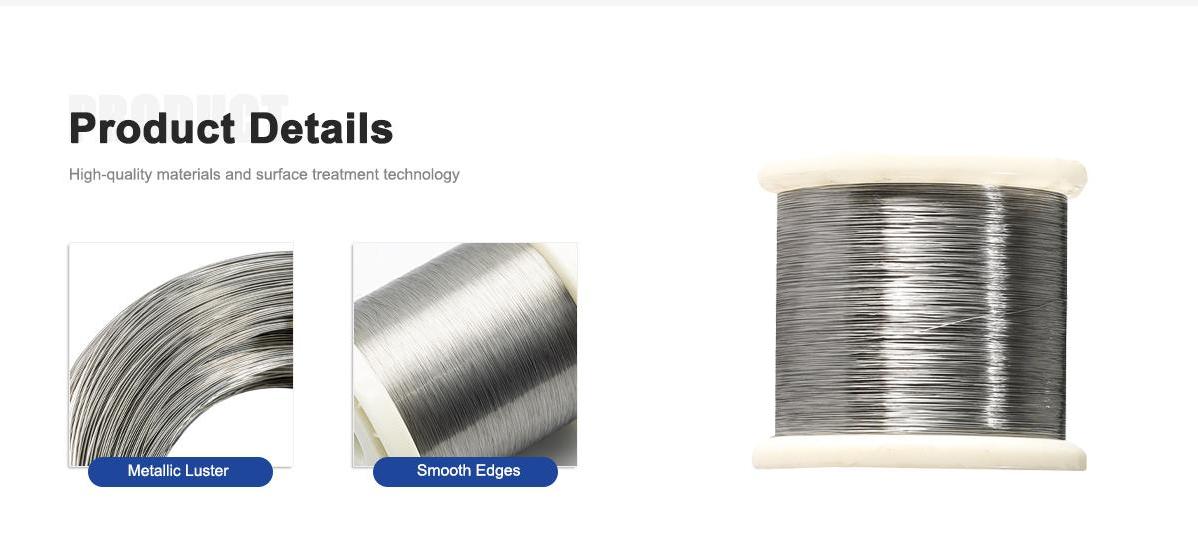

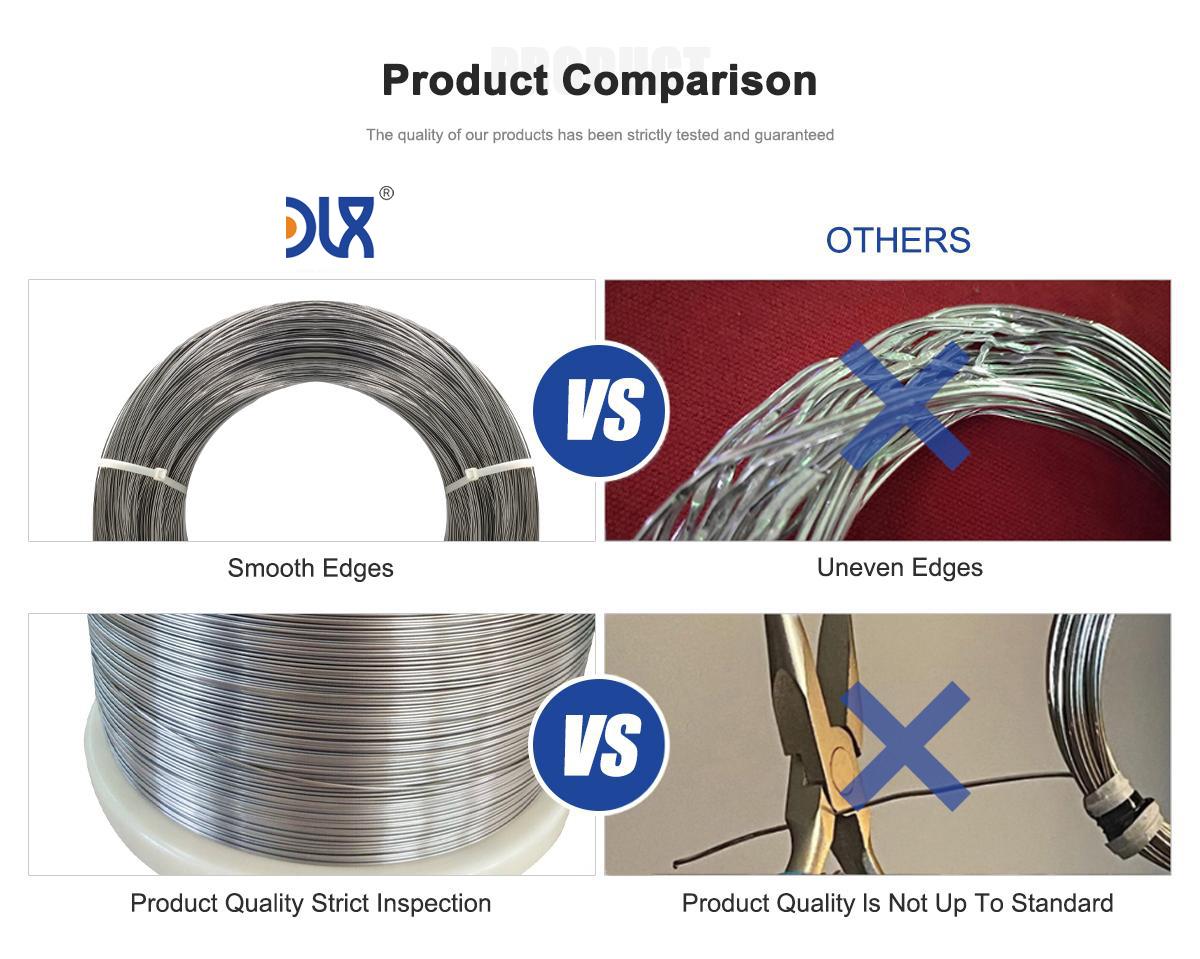

DLX provides 0Cr21Al6 FeCrAl wire with a strong focus on quality assurance, customization, and client support. Our production ensures precise chemical composition and tight tolerance control, guaranteeing consistent performance under extreme conditions. Customers rely on us for:

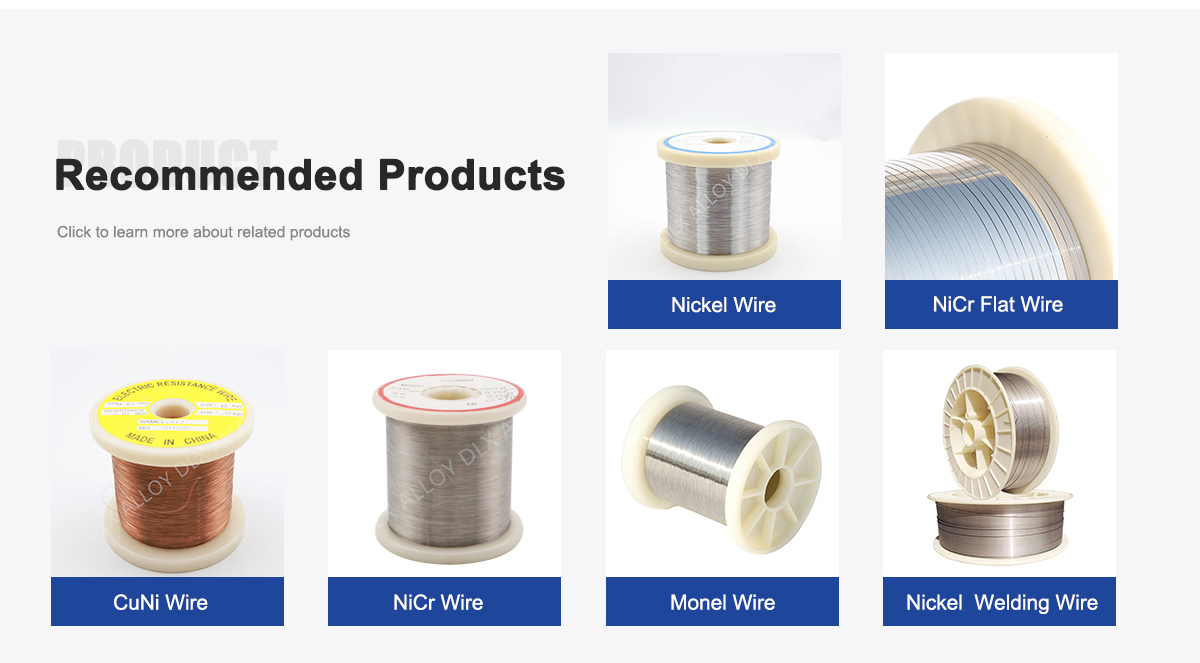

Customization: Availability in multiple forms, including wire, strip, and coil.

Technical Guidance: Helping buyers compare alloy options and select the right grade for their application.

Global Supply Capability: Fast and reliable logistics to international markets.

Competitive Advantage: Balanced pricing with premium-quality assurance.

Where competitors may only deliver standard-grade material, DLX emphasizes tailored solutions, ensuring customers receive alloys suited to their specific operational environments.

Comparative Advantages

Against alloys like 0Cr19Al3, 0Cr21Al6 offers higher aluminum content, leading to improved oxidation resistance and higher service temperatures. While 0Cr23Al5 can withstand slightly higher limits, it is often unnecessary for applications below 1350°C, making 0Cr21Al6 a cost-effective and efficient choice. Compared with nickel-chromium alloys, 0Cr21Al6 provides higher maximum service temperatures at a lower cost, aligning perfectly with industries prioritizing both performance and efficiency.

The market outlook for 0Cr21Al6 FeCrAl wire is positive, with rising demand in heating technologies, energy-saving systems, and advanced manufacturing. DLX continues to invest in R&D to optimize production processes, ensuring that our clients receive innovative solutions with consistent quality. By offering reliable materials and professional technical support, DLX positions itself as a trusted long-term partner for industries worldwide.

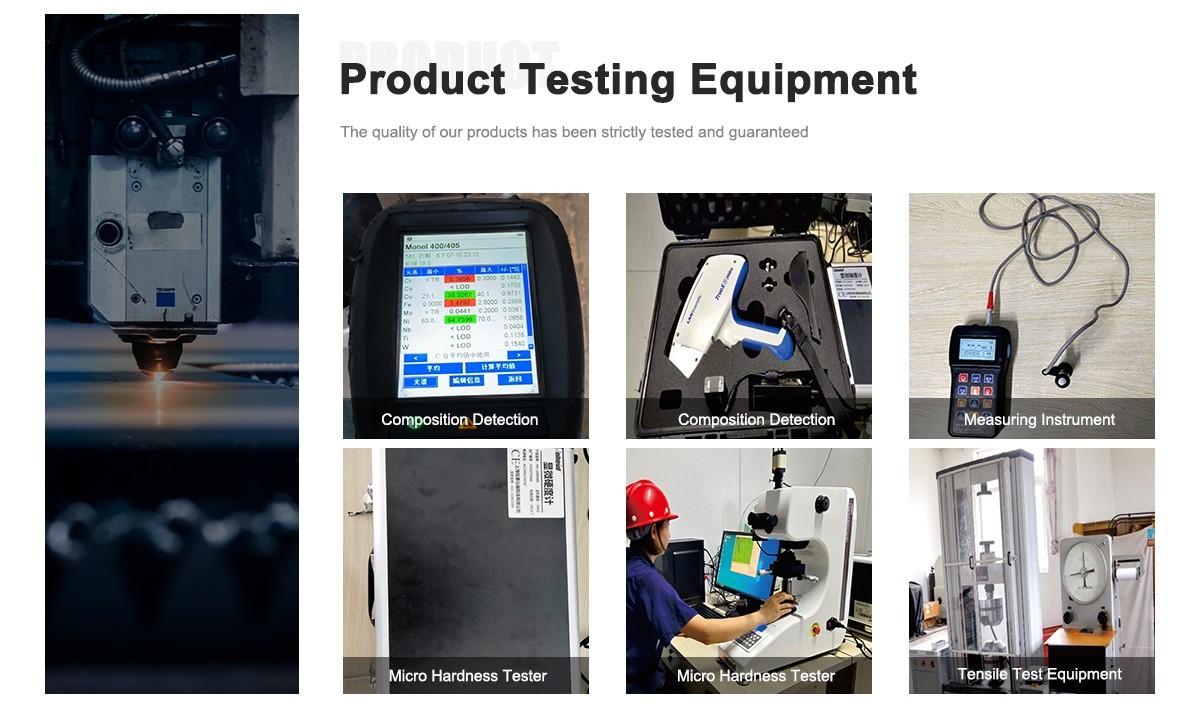

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing: