0Cr21Al6 alloy heating wire is a premium FeCrAl (iron-chromium-aluminum) material designed to withstand extreme temperatures and continuous operation. With a composition of approximately 21% chromium and 6% aluminum, this alloy stands out for its ability to combine high strength with excellent oxidation resistance. Industries worldwide rely on it for electric heating systems, resistors, and furnaces that demand long-lasting stability and cost-effective performance.

For more details, pls directly contact us.

The strength of 0Cr21Al6 lies in its protective aluminum oxide (Al₂O₃) film that develops on the surface during high-temperature use. This dense oxide layer shields the material from rapid oxidation, ensuring that the wire maintains its integrity even after thousands of heating cycles. Compared with alloys that contain less aluminum, 0Cr21Al6 offers superior protection at higher temperatures, making it ideal for prolonged use in harsh thermal conditions.

Key technical highlights include:

-

Resistivity: Stable electrical resistivity ensures uniform heating output.

-

High-Temperature Resistance: Service life up to 1350°C without significant degradation.

-

Mechanical Strength: Strong resistance to creep and deformation under load.

-

Durability: Extended operating lifespan compared with nickel-based alloys in many applications.

-

Cost Performance: More economical than NiCr alloys while offering higher maximum service temperatures.

These properties make 0Cr21Al6 one of the most widely applied FeCrAl alloys in global heating technology.

|

Alloy Nomenclature Performance |

0Cr21Al4 |

0Cr27Al7Mo2 |

||||||

|

Chemical Compostion (%) |

Cr |

12.0-15.0 |

23.0-26.0 |

19.0-22.0 |

20.5-23.5 |

18.0-21.0 |

21.0-23.0 |

26.5-27.8 |

|

Al |

4.0-6.0 |

4.5-6.5 |

5.0-7.0 |

4.2-5.3 |

3.0-4.2 |

5.0-7.0 |

6.0-7.0 |

|

|

Re |

Opportune |

Opportune |

Opportune |

Opportune |

Opportune |

Opportune |

Opportune |

|

|

Fe |

Rest |

Rest |

Rest |

Rest |

Rest |

Rest |

Rest |

|

|

-- |

-- |

-- |

-- |

-- |

-- |

-- |

||

|

Max.Continuous service temp. of element |

950 |

1250 |

1250 |

1250 |

1100 |

1350 |

1400 |

|

|

Resistivity at 20C(μΩ.m) |

1.25 |

1.42 |

1.42 |

1.35 |

1.23 |

1.45 |

1.53 |

|

|

Density(g/cm) |

7.4 |

7.1 |

7.16 |

7.25 |

7.35 |

7.1 |

7.1 |

|

|

Thermal Conductivity(KJ/m.h) |

52.7 |

46.1 |

63.2 |

60.2 |

46.9 |

46.1 |

-- |

|

|

Coefficient of lines expansion(αx10-6/℃) |

15.4 |

16 |

14.7 |

15 |

13.5 |

16 |

16 |

|

|

Melting Point Approx(degree) |

1450 |

1500 |

1500 |

1500 |

1500 |

1510 |

1520 |

|

|

Tensile Strength(N/mm) |

580-680 |

630-780 |

630-780 |

630-780 |

600-700 |

650-800 |

680-830 |

|

|

Elongation at rupture(%) |

>16 |

>12 |

>12 |

>12 |

>12 |

>12 |

>10 |

|

|

Variation of area(%) |

65-75 |

60-75 |

65-75 |

65-75 |

65-75 |

65-75 |

65-75 |

|

|

Repeat Bending frequency(F/R) |

>5 |

>5 |

>5 |

>5 |

>5 |

>5 |

>5 |

|

|

Hardness(H.B.) |

200-260 |

200-260 |

200-260 |

200-260 |

200-260 |

200-260 |

200-260 |

|

|

continuous service time(Hours/ ºC) |

-- |

≥80/1300 |

≥80/1300 |

≥80/1300 |

≥80/1250 |

≥80/1350 |

≥80/1350 |

|

|

Micrographic structure |

Ferrite |

Ferrite |

Ferrite |

Ferrite |

Ferrite |

Ferrite |

Ferrite |

|

|

Magnetic properties |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

Magnetic |

|

|

Shape |

Size (mm) |

|

Wire |

0.05-7.5 |

|

Rod |

8-50 |

|

Ribbon |

(0.05-0.35)*(0.5-6.0) |

|

Strip |

(0.5-2.5)*(5-180) |

For more details, pls directly contact us.

The adaptability of 0Cr21Al6 heating wire is reflected in its widespread use across different sectors:

-

Industrial Furnaces and Kilns: As core heating elements for metal treatment, ceramics, and glass processing.

-

Resistors and Electrical Components: In wire-wound resistors, rheostats, and precision electronic systems.

-

Household Appliances: Electric stoves, ovens, and dryers benefit from its consistent performance.

-

Energy and Power Systems: Heating elements for energy-saving equipment, power plants, and renewable energy solutions.

-

Automotive and Aerospace: Applied in heat-resistant components where durability is critical.

Its versatility makes it not just a specialized alloy, but a mainstream choice in industries requiring dependable high-temperature heating.

The demand for FeCrAl alloys such as 0Cr21Al6 continues to grow globally. Industrialization, electrification, and sustainability initiatives drive the need for high-efficiency heating materials. Manufacturers are increasingly focused on reducing energy waste and extending the life cycle of heating equipment, leading to greater adoption of advanced alloys.

Nickel prices remain volatile in the global market, which further enhances the attractiveness of FeCrAl alloys as cost-effective alternatives. 0Cr21Al6 is particularly appealing to industries in Europe, North America, and Asia that are seeking reliable, high-performance heating materials without the expense of high-nickel alloys.

Comparison Table: 0Cr21Al6 vs Other Heating Alloys

| Alloy Grade | Composition (Cr/Al %) | Max Service Temp (°C) | Density (g/cm³) | Tensile Strength (MPa) | Typical Applications |

|---|---|---|---|---|---|

| 0Cr19Al3 | Cr 19%, Al 3% | ~1200 | 7.2 | 650–850 | Household heating coils, small furnaces |

| 0Cr21Al6 | Cr 21%, Al 6% | ~1350 | 7.25 | 650–900 | Industrial heating equipment, resistors, kilns |

| 0Cr23Al5 | Cr 23%, Al 5% | ~1400 | 7.3 | 650–900 | High-temperature furnaces, metallurgy |

| Ni80Cr20 | Ni 80%, Cr 20% | ~1100 | 8.4 | 700–900 | Lab equipment, electric heaters, resistors |

0Cr21Al6 has equivalents recognized in multiple international systems, ensuring compatibility and acceptance across markets:

-

USA: Comparable to certain FeCrAl grades with similar Cr/Al ratios.

-

Germany: DIN-standard FeCrAl compositions.

-

France: AFNOR FeCrAl alloy types.

-

Russia: Х23Ю5Т (X23Yu5T) and related high-strength FeCrAl grades.

These equivalents highlight the alloy’s international reach and credibility in both established and emerging industrial markets.

DLX Company Perspective

At DLX, we specialize in the production and supply of 0Cr21Al6 alloy heating wire, offering customers a complete package of quality, customization, and technical support. Our advantages include:

-

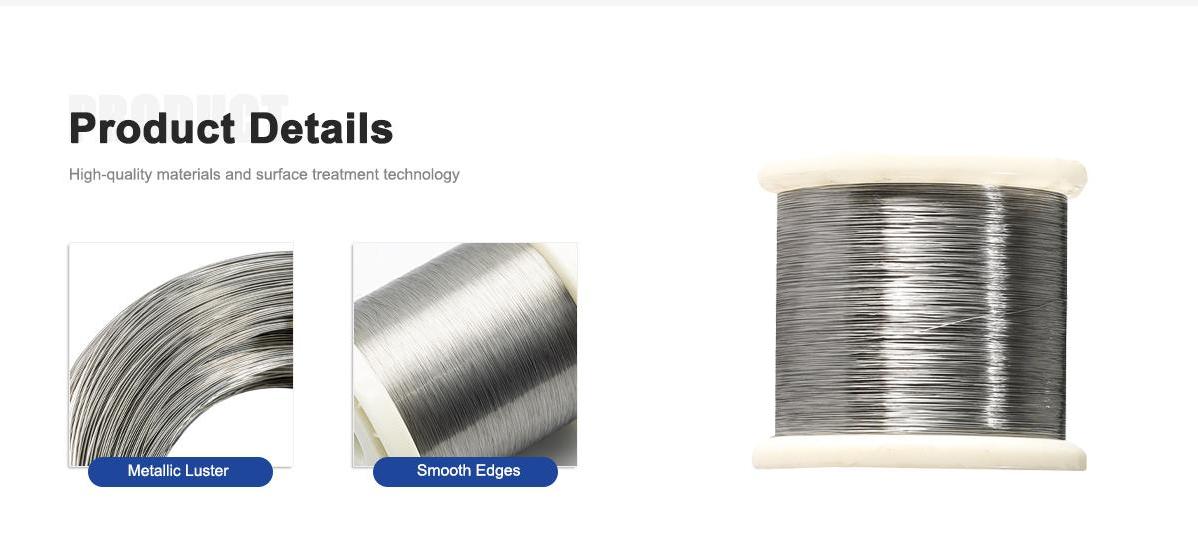

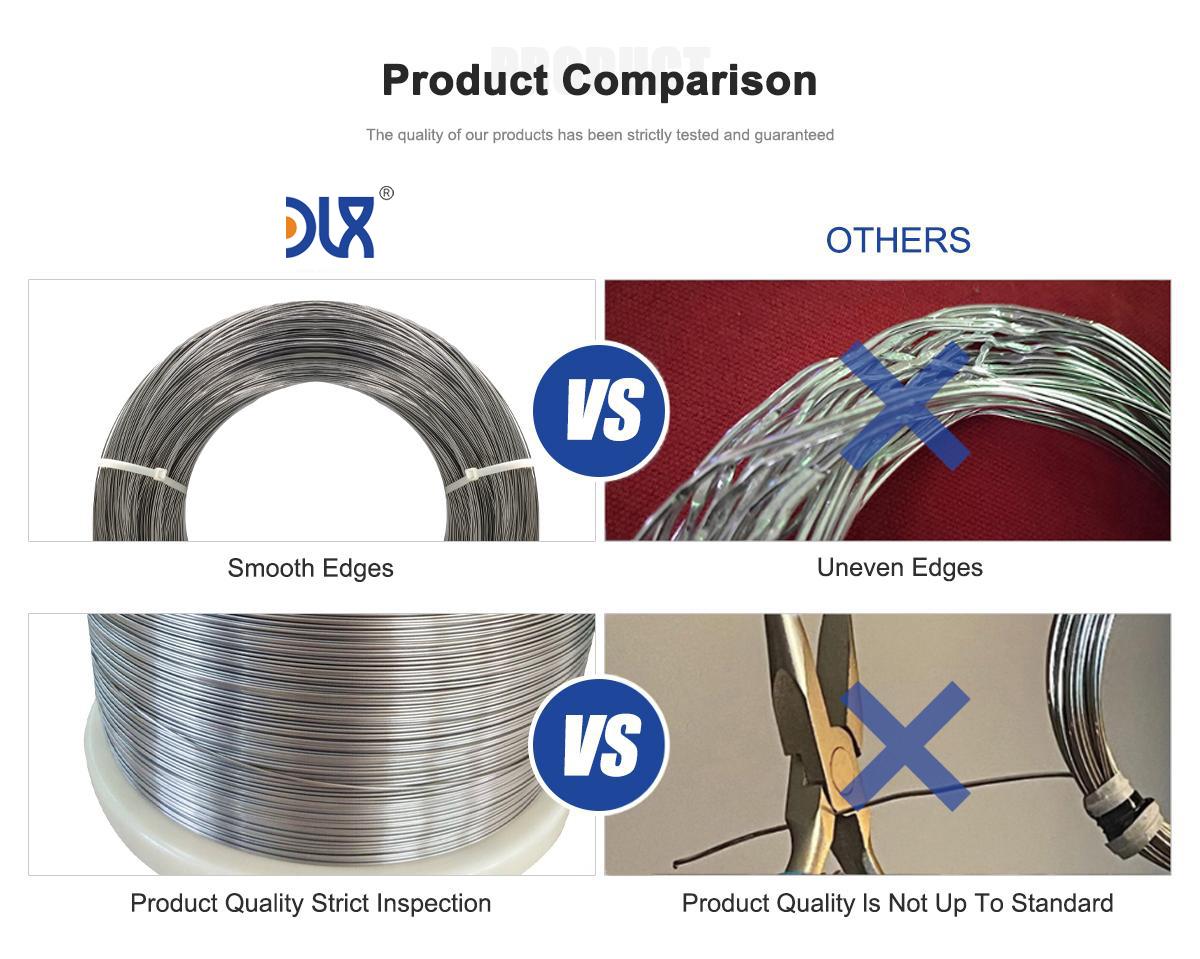

Precision Manufacturing: We maintain strict control over chemical composition and wire dimensions, ensuring stable resistivity and long-term performance.

-

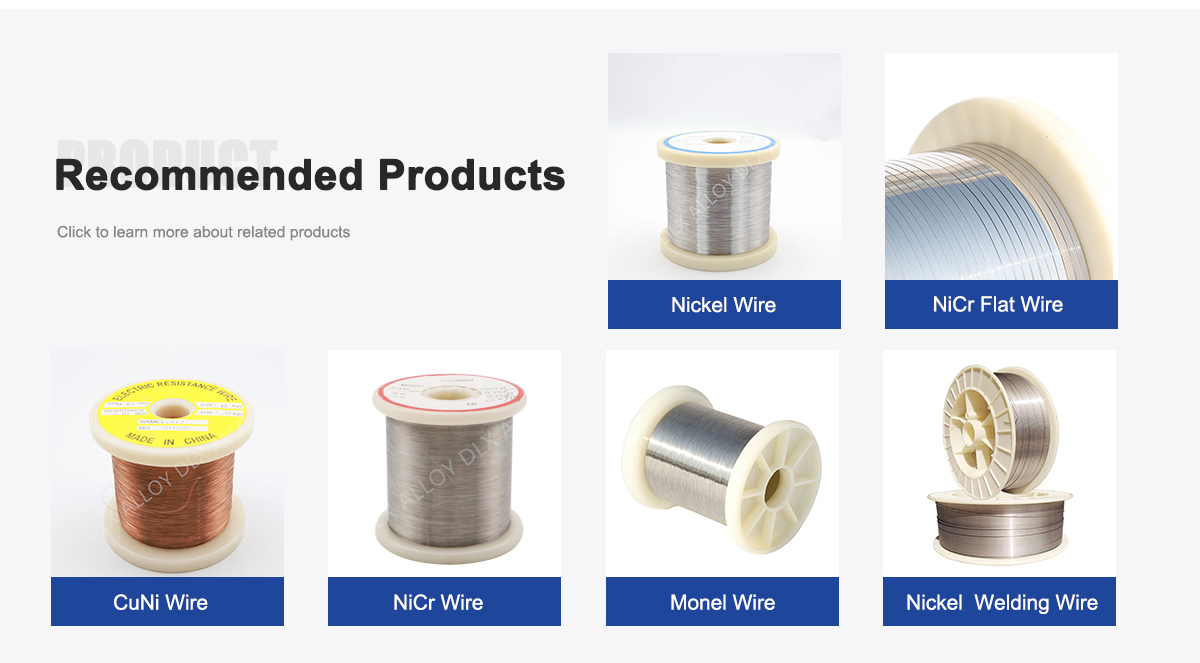

Product Range: We provide the alloy in multiple forms—wire, strip, and coil—to meet different customer requirements.

-

Technical Consultation: Many customers require guidance in selecting between 0Cr19Al3, 0Cr21Al6, or 0Cr23Al5. Our experts help match the right alloy to the application, saving both time and costs.

-

Reliable Supply Chain: With a strong logistics network, DLX ensures timely deliveries across Europe, North America, Asia, and beyond.

-

Customer-Centric Approach: We don’t just deliver materials; we deliver tailored solutions that support long-term operational success.

This customer-oriented strategy allows DLX to build long-term partnerships with clients worldwide, rather than just one-time transactions.

When compared to 0Cr19Al3, 0Cr21Al6 demonstrates better resistance to oxidation and higher temperature limits, making it the stronger choice for industrial heating equipment. Against 0Cr23Al5, it holds a balance between cost and performance, as 0Cr23Al5 may only be necessary in ultra-high-temperature applications above 1350°C. Compared with Ni80Cr20, 0Cr21Al6 offers a higher service temperature at a lower cost, making it more suitable for long-term, heavy-duty applications.

Future Outlook

As industries modernize and transition toward sustainable energy solutions, high-strength FeCrAl alloys like 0Cr21Al6 will see even greater demand. The alloy’s ability to deliver consistent performance while reducing material costs positions it as a key material for next-generation heating technologies.

DLX is investing in continuous improvement, R&D, and quality management to ensure our customers gain maximum value from our materials. By combining reliable supply with technical expertise, DLX is not just a supplier of 0Cr21Al6 alloy heating wire, but a trusted partner helping industries optimize efficiency and durability.

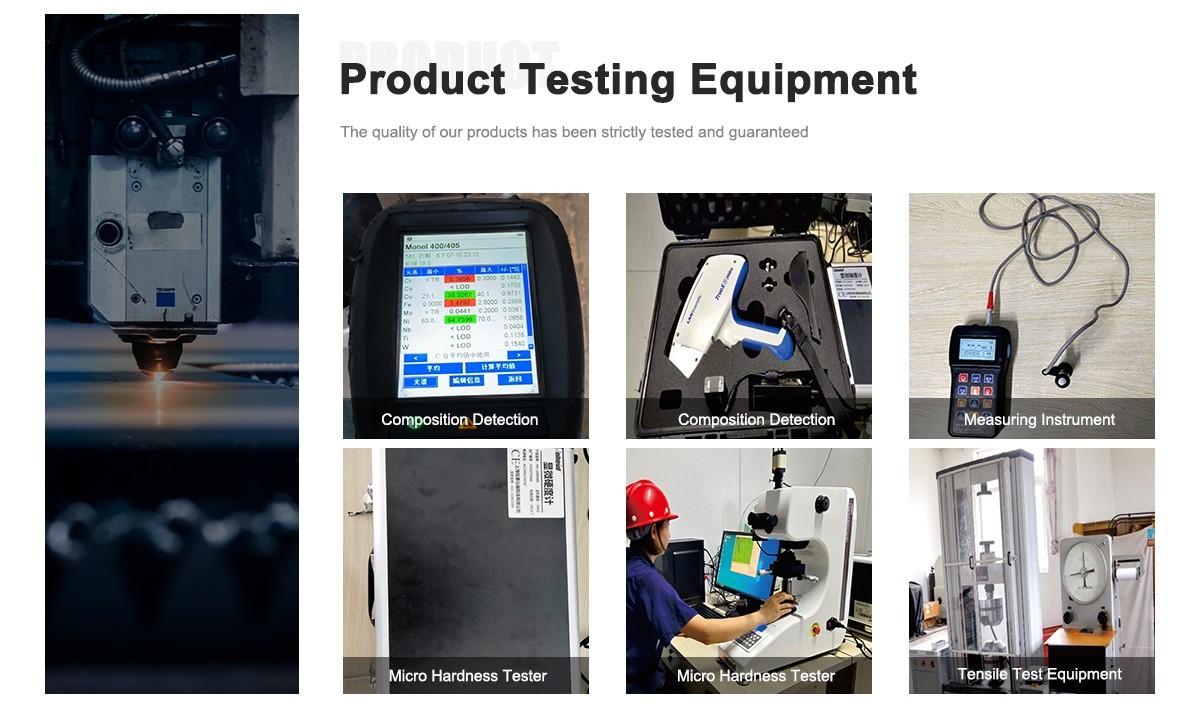

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing: